Mechanics of Materials

Introduction to Mechanics of Materials

Mechanics of Materials, often referred to as Strength of Materials, is a fundamental branch of engineering science. It explores how solid objects respond to applied forces, specifically focusing on the internal stresses and strains that these forces cause within the material. Essentially, it's the study of the relationship between external loads and the resulting internal forces and deformations in a body. This field provides the analytical tools necessary to predict how much a material will deform or whether it will break under specific loading conditions. Understanding these principles is crucial for designing safe and reliable structures and mechanical components. Even for those just beginning to explore engineering, the core ideas of how things bend, stretch, or break under pressure form an intuitive entry point into this fascinating discipline.

Working in Mechanics of Materials can be incredibly engaging. Imagine being able to predict exactly how a bridge will behave under the weight of traffic or how an airplane wing will flex during flight. This predictive power is a cornerstone of the field. Furthermore, Mechanics of Materials is a highly interdisciplinary field, finding applications in civil, mechanical, aerospace, and biomedical engineering, among others. This means that professionals in this area often work on diverse and exciting projects, from designing advanced new materials to ensuring the safety of critical infrastructure. The ability to contribute to innovations that directly impact society, such as developing lighter and stronger materials for more fuel-efficient vehicles or creating more durable and biocompatible medical implants, is a significant draw for many in this profession.

What is Mechanics of Materials?

Mechanics of Materials delves into the behavior of solid bodies when subjected to various types of forces or loads. It's a branch of mechanics that studies the internal effects of stress and strain in a solid body that is subjected to an external loading. The primary goal is to understand how materials deform and potentially fail under these loads, enabling engineers to design structures and components that can safely withstand expected forces. This field is a cornerstone of many engineering disciplines because it provides the foundational knowledge for designing everything from towering skyscrapers and long-span bridges to intricate mechanical devices and advanced aerospace vehicles.

The principles of Mechanics of Materials allow engineers to analyze and predict the mechanical behavior of structures and components. This involves calculating stresses (the internal forces distributed over a material's cross-section) and strains (the resulting deformation or change in shape). By understanding these concepts, engineers can select appropriate materials for a given application, determine safe load limits, and optimize designs for efficiency and durability. It's a field that blends theoretical understanding with practical application, ensuring that the things we build are both functional and safe.

For individuals new to the concept, imagine stretching a rubber band. As you pull on it (apply a load), it elongates (experiences strain), and internal forces develop within it (stress). If you pull too hard, it will eventually break (fail). Mechanics of Materials provides the scientific framework to analyze these phenomena in a quantitative way, not just for simple rubber bands, but for complex engineering materials and structures.

A Brief History of Mechanics of Materials

The study of how materials behave under load has ancient roots, with early builders and artisans relying on empirical rules and experience. However, the formal development of Mechanics of Materials as a scientific discipline began much later. Figures like Leonardo da Vinci in the 15th and 16th centuries sketched experiments to test the strength of wires, and Galileo Galilei in the 17th century conducted investigations into the strength of beams, laying some of the earliest groundwork. These early explorations were often a blend of observation and attempts at theoretical explanation.

The 17th and 18th centuries saw significant advancements. Robert Hooke formulated his famous law in 1678, establishing the linear relationship between force and displacement (and by extension, stress and strain) for elastic materials. Mathematicians and physicists like Leonhard Euler and Daniel Bernoulli made crucial contributions to understanding phenomena like the buckling of columns and the behavior of beams. Euler, for instance, developed the mathematical theory for columns long before extensive experimental validation was available. This period was characterized by the development of the mechanics of simple structural elements.

The 19th century brought more sophisticated mathematical models. Augustin-Louis Cauchy introduced the concept of stress as a tensor, allowing for a more complete analysis of the internal forces within a material. The theories of elasticity and plasticity were further developed by prominent scientists of the era. The 20th century and beyond witnessed the advent of powerful computational tools, such as the Finite Element Method (FEM), which revolutionized the ability to analyze complex structures and material behaviors. Key figures like Stephen Timoshenko are considered important founding pioneers in the field. The historical development of Mechanics of Materials is a fascinating interplay of theoretical insights and experimental validation, continuously evolving to meet new engineering challenges.

These foundational books offer a comprehensive look into the principles discussed:

Why is Mechanics of Materials Relevant Today?

Mechanics of Materials remains profoundly relevant in modern engineering and technology. Its principles are fundamental to the design and analysis of a vast array of structures and devices we rely on daily. From ensuring the structural integrity of buildings, bridges, and dams to optimizing the performance of automobiles, aircraft, and spacecraft, Mechanics of Materials provides the essential tools for engineers. It allows engineers to predict how materials will respond to various loads and environmental conditions, which is critical for preventing failures and ensuring safety.

The field is also at the forefront of innovation. As engineers strive to create more efficient, sustainable, and resilient technologies, a deep understanding of material behavior is indispensable. This includes the development of new and advanced materials, such as composites and smart materials, which offer unique properties tailored for specific applications. For example, in aerospace engineering, Mechanics of Materials is crucial for designing lightweight yet strong structures that can withstand extreme conditions. In biomechanics, it informs the design of medical implants and prosthetic devices that are compatible with the human body and can bear physiological loads.

Furthermore, the increasing complexity of engineering systems and the demand for higher performance necessitate sophisticated analysis techniques, many of which are rooted in Mechanics of Materials. The ongoing development of computational tools, like Finite Element Analysis (FEA), allows for more detailed and accurate simulations of material behavior, pushing the boundaries of what is possible in engineering design. As we face global challenges such as climate change and resource scarcity, the ability to design more durable, lightweight, and resource-efficient structures and products makes Mechanics of Materials more critical than ever.

For those looking to delve deeper into specific applications, consider these resources:

Core Concepts in Mechanics of Materials

To understand Mechanics of Materials, one must first grasp its fundamental concepts. These principles form the bedrock upon which all subsequent analyses and designs are built. They describe how materials internally react to external forces and how they deform as a result. Mastering these core ideas is the first step towards applying Mechanics of Materials to solve real-world engineering problems.

Stress and Strain: The Language of Deformation

Stress and strain are two of the most fundamental concepts in Mechanics of Materials. Stress (often denoted by the Greek letter sigma, σ, or tau, τ, for shear stress) is a measure of the internal forces acting within a deformable body. Specifically, it is the force per unit area over which the internal forces are distributed. Imagine pulling on a rope; the tension you feel is related to the stress within the rope's fibers. Stress can be normal (perpendicular to a surface, like tensile or compressive stress) or shear (parallel to a surface).

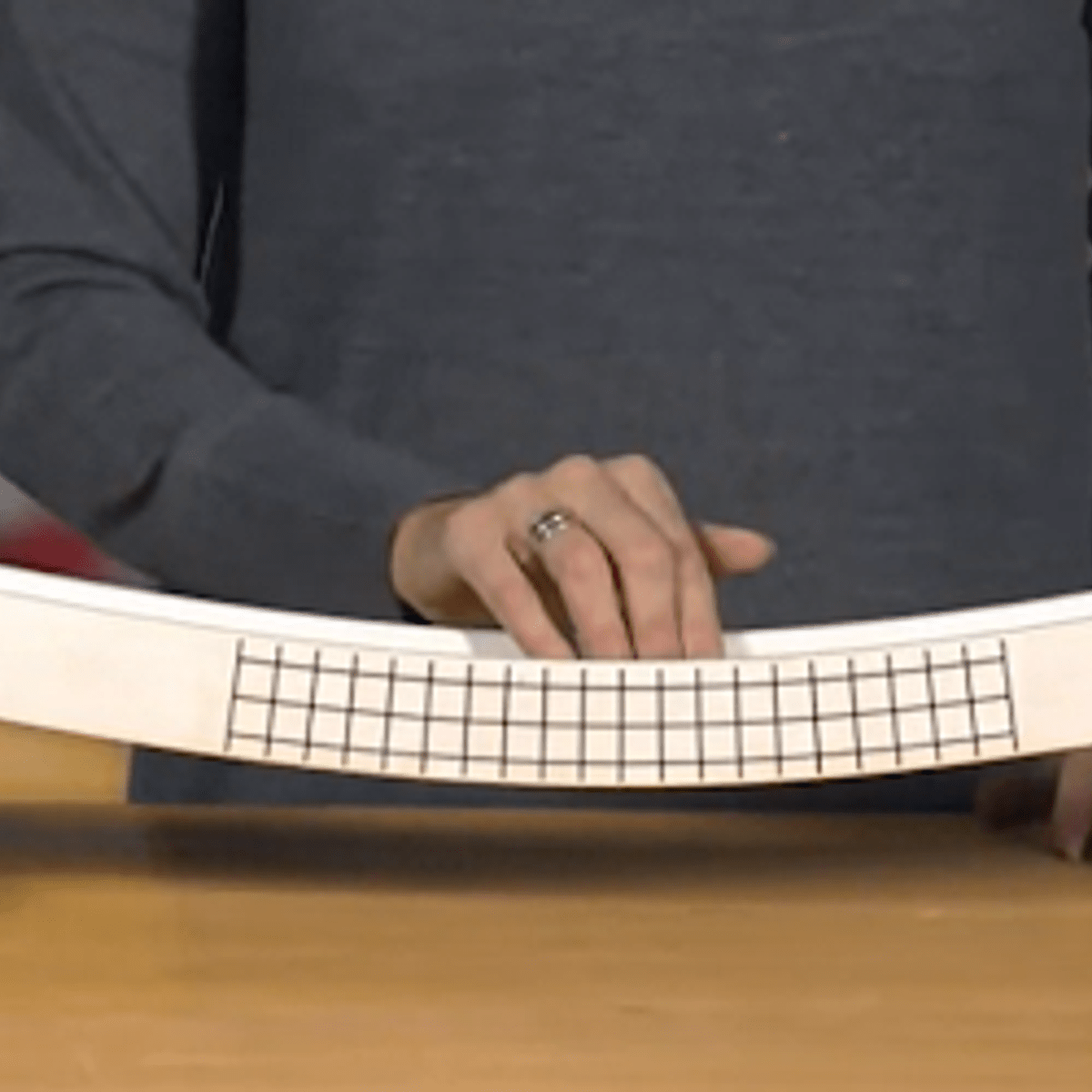

Strain (often denoted by the Greek letter epsilon, ε, or gamma, γ, for shear strain) is the measure of deformation representing the displacement between particles in the body relative to a reference length. It quantifies how much an object deforms under load. If you stretch that same rope, the amount it elongates relative to its original length is a measure of strain. Like stress, strain can also be normal (representing elongation or contraction) or shear (representing a change in angle between lines that were originally perpendicular).

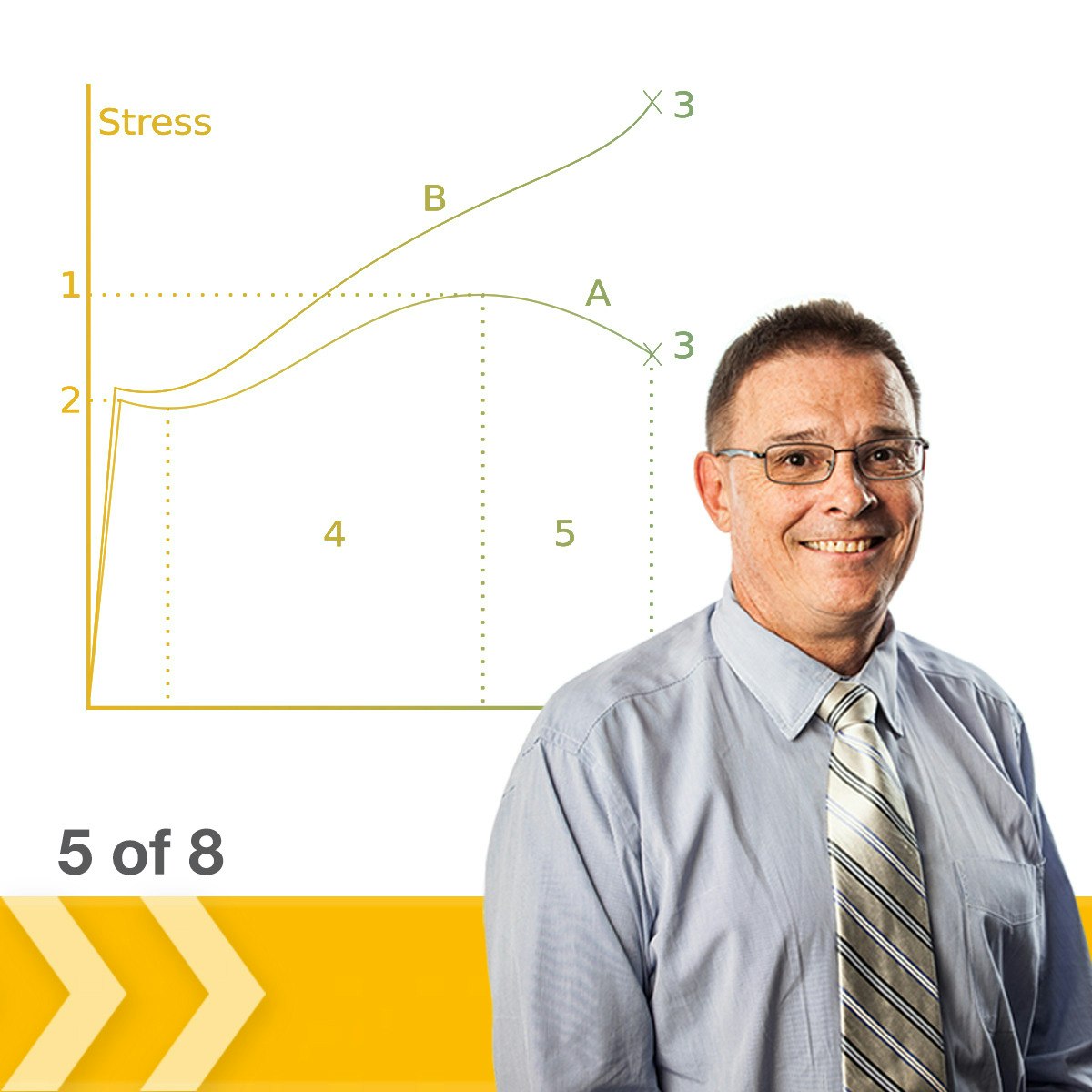

The relationship between stress and strain is a critical aspect of material behavior and is often depicted graphically in a stress-strain curve. This curve reveals important properties of the material, such as its stiffness and strength. Understanding stress and strain allows engineers to predict how a component will deform under load and whether it is likely to yield or fracture.

These introductory courses provide a solid grounding in stress, strain, and their relationships:

To supplement your learning, these books offer detailed explanations and examples:

Elasticity vs. Plasticity: How Materials Respond and Recover

Materials respond to applied loads in different ways, and two key behaviors are elasticity and plasticity. Elasticity describes a material's ability to return to its original shape and size after an applied load is removed. Think of a spring: when you stretch it within certain limits and then release it, it snaps back to its original form. This reversible deformation is characteristic of elastic behavior. Within the elastic region, stress is typically proportional to strain, a relationship famously described by Hooke's Law.

Plasticity, on the other hand, describes permanent deformation that remains even after the applied load is removed. If you bend a paperclip significantly, it doesn't spring back completely; it retains some of its bent shape. This is an example of plastic deformation. When a material is loaded beyond its elastic limit (also known as the yield point), it enters the plastic region. Understanding the onset of plastic deformation is crucial in engineering design, as it often signifies the limit of a component's functional usefulness or the beginning of potential failure mechanisms.

The distinction between elastic and plastic behavior is vital for predicting how structures will perform under various loading conditions. For many applications, designs aim to keep stresses within the elastic range to ensure that components do not permanently deform during service. However, in some situations, such as in metal forming processes or in structures designed to absorb energy during impact, plastic deformation is intentionally utilized.

These courses delve into the complexities of material behavior, including elastic and plastic responses:

For further reading on elasticity and plasticity, consider these texts:

Key Material Properties

Several intrinsic properties define how a material behaves mechanically. These properties are determined through experimental testing and are essential inputs for engineering design and analysis. One of the most important is Young's Modulus (often denoted by E), also known as the modulus of elasticity. It measures a material's stiffness or resistance to elastic deformation under tensile or compressive stress. A material with a high Young's Modulus is very stiff, like steel, while a material with a low Young's Modulus is more flexible, like rubber.

Another crucial property is Poisson's Ratio (denoted by the Greek letter nu, ν). It describes the phenomenon where a material tends to contract (or expand) in directions perpendicular to the direction of stretching (or compressing). For example, when you stretch a rubber band, it not only gets longer but also thinner. Poisson's Ratio quantifies this effect. For most materials, Poisson's ratio falls between 0.0 and 0.5.

Other important properties include yield strength (the stress at which a material begins to deform plastically), ultimate tensile strength (the maximum stress a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract), and fracture strength (the stress at which the material breaks). Ductility (a material's ability to deform plastically before fracturing) and toughness (a material's ability to absorb energy and plastically deform before fracturing) are also critical considerations in material selection. Understanding these properties allows engineers to choose the most suitable material for a specific application, balancing requirements for strength, stiffness, weight, cost, and other factors.

This course can help you understand how these properties are determined and applied:

Mathematical Tools and Models

Mechanics of Materials relies heavily on mathematical models to describe and predict the behavior of materials under load. These models translate physical principles into equations that can be solved to determine stresses, strains, and deformations. Engineers use these tools to analyze complex structures and ensure their designs are safe and efficient. The mathematical rigor involved can be challenging, but it is essential for accurate engineering analysis.

Equilibrium and Compatibility Equations

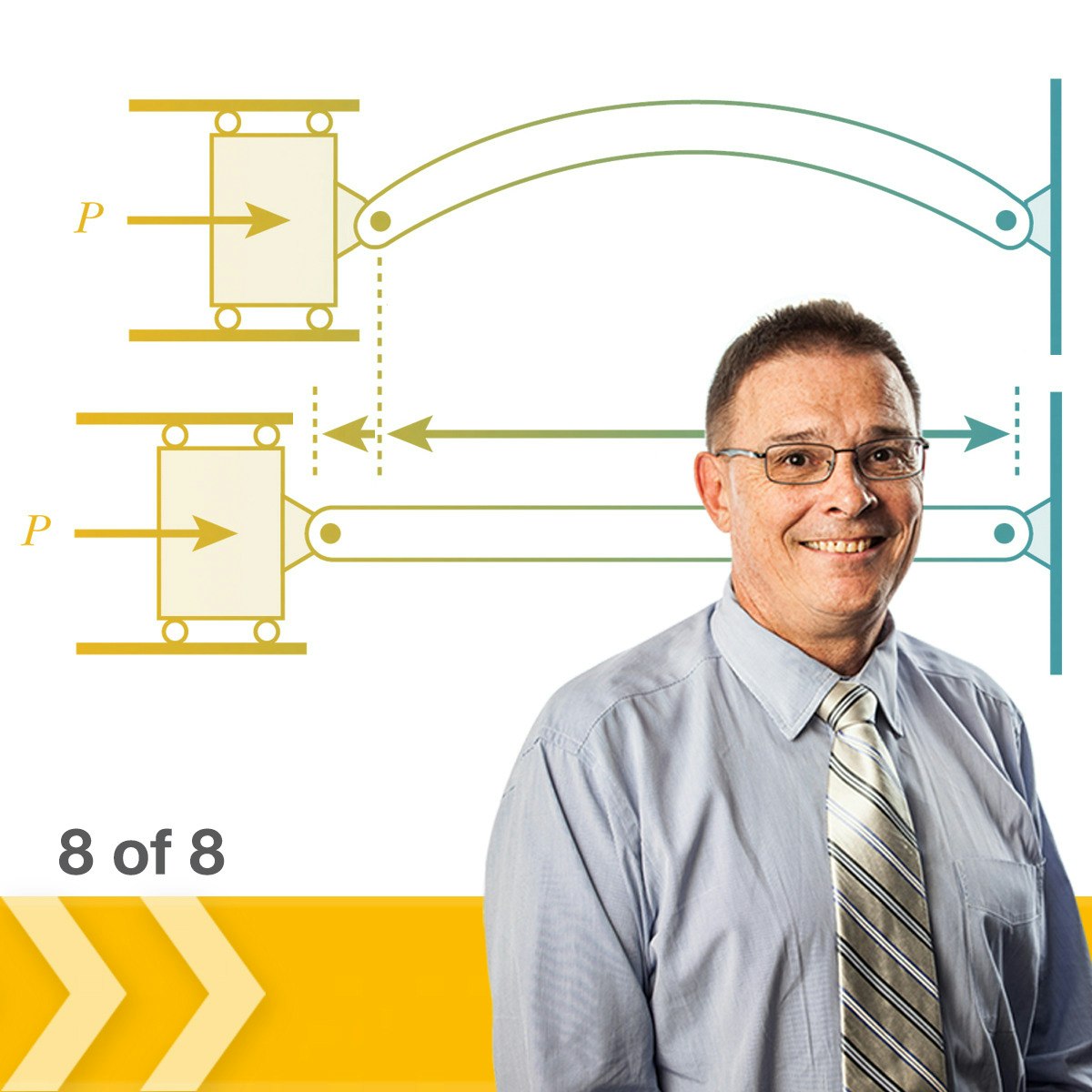

At the heart of analyzing any structure or component in Mechanics of Materials are the principles of equilibrium. For a body to be in static equilibrium, the sum of all external forces and moments acting on it must be zero. This means the body is not accelerating linearly or rotating. Engineers apply these equilibrium equations (ΣF_x = 0, ΣF_y = 0, ΣF_z = 0, ΣM_x = 0, ΣM_y = 0, ΣM_z = 0) to determine unknown forces, such as support reactions or internal forces within members of a structure.

Beyond external equilibrium, internal equilibrium must also be satisfied at every point within the material. This leads to differential equations of equilibrium that relate the rates of change of stress components within the body. These equations ensure that any small element within the material is also in force and moment balance.

Complementary to equilibrium are compatibility equations. These equations ensure that the deformations (strains) within a body are geometrically consistent. In other words, the material must deform in a way that it remains a continuous body without gaps or overlaps, unless fracture occurs. Compatibility conditions relate the different components of strain to ensure that they can be derived from a continuous displacement field. Together, equilibrium equations, compatibility equations, and the material's constitutive laws (which describe the stress-strain relationship) form a complete set of equations for solving problems in Mechanics of Materials.

Introduction to Finite Element Analysis (FEA)

For complex geometries or loading conditions, obtaining exact analytical solutions to the governing equations of Mechanics of Materials can be incredibly difficult or even impossible. This is where numerical methods like Finite Element Analysis (FEA) become invaluable. FEA is a powerful computational technique used to simulate how a physical product or structure behaves under various physical conditions, such as forces, heat, vibration, or fluid flow.

In FEA, a complex object is broken down (discretized) into a large number of smaller, simpler shapes called "finite elements." These elements are interconnected at points called "nodes." The governing equations of Mechanics of Materials are then applied to each element, and a system of algebraic equations is formed for the entire assembly. Solving this system of equations, typically with the aid of a computer, provides an approximate solution for the stresses, strains, and displacements throughout the object.

FEA has revolutionized engineering design, allowing for detailed analysis of intricate structures and the optimization of designs before physical prototypes are built. It is widely used across many industries, including automotive, aerospace, civil engineering, and biomedical engineering, to predict performance, identify potential failure points, and improve product designs. While FEA is a powerful tool, it's crucial to understand its underlying principles and limitations to interpret results correctly and avoid errors.

This course offers an introduction to the concepts behind FEA:

For those interested in the broader field of computational approaches, this book provides context:

Analytical vs. Computational Approaches

In Mechanics of Materials, problems can be approached using either analytical methods or computational methods. Analytical methods involve deriving exact mathematical solutions to the governing equations. These solutions are typically in the form of formulas or closed-form expressions. Analytical solutions are highly valuable because they provide direct insight into how different parameters influence the behavior of a structure. They are often used for simpler geometries and loading conditions where the underlying assumptions (e.g., linear elasticity, small deformations) hold true.

However, for many real-world engineering problems, structures are geometrically complex, materials may have non-linear behavior, or loading conditions can be intricate. In such cases, finding an exact analytical solution is often not feasible. This is where computational approaches, most notably Finite Element Analysis (FEA), come into play. Computational methods use numerical techniques to approximate the solution to the governing equations. They allow engineers to analyze very complex systems that would be intractable with analytical methods alone.

Both approaches have their strengths and weaknesses. Analytical methods offer precise understanding and are excellent for validating fundamental concepts and simple designs. Computational methods provide the power to tackle complex, real-world problems and explore design variations quickly. Often, a combination of both is used: analytical solutions might be used to verify the results of a computational model for a simplified case, or to provide initial estimates for a more complex analysis. A good engineer understands when to apply each type of approach and how to interpret the results from both.

Consider these courses for a deeper dive into analytical and computational structural mechanics:

Testing and Experimentation

While theoretical models and mathematical equations form the backbone of Mechanics of Materials, experimental testing is equally crucial. Experiments provide the data needed to determine material properties, validate theoretical predictions, and understand how materials behave under real-world conditions. Without rigorous testing, the most sophisticated theories would remain unverified and potentially unreliable for practical engineering applications.

Common Material Tests

Engineers employ a variety of standardized tests to characterize the mechanical properties of materials. One of the most common is the tensile test. In this test, a specimen of a standard shape and size is subjected to a gradually increasing pulling force (tension) until it fractures. During the test, the applied load and the elongation of the specimen are continuously measured. The data obtained is used to create a stress-strain curve, from which key properties like Young's modulus, yield strength, ultimate tensile strength, and ductility can be determined.

Compression tests are similar to tensile tests, but the specimen is subjected to a squeezing force (compression). These tests are important for materials that are primarily used in compression, such as concrete or certain types of plastics and composites. Torsion tests involve twisting a specimen to determine its behavior under shear stress. This is particularly relevant for designing shafts and other components subjected to twisting loads. Other common tests include bending tests (to evaluate flexural strength and stiffness), hardness tests (to measure resistance to indentation), and impact tests (to assess a material's ability to withstand sudden loads or shocks).

These tests are typically performed under controlled laboratory conditions, following standardized procedures (e.g., ASTM standards) to ensure consistency and comparability of results. The data from these tests are fundamental for material selection, design calculations, and quality control in manufacturing.

These courses touch upon the principles underlying material testing:

Non-Destructive Testing (NDT) Techniques

Non-Destructive Testing (NDT), also known as Non-Destructive Examination (NDE) or Non-Destructive Inspection (NDI), encompasses a range of analysis techniques used to evaluate the properties of a material, component, or system without causing damage. This is a crucial advantage, as it allows for the inspection of parts that are in service or finished products without impairing their future usefulness. NDT methods are widely used for quality control, flaw detection, and structural integrity assessment in various industries.

Common NDT methods include Visual Testing (VT), which is often the first step and can involve aids like magnifiers or borescopes. Liquid Penetrant Testing (PT) is used to detect surface-breaking defects in non-porous materials by applying a colored or fluorescent dye that seeps into cracks. Magnetic Particle Testing (MT) is suitable for ferromagnetic materials to find surface and near-surface flaws by magnetizing the part and applying iron particles that accumulate at defect locations. Ultrasonic Testing (UT) employs high-frequency sound waves that are transmitted into a material; reflections or changes in the wave pattern can indicate internal flaws or measure thickness. Radiographic Testing (RT) uses X-rays or gamma rays to create an image of the internal structure, revealing voids, inclusions, or cracks. Other techniques include Eddy Current Testing (ET), Acoustic Emission Testing (AET), and Infrared Thermography (IRT).

The selection of an appropriate NDT method depends on factors such as the material type, the type and location of potential defects, the geometry of the component, and accessibility. NDT plays a vital role in ensuring safety and reliability, from inspecting welds in pipelines and pressure vessels to examining aircraft components for fatigue cracks.

This book provides a deeper look into NDT for specific material types:

Interpreting Experimental Data

Collecting data from material tests or NDT inspections is only the first step; accurately interpreting that data is critical for making sound engineering decisions. Data interpretation involves understanding the significance of the measurements, identifying trends or anomalies, and relating the findings back to the material's properties and the component's expected performance. This often requires a solid understanding of the test method itself, including its limitations and potential sources of error.

For example, in a tensile test, the resulting stress-strain curve provides a wealth of information. The slope of the initial linear portion gives Young's modulus, the point where the curve deviates from linearity indicates the yield strength, and the highest point on the curve represents the ultimate tensile strength. The area under the curve can be related to the material's toughness. Statistical analysis may be necessary when dealing with multiple samples to account for material variability and experimental uncertainty.

In NDT, interpretation can be more subjective and often relies on the skill and experience of certified inspectors. For instance, interpreting a radiograph requires identifying subtle changes in image density that might indicate a flaw, or in ultrasonic testing, distinguishing between signals from actual defects and those from geometric features of the part. Proper calibration of equipment and adherence to standardized procedures are essential for reliable data. Ultimately, the goal of data interpretation is to characterize the material accurately or to assess the condition of a component so that informed decisions can be made regarding its suitability for a given application or its continued service life.

Real-World Applications

The principles of Mechanics of Materials are not confined to textbooks and laboratories; they are the unseen foundation of much of the engineered world around us. From the mundane to the cutting-edge, understanding how materials respond to forces is critical for the design, construction, and maintenance of countless structures and devices. Exploring these applications reveals the broad impact and interdisciplinary nature of this essential engineering field.

Civil Engineering: Building the World Around Us

In civil engineering, Mechanics of Materials is indispensable for designing and analyzing structures such as bridges, buildings, tunnels, and dams. Engineers in this field must ensure that these structures can safely withstand various loads, including the weight of the structure itself (dead loads), the weight of occupants and furnishings (live loads), environmental loads like wind and snow, and even dynamic loads from earthquakes or traffic. Understanding how materials like steel, concrete, timber, and composites behave under stress and strain is fundamental to achieving safe and economical designs.

For instance, when designing a bridge, engineers use Mechanics of Materials to calculate the stresses and deflections in beams, columns, and cables under anticipated traffic and environmental conditions. This allows them to select appropriate materials and member sizes to prevent failure or excessive deformation. Similarly, in the design of high-rise buildings, analyzing the stresses in structural frames and foundations is crucial to ensure stability, especially against wind forces and seismic activity. The principles of buckling, shear, bending, and torsion are constantly applied to ensure the longevity and safety of civil infrastructure.

Moreover, Mechanics of Materials plays a role in assessing the condition of existing infrastructure. Techniques like non-destructive testing can help identify deterioration or damage in aging structures, allowing engineers to make informed decisions about repair, retrofitting, or replacement.

These courses are relevant for understanding structural behavior in civil engineering contexts:

Aerospace Engineering: Reaching for the Skies and Beyond

Aerospace engineering relies heavily on Mechanics of Materials for the design and analysis of aircraft, spacecraft, missiles, and satellites. The primary challenge in aerospace is often to create structures that are both extremely lightweight and exceptionally strong to withstand the severe aerodynamic forces, extreme temperatures, and vibrational loads encountered during flight and space missions. This necessitates the use of advanced materials, including high-strength aluminum alloys, titanium alloys, and, increasingly, composite materials.

Engineers use Mechanics of Materials to analyze the stresses in an aircraft's wings, fuselage, and engine components to ensure they don't fail under flight loads. Concepts like fatigue (failure under repeated loading cycles) and fracture mechanics (the study of how cracks initiate and propagate) are critical, as aerospace structures are subjected to many cycles of loading and unloading. The selection of materials with good fatigue resistance and fracture toughness is paramount for safety and reliability. Furthermore, understanding the behavior of materials at high and low temperatures is essential, as aircraft and spacecraft experience wide temperature variations.

The development and application of smart materials, which can sense and respond to their environment, is also an active area in aerospace, with potential applications in adaptive wing structures and vibration control. Mechanics of Materials provides the fundamental understanding needed to integrate these innovative materials into next-generation aerospace vehicles.

For those interested in aerospace applications, these resources are a good starting point:

Biomechanics: Engineering the Human Body

Biomechanics applies the principles of mechanics, including Mechanics of Materials, to biological systems. This interdisciplinary field has a wide range of applications, particularly in medicine and healthcare. Understanding the mechanical properties of biological tissues such as bone, cartilage, tendons, ligaments, and blood vessels is crucial for diagnosing and treating injuries and diseases, as well as for designing medical devices and implants.

For example, in orthopedics, Mechanics of Materials is used to design artificial joints (like hip and knee replacements) that can withstand the loads experienced during daily activities and are biocompatible with the surrounding tissues. It also helps in understanding how bones fracture and how internal fixation devices (like plates and screws) can be designed to promote healing. In cardiovascular engineering, the mechanical properties of blood vessels and heart valves are studied to understand diseases like atherosclerosis and to design artificial heart valves and stents. Even at the cellular level, the mechanical forces experienced by cells can influence their behavior, a field known as mechanobiology.

Sports biomechanics uses mechanical principles to analyze human movement to improve athletic performance and reduce the risk of injury. The design of protective equipment, like helmets and padding, also relies on an understanding of how materials absorb and distribute impact forces. As our understanding of biological materials and systems grows, the applications of Mechanics of Materials in biomechanics continue to expand, leading to innovations that improve human health and quality of life.

These courses and books provide insights into the intersection of mechanics and biological systems:

Delving Deeper: Advanced Topics

Once the fundamental principles of Mechanics of Materials are mastered, a vast landscape of advanced topics opens up. These areas address more complex material behaviors and failure mechanisms, often requiring more sophisticated analytical and computational tools. For researchers and specialists, these advanced topics are at the forefront of materials science and engineering innovation, tackling some of the most challenging problems in the field.

Fracture Mechanics and Fatigue Analysis

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It aims to understand the conditions under which a pre-existing crack or flaw in a material will grow and potentially lead to catastrophic failure, even if the overall applied stress is below the material's yield strength. This is a critical consideration in the design of structures where flaws might be present due to manufacturing processes or in-service damage, such as in pressure vessels, pipelines, aircraft structures, and bridges. Key concepts in fracture mechanics include stress intensity factors, which characterize the stress field near a crack tip, and fracture toughness, which is a material property that measures its resistance to crack propagation.

Fatigue is the weakening of a material caused by repeatedly applied loads. It is a progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Even if the maximum stress in each cycle is well below the material's static yield strength, cracks can initiate and grow over time, eventually leading to failure. Fatigue is a major cause of failure in many engineering components, particularly those subjected to vibration or repeated operational cycles, such as rotating machinery, vehicle components, and aircraft structures. Fatigue analysis involves predicting the life of a component under cyclic loading conditions, often using S-N curves (stress versus number of cycles to failure) and methodologies like Miner's rule for cumulative damage assessment.

Understanding and applying the principles of fracture mechanics and fatigue analysis are essential for ensuring the long-term reliability and safety of many engineering systems. These fields often involve detailed stress analysis, material testing, and non-destructive evaluation to detect and monitor cracks.

These books offer in-depth knowledge on these critical areas:

Composite Materials and Anisotropy

Composite materials are engineered materials made from two or more constituent materials with significantly different physical or chemical properties which, when combined, produce a material with characteristics different from the individual components. Common examples include reinforced plastics (like carbon fiber or glass fiber reinforced polymers), metal matrix composites, and ceramic matrix composites. Composites are often prized for their high strength-to-weight ratios, stiffness, and corrosion resistance, making them ideal for applications in aerospace, automotive, marine, and sporting goods industries.

A key characteristic of many composite materials is anisotropy. Anisotropic materials exhibit different mechanical properties when measured in different directions. This is in contrast to isotropic materials, which have uniform properties in all directions. For example, a unidirectional fiber-reinforced composite will be very strong and stiff in the direction of the fibers but significantly weaker and more flexible in the direction perpendicular to the fibers. This directional dependence of properties makes the analysis of composite structures more complex than that of isotropic materials.

The mechanics of composite materials involves understanding how the properties of the constituent materials (the reinforcement, like fibers, and the matrix, like a polymer resin) combine to give the overall properties of the composite. This includes analyzing stress and strain distributions within the different phases and predicting failure modes, which can be more complex in composites (e.g., delamination, fiber breakage, matrix cracking). Specialized theories, like classical lamination theory, are used to design and analyze structures made from layered composite laminates.

These resources are excellent for learning about composite materials:

Thermomechanical Coupling Effects

Thermomechanical coupling refers to the interaction between the thermal and mechanical behavior of materials. Changes in temperature can cause materials to expand or contract (thermal strain), and these strains can induce stresses if the material is constrained. Conversely, mechanical deformation can sometimes generate heat within a material, particularly during rapid plastic deformation or cyclic loading.

Understanding thermomechanical coupling is crucial in many engineering applications where components are subjected to both mechanical loads and significant temperature variations. For example, in gas turbines and jet engines, components operate at very high temperatures while also experiencing high mechanical stresses. The design of these components must account for thermal expansion, creep (time-dependent deformation at elevated temperatures), and thermal fatigue. Similarly, in electronic packaging, differences in the thermal expansion coefficients of various materials can lead to stresses during temperature cycling, potentially causing failure of solder joints or other components.

The analysis of thermomechanical problems often involves solving coupled equations that consider both the heat transfer within the material and its mechanical response. Material properties like the coefficient of thermal expansion, thermal conductivity, and specific heat capacity, as well as how mechanical properties (like Young's modulus and yield strength) change with temperature, are essential inputs for such analyses. Advanced computational tools are often used to simulate these complex interactions.

Educational Pathways in Mechanics of Materials

A career involving Mechanics of Materials typically begins with a strong educational foundation in engineering. Several pathways exist, from undergraduate degrees that introduce core concepts to advanced graduate studies focusing on specialized research. Developing both theoretical knowledge and practical skills is key to success in this demanding yet rewarding field. OpenCourser offers a vast library of engineering courses to help learners at all stages.

University Degrees and Core Coursework

A bachelor's degree in Mechanical Engineering or Civil Engineering is the most common starting point for a career related to Mechanics of Materials. These programs typically include foundational courses in physics, calculus, and chemistry, followed by core engineering science courses such as Statics, Dynamics, Thermodynamics, Fluid Mechanics, and, of course, Mechanics of Materials (often called Strength of Materials). The Mechanics of Materials course itself usually covers topics like stress, strain, axial loading, torsion, bending, shear, stress and strain transformation, beam deflections, and column buckling.

Beyond the introductory course, students may take more advanced courses in solid mechanics, stress analysis, finite element analysis, or material science, depending on their interests and career goals. Many programs also include laboratory components where students can perform material tests and gain hands-on experience. A strong grasp of mathematical principles and problem-solving skills is essential for success in these courses.

For those aspiring to careers in research, academia, or highly specialized engineering roles, a graduate degree (Master's or Ph.D.) is often necessary. Graduate programs allow for deeper specialization in areas like fracture mechanics, composite materials, computational mechanics, or biomechanics.

These online courses can serve as excellent supplements to university coursework or as refreshers for fundamental concepts:

The Role of Online Courses and Self-Study

Online courses offer a flexible and accessible way to build a foundational understanding of Mechanics of Materials or to supplement formal education. Platforms like Coursera, edX, and Udemy host a variety of courses taught by university professors and industry experts, covering topics from introductory principles to more advanced applications. These courses can be particularly useful for students looking to reinforce concepts learned in traditional lectures, for professionals seeking to refresh their knowledge or learn about new developments, or for individuals considering a career transition into engineering.

Self-study using textbooks, online resources, and open-source software can also be a valuable component of learning Mechanics of Materials. Many classic textbooks are available, offering detailed explanations, worked examples, and practice problems. OpenCourser's extensive catalog allows learners to search for thousands of online courses and books to find resources that match their learning style and goals. The "Save to list" feature on OpenCourser can help learners curate their own learning paths and track their progress.

While online courses and self-study can provide significant knowledge, it's important to recognize their role within the broader educational landscape. For aspiring professional engineers, a formal degree from an accredited institution is typically required for licensure and many employment opportunities. However, online resources are excellent tools for lifelong learning, skill enhancement, and exploring new areas of interest within the vast field of Mechanics of Materials.

These courses are excellent starting points for those looking to learn online:

Consider these widely respected textbooks for self-paced learning:

Developing Practical Skills: Labs and Projects

While theoretical understanding is crucial, Mechanics of Materials is ultimately an applied science. Developing practical skills through laboratory work and hands-on projects is essential for translating knowledge into real-world engineering solutions. Many university programs incorporate lab sessions where students conduct experiments like tensile tests, bending tests, or hardness tests. These labs allow students to see firsthand how materials behave under load, learn how to operate testing equipment, and practice collecting and analyzing experimental data.

Engaging in design projects, whether as part of coursework or through extracurricular activities like student engineering competitions, provides invaluable experience. These projects often require students to apply Mechanics of Materials principles to design, analyze, build, and test a structure or device. This process helps solidify theoretical concepts and develops important skills in problem-solving, teamwork, and communication. For example, designing a lightweight bridge to carry a specific load or a component for a racing vehicle involves careful material selection and stress analysis.

For those learning online or through self-study, seeking opportunities for practical application is equally important. This might involve personal projects, using simulation software (some of which have free or student versions) to analyze designs, or even volunteering for projects that involve material testing or structural analysis. The OpenCourser Learner's Guide offers articles on how to structure self-learning and find projects to supplement online coursework, helping learners bridge the gap between theory and practice.

Career Paths and Professional Development

A strong foundation in Mechanics of Materials opens doors to a wide array of career opportunities across numerous industries. From entry-level engineering roles to specialized research positions and management, the skills honed in this field are highly valued. Continuous learning and professional development are key to advancing in this dynamic and evolving domain. According to the U.S. Bureau of Labor Statistics, employment for materials engineers is projected to grow 7 percent from 2023 to 2033, which is faster than the average for all occupations. Similarly, the global Engineering Materials market is expected to see significant growth.

Typical Entry-Level Positions

Graduates with a bachelor's degree in engineering and a solid understanding of Mechanics of Materials can find entry-level positions in various sectors. In manufacturing, roles might include design engineer, stress analyst, or materials engineer, focusing on the design and testing of components and products. In the construction industry, graduates might work as structural engineers or field engineers, involved in the design and oversight of building and infrastructure projects. The aerospace and automotive industries also offer numerous opportunities for engineers with expertise in solid mechanics and material behavior, working on tasks like structural analysis, component design, and material selection.

Entry-level engineers typically work under the supervision of more experienced professionals, gaining practical experience and applying their academic knowledge to real-world problems. Responsibilities might include performing calculations, using CAD (Computer-Aided Design) and FEA (Finite Element Analysis) software, assisting with material testing, and preparing technical reports. Strong analytical and problem-solving skills, attention to detail, and the ability to work effectively in a team are crucial for success in these roles.

While a Professional Engineering (PE) license is not always required for entry-level positions, particularly in manufacturing, it can become important for career advancement, especially for those in consulting or roles involving public safety. Many engineers pursue the Fundamentals of Engineering (FE) exam, the first step towards PE licensure, around the time of graduation or shortly thereafter.

For those starting their journey, these courses can help build essential skills:

Gaining Certifications and Licensure

For many engineers, particularly those whose work directly impacts public safety (such as in civil or structural engineering), obtaining a Professional Engineer (PE) license is a significant career milestone. Licensure requirements typically include graduating from an ABET-accredited engineering program, passing the Fundamentals of Engineering (FE) exam, gaining several years of progressive engineering experience under a licensed PE, and finally, passing the Principles and Practice of Engineering (PE) exam in their specific discipline. The PE license allows engineers to take legal responsibility for their work, sign and seal engineering documents, and offer services directly to the public.

Beyond the PE license, various professional organizations offer certifications in specialized areas of Mechanics of Materials or related fields. For example, certifications might be available in non-destructive testing (NDT), welding inspection, or specific areas of materials science like metallography or composites. These certifications can demonstrate a high level of expertise and commitment to a particular specialty, potentially enhancing career opportunities and earning potential. Continuous learning through professional development courses, workshops, and conferences is also essential for staying current with advancements in the field.

Navigating the requirements for licensure and certification can seem daunting, but it's a well-trodden path. For those considering this route, remember that each step builds upon the last. Focus on excelling in your foundational education, gaining relevant work experience, and then preparing diligently for the required examinations. The rewards, in terms of professional standing and career opportunities, can be substantial.

This book might be useful for those specifically in patent-related aspects, which can intersect with advanced material development:

Advancement and Specialization Opportunities

Career advancement in fields related to Mechanics of Materials can take many forms. With experience, engineers may take on projects of increasing complexity and responsibility, lead engineering teams, or move into project management roles. Further specialization can also lead to advancement. This might involve developing deep expertise in a particular area such as fracture mechanics, computational mechanics (FEA), composite materials, NDT, or a specific application area like aerospace structures or biomedical implants.

Pursuing a graduate degree (Master's or Ph.D.) is a common path for those interested in research and development (R&D) roles, academia, or highly specialized technical positions. A Ph.D. is often essential for faculty positions in universities and for leading advanced research programs in industry or government labs. Advanced degrees can equip engineers with the cutting-edge knowledge and research skills needed to tackle complex challenges and drive innovation in materials science and engineering mechanics.

Another avenue for advancement is moving into management or leadership roles, which may involve overseeing engineering departments, managing large-scale projects, or contributing to strategic decision-making within an organization. For these roles, in addition to strong technical skills, abilities in communication, leadership, and business acumen become increasingly important. Some engineers may also choose to leverage their technical expertise to transition into related fields such as technical sales, consulting, or entrepreneurship, perhaps by starting their own engineering firms or developing new material technologies. The path you choose will depend on your individual interests, skills, and career aspirations. The journey can be challenging, but the opportunities for growth and impact are significant.

Consider these related fields for potential specialization or career pivots:

The Evolving Landscape of Mechanics of Materials

The field of Mechanics of Materials is not static; it is continuously evolving in response to new technological advancements, societal needs, and scientific discoveries. Emerging trends are shaping the future of how engineers design, analyze, and utilize materials. Staying abreast of these developments is crucial for professionals in the field to remain competitive and contribute to cutting-edge innovations. The demand for materials engineers is expected to grow, driven by the need for new materials and manufacturing processes.

Innovations in Smart Materials and Nanotechnology

Smart materials and nanotechnology are two rapidly advancing areas with profound implications for Mechanics of Materials. Smart materials, also known as intelligent or responsive materials, are designed to have one or more properties that can be significantly changed in a controlled fashion by external stimuli, such as stress, temperature, moisture, pH, electric or magnetic fields. Examples include piezoelectric materials (which generate an electric charge in response to mechanical stress and vice versa), shape memory alloys (which can return to their original shape after deformation when heated), and magnetorheological fluids (whose viscosity changes in response to a magnetic field). Mechanics of Materials plays a crucial role in understanding the behavior of these materials and integrating them into applications like sensors, actuators, adaptive structures, and vibration damping systems, particularly in fields like aerospace and robotics.

Nanotechnology involves the manipulation of matter on an atomic, molecular, and supramolecular scale (typically 1 to 100 nanometers). At this scale, materials can exhibit unique mechanical, electrical, and optical properties that differ significantly from their bulk counterparts. Nanomaterials, such as carbon nanotubes, graphene, and quantum dots, offer exciting possibilities for creating materials with unprecedented strength, conductivity, or reactivity. Understanding the mechanics of these nanoscale structures and how they interact is a key research area. Applications range from developing ultra-strong lightweight composites to creating new sensors and energy storage devices. The global nanomaterials and nanotechnology market is projected for significant growth.

The integration of smart materials and nanotechnology is leading to the development of multifunctional materials and systems with enhanced performance and capabilities.

These resources touch on areas related to advanced material structures:

Sustainability and Green Materials

Growing global concerns about environmental impact and resource depletion are driving a significant push towards sustainability in materials engineering. This involves developing and utilizing materials that are more environmentally friendly throughout their lifecycle, from raw material extraction and processing to manufacturing, use, and end-of-life disposal or recycling. Mechanics of Materials plays a vital role in this effort by helping engineers design products that are more durable, require less material (lightweighting), and can be made from sustainable resources.

Research is focused on developing "green materials," which include biodegradable polymers derived from renewable resources, recycled materials, and materials with lower embodied energy (the energy required to produce them). Understanding the mechanical properties and long-term performance of these sustainable alternatives is crucial for their successful adoption in various applications, from packaging and consumer goods to construction and automotive components. For example, engineers are exploring the use of natural fibers (like flax or hemp) as reinforcement in composites, or developing new alloys that are easier to recycle without loss of properties.

Furthermore, Mechanics of Materials principles contribute to designing for durability and longevity, which reduces the need for premature replacement and conserves resources. Optimizing designs to minimize material usage without compromising safety or performance is another key aspect of sustainable engineering. The global sustainable materials market is experiencing substantial growth as industries seek to meet environmental regulations and consumer demand for greener products.

The Role of AI and Machine Learning in Material Design

Artificial Intelligence (AI) and Machine Learning (ML) are rapidly emerging as powerful tools in materials science and engineering, including Mechanics of Materials. These computational techniques can analyze vast amounts of data from experiments, simulations, and literature to accelerate the discovery and design of new materials with desired properties. For instance, ML algorithms can be trained to predict material properties based on chemical composition or processing parameters, significantly reducing the time and cost associated with traditional trial-and-error experimentation.

AI can also be used to optimize material structures and manufacturing processes. In computational mechanics, AI can enhance the efficiency and accuracy of simulations, or even develop surrogate models that can rapidly predict material behavior without the need for full-scale FEA. AI-driven approaches are being explored for tasks like identifying defects in materials from NDT data, predicting material failure, and designing customized materials for specific applications (e.g., "designer alloys" or architected materials with tailored mechanical responses).

While AI and ML offer immense potential, their effective application in Mechanics of Materials requires a strong understanding of the underlying physical principles. Engineers in this field will increasingly need to be conversant with data science techniques and be able to integrate these tools into their workflows. The synergy between domain expertise in mechanics and the power of AI is expected to drive significant innovations in the years to come.

For a look at how AI is impacting engineering broadly, information can be found through resources like Amtec's article on AI and Automation in the Engineering Workforce.

Frequently Asked Questions for Career Explorers

Embarking on a career path related to Mechanics of Materials can bring up many questions, especially for those new to the field or considering a career change. Addressing these common concerns can help you make informed decisions and set realistic expectations. It's a challenging field, but one with significant rewards and opportunities for those who are passionate about understanding and shaping the physical world.

What are the essential skills for an entry-level position?

For an entry-level position in Mechanics of Materials or a related engineering role, a strong foundation in core engineering principles is paramount. This includes a solid understanding of statics, dynamics, thermodynamics, and, of course, the fundamentals of stress, strain, material properties, and failure theories. Proficiency in mathematics, particularly calculus and differential equations, is crucial for analytical problem-solving. Employers also look for familiarity with engineering design processes and the ability to apply theoretical knowledge to practical problems.

Beyond technical knowledge, several soft skills are highly valued. Strong analytical and critical thinking skills are essential for diagnosing problems and developing solutions. Good communication skills, both written and verbal, are necessary for collaborating with team members, presenting findings, and writing technical reports. Attention to detail is critical, as small errors in calculations or assumptions can have significant consequences in engineering design. Familiarity with common engineering software, such as CAD tools and FEA packages, is also increasingly expected, even at the entry level. A willingness to learn and adapt is also important, as technology and engineering practices are constantly evolving.

If you're building these skills, remember that practical experience through internships, co-op programs, or significant academic projects can greatly enhance your resume and demonstrate your capabilities to potential employers. Don't be discouraged if you don't feel like an expert in all these areas right away; entry-level roles are understood to be learning opportunities as well.

What are the typical salary expectations?

Salary expectations for roles involving Mechanics of Materials can vary significantly based on factors such as geographic location, industry, company size, level of education, years of experience, and specific job responsibilities. According to the U.S. Bureau of Labor Statistics, the median annual wage for materials engineers was $108,310 in May 2024. The lowest 10 percent earned less than $68,040, and the highest 10 percent earned more than $172,000. For mechanical engineers, a closely related field, the median annual salary was reported as $87,370 by the BLS in earlier data, with experienced engineers and those with Master's degrees typically earning more. Some sources indicate entry-level salaries for mechanical engineers ranging from $60,000 to $80,000, with potential for significant increases with experience. For instance, a mechanical maintenance engineer could expect an average annual pay of around $81,593 as of early 2025, with a range depending on experience and location. It's worth noting that salaries can differ even for similar roles; for example, a Mechanical/Materials Engineer Co-op position might have a different compensation structure.

Industries that typically offer higher compensation include aerospace, oil and gas, and specialized manufacturing sectors. Engineers with advanced degrees (Master's or Ph.D.) or those who have obtained a Professional Engineer (PE) license often command higher salaries. It's advisable to research salary benchmarks for your specific location and target industry using resources like the U.S. Bureau of Labor Statistics Occupational Outlook Handbook, professional engineering organizations, and online salary aggregators.

While salary is an important consideration, it's also valuable to weigh other factors such as benefits, work-life balance, opportunities for growth and development, and the intrinsic satisfaction of the work itself when evaluating career options.

How is automation impacting roles in material engineering?

Automation, including robotics and AI-driven systems, is transforming many aspects of materials engineering, from research and development to manufacturing and testing. In manufacturing, automated systems can handle repetitive tasks with high precision, improve efficiency, enhance quality control, and take over hazardous jobs, leading to safer work environments. This can mean a shift in the types of roles available, with a potential decrease in demand for manual labor in some areas but an increased need for engineers who can design, implement, and maintain these automated systems.

In materials discovery and design, AI and machine learning are being used to accelerate the process of identifying new materials with desired properties, analyzing experimental data, and optimizing material formulations. This doesn't necessarily replace materials engineers but rather augments their capabilities, allowing them to tackle more complex problems and innovate faster. Engineers may need to develop skills in data analysis, computational modeling, and working with AI tools.

The impact of automation is not uniform across all roles. While some routine tasks may become automated, the need for critical thinking, problem-solving, creativity, and expertise in fundamental engineering principles remains strong. Engineers who can adapt to new technologies and embrace lifelong learning will be best positioned to thrive in this evolving landscape. The focus may shift from performing routine calculations or tests to interpreting complex data generated by automated systems, designing more sophisticated materials and products, and managing integrated manufacturing systems. This transition can be challenging, but it also opens up exciting new avenues for innovation and career development.

What is the global demand for material engineers?

The global demand for materials engineers and professionals with expertise in Mechanics of Materials is generally positive and expected to grow. This demand is driven by several factors, including ongoing industrialization in developing economies, the need for innovation in established industries, and the pursuit of solutions to global challenges such as sustainable development and resource efficiency. Industries like aerospace, automotive, electronics, energy (both conventional and renewable), healthcare (biomedical devices), and construction all rely heavily on advancements in materials science and engineering.

Specific regions and countries may experience varying levels of demand based on their industrial base and investment in research and development. For example, regions with strong manufacturing sectors or significant aerospace or automotive industries are likely to have a steady demand for materials engineers. The increasing focus on advanced materials, such as composites, smart materials, and nanomaterials, is also creating new opportunities globally. According to some market analyses, the global Engineering Materials market is projected to expand significantly in the coming years. Enrollment numbers in materials science and engineering programs have also seen growth, indicating an increasing interest and recognition of the importance of this field.

For individuals considering a career in this field, it's beneficial to stay informed about global industry trends and a willingness to be geographically flexible can sometimes open up more opportunities. Developing a strong skillset, potentially including proficiency in multiple languages or experience in international collaborations, can also be advantageous in a globalized job market.

How can one balance fieldwork versus computational roles?

Careers related to Mechanics of Materials can offer a spectrum of work environments, ranging from hands-on fieldwork and laboratory testing to purely computational and office-based roles. The balance between these often depends on the specific industry, job function, and individual preferences. Some engineers thrive in the dynamic environment of a manufacturing plant, construction site, or testing lab, enjoying the tangible aspects of working with materials and equipment. Others may prefer the analytical challenges of computational modeling, simulation, and data analysis in an office setting.

Many roles, however, involve a blend of both. For example, a design engineer might spend time developing models on a computer but also oversee the prototyping and testing of their designs. A failure analyst might conduct on-site investigations and collect samples (fieldwork), then perform laboratory tests and computational simulations to determine the cause of failure. Even in primarily computational roles, understanding the practical limitations and realities of material behavior and testing is crucial for developing accurate models and interpreting results meaningfully.

Choosing a path that aligns with your interests and work style is important. If you enjoy hands-on work, look for roles in manufacturing, quality control, experimental research, or field engineering. If you are passionate about mathematical modeling and simulation, positions in R&D, computational analysis, or software development might be a better fit. It's also possible to transition between roles with different balances of fieldwork and computational tasks as your career progresses and your interests evolve. Gaining experience in both areas early in your career can provide a broader perspective and make you a more versatile engineer.

What are the best ways to pursue continuing education for career advancement?

Continuous learning is vital for career advancement in the dynamic field of Mechanics of Materials. One primary route is pursuing formal advanced degrees, such as a Master's or Ph.D., particularly for those aiming for specialized technical roles, research positions, or academic careers. These programs offer in-depth knowledge and research experience in specific sub-fields.

For working professionals, many universities offer part-time graduate programs or graduate certificates that can be pursued while maintaining employment. Professional organizations often provide a wealth of resources, including workshops, seminars, webinars, and conferences, which are excellent for learning about the latest advancements, networking with peers, and earning professional development hours (PDHs) often required to maintain a PE license. Industry-specific training courses and certifications, for example in NDT methods or specialized software, can also enhance skills and marketability.

Online learning platforms, like those searchable on OpenCourser, offer a vast array of courses on specific topics within Mechanics of Materials, software tools (like FEA packages), and related disciplines such as data science or project management. These can be a flexible and cost-effective way to acquire new skills or refresh existing knowledge. Subscribing to academic journals and industry publications, and actively participating in professional communities, either online or in person, also contributes to ongoing learning. Ultimately, a proactive approach to identifying knowledge gaps and seeking out relevant educational opportunities is key to long-term career growth in this ever-evolving field. You can also explore the OpenCourser Notes blog for articles on leveraging online courses for professional development.

Concluding Thoughts

Mechanics of Materials is a rich and rewarding field that forms a critical pillar of modern engineering. It provides the intellectual tools to understand and predict how materials and structures behave under the influence of forces, enabling the design and creation of the physical world around us. From ensuring the safety of bridges and buildings to enabling the development of advanced aerospace vehicles and life-saving biomedical devices, its applications are vast and impactful.

The journey to mastering Mechanics of Materials requires dedication, a strong grasp of fundamental principles, and a continuous desire to learn. Whether you are a student just beginning to explore this area, a professional looking to deepen your expertise, or someone considering a career change, the path involves rigorous study, practical application, and an appreciation for both theoretical understanding and experimental validation. The challenges are real, but the opportunities to contribute to innovation, solve complex problems, and make a tangible difference in the world are immense. As technology continues to evolve, with advancements in smart materials, nanotechnology, and computational tools, the field of Mechanics of Materials will undoubtedly continue to offer exciting frontiers for exploration and discovery.