Fluid Dynamics Engineer

Illuminating the Path: A Career as a Fluid Dynamics Engineer

Fluid Dynamics Engineering is a specialized branch of engineering focused on the study of fluid flow—liquids and gases—and its effects on systems and environments. Professionals in this field, known as Fluid Dynamics Engineers or often Computational Fluid Dynamics (CFD) Engineers, apply principles of fluid mechanics, thermodynamics, and heat transfer to design, analyze, and optimize a vast array of processes and products. This discipline is crucial for understanding everything from the airflow around a Formula 1 car to the circulation of blood in the human body, or the atmospheric currents shaping our weather.

Working as a Fluid Dynamics Engineer can be incredibly engaging. Imagine using sophisticated software to simulate the behavior of air around a next-generation aircraft, contributing to more fuel-efficient designs. Consider the challenge of modeling the complex flow of coolants in a nuclear reactor to enhance safety, or designing more effective wind turbines to harness renewable energy. These are the kinds of impactful problems Fluid Dynamics Engineers tackle daily, blending deep theoretical knowledge with cutting-edge computational tools.

What is Fluid Dynamics Engineering?

At its core, fluid dynamics is the science of fluids (liquids and gases) in motion. Fluid Dynamics Engineering takes these scientific principles and applies them to solve real-world engineering problems. This often involves predicting fluid behavior, such as velocity, pressure, temperature, and density, in various scenarios. Because the underlying physics can be incredibly complex, especially with turbulent flows or interactions between multiple fluids, engineers in this field increasingly rely on Computational Fluid Dynamics (CFD). CFD utilizes numerical methods and algorithms to solve and analyze problems involving fluid flows, often requiring powerful computing resources.

The applications of fluid dynamics are remarkably diverse. If it involves a liquid or a gas in motion, a Fluid Dynamics Engineer could be involved. This breadth means that the career can take many exciting turns, allowing for specialization in areas that align with personal interests, from the microscopic scale of microfluidics to the macroscopic scale of weather systems or ocean currents.

This field is essential for innovation and efficiency. By understanding and predicting how fluids behave, engineers can improve the performance of vehicles, optimize energy production, design safer chemical plants, develop advanced medical devices, and even contribute to environmental protection by modeling pollutant dispersion. The insights gained from fluid dynamics analysis can lead to significant cost savings, enhanced safety, and more sustainable technologies.

The Role of a Fluid Dynamics Engineer

A Fluid Dynamics Engineer, particularly one specializing in CFD, typically undertakes a range of responsibilities. These often begin with defining the problem and understanding the specific requirements of a project. This might involve studying the geometry of an object (like a car or an airplane wing) or a system (like a pipeline or a combustion chamber) that interacts with a fluid. They then prepare this geometry for simulation, which can involve cleaning up computer-aided design (CAD) files and simplifying complex features to make the computational analysis feasible.

A significant part of the role involves creating a "mesh" or grid over the geometry, which divides the fluid domain into a large number of small cells where the governing equations will be solved. The quality of this mesh is crucial for accurate results. The engineer then sets up the simulation by selecting appropriate physical models (e.g., turbulence models), defining boundary conditions (like inlet velocities or outlet pressures), and choosing numerical methods. Running the simulation, often on high-performance computing clusters, is the next step, followed by the critical task of post-processing and interpreting the vast amounts of data generated. This involves visualizing flow patterns, extracting key parameters like forces or heat transfer rates, and validating the results against experimental data or theoretical predictions.

Finally, Fluid Dynamics Engineers communicate their findings to other engineers, designers, or clients, often providing recommendations for design modifications or optimizations. This requires strong analytical and problem-solving skills, attention to detail, and effective communication abilities. They act as crucial links in the design and development process, helping to refine concepts and ensure optimal performance and safety.

Industries and Specializations

Fluid Dynamics Engineers are sought after in a wide array of industries due to the fundamental nature of fluid mechanics. The aerospace industry relies heavily on fluid dynamics for aircraft and spacecraft design, focusing on aerodynamics to optimize lift, reduce drag, and understand combustion in engines. Similarly, the automotive sector employs these engineers to improve vehicle aerodynamics for fuel efficiency, manage engine cooling, and optimize internal combustion processes. The energy sector, including traditional power generation (like turbines in power plants) and renewable energy (such as wind turbine design and tidal energy), offers numerous opportunities.

Other significant industries include chemical processing, where engineers design and optimize reactors, mixing processes, and pipeline transport; environmental engineering, for modeling pollution dispersion, water treatment processes, and weather patterns; and biomedical engineering, for analyzing blood flow, respiratory systems, and designing medical devices like artificial hearts or drug delivery systems. Even fields like manufacturing, civil engineering (e.g., bridge aerodynamics, dam spillways), and sports (e.g., optimizing athlete performance or equipment design) benefit from fluid dynamics expertise.

Within these industries, engineers can specialize in various sub-fields. Aerodynamics, focusing on the flow of air and other gases, is a major specialization, particularly in aerospace and automotive sectors. Hydrodynamics deals with liquid flows, relevant in naval architecture, civil engineering, and oceanography. Other specializations might include multiphase flow (flows involving more than one fluid or phase, like bubbles in water or droplets in air), heat transfer, combustion modeling, or biofluid mechanics. Many engineers also specialize in the computational aspect itself, becoming experts in CFD software development, high-performance computing, or advanced numerical methods.

Core Concepts in Fluid Dynamics

To excel as a Fluid Dynamics Engineer, a strong grasp of fundamental principles is essential. These concepts form the bedrock upon which all analysis and design work is built. Understanding these ideas allows engineers to interpret simulation results correctly, make informed decisions about modeling approaches, and ultimately, develop innovative solutions to complex fluid flow problems.

The study of fluid dynamics can appear daunting at first, with its array of equations and terminology. However, at its heart, it's about understanding how forces and energy interact within and around fluids. Whether you're considering the smooth, predictable flow of honey or the chaotic, swirling patterns of a river rapid, the same fundamental physical laws apply.

Fundamental Principles: An ELI5 Approach

Imagine you're playing with water in a bathtub. Fluid dynamics, at a very simple level, tries to explain what the water is doing and why. If you push the water, it moves. That push is a force. The water also has properties like how "thick" or "sticky" it is – scientists call this viscosity. Honey is very viscous (thick and sticky), so it flows slowly. Water is less viscous, so it flows easily.

Now, if you stir the water gently, it might flow in smooth, orderly layers. This is called laminar flow. But if you splash or stir it really fast, the water goes everywhere in a messy, chaotic way. That's called turbulent flow. Turbulent flow is much harder to predict than laminar flow, and it's something Fluid Dynamics Engineers spend a lot of time studying. Think of smoke rising from a candle: at first, it's a smooth stream (laminar), but then it becomes all swirly and mixed up (turbulent).

To describe how fluids move, scientists and engineers use a set of complex mathematical equations. The most famous of these are the Navier-Stokes equations. You don't need to solve them by hand for a career (computers do that!), but understanding what they represent is key. Essentially, they are like a very detailed instruction manual for how fluids should behave, taking into account things like pressure, velocity, viscosity, and forces acting on the fluid. They are based on fundamental principles of physics, such as the conservation of mass (you can't create or destroy fluid out of nowhere), conservation of momentum (a fluid in motion tends to stay in motion unless a force acts on it – Newton's second law applied to fluids), and conservation of energy (energy within the fluid system changes form but isn't lost).

These core ideas—viscosity, the difference between laminar and turbulent flow, and the fundamental conservation laws embodied in equations like Navier-Stokes—are what engineers use to analyze everything from how air flows over a plane wing to how water moves through a pipe.

To build a solid understanding of these foundational topics, exploring introductory texts can be very beneficial. These often break down complex ideas into more digestible parts, providing a strong starting point for further study.

Key Computational Tools and Techniques

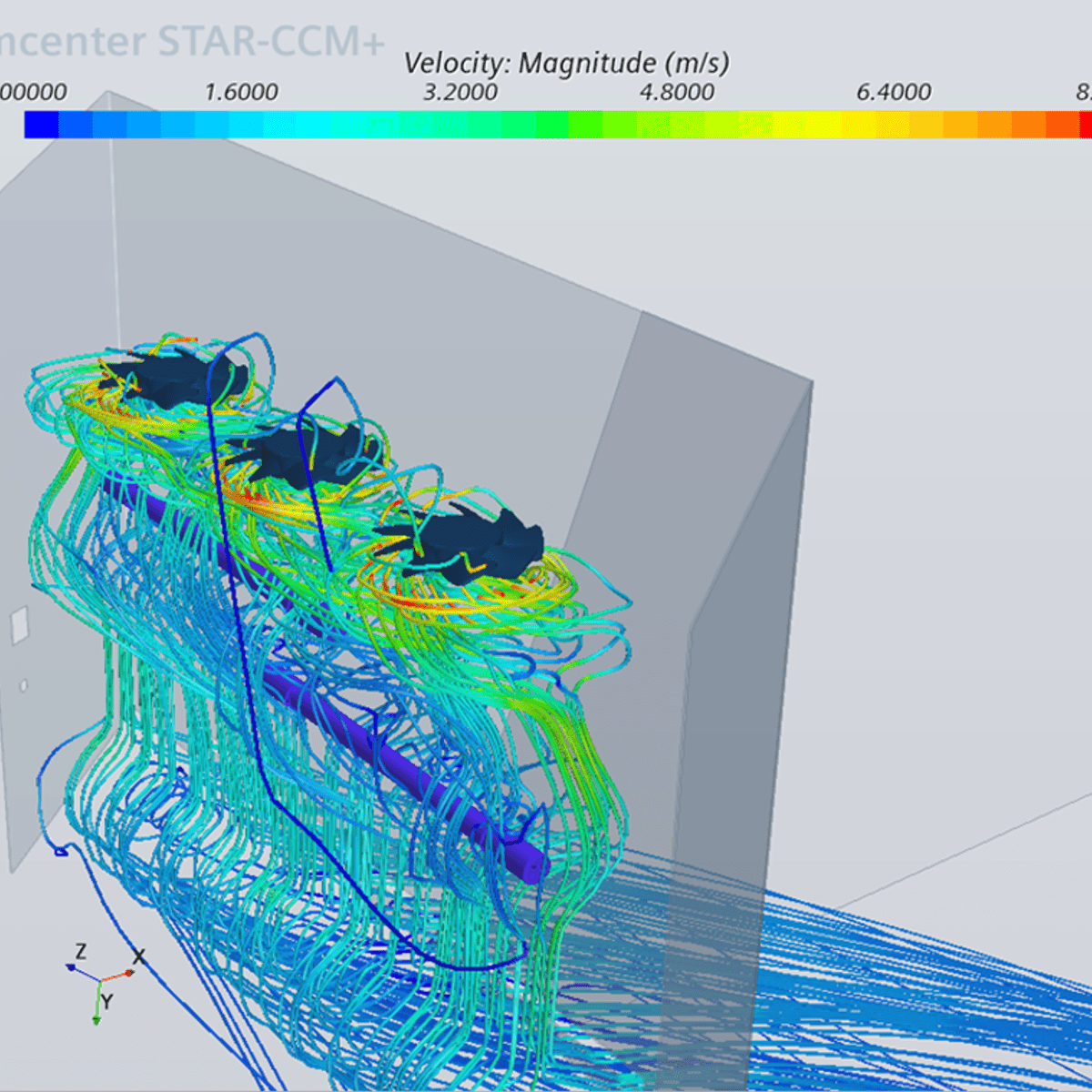

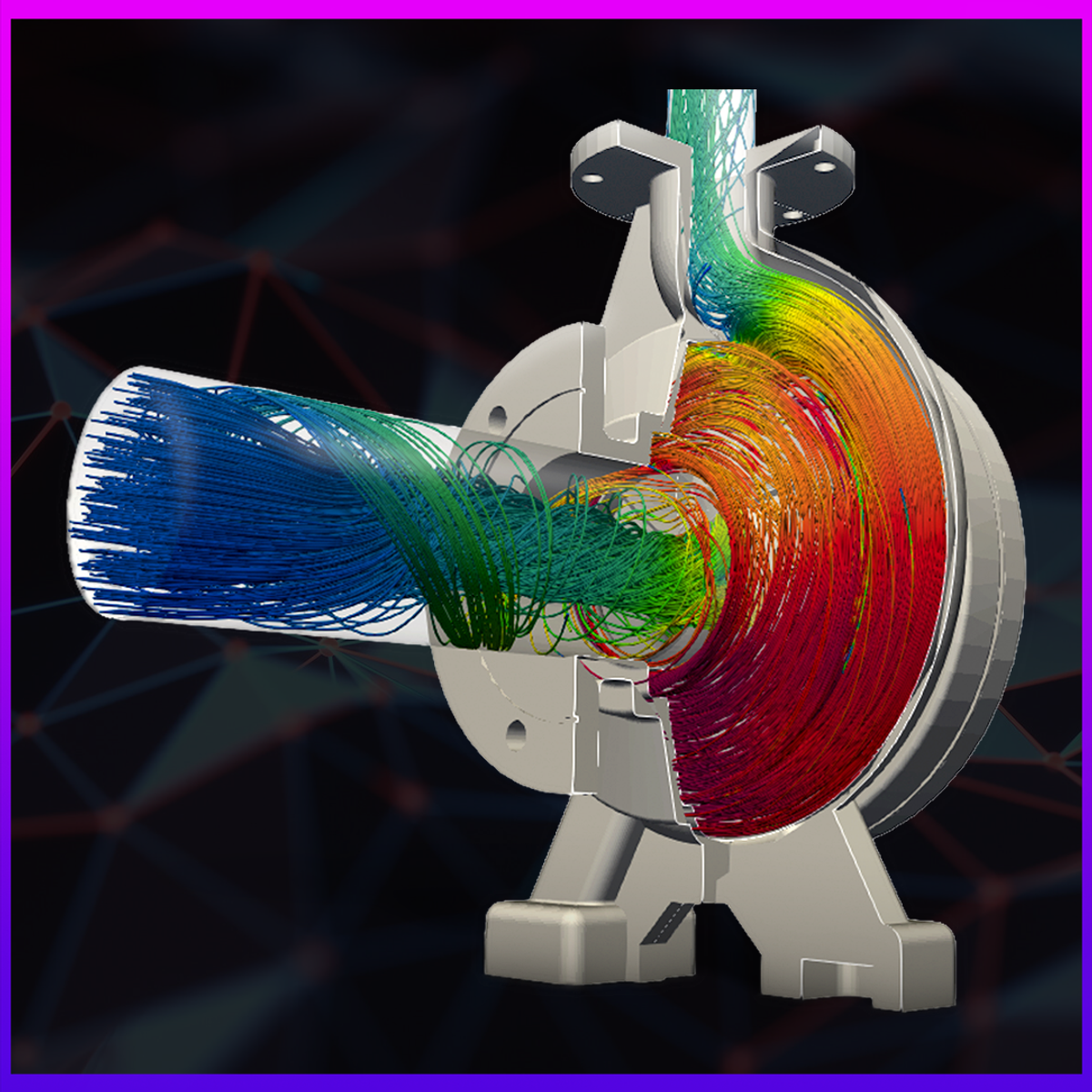

Modern Fluid Dynamics Engineering heavily relies on computational tools, primarily Computational Fluid Dynamics (CFD) software. These software packages allow engineers to build virtual models of their systems and simulate fluid flow numerically. Popular commercial CFD software includes ANSYS Fluent, Siemens STAR-CCM+, COMSOL Multiphysics, and others. There are also powerful open-source options like OpenFOAM. Proficiency in at least one major CFD package is often a requirement for Fluid Dynamics Engineers.

The CFD process generally involves three main stages: pre-processing, solving, and post-processing. Pre-processing includes defining the geometry of the problem, generating a computational mesh (a grid of cells or elements that discretizes the domain), and setting up the physical models and boundary conditions. Mesh generation is a critical skill, as the quality and resolution of the mesh significantly impact the accuracy and computational cost of the simulation.

The "solving" stage involves the CFD software numerically solving the governing equations (like the Navier-Stokes equations) iteratively for each cell in the mesh. This is computationally intensive and often requires high-performance computing (HPC) resources, especially for large or complex simulations. Post-processing is where the engineer visualizes and analyzes the simulation results. This can involve generating contour plots of pressure or velocity, vector plots showing flow direction, streamlines, and calculating quantitative data like forces, flow rates, or heat transfer coefficients. Data visualization tools are key for interpreting the large datasets produced by CFD simulations.

Beyond the core CFD software, engineers may also use CAD software for geometry creation and modification, scripting languages like Python or MATLAB for automating tasks, customizing models, or performing data analysis, and various data visualization tools. Understanding numerical methods for solving partial differential equations is also beneficial.

For those looking to gain hands-on experience with CFD tools and fundamental concepts, several online courses offer practical introductions. These can be invaluable for building foundational skills and understanding the workflow of a CFD analysis.

These courses provide a good starting point for learning the practical aspects of CFD simulation and the underlying principles.

Material Science in Fluid Systems

While fluid dynamics primarily focuses on the behavior of fluids, the properties of the materials that contain or interact with these fluids are also crucial. Material science considerations play a significant role in the design and analysis of fluid systems. For instance, the choice of material for a pipe can affect its roughness, which in turn influences the friction and pressure drop of the fluid flowing through it. The material's ability to withstand temperature and pressure, and its resistance to corrosion by the fluid, are critical for safety and longevity.

In heat transfer applications, the thermal conductivity of the materials involved is paramount. For example, in a heat exchanger, materials with high thermal conductivity are desired for the surfaces separating the hot and cold fluids to maximize heat transfer efficiency. Conversely, insulating materials with low thermal conductivity are used to minimize heat loss from a system. The specific heat capacity of a material also influences how quickly it heats up or cools down.

Furthermore, in applications involving very high velocities or aggressive fluids, issues like erosion and cavitation (the formation and collapse of vapor bubbles in a liquid) can cause significant damage to material surfaces. Selecting materials with appropriate hardness, toughness, and chemical resistance is essential to mitigate these effects. Understanding the interaction between fluids and solid surfaces, including phenomena like wetting and surface tension, also falls under the umbrella of material considerations relevant to fluid dynamics.

For individuals interested in how material properties influence fluid behavior and system design, foundational knowledge in materials science and thermodynamics is beneficial. You can explore relevant courses and books through resources like OpenCourser's science section.

Understanding these interactions is vital for designing robust and efficient fluid systems. The following book offers insights into the properties of fluids and the materials they interact with.

Academic Pathways to Fluid Dynamics Engineering

Embarking on a career as a Fluid Dynamics Engineer typically begins with a strong educational foundation in engineering. The specific path can vary, but certain degrees and areas of study are particularly relevant. For those in high school or early university, understanding these pathways can help in course selection and academic planning.

This field often requires a deep understanding of mathematical principles and physical laws. Therefore, a rigorous academic program is usually the first step. While the journey might seem demanding, the intellectual stimulation and the potential to contribute to significant technological advancements make it a rewarding pursuit for many.

Relevant Undergraduate Degrees

The most common undergraduate degrees for aspiring Fluid Dynamics Engineers are in Mechanical Engineering or Aerospace Engineering. These programs typically provide a broad education in engineering fundamentals, including thermodynamics, fluid mechanics, heat transfer, solid mechanics, and mathematics, all of which are crucial for fluid dynamics. Chemical Engineering is another relevant degree, especially for those interested in fluid dynamics within chemical reactors, separation processes, or multiphase flows.

During an undergraduate program, students interested in fluid dynamics should focus on elective courses that delve deeper into fluid mechanics, aerodynamics, heat transfer, and computational methods. Gaining early exposure to CAD software and possibly some introductory CFD concepts or tools can also be advantageous. Many universities offer opportunities for undergraduate research projects, which can provide invaluable hands-on experience in a specific area of fluid dynamics.

It's also beneficial to develop strong programming skills, particularly in languages like Python or MATLAB, as these are often used for data analysis, scripting, and automation in engineering workflows. While a bachelor's degree can be sufficient for some entry-level positions, particularly those focused on applying existing CFD tools under supervision, many advanced roles, especially in research and development, may require further education.

For those exploring foundational aerospace concepts online, courses can offer a great introduction to the field.

Graduate Research Opportunities

For individuals seeking to specialize deeply in fluid dynamics, pursue research, or qualify for more advanced engineering roles, a graduate degree (Master's or Ph.D.) is often recommended and sometimes required. Graduate programs offer the chance to focus intensively on specific areas of fluid dynamics, such as turbulence, computational methods, multiphase flow, aerodynamics, or a particular application area (e.g., biomedical flows, environmental flows).

Master's programs typically involve advanced coursework and often a research project or thesis. A Ph.D. program is centered around original research culminating in a dissertation that contributes new knowledge to the field. During graduate studies, students gain in-depth theoretical knowledge, develop advanced research skills, and often become highly proficient with specialized computational tools and experimental techniques. They work closely with faculty members who are experts in their respective fields.

Many universities with strong engineering programs have dedicated fluid dynamics laboratories and research groups. These groups often collaborate with industry partners or government agencies, providing students with opportunities to work on real-world problems and build professional networks. Pursuing graduate research can open doors to positions in industrial R&D, academia, and national research laboratories. For those interested in developing new CFD methodologies or pushing the boundaries of fluid dynamics science, a Ph.D. is typically the standard path.

Online platforms are increasingly offering specialized courses that can supplement graduate studies or provide specific skills relevant to research in fluid dynamics. These can be particularly useful for learning new software, numerical techniques, or exploring interdisciplinary applications.

These advanced courses provide a deeper dive into specific computational techniques and software used in fluid dynamics research and application.

[course] An Introduction to Computational Fluid DynamicsFurthering your knowledge with comprehensive texts on turbulence and computational methods is highly recommended for graduate-level understanding.

Key Coursework and Laboratory Requirements

Regardless of whether one stops at a bachelor's degree or pursues graduate studies, certain coursework is fundamental for a Fluid Dynamics Engineer. Core subjects include multiple courses in Fluid Mechanics, covering topics from basic principles like fluid statics and Bernoulli's equation to more advanced topics like viscous flow, boundary layers, potential flow, and compressible flow. Thermodynamics and Heat Transfer (conduction, convection, radiation) are also essential.

Strong mathematical skills are a must, with coursework in Calculus (differential and integral), Differential Equations, Linear Algebra, and Numerical Methods being critical. Courses that introduce Computational Fluid Dynamics (CFD) principles and the use of CFD software are increasingly standard and highly valuable. Depending on the specialization, courses in aerodynamics, gas dynamics, turbulence, multiphase flow, or specific application areas like propulsion or biomedical engineering might be relevant.

Laboratory work provides practical experience and reinforces theoretical concepts. Typical undergraduate engineering labs might involve experiments to measure fluid properties, visualize flow patterns, determine pressure drops in pipes, or analyze the performance of pumps and turbines. For those specializing in fluid dynamics, more advanced labs could involve wind tunnel testing, particle image velocimetry (PIV) to measure flow velocities, or hands-on experience with CFD software to simulate and validate experimental results. These practical experiences are crucial for developing an intuitive understanding of fluid behavior and for learning how to design and conduct experiments, as well as analyze data.

Online courses can effectively supplement traditional coursework by providing focused training on specific software or techniques that might not be covered in depth in a standard curriculum. For example, learning advanced meshing techniques or specific turbulence models through an online module can be a great way to enhance your skillset. OpenCourser's extensive catalog, searchable via OpenCourser.com, can help find such specialized learning opportunities.

These courses offer practical application and deeper understanding of tools and techniques vital in fluid dynamics.

Career Progression in Fluid Dynamics

The career path for a Fluid Dynamics Engineer can be diverse and rewarding, offering opportunities for technical specialization, project leadership, and management. Progression often depends on a combination of experience, continuous learning, performance, and sometimes further education or certifications. Understanding the typical trajectory can help aspiring and early-career engineers plan their development.

Starting roles often focus on applying established methods and tools, while senior positions involve more complex problem-solving, innovation, and strategic oversight. The journey allows individuals to deepen their expertise in specific niches or broaden their understanding across different applications of fluid dynamics.

Entry-Level Roles and Typical Career Trajectories

Entry-level positions for Fluid Dynamics Engineers, often titled Junior CFD Engineer, CFD Analyst, or similar, typically require a bachelor's degree in a relevant engineering field like mechanical or aerospace engineering. In these roles, engineers usually work under the guidance of more senior staff. Responsibilities might include preparing CAD geometry for analysis, generating computational meshes, setting up and running CFD simulations using established software and methodologies, post-processing results, and assisting in the preparation of reports and presentations.

With a few years of experience (e.g., 3+ years for a "CFD Engineer" title), engineers take on more responsibility. They might be tasked with independently managing smaller projects or specific aspects of larger projects, developing more complex simulation models, troubleshooting simulation issues, and performing more in-depth analysis and interpretation of results. They begin to develop a deeper understanding of specific turbulence models, numerical methods, and the nuances of applying CFD to particular types of problems.

As engineers gain more expertise and demonstrate strong technical and problem-solving skills, they can progress to Senior CFD Engineer roles. Senior engineers often tackle the most challenging technical problems, may lead small teams, mentor junior engineers, and contribute to the development of new methodologies or best practices within their organization. They might also be involved in validating simulation results against experimental data and communicating findings to a wider range of stakeholders, including non-specialists.

Specialization Paths

As Fluid Dynamics Engineers advance in their careers, many choose to specialize in particular areas. These specializations can be driven by industry demands, personal interests, or opportunities within their organizations. One common area of specialization is Aerodynamics, which involves the study of air and other gases in motion, particularly around solid objects. This is crucial in the aerospace industry for aircraft and spacecraft design, and in the automotive industry for optimizing vehicle performance and fuel efficiency. Engineers might focus on external aerodynamics (flow around bodies) or internal aerodynamics (flow through engines or ducts).

Another major specialization is Hydrodynamics, which focuses on the flow of liquids, primarily water. This is vital in naval architecture (ship design), offshore engineering (design of oil rigs and platforms), civil engineering (design of dams, canals, and pipelines), and environmental engineering (modeling of rivers, estuaries, and coastal flows). Other specialized paths include focusing on Turbulence Modeling, which is a complex and critical aspect of many fluid flows, or Multiphase Flow, dealing with systems where multiple fluids or phases (e.g., liquid-gas, solid-liquid) interact. Combustion analysis, heat transfer specialization, and biofluid mechanics (e.g., blood flow, respiratory mechanics) are also distinct paths.

Many engineers also specialize in the computational aspects, becoming experts in specific CFD software, developing custom simulation tools, focusing on high-performance computing for CFD, or advancing numerical algorithms. Some may also specialize in experimental fluid dynamics, designing and conducting physical experiments to validate CFD models or to study phenomena that are difficult to simulate accurately. The choice of specialization often shapes the long-term career trajectory and the types of problems an engineer will tackle.

For those interested in the intricacies of turbulent flows, which is a significant area of specialization and research, dedicated texts are essential.

Leadership Roles and Advanced Technical Positions

With significant experience and a proven track record, Fluid Dynamics Engineers can advance into leadership and advanced technical roles. Leadership positions might include Lead CFD Engineer, Engineering Manager, or Project Manager. In these roles, individuals are responsible for overseeing teams of engineers, managing complex projects, allocating resources, and ensuring that technical objectives are met. They provide technical guidance, mentor team members, and interface with other departments or clients. Strong communication, interpersonal, and project management skills become increasingly important at this stage.

For those who wish to remain primarily focused on deep technical work rather than direct management, advanced technical positions such as Principal CFD Engineer or Technical Fellow are often available, especially in larger organizations or research institutions. These roles recognize individuals for their exceptional technical expertise and contributions. Principal Engineers often serve as key technical advisors, lead the development of innovative solutions to the most challenging problems, drive research and development efforts, and represent the organization in technical forums. They may be responsible for setting technical direction, pioneering new simulation capabilities, or solving problems that have a major impact on the business or scientific field.

Movement into these senior roles typically requires many years of experience, a deep understanding of fluid dynamics principles and computational methods, and a history of successful project execution and innovation. Continuous learning, staying abreast of the latest advancements in CFD technology and fluid mechanics research, and often a postgraduate degree (especially for research-intensive or principal engineer roles) are common characteristics of individuals in these positions. Some may also pursue professional certifications or become active in professional societies to further demonstrate their expertise and leadership in the field.

Industry Applications and Innovations

Fluid Dynamics Engineering is not just a theoretical discipline; it is a field that drives innovation and solves critical problems across a multitude of industries. The ability to understand, predict, and control fluid behavior enables engineers to design more efficient, safer, and sustainable technologies. From harnessing the power of the wind to launching rockets into space, fluid dynamics plays a pivotal role.

The ongoing advancements in computational power and simulation techniques are continuously expanding the frontiers of what is possible. This leads to exciting new applications and improvements in existing technologies, making it a dynamic and evolving career choice. The impact of this field is tangible, contributing to advancements that shape our daily lives and our future.

Renewable Energy Systems Design

Fluid dynamics is absolutely critical in the design and optimization of renewable energy systems. In wind energy, for example, CFD is used extensively to analyze the airflow around wind turbine blades, optimizing their aerodynamic shape for maximum energy capture and structural integrity. Engineers also use CFD to study the wake effects within wind farms (how turbulence from one turbine affects those downstream) to optimize turbine placement and overall farm efficiency. This modeling helps in maximizing power output while minimizing land use and material costs.

For hydroelectric power, fluid dynamics helps in designing efficient turbine runners, optimizing water flow through dams and spillways, and assessing environmental impacts like fish passage. In the emerging field of tidal and wave energy, CFD is used to model the complex interaction of ocean currents and waves with energy harvesting devices, helping to design robust and efficient systems that can withstand harsh marine environments. Even in solar energy, particularly concentrated solar power, fluid dynamics is important for understanding heat transfer fluids and air flow around heliostats or parabolic troughs.

The drive towards a sustainable energy future means that the demand for expertise in designing efficient renewable energy systems is growing. Fluid Dynamics Engineers contribute directly to this transition by improving the performance and reducing the cost of these clean energy technologies. Their work helps to make renewable energy more competitive and accessible, playing a vital role in addressing climate change.

Exploring general fluid mechanics principles can provide a strong basis for understanding these specialized applications.

Aerospace Propulsion Systems Development

The development of aerospace propulsion systems, from jet engines for commercial aircraft to rocket engines for space exploration, is deeply rooted in fluid dynamics and thermodynamics. Fluid Dynamics Engineers play a crucial role in analyzing and designing the complex internal flows within these engines. This includes modeling the airflow through compressors and turbines, the mixing of fuel and air in combustion chambers, and the high-speed exhaust flow through nozzles.

In jet engines, engineers use CFD to optimize blade designs for efficiency and durability, manage cooling flows to protect components from extreme temperatures, and reduce noise emissions. For rocket engines, fluid dynamics is essential for understanding the behavior of propellants (often cryogenic fluids), the combustion process under extreme pressures and temperatures, and the design of nozzles that can efficiently convert thermal energy into thrust. Hypersonic propulsion, for vehicles traveling at many times the speed of sound, presents even more extreme fluid dynamics challenges.

Accuracy in these simulations is paramount, as even small improvements in efficiency or reductions in weight can have significant impacts on aircraft performance or payload capacity for spacecraft. Engineers in this subfield often work with highly complex physics, including compressible flows, chemically reacting flows, and extreme heat transfer. The pursuit of faster, more efficient, and more reliable propulsion systems continues to drive innovation in this area of fluid dynamics.

For those aspiring to work in this cutting-edge field, specialized knowledge is key. Online courses can offer insights into specific software and advanced simulation techniques used in aerospace.

A deeper understanding of transport phenomena is also beneficial for propulsion systems.

Environmental Impact Mitigation Strategies

Fluid Dynamics Engineering plays a significant role in understanding and mitigating the environmental impact of various human activities and natural phenomena. For instance, CFD is used to model the dispersion of pollutants in the atmosphere from industrial sources or vehicle emissions, helping to predict air quality and assess the effectiveness of pollution control strategies. This information is vital for urban planning and for ensuring that industrial facilities comply with environmental regulations.

In water resource management, fluid dynamics helps in modeling flows in rivers, lakes, and groundwater systems. This can be used to predict the spread of contaminants, design effective water treatment plants, manage flood risks, and assess the impact of climate change on water availability. Coastal engineers use fluid dynamics to understand sediment transport, erosion, and the impact of storm surges, which is crucial for designing coastal protection structures.

Fluid dynamics is also applied in waste management, for example, in optimizing the design of landfills to control leachate and gas migration. In the context of oil spills or chemical accidents, CFD models can predict how hazardous materials might spread in water bodies or in the air, aiding in emergency response and cleanup efforts. By providing a deeper understanding of these complex environmental flows, Fluid Dynamics Engineers contribute to developing more effective strategies for protecting our environment and ensuring sustainable development.

Individuals passionate about applying engineering skills to environmental challenges can find many opportunities within fluid dynamics. You can explore relevant topics further on OpenCourser's Environmental Sciences section.

Technical Challenges in Modern Fluid Dynamics

Despite significant advancements, Fluid Dynamics Engineering continues to face complex technical challenges. These challenges often push the boundaries of current computational capabilities, physical understanding, and experimental techniques. Overcoming these hurdles is key to unlocking further innovations in various fields, from energy and transportation to medicine and environmental science.

Addressing these challenges requires ongoing research, development of new methodologies, and often a multidisciplinary approach. For engineers in the field, these complexities also represent exciting opportunities to contribute to cutting-edge science and engineering.

Multiphase Flow Complexities

Modeling multiphase flows—systems involving simultaneous flow of materials in different phases (e.g., gas-liquid, liquid-solid, gas-solid, or gas-liquid-solid)—presents a significant challenge in fluid dynamics. Examples of multiphase flows are abundant in nature and industry, including rainwater falling through air, bubbles rising in a carbonated drink, sediment transport in rivers, fluidized bed reactors in chemical plants, steam generation in boilers, and oil and gas transport in pipelines.

The complexity arises from the interactions between the different phases at their interfaces. These interfaces can be highly dynamic and can change shape, break up, or coalesce. Accurately tracking these interfaces and modeling the transfer of mass, momentum, and energy across them is computationally demanding and requires specialized numerical techniques. Different flow regimes can exist within multiphase systems (e.g., bubbly flow, slug flow, annular flow), and predicting the transitions between these regimes is often difficult.

Developing robust and accurate CFD models for multiphase flows is an active area of research. Challenges include dealing with large density and viscosity ratios between phases, modeling surface tension effects, and handling phase change phenomena like boiling and condensation. Progress in this area is crucial for optimizing many industrial processes, improving the safety of nuclear reactors, designing more efficient separation equipment, and understanding various natural phenomena.

For foundational knowledge in fluid mechanics that underpins the understanding of such complex flows, several texts are invaluable.

High-Performance Computing Requirements

Many cutting-edge fluid dynamics simulations, especially those involving complex geometries, turbulent flows, or multiphase phenomena, are incredibly computationally demanding. Accurately resolving all the relevant scales of motion in a turbulent flow, for example, using Direct Numerical Simulation (DNS), can require billions of grid cells and enormous amounts of computing time, often feasible only on the largest supercomputers. Even less detailed methods like Large Eddy Simulation (LES) or Reynolds-Averaged Navier-Stokes (RANS) simulations for industrial-scale problems can necessitate significant High-Performance Computing (HPC) resources.

The need for HPC poses challenges in terms of access to supercomputing facilities, the cost of hardware and software licenses, and the expertise required to efficiently utilize these massively parallel systems. Developing CFD codes that can scale effectively on modern HPC architectures (which increasingly feature heterogeneous processors like GPUs) is an ongoing task. Efficiently managing and analyzing the massive datasets generated by large-scale simulations is another significant hurdle.

While cloud computing is making HPC resources more accessible to a wider range of users, the fundamental challenge of the computational cost of high-fidelity simulations remains. Researchers and engineers are continuously working on developing more efficient numerical algorithms, improved physical models that require less computational resolution (like advanced turbulence models), and leveraging techniques like machine learning to accelerate simulations or create surrogate models.

Experimental Validation of Simulations

While CFD provides powerful predictive capabilities, the results of simulations must always be viewed with a degree of critical assessment. Experimental validation is a crucial step in the CFD workflow to ensure that the numerical models accurately represent the real-world physics. This involves comparing simulation results (e.g., velocities, pressures, forces) against data obtained from carefully designed physical experiments.

However, conducting high-quality experiments for fluid dynamics can be challenging and expensive. It requires specialized facilities like wind tunnels or water channels, sophisticated measurement instrumentation (e.g., Laser Doppler Velocimetry, Particle Image Velocimetry, hot-wire anemometry), and careful control of experimental conditions. Furthermore, obtaining detailed, spatially resolved data from experiments that can be directly compared with CFD results is often difficult, especially for complex, three-dimensional, or unsteady flows.

Discrepancies between simulation and experimental results can arise from various sources, including uncertainties in the experimental measurements, simplifications or inaccuracies in the CFD model (e.g., turbulence model assumptions, mesh resolution), or errors in defining boundary conditions. The process of identifying the sources of these discrepancies and refining the CFD model or experimental setup is an iterative and often time-consuming part of research and development. Despite these challenges, experimental validation remains indispensable for building confidence in CFD predictions and for advancing the fundamental understanding of fluid phenomena.

Advanced computational techniques are constantly being developed and refined, and understanding these is key for researchers and practitioners.

Ethical Considerations in Fluid Engineering

Like all engineering disciplines, Fluid Dynamics Engineering carries significant ethical responsibilities. The work of Fluid Dynamics Engineers can have profound impacts on public safety, environmental health, and resource utilization. Therefore, a strong ethical framework is essential to guide decision-making and ensure that projects are conducted responsibly and for the benefit of society.

Engineers in this field must be mindful of the broader consequences of their designs and analyses. This includes considering not only the technical performance but also the societal and environmental implications of their work. Upholding professional integrity and prioritizing public welfare are paramount.

Environmental Sustainability Practices

Fluid Dynamics Engineers have a crucial role to play in promoting environmental sustainability. Many engineering projects involving fluid flow can have significant environmental consequences, and it is the ethical responsibility of engineers to minimize negative impacts and seek sustainable solutions. For example, when designing industrial processes, engineers should strive to optimize energy efficiency, reduce greenhouse gas emissions, and minimize waste generation. This might involve using CFD to design more efficient combustion systems, improve heat recovery, or optimize mixing processes to reduce energy consumption.

In the context of transportation, Fluid Dynamics Engineers contribute to sustainability by designing more aerodynamic vehicles (cars, trucks, airplanes) that consume less fuel and produce fewer emissions. In environmental engineering itself, they develop models to predict the fate and transport of pollutants in air and water, aiding in the design of effective remediation strategies and pollution control measures. They also work on optimizing renewable energy systems, like wind turbines and tidal energy converters, to maximize clean energy production.

Ethical practice in this context means being honest about the potential environmental impacts of a project, advocating for environmentally sound design choices, and staying informed about sustainable technologies and practices. It also involves considering the full lifecycle of a product or system, from material extraction and manufacturing to operation and disposal.

Safety Protocols in Fluid System Design

Ensuring the safety of fluid systems is a primary ethical obligation for Fluid Dynamics Engineers. Many fluid systems operate under high pressures, high temperatures, or involve hazardous materials, and failures can have catastrophic consequences, including loss of life, environmental damage, and significant economic losses. Engineers must exercise due diligence in their design and analysis to identify potential hazards and incorporate appropriate safety measures.

This involves accurately predicting fluid behavior under various operating conditions, including normal operation, upset conditions, and emergency scenarios. For example, in the design of chemical plants or nuclear reactors, engineers must analyze potential accident scenarios, such as pipe breaks or equipment malfunctions, and design safety systems (e.g., pressure relief valves, emergency cooling systems) to mitigate the consequences. CFD can be a powerful tool for these safety analyses, helping to simulate complex accident progressions and evaluate the effectiveness of safety features.

Adherence to relevant codes, standards, and regulations is essential. However, ethical responsibility often goes beyond mere compliance. Engineers should use their professional judgment to identify and address potential safety risks even if they are not explicitly covered by existing regulations. This includes thorough validation of models, transparent communication of risks, and a commitment to continuous improvement in safety practices.

Resource Allocation Optimization Ethics

Fluid Dynamics Engineers are often involved in projects that require significant resources, including financial investment, materials, energy, and human effort. Ethical considerations arise in how these resources are allocated and utilized. Engineers have a responsibility to use resources efficiently and to avoid waste. This means striving for designs that are not only technically sound but also economically viable and sustainable in the long term.

For example, when designing a pipeline system, an engineer might use fluid dynamics analysis to optimize pipe diameters and pump selections to minimize both initial construction costs and long-term energy consumption for pumping. In manufacturing processes, optimizing fluid flow in cooling or heating systems can reduce energy usage and improve product quality, thereby making better use of resources.

Ethical resource allocation also involves considering the broader societal impacts of projects. For instance, in water resource management, decisions about how to allocate scarce water resources among different users (e.g., agriculture, industry, domestic consumption) have significant social and economic implications. Fluid Dynamics Engineers providing technical input for such decisions should be aware of these broader contexts and strive for solutions that are equitable and serve the public interest. This may involve transparently presenting different options and their associated trade-offs to decision-makers and the public.

Global Job Market Analysis

The job market for Fluid Dynamics Engineers, particularly those with Computational Fluid Dynamics (CFD) skills, is influenced by trends in several key industries and by broader economic factors. Understanding these market dynamics can help individuals make informed career planning decisions. Generally, the field offers robust opportunities due to its critical role in innovation and problem-solving across diverse sectors.

The demand is often tied to investment in research and development, the drive for greater efficiency and sustainability, and the adoption of advanced simulation technologies by industries. As computational power increases and CFD tools become more sophisticated and accessible, their application continues to expand, creating ongoing needs for skilled engineers.

Geographic Demand Hotspots

The demand for Fluid Dynamics Engineers often correlates with regions that have strong concentrations of industries heavily reliant on this expertise. North America, particularly the United States, has a significant demand driven by its large aerospace, automotive, and energy sectors, as well as extensive research and development activities. Many leading technology companies and research institutions are based in this region.

Europe also represents a major market, with countries like Germany, France, and the UK having well-established automotive, aerospace, and manufacturing industries that utilize CFD extensively. The region's focus on renewable energy and environmental regulations further fuels demand. The Asia-Pacific region is experiencing rapid growth in the CFD market, driven by industrialization, particularly in countries like China, India, Japan, and South Korea. These nations are investing heavily in manufacturing, automotive, electronics, and aerospace, leading to increased adoption of CFD solutions.

Specific industrial clusters within these broader regions can also be hotspots. For example, areas with a high concentration of automotive R&D, aerospace manufacturing, or energy companies will naturally have a higher demand for Fluid Dynamics Engineers. The Middle East also shows growing interest, particularly in the oil and gas, construction, and water resource management sectors.

Industry Growth Projections

The overall market for Computational Fluid Dynamics (CFD) software and services has been showing steady growth and is projected to continue expanding. For instance, some market analyses project the global CFD market to grow significantly in the coming years, with Compound Annual Growth Rates (CAGRs) typically ranging from around 7% to over 9%, and some even higher. One report valued the global CFD market at $2.6 billion in 2023 and projected it to reach $5.3 billion by 2033, growing at a CAGR of 7.2%. Another report estimated the market to reach $3.8 billion by 2030 from $2 billion in 2022, with an 8.3% CAGR. A different projection sees the market growing from $2.895 billion in 2025 to $6.427 billion by 2035, at a CAGR of 8.3%. These figures indicate a healthy demand for CFD capabilities.

This growth is driven by several factors, including the increasing complexity of engineering designs, the need to reduce product development times and costs by minimizing physical prototyping, and the growing emphasis on energy efficiency and sustainability. Advancements in high-performance computing (HPC), cloud-based CFD solutions that improve accessibility, and the integration of AI and machine learning into simulation workflows are also contributing to market expansion. Industries like aerospace and defense, automotive, energy (including renewables), electronics, and healthcare are expected to continue being major adopters of CFD.

The demand for CFD services, including consulting and outsourced simulations, is also expected to grow, particularly among small and medium-sized enterprises (SMEs) that may lack in-house expertise or computational resources. As industries increasingly embrace digital transformation and simulation-driven design, the role of Fluid Dynamics Engineers in leveraging these powerful tools will remain critical.

Competitive Skill Requirements

To be competitive in the job market, Fluid Dynamics Engineers need a strong combination of technical and soft skills. A solid educational foundation, typically a bachelor's or master's degree in Mechanical, Aerospace, or Chemical Engineering, is fundamental. Strong knowledge of fluid mechanics, thermodynamics, heat transfer, and numerical methods is essential.

Proficiency in industry-standard CFD software (e.g., ANSYS Fluent, STAR-CCM+, OpenFOAM) is a primary requirement. This includes skills in geometry preparation, mesh generation, solver setup, and post-processing. Familiarity with CAD software is also important. Programming skills, particularly in Python or MATLAB, are increasingly valuable for automation, data analysis, and model customization.

Beyond technical skills, employers look for strong analytical and problem-solving abilities, attention to detail, and the capacity to work independently as well as collaboratively in a team environment. Effective communication skills, both written and verbal, are crucial for presenting complex technical information clearly to diverse audiences. As projects often involve interdisciplinary teams, the ability to collaborate with engineers from other specializations is also key. A willingness to learn and adapt to new technologies and methodologies is vital in this rapidly evolving field. For more senior roles, project management and leadership skills become increasingly important.

To develop some of these competitive skills, especially in specific software or advanced techniques, online courses can be a valuable resource. Consider exploring platforms like OpenCourser's engineering section for relevant options.

Professional Development Strategies

A career in Fluid Dynamics Engineering is one of continuous learning and adaptation. The field is constantly evolving with advancements in computational methods, software tools, and scientific understanding. To remain competitive and advance professionally, engineers must actively engage in ongoing professional development. This involves not only keeping technical skills sharp but also cultivating broader professional competencies.

Strategies for professional development can range from formal education and certifications to informal learning and networking. A proactive approach to skill enhancement and career growth is essential for long-term success in this dynamic and challenging field.

Continuing Education Opportunities

Continuing education is vital for Fluid Dynamics Engineers to stay abreast of the latest advancements. This can take many forms. Short courses and workshops, often offered by software vendors, professional organizations, or universities, can provide focused training on new software features, advanced modeling techniques, or emerging application areas. Many of these are now available online, offering flexibility for working professionals. Platforms like OpenCourser can help locate relevant fluid dynamics courses.

For some, pursuing a Master's or even a Ph.D. degree part-time while working may be a viable option for deeper specialization or a career shift towards research or academia. Online Master's programs in engineering disciplines related to fluid mechanics or computational engineering are becoming more common, providing another avenue for advanced learning.

Reading technical journals (e.g., Journal of Fluid Mechanics, Computers & Fluids, International Journal for Numerical Methods in Fluids), conference proceedings, and industry publications is crucial for keeping up with new research and trends. Attending conferences, seminars, and webinars also offers valuable learning opportunities and insights into the latest developments. Many companies also support internal training programs or provide resources for external learning to help their engineers maintain technical currency.

These advanced courses can help professionals deepen their understanding of specific CFD aspects, which is crucial for continuing education.

Professional Certification Programs

While not always mandatory in the same way as a Professional Engineer (PE) license might be for certain civil or mechanical engineering roles (depending on jurisdiction and specific job duties), specialized certifications can enhance a Fluid Dynamics Engineer's credentials and demonstrate a high level of expertise in specific areas. Some software vendors offer certification programs for their CFD tools, which can validate proficiency in using that particular software package. These can be beneficial for showcasing practical skills to employers.

Professional organizations related to engineering (like ASME - American Society of Mechanical Engineers, or AIAA - American Institute of Aeronautics and Astronautics) may offer broader professional development programs or credentials, though specific "Fluid Dynamics Engineer" certifications are less common than general engineering licensures. For those involved in project management, certifications like the Project Management Professional (PMP) can be valuable.

The decision to pursue a particular certification should be based on career goals, industry relevance, and employer expectations. In many research-focused or highly specialized roles, a strong publication record, advanced degrees, and demonstrated expertise through successful projects often carry more weight than specific certifications. However, for roles emphasizing application of specific tools or project leadership, relevant certifications can be a useful differentiator.

Industry Networking Approaches

Networking is a crucial aspect of professional development for Fluid Dynamics Engineers, as it is for any professional. Building a strong professional network can lead to new job opportunities, collaborations, mentorship, and access to valuable information and insights. Attending industry conferences, workshops, and seminars is an excellent way to meet peers, experts, and potential employers. Actively participating by asking questions or presenting your own work can enhance visibility.

Joining professional organizations like ASME, AIAA, or specialized groups focused on fluid mechanics or CFD provides numerous networking opportunities through local chapter meetings, national events, and online forums. Volunteering for committees or leadership roles within these organizations can further expand your network and demonstrate commitment to the profession.

Online platforms like LinkedIn are also powerful tools for professional networking. Connecting with colleagues, alumni, and leaders in the field, joining relevant groups, and participating in discussions can help maintain and grow your network. Building relationships with academic researchers, software vendors, and engineers in complementary fields can also be beneficial. Mentorship, both finding a mentor and eventually mentoring others, is another valuable networking and development activity. A mentor can provide guidance, advice, and support throughout your career journey.

Frequently Asked Questions

Navigating a career path, especially in a specialized field like Fluid Dynamics Engineering, often brings up many questions. This section aims to address some common queries that aspiring or practicing engineers might have. These answers provide practical insights to help individuals make informed decisions about their careers.

Can I become a Fluid Dynamics Engineer without a traditional engineering degree?

While the most direct path to becoming a Fluid Dynamics Engineer is through a traditional engineering degree (like Mechanical, Aerospace, or Chemical Engineering), it is not entirely impossible to enter the field from a different background, though it is more challenging. Individuals with strong degrees in physics or applied mathematics, particularly if they have focused on fluid mechanics, continuum mechanics, or numerical methods, might be able to transition into certain roles, especially in research or software development.

However, they would likely need to supplement their education with specific engineering knowledge and demonstrate proficiency in CFD tools and engineering problem-solving. This might involve taking additional coursework, pursuing a relevant Master's degree in engineering, or gaining significant practical experience through projects or internships. For many applied engineering roles, an accredited engineering degree is a standard requirement due to the need for a broad understanding of engineering principles and practices. It's advisable to research specific job requirements in your target industry and roles.

What level of programming language proficiency is typically required?

The required level of programming proficiency can vary depending on the specific role. For many application-focused CFD engineers whose primary job is to use commercial CFD software to solve problems, a basic to intermediate understanding of scripting languages like Python or MATLAB can be very beneficial for automating repetitive tasks, custom data analysis, and creating simple macros or user-defined functions (UDFs) within the CFD software. Strong proficiency is often preferred.

For roles in CFD software development, research positions involving the creation of new numerical methods or turbulence models, or positions requiring extensive customization of CFD codes (e.g., in open-source environments like OpenFOAM), a much higher level of programming proficiency is usually necessary. This would typically involve expertise in languages like C++, Fortran, or Python, along with a deep understanding of software engineering principles, numerical algorithms, and parallel computing. So, while not every Fluid Dynamics Engineer needs to be an expert programmer, having some level of coding skill is increasingly an advantage, and for certain career paths, it's essential.

How is the industry demand for CFD specialists evolving?

The demand for CFD specialists has been steadily growing and is projected to continue this trend. This is driven by several factors: industries are increasingly relying on simulation to accelerate product development, reduce physical testing costs, and optimize designs for performance and efficiency. The push for sustainability and energy efficiency across sectors like automotive, aerospace, and energy also fuels demand for CFD analysis to design more environmentally friendly products and processes.

Furthermore, advancements in high-performance computing and the increasing sophistication and accessibility of CFD software (including cloud-based solutions) are expanding the range of problems that can be tackled with CFD, opening up new application areas. The integration of AI and machine learning with CFD is also an emerging trend that could further enhance capabilities and create new opportunities. While there might be fluctuations based on economic conditions or specific industry trends, the long-term outlook for skilled CFD specialists appears positive due to the fundamental importance of fluid dynamics in so many engineering disciplines.

What are typical work-life balance considerations for a Fluid Dynamics Engineer?

Work-life balance for a Fluid Dynamics Engineer can vary significantly depending on the industry, company culture, project deadlines, and specific role. In general, like many engineering professions, there can be periods of intense work, especially when approaching project deadlines or during critical phases of development. Running complex simulations can sometimes require monitoring processes outside of standard working hours, although automation and remote access capabilities are improving this aspect.

Companies with strong project management practices and a focus on employee well-being are more likely to offer a better work-life balance. Roles in research or academia might offer more flexibility in terms of work hours but can also involve the pressure of grant deadlines or publication targets. Industries known for rapid development cycles, like motorsport or some consumer electronics, might have more demanding schedules at times. It is always advisable to inquire about company culture and work-life balance expectations during the interview process. Many companies are increasingly recognizing the importance of work-life balance for employee productivity and retention.

Are there opportunities for patent development in this field?

Yes, there are certainly opportunities for patent development in Fluid Dynamics Engineering. Innovations in this field can lead to novel designs, processes, or methodologies that offer a competitive advantage or solve a previously intractable problem. These innovations can be patentable if they meet the criteria of novelty, non-obviousness, and utility.

Examples of patentable inventions could include new aerodynamic designs for vehicles or aircraft that significantly reduce drag, innovative cooling systems for electronics or engines, novel designs for medical devices involving fluid flow, new types of sensors for fluid measurement, improved components for renewable energy systems (like turbine blades), or even new algorithms or techniques within CFD software that provide unique capabilities. Engineers working in research and development roles, particularly in industry or at research institutions, are often at the forefront of such innovations. Companies often encourage and support patent applications to protect their intellectual property and commercialize their inventions.

How feasible is transitioning between different industries as a Fluid Dynamics Engineer?

Transitioning between different industries is quite feasible for a Fluid Dynamics Engineer because the fundamental principles of fluid mechanics and the core skills in CFD are transferable across many sectors. For example, an engineer with experience in aerodynamics in the automotive industry may find their skills applicable to the aerospace industry, or even to wind energy for turbine blade design. Similarly, expertise in heat transfer and multiphase flow gained in the chemical processing industry could be valuable in the energy sector or in designing thermal management systems for electronics.

While the core skills are transferable, some adaptation and learning specific to the new industry will likely be required. This might involve understanding new regulatory environments, different design constraints, or industry-specific software or methodologies. However, the strong analytical, problem-solving, and computational skills developed as a Fluid Dynamics Engineer provide a solid foundation for such transitions. Networking within the target industry, taking relevant short courses, or highlighting transferable skills on a resume can facilitate a smoother transition.

Conclusion

The field of Fluid Dynamics Engineering offers a challenging yet deeply rewarding career path for those fascinated by the intricate dance of liquids and gases. It is a discipline that combines fundamental scientific principles with advanced computational tools to solve some of the most pressing problems in aerospace, automotive, energy, environmental science, and beyond. From designing the next generation of fuel-efficient aircraft to optimizing renewable energy systems and mitigating environmental impacts, Fluid Dynamics Engineers are at the forefront of innovation and technological advancement. While the journey requires a rigorous academic foundation and a commitment to lifelong learning, the opportunity to make a tangible impact on the world and to continuously engage with intellectually stimulating problems makes it an attractive prospect. For individuals with a strong aptitude for mathematics and physics, a curiosity about how things work, and a desire to contribute to a better future, a career as a Fluid Dynamics Engineer can be an exceptionally fulfilling endeavor. As you explore this path, resources like OpenCourser can provide valuable tools for finding courses and literature to build your knowledge and skills in this dynamic field.