Computational Fluid Dynamics

ving into the World of Computational Fluid Dynamics

Computational Fluid Dynamics, or CFD, is a fascinating and powerful branch of engineering and physics that uses numerical analysis and data structures to solve and analyze problems involving fluid flows. At its core, CFD allows us to simulate how liquids and gases interact with surfaces and with each other. Think of it as a virtual wind tunnel or a digital water channel, where complex scenarios can be modeled and tested without the need for expensive and time-consuming physical experiments. This capability opens doors to understanding everything from the airflow around a Formula 1 car to the circulation of blood in an artery.

What makes working in CFD particularly engaging is its blend of theoretical understanding and practical application. Professionals in this field get to visualize and predict how fluids will behave in incredibly diverse situations, contributing to the design of more efficient airplanes, cleaner power plants, and even more effective medical devices. The thrill of seeing your simulations accurately predict real-world phenomena, or using your analysis to solve a critical engineering challenge, can be immensely satisfying. Furthermore, the interdisciplinary nature of CFD means you'll constantly be learning and applying knowledge from various fields like mathematics, physics, and computer science.

Introduction to Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) is a science that employs numerical methods and algorithms to analyze and solve problems involving fluid flows. It essentially allows for the creation of virtual experiments, providing insights into how fluids (liquids and gases) behave under various conditions. This field sits at the intersection of fluid mechanics, mathematics, and computer science, using computational power to simulate the interaction of liquids and gases with surfaces defined by boundary conditions.

For those new to the concept, imagine trying to predict how smoke from a chimney will spread in the wind, or how water will flow around a ship's hull. CFD provides the tools to model these scenarios on a computer, offering a detailed look at the fluid's velocity, pressure, temperature, and other characteristics. This is achieved by breaking down the problem into many small pieces (a process called discretization) and solving the governing equations of fluid motion for each piece.

What is Computational Fluid Dynamics (CFD)?

At its heart, Computational Fluid Dynamics is about using computers to simulate fluid behavior. This involves solving the fundamental equations that govern fluid motion, most notably the Navier-Stokes equations. These equations describe how the velocity, pressure, temperature, and density of a moving fluid are related. Because these equations are often too complex to solve analytically for most real-world problems, CFD relies on numerical methods to approximate their solutions.

The process typically starts with creating a digital model of the geometry of interest – this could be an airplane wing, a heat exchanger, or even a human heart. This geometry is then divided into a multitude of small cells, forming what is known as a mesh or grid. The governing equations are then solved iteratively for each cell in this mesh. The more cells in the mesh, the more accurate the solution can be, but this also increases the computational resources required.

CFD allows engineers and scientists to perform "virtual experiments" which can be more cost-effective and faster than physical testing. It provides a detailed view of fluid flow that might be difficult or impossible to obtain through experimental methods alone. This detailed information can be used to optimize designs, understand complex flow phenomena, and predict performance.

A Brief History: From Theory to Simulation

The journey of Computational Fluid Dynamics began long before the advent of powerful digital computers. The theoretical foundations were laid by mathematicians and physicists like Leonhard Euler and Claude-Louis Navier in the 18th and 19th centuries, who formulated the fundamental equations of fluid motion. However, solving these complex, non-linear partial differential equations for anything but the simplest cases proved to be an insurmountable challenge using analytical methods alone.

The real breakthrough for CFD came with the development of the digital computer in the mid-20th century. Early pioneers began exploring numerical techniques to approximate solutions to the fluid flow equations. Initial efforts were focused on simpler, often two-dimensional, problems due to the limited computational power available. As computers became more powerful and algorithms more sophisticated, the complexity and scope of problems that could be tackled with CFD grew significantly.

Throughout the latter half of the 20th century and into the 21st, CFD has evolved from a niche research tool to an indispensable part of the engineering design and analysis process across numerous industries. The continuous improvement in computing hardware, numerical algorithms, and visualization techniques has made CFD more accessible, accurate, and versatile than ever before.

Why Use CFD? Advantages Over Traditional Experiments

While traditional experimental fluid dynamics (using wind tunnels, water tanks, etc.) remains valuable, Computational Fluid Dynamics offers several distinct advantages. One of the primary benefits is cost-effectiveness. Building physical prototypes and conducting extensive experimental tests can be very expensive and time-consuming. CFD allows for numerous design iterations and "what-if" scenarios to be explored relatively quickly and cheaply on a computer.

CFD provides comprehensive data. In a physical experiment, measurements can typically only be taken at a limited number of points. A CFD simulation, on the other hand, can provide detailed information about the flow field (velocity, pressure, temperature, etc.) at every point within the computational domain. This allows for a much deeper understanding of the fluid behavior. Furthermore, CFD allows for the simulation of conditions that may be difficult, dangerous, or impossible to replicate in a physical experiment, such as extreme temperatures, high pressures, or hazardous materials.

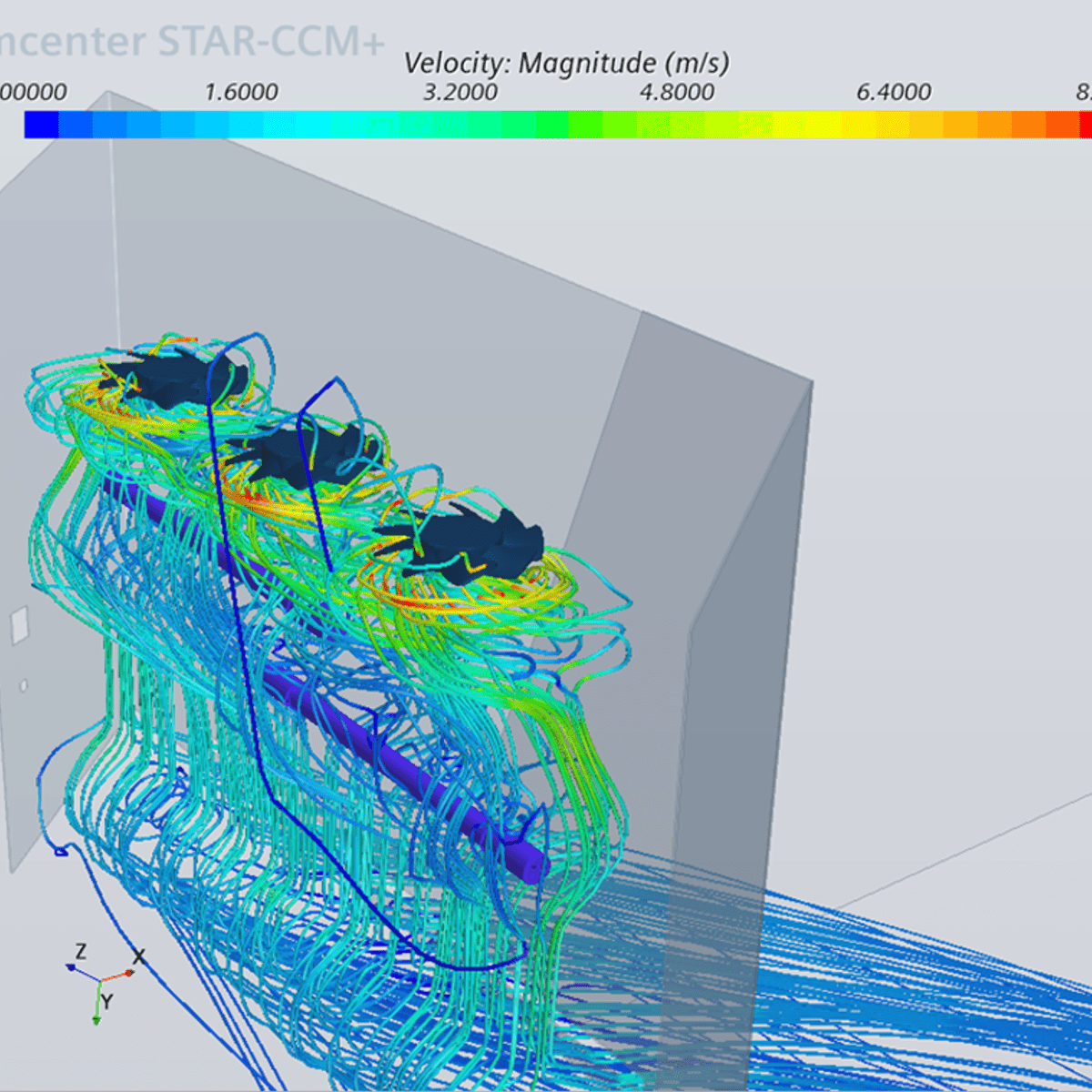

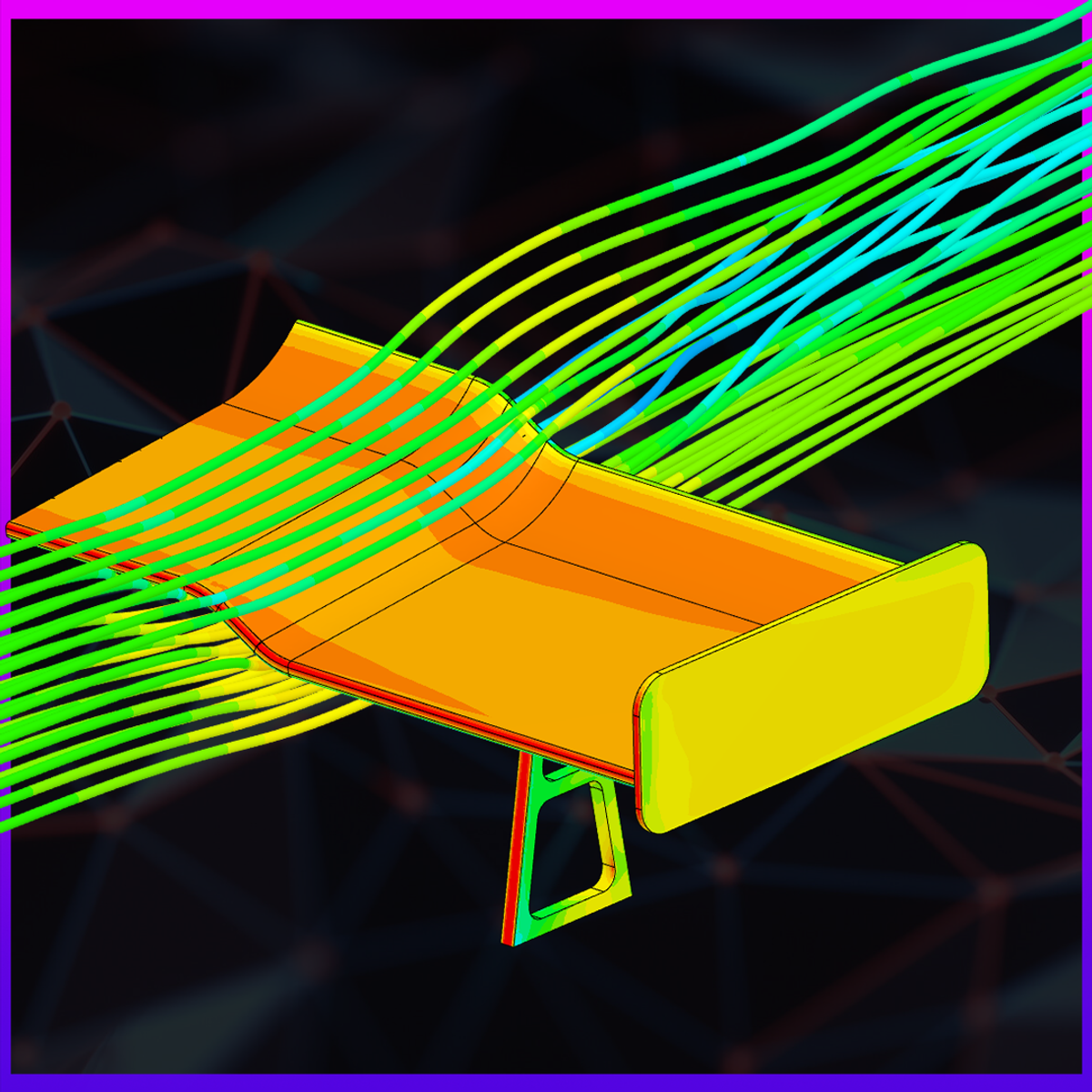

Another key advantage is the ability to visualize flow patterns. Sophisticated post-processing tools allow engineers to create compelling visual representations of fluid flow, making it easier to understand complex phenomena and communicate results. While physical flow visualization techniques exist, CFD often provides a clearer and more detailed picture. It's important to remember, however, that CFD is a modeling tool, and its accuracy depends on the quality of the model, the assumptions made, and the validation against experimental data. Often, CFD and experimental methods are used in a complementary fashion.

Where is CFD Used? An Interdisciplinary Tool

The applications of Computational Fluid Dynamics are incredibly broad and span a multitude of industries. Its ability to model and predict fluid behavior makes it an invaluable tool in any field where fluid flow plays a critical role. From designing more fuel-efficient cars and airplanes to optimizing manufacturing processes and understanding environmental phenomena, CFD is at the forefront of innovation.

In the aerospace industry, CFD is essential for designing aircraft and spacecraft, analyzing aerodynamic performance, and studying combustion in engines. The automotive sector heavily relies on CFD to optimize vehicle aerodynamics for better fuel efficiency and stability, as well as for designing engine cooling systems and passenger comfort. The energy industry uses CFD for a wide range of applications, including the design of wind turbines, gas turbines, nuclear reactors, and oil and gas pipelines.

Beyond these traditional engineering fields, CFD is also making significant inroads into biomedical engineering (e.g., simulating blood flow in arteries or airflow in the respiratory system), environmental engineering (e.g., modeling pollutant dispersion or weather patterns), chemical processing (e.g., designing reactors and mixing processes), and even sports (e.g., optimizing the aerodynamics of bicycles or swimsuits). This interdisciplinary nature means that skills in CFD are highly transferable and can open doors to a wide variety of career paths.

These courses offer a solid introduction to the fundamental concepts and applications of Computational Fluid Dynamics.

For those looking to delve deeper into the subject, these books provide comprehensive coverage of CFD principles and practices.

You may also find these related topics interesting as you explore CFD.

Core Mathematical Frameworks

Understanding the mathematical underpinnings of Computational Fluid Dynamics is crucial for anyone looking to truly master the field. While modern CFD software often handles the complex calculations, a solid grasp of the fundamental equations and numerical techniques allows for more effective use of these tools, better interpretation of results, and the ability to troubleshoot and customize simulations. This section delves into the essential mathematical concepts that form the backbone of CFD.

At the highest level, CFD seeks to solve a set of partial differential equations that describe the motion of fluids. These equations, derived from fundamental physical laws, capture the intricate dance of velocity, pressure, and temperature within a fluid flow. However, due to their complexity, especially for turbulent flows or complex geometries, direct analytical solutions are rarely possible. This necessitates the use of sophisticated numerical methods to approximate these solutions, which introduces concepts like discretization, mesh generation, and turbulence modeling.

The Governing Equations: Navier-Stokes and Euler

The cornerstone of most CFD analyses are the Navier-Stokes equations. These are a set of non-linear partial differential equations that describe the motion of viscous fluid substances. They arise from applying Newton's second law to fluid motion, together with the assumption that the fluid stress is the sum of a diffusing viscous term (proportional to the gradient of velocity) and a pressure term. For many practical applications, these equations provide a remarkably accurate description of fluid behavior, from the gentle flow of air over a wing to the chaotic mixing in a chemical reactor.

The Navier-Stokes equations account for viscosity, which is a measure of a fluid's resistance to flow. In situations where viscous forces are negligible compared to inertial forces (for example, in high-speed gas dynamics or far from solid boundaries), the Navier-Stokes equations can be simplified to the Euler equations. The Euler equations describe the motion of an inviscid (zero viscosity) fluid. While simpler, they still capture important phenomena like shock waves and are a valuable tool in specific aerodynamic applications.

Solving these equations, whether in their full Navier-Stokes form or the simplified Euler form, is the primary goal of CFD. The complexity of these equations, particularly their non-linear nature, is what makes CFD a computationally intensive field.

These courses provide a deeper dive into the mathematical equations and their applications in CFD.

To further explore the mathematical foundations, these books are excellent resources.

Tackling Turbulence: Modeling Approaches

Turbulence is a complex flow regime characterized by chaotic and stochastic property changes. It's ubiquitous in nature and in many engineering applications, from the flow of air over an airplane wing to the mixing of fuel and air in an engine. Directly simulating all the scales of turbulent motion, from the largest eddies down to the smallest dissipative scales (a method known as Direct Numerical Simulation or DNS), is computationally prohibitive for most practical problems due to the vast range of length and time scales involved.

Therefore, CFD relies on turbulence models to predict the effects of turbulence without resolving all of its intricate details. These models are sets of equations that approximate the impact of the unresolved turbulent fluctuations on the mean flow. Common approaches include Reynolds-Averaged Navier-Stokes (RANS) models, which solve for the time-averaged flow properties and model all scales of turbulence. RANS models, such as k-epsilon and k-omega SST, are widely used in industrial CFD due to their relatively low computational cost.

Another approach is Large Eddy Simulation (LES), where the large, energy-containing turbulent eddies are directly resolved by the simulation, while the smaller, more universal subgrid-scale eddies are modeled. LES is more computationally expensive than RANS but can provide more accurate results for flows with significant unsteady features or large-scale turbulent structures. Hybrid RANS-LES methods, like Detached Eddy Simulation (DES), attempt to combine the efficiency of RANS in near-wall regions with the accuracy of LES in separated flow regions. The choice of turbulence model is a critical decision in any CFD analysis and depends on the specific flow problem, the desired accuracy, and the available computational resources.

For those interested in the specific challenges of turbulence, these courses and books offer valuable insights.

Creating the Canvas: Mesh Generation Techniques

Before the governing equations can be solved numerically, the continuous physical domain of the fluid flow problem must be divided into a discrete set of smaller volumes or cells. This process is known as mesh generation or grid generation, and the resulting collection of cells is called the mesh or grid. The quality of the mesh significantly impacts the accuracy, convergence, and computational cost of the CFD simulation. A poorly generated mesh can lead to inaccurate results or even cause the simulation to fail.

There are various types of mesh elements, including hexahedra (bricks), tetrahedra, prisms, and pyramids, which can be arranged in structured or unstructured layouts. Structured meshes have a regular connectivity, meaning each node has a fixed number of neighbors, which can simplify numerical algorithms and lead to efficient solutions. However, generating structured meshes for complex geometries can be challenging. Unstructured meshes, on the other hand, offer greater flexibility in handling complex shapes as the connectivity between cells is arbitrary. They are generally easier to generate automatically for intricate geometries but can sometimes lead to higher memory requirements and computational costs.

Key considerations in mesh generation include cell size, cell quality (e.g., skewness, aspect ratio), and mesh density. The mesh needs to be fine enough in regions of high gradients (e.g., near walls, in wakes, or around shock waves) to accurately capture the flow physics, but coarser in regions where the flow is less complex to save computational resources. Techniques like adaptive mesh refinement, where the mesh is automatically refined in specific areas based on the evolving solution, are often employed to optimize mesh quality and efficiency. The art and science of mesh generation remain a critical skill for CFD practitioners.

Understanding mesh generation is fundamental. These courses can provide a practical introduction.

Ensuring Accuracy: Convergence and Error Analysis

Once a CFD simulation is set up and running, it's crucial to monitor its progress and assess the quality of the results. Two key aspects of this are convergence and error analysis. Convergence refers to the state where the solution to the discretized equations no longer changes significantly with further iterations of the numerical solver. In simpler terms, the simulation has reached a stable or steady-state solution (or a statistically steady state for unsteady simulations).

Monitoring residuals, which are measures of the imbalance in the solved equations, is a common way to assess convergence. As the solution converges, the residuals should decrease by several orders of magnitude. However, low residuals alone do not guarantee an accurate solution. It's also important to monitor key physical quantities of interest (e.g., lift, drag, pressure drop) to ensure they have reached stable values.

Error analysis involves identifying and quantifying the different sources of error in a CFD simulation. These can include modeling errors (due to simplifying assumptions in the physical model or turbulence model), discretization errors (due to approximating the continuous equations on a discrete mesh), and numerical errors (due to the iterative solution process). Grid independence studies, where simulations are run on progressively finer meshes, are often performed to estimate the discretization error and ensure that the solution is not overly sensitive to the mesh resolution. Validation, which involves comparing CFD results with experimental data or analytical solutions, is the ultimate test of a simulation's accuracy and reliability.

Industry-Specific Applications

The true power and versatility of Computational Fluid Dynamics become evident when we explore its diverse applications across various industries. From shaping the vehicles that transport us to optimizing energy generation and even advancing medical treatments, CFD plays a pivotal role in innovation and problem-solving. This section highlights some key sectors where CFD has made a significant impact, showcasing the breadth of its utility and the exciting challenges it helps address.

By enabling engineers and scientists to simulate and analyze fluid flow with remarkable detail, CFD provides insights that drive design improvements, enhance efficiency, and ensure safety. The ability to perform virtual testing reduces the reliance on costly and time-consuming physical prototypes, accelerating the development cycle and fostering innovation. As computational power continues to grow and numerical methods become more sophisticated, the range and complexity of problems that can be tackled with CFD are constantly expanding.

Aerospace: Simulating the Extremes of Flight

In the aerospace industry, Computational Fluid Dynamics is an indispensable tool. It is used extensively in the design and analysis of aircraft, spacecraft, missiles, and their propulsion systems. CFD allows engineers to simulate airflow around complex geometries, predict aerodynamic forces like lift and drag, analyze shock wave patterns in supersonic flight, and study the intricate details of combustion within jet engines and rocket motors.

One of the critical applications is in optimizing wing design for maximum lift and minimum drag, leading to more fuel-efficient aircraft. CFD is also used to analyze the performance of high-lift devices like flaps and slats during takeoff and landing, ensuring safe operation. For supersonic and hypersonic vehicles, CFD is crucial for understanding and mitigating the effects of strong shock waves and extreme aerodynamic heating. Furthermore, it aids in the design of quieter aircraft by modeling and reducing engine and airframe noise.

The ability to simulate these complex phenomena reduces the need for extensive and expensive wind tunnel testing and flight tests, although physical testing remains essential for validation. As aerospace systems become more complex and performance demands increase, the role of CFD in pushing the boundaries of flight will only continue to grow.

These courses provide specific insights into aerospace applications of CFD.

For those interested in the aerodynamics of flight, these books offer in-depth knowledge.

Energy Sector: Optimizing Power Generation and Extraction

The energy sector relies heavily on Computational Fluid Dynamics for a wide array of applications, aiming to improve efficiency, reduce environmental impact, and ensure the safety of energy generation and extraction processes. From designing more efficient wind turbines and gas turbines to optimizing combustion in power plants and modeling flow in oil and gas pipelines, CFD provides critical insights.

In renewable energy, CFD is instrumental in the aerodynamic design of wind turbine blades to maximize energy capture and in siting wind farms by simulating wind flow patterns over complex terrains. For fossil fuel power plants, CFD helps optimize burner design for more complete combustion, reducing pollutant emissions like NOx and SOx. It's also used to model heat transfer in boilers and heat exchangers to improve thermal efficiency. In the nuclear industry, CFD is vital for analyzing coolant flow and heat transfer within reactor cores, ensuring safe and efficient operation.

Furthermore, in the oil and gas industry, CFD simulates multiphase flow (oil, gas, and water) in pipelines and reservoirs, helping to optimize extraction processes and manage flow assurance issues like slugging or wax deposition. As the world transitions towards cleaner energy sources, CFD will continue to be a key technology in designing and optimizing the next generation of energy systems.

These courses can help you understand how CFD is applied in the energy sector, particularly in designing and optimizing energy systems.

The following book delves into heat transfer applications, which are critical in the energy sector.

Biomedical Engineering: Modeling Life's Flows

Computational Fluid Dynamics is increasingly being applied in the field of biomedical engineering to understand and analyze biological flows within the human body. This has opened up new avenues for diagnosing diseases, designing medical devices, and planning surgical interventions. The ability to simulate complex physiological flows non-invasively offers significant advantages over traditional experimental methods.

One of the most prominent applications is in cardiovascular modeling. CFD can simulate blood flow through arteries and veins, helping to identify regions prone to plaque formation (atherosclerosis), analyze the performance of artificial heart valves and stents, and plan surgeries for aneurysms or congenital heart defects. For instance, by simulating blood flow in a patient-specific model of an aorta, surgeons can better predict the outcome of a stent placement or bypass graft.

Other biomedical applications include simulating airflow in the respiratory system to understand diseases like asthma or to optimize drug delivery via inhalers. CFD is also used in designing bioreactors for tissue engineering, analyzing the flow of cerebrospinal fluid in the brain, and even modeling the mechanics of cell movement. As medical imaging techniques provide increasingly detailed anatomical data, and computational power continues to grow, the role of CFD in personalized medicine and healthcare innovation is set to expand significantly.

Automotive Industry: Streamlining Designs for Performance and Efficiency

In the competitive automotive industry, Computational Fluid Dynamics is a cornerstone of vehicle design and development. It is used extensively to optimize vehicle aerodynamics, improve engine performance and efficiency, manage thermal systems, and enhance passenger comfort. The insights gained from CFD simulations help engineers design cars that are more fuel-efficient, faster, safer, and more enjoyable to drive.

Aerodynamic optimization is a primary application. CFD allows engineers to visualize and quantify airflow around the car body, identifying areas of high drag or lift. This information is used to shape the vehicle to reduce air resistance, which directly impacts fuel economy and high-speed stability. It's also crucial in motorsport, like Formula 1, where aerodynamic performance is paramount. [rlccan]

Beyond external aerodynamics, CFD is used to analyze airflow through the engine compartment for cooling, to optimize the intake and exhaust manifolds for better engine breathing, and to simulate combustion processes within the engine cylinders for improved efficiency and reduced emissions. Thermal management, such as designing efficient radiator and brake cooling systems, also benefits significantly from CFD analysis. Furthermore, CFD helps in designing climate control systems that provide optimal heating, ventilation, and air conditioning (HVAC) for passenger comfort.

These courses are tailored for automotive applications, particularly in aerodynamics.

Computational Infrastructure

The power and utility of Computational Fluid Dynamics are intrinsically linked to the computational infrastructure that supports it. Solving the complex equations governing fluid flow, especially for large and detailed simulations, demands significant computational resources. This section explores the hardware and software environments that enable modern CFD, from high-performance computing clusters to the rise of cloud-based solutions and the impact of specialized hardware like GPUs.

As CFD models become more sophisticated and the demand for higher fidelity simulations increases, the requirements for computational power, memory, and data storage continue to grow. Understanding the landscape of computational infrastructure is therefore essential for anyone involved in performing or managing CFD analyses. Efficiently leveraging these resources is key to obtaining timely and accurate results, making informed engineering decisions, and pushing the boundaries of what can be simulated.

Powering Simulations: High-Performance Computing (HPC) Cluster Requirements

For many industrial-scale and research-level Computational Fluid Dynamics simulations, standard desktop computers are insufficient. These complex analyses often require the immense processing power and memory capacity of High-Performance Computing (HPC) clusters. An HPC cluster is essentially a group of interconnected computers (nodes) that work together as a single, powerful system. Each node typically contains multiple processor cores and a significant amount of RAM.

The key requirements for an HPC cluster geared towards CFD include multi-core CPUs (processors with many individual processing units), large amounts of RAM (Random Access Memory) to handle large mesh sizes and datasets, and high-speed interconnects (like InfiniBand) between nodes to ensure efficient communication during parallel computations. CFD software is often designed to run in parallel, meaning the computational workload is distributed across multiple cores or nodes, significantly reducing the overall simulation time. The number of cores can range from tens to hundreds of thousands for very large-scale simulations.

Sufficient data storage is also crucial, as CFD simulations can generate vast amounts of data, especially for unsteady or highly detailed models. The choice of operating system (often Linux-based, like CentOS, for HPC environments) and workload management software (like Slurm or PBS) are also important considerations for efficiently managing and scheduling CFD jobs on a cluster. Building and maintaining an in-house HPC cluster can be a significant investment, but it provides dedicated resources and control for organizations with substantial CFD needs.

These resources provide insights into leveraging high-performance computing for CFD.

CFD in the Cloud: Scalability and Accessibility

Cloud computing has emerged as a powerful alternative or supplement to on-premises High-Performance Computing (HPC) clusters for running Computational Fluid Dynamics simulations. Cloud-based CFD solutions offer several advantages, particularly in terms of scalability, accessibility, and cost-effectiveness for certain users. Instead of investing in and maintaining expensive physical hardware, users can rent computational resources from cloud providers on a pay-as-you-go basis.

One of the primary benefits is scalability. Cloud platforms allow users to easily scale up or down their computational resources based on the demands of their specific simulations. This means access to a virtually unlimited pool of processing power and memory when needed, without the constraints of fixed on-premises hardware. This flexibility is particularly valuable for organizations with fluctuating CFD workloads or those needing to run exceptionally large simulations occasionally.

Accessibility is another key advantage. Users can access cloud-based CFD platforms and their simulation results from anywhere with an internet connection. This facilitates collaboration among geographically dispersed teams. Furthermore, cloud providers often offer pre-configured environments with popular CFD software and HPC tools, simplifying the setup process. While concerns about data security and the long-term costs for very heavy users exist, cloud CFD is rapidly gaining traction and democratizing access to high-end simulation capabilities.

The Role of GPUs: Accelerating Computations

Graphics Processing Units (GPUs), originally designed for rendering graphics in video games, have found a significant role in accelerating scientific computations, including Computational Fluid Dynamics. GPUs are highly parallel processors, meaning they contain thousands of smaller cores designed to handle many tasks simultaneously. This architecture is well-suited for certain types of calculations prevalent in CFD solvers.

By offloading computationally intensive portions of the CFD code to GPUs, significant speedups can be achieved compared to running solely on CPUs (Central Processing Units). This can drastically reduce simulation times, allowing engineers to perform more simulations, explore more design variations, or run higher-fidelity models within the same timeframe. Several commercial and open-source CFD software packages now offer GPU acceleration capabilities.

However, not all parts of a CFD workflow benefit equally from GPU acceleration, and effectively utilizing GPUs often requires specific coding practices and algorithms. The memory capacity on GPUs can also be a limiting factor for very large models compared to system RAM accessible by CPUs. Despite these considerations, the trend of leveraging GPUs for CFD is growing, driven by the continuous improvement in GPU performance and the increasing demand for faster simulation turnaround times. The synergy between CPU and GPU computing is likely to be a key feature of future HPC systems for CFD.

Managing the Deluge: Data Storage and Management Strategies

Computational Fluid Dynamics simulations, particularly those involving large meshes, unsteady flows, or complex physics, can generate enormous amounts of data. A single simulation might produce terabytes of information, including mesh files, solver setup files, and voluminous result files containing variables like velocity, pressure, and temperature at millions or even billions of points in space and time. Effectively managing this data deluge is a critical aspect of the CFD workflow.

Robust data storage solutions are essential. This often involves high-capacity, high-performance storage systems, such as Network Attached Storage (NAS) or Storage Area Networks (SAN), capable of handling large files and providing fast access for both writing simulation output and post-processing. Data archiving strategies are also important for long-term storage of valuable simulation results, especially for projects that may need to be revisited or for regulatory compliance.

Beyond just storage, effective data management involves practices for organizing, cataloging, and retrieving simulation data. This includes consistent naming conventions, metadata tagging, and potentially the use of specialized data management software. Efficient data transfer mechanisms are also crucial, especially when dealing with remote HPC clusters or cloud-based solutions. As the scale and complexity of CFD simulations continue to increase, so too does the importance of well-planned data storage and management strategies to ensure that the valuable insights generated by CFD are not lost or inaccessible.

Academic Pathways

For individuals aspiring to a career in Computational Fluid Dynamics, a strong academic foundation is paramount. This field demands a deep understanding of fluid mechanics, mathematics, and computational science. This section outlines the typical educational journey, from undergraduate prerequisites to specialized graduate studies and research opportunities, providing a roadmap for students interested in pursuing this challenging and rewarding discipline.

The path to becoming a CFD professional often involves a rigorous curriculum that builds knowledge layer by layer. It starts with fundamental science and math courses and progresses to more specialized engineering and computational subjects. Beyond coursework, gaining practical experience through projects, internships, and research is highly beneficial. The interdisciplinary nature of CFD also means that collaborations with researchers and practitioners from other fields can enrich one's academic experience and open up diverse career possibilities.

Laying the Groundwork: Undergraduate Prerequisites

A successful journey into Computational Fluid Dynamics typically begins with a strong undergraduate education in an engineering discipline, most commonly mechanical, aerospace, or chemical engineering. Physics or applied mathematics can also provide a suitable foundation. Regardless of the specific major, certain core subjects are essential prerequisites for more advanced CFD studies.

A solid understanding of fluid mechanics is, of course, fundamental. This includes concepts like fluid statics, kinematics, conservation laws (mass, momentum, and energy), dimensional analysis, and an introduction to viscous flows and turbulence. Equally important is a strong mathematical background, particularly in calculus (including multivariable calculus and vector calculus), differential equations (both ordinary and partial differential equations or PDEs), linear algebra, and numerical methods. Numerical methods courses will introduce techniques for solving equations computationally, which is the essence of CFD.

Additionally, courses in thermodynamics and heat transfer are highly relevant, as many CFD problems involve thermal effects. Proficiency in a programming language commonly used in scientific computing, such as Python, MATLAB, Fortran, or C++, is also extremely valuable for developing custom tools, automating tasks, or even modifying CFD codes. A good grasp of these foundational subjects will prepare students for the more specialized topics encountered in graduate-level CFD courses.

These courses can help build the necessary undergraduate-level understanding for CFD.

Foundational books in fluid mechanics and numerical methods are key at this stage.

Advanced Studies: Specialized Graduate Programs

While an undergraduate degree provides the foundational knowledge, a graduate degree (Master's or Ph.D.) is often necessary for those seeking to specialize in Computational Fluid Dynamics, particularly for research-oriented roles or positions requiring advanced analysis and development. Specialized graduate programs offer in-depth coursework and research opportunities in various aspects of CFD.

Typical graduate-level CFD courses delve deeper into the derivation and application of the governing equations of fluid motion, advanced numerical methods for solving these equations (such as finite difference, finite volume, and finite element methods), turbulence modeling techniques (RANS, LES, DNS), mesh generation strategies, and post-processing and visualization of CFD data. Students will also likely gain hands-on experience with commercial or open-source CFD software packages through projects and assignments.

Many universities offer specialized tracks or research groups focused on CFD within their mechanical, aerospace, or chemical engineering departments. Some institutions may even have dedicated interdisciplinary programs in computational science and engineering that include a strong CFD component. When choosing a graduate program, it's important to consider the research interests of the faculty, the available computational resources, and opportunities for collaboration with industry or other research institutions.

These advanced courses are suitable for graduate-level exploration or for professionals looking to deepen their expertise.

Advanced texts are crucial for graduate studies.

Pushing Boundaries: Research Opportunities

Computational Fluid Dynamics is a vibrant and continually evolving field with numerous opportunities for cutting-edge research. Graduate students, particularly those pursuing a Ph.D., and academic researchers are at the forefront of advancing the science and technology of CFD. Research in CFD can span a wide spectrum, from fundamental theoretical developments to the application of CFD to solve challenging real-world problems.

One major area of research is the development and improvement of turbulence models. Despite decades of effort, accurately and efficiently modeling turbulence remains a significant challenge, and researchers are constantly exploring new approaches, including data-driven methods and machine learning techniques. Another active research area is the development of more accurate, robust, and efficient numerical algorithms, particularly for complex multiphysics problems (e.g., fluid-structure interaction, reacting flows, multiphase flows) and for emerging high-performance computing architectures.

Mesh generation techniques, especially for very complex geometries and for adaptive meshing, continue to be an area of active investigation. Furthermore, there is ongoing research into uncertainty quantification in CFD, which aims to assess the confidence in simulation results given uncertainties in input parameters, models, and numerical methods. Application-focused research involves using CFD to gain new insights into physical phenomena or to design novel engineering systems across diverse fields like aerospace, energy, biomedical engineering, and environmental science.

Bridging Disciplines: Interdisciplinary Collaborations

The inherently interdisciplinary nature of Computational Fluid Dynamics fosters numerous opportunities for collaboration with researchers and practitioners from a wide range of other fields. Fluid flow is a fundamental phenomenon in many scientific and engineering disciplines, and CFD provides a powerful tool for studying these flows in diverse contexts. These collaborations can lead to new insights, innovative solutions, and the cross-pollination of ideas.

For example, in biomedical engineering, CFD specialists collaborate with medical doctors and biologists to model blood flow in patient-specific anatomies or to simulate airflow in the lungs. In environmental science, collaborations with atmospheric scientists or oceanographers can lead to better models of pollutant dispersion, weather prediction, or climate change. In materials science, CFD can be coupled with models of material behavior to simulate processes like casting or additive manufacturing.

These interdisciplinary projects often require integrating knowledge and techniques from different fields. For instance, a project modeling fluid-structure interaction might involve combining CFD with computational solid mechanics. Similarly, simulating reacting flows requires integrating CFD with chemical kinetics. Such collaborations not only enrich the research but also equip students and professionals with a broader skillset and a more holistic understanding of complex systems. Many universities and research institutions actively promote interdisciplinary research centers and initiatives that facilitate these types of collaborations.

Professional Development

A career in Computational Fluid Dynamics is not just about acquiring academic qualifications; it's a journey of continuous learning and professional growth. As the field evolves with new technologies, software tools, and application areas, staying current and honing one's skills is crucial for long-term success. This section explores various avenues for professional development, from industry certifications and software-specific training to the importance of networking through conferences and mentorship.

For early-career professionals, navigating the landscape of professional development can seem daunting. However, by proactively seeking out opportunities to learn, connect, and contribute, individuals can build a strong professional profile and advance their careers. Whether you are aiming to deepen your technical expertise, expand your professional network, or move into leadership roles, a commitment to lifelong learning is key in the dynamic field of CFD.

Staying Sharp: Industry Certifications

While a strong academic background is the primary entry point into the field of Computational Fluid Dynamics, industry certifications can sometimes serve as a valuable supplement, demonstrating a certain level of proficiency or specialization. Unlike some other professions where certifications are mandatory for practice, in CFD, they are generally optional but can be a way to enhance credentials, particularly for those focused on specific software or application areas.

Organizations like the American Institute of Aeronautics and Astronautics (AIAA) occasionally offer professional development courses or workshops related to CFD, though a formal, universally recognized "CFD certification" is not standard across the industry. More commonly, certifications might be offered by software vendors for proficiency in their specific CFD tools (e.g., Ansys Fluent, Siemens Simcenter STAR-CCM+, OpenFOAM-based training). These software-specific certifications can be beneficial if a particular tool is widely used in your target industry or by your employer.

It's important to weigh the cost and time investment of any certification against its potential benefits for your specific career goals. Often, a strong portfolio of successfully completed projects and a solid understanding of fundamental CFD principles will carry more weight than a multitude of certifications. However, in certain contexts, a relevant certification can help you stand out or demonstrate a commitment to continuous professional development.

Mastering the Tools: Software-Specific Training

Proficiency in one or more Computational Fluid Dynamics software packages is a practical necessity for most CFD professionals. While a conceptual understanding of CFD principles is vital, the ability to effectively use these complex software tools to set up, run, and analyze simulations is what allows engineers to solve real-world problems. There is a wide array of commercial and open-source CFD software available, each with its own strengths, weaknesses, and user interface.

Commercial software packages like Ansys Fluent, Siemens Simcenter STAR-CCM+, COMSOL Multiphysics, and Autodesk CFD are widely used in industry and often come with extensive documentation, technical support, and training programs offered by the vendors or authorized training partners. These training programs can range from introductory courses covering the basics of the software to advanced workshops focusing on specific applications or modeling techniques.

Open-source CFD software, with OpenFOAM being the most prominent example, offers a high degree of flexibility and customization but typically has a steeper learning curve. [kv7pda] While official vendor-led training might be less common for open-source tools, there is a wealth of community-generated tutorials, online forums, and third-party training providers. Investing time in software-specific training, whether formal or self-directed, is crucial for becoming an efficient and effective CFD practitioner. Many online learning platforms also offer courses focused on specific CFD software. OpenCourser, for example, allows you to explore a variety of software tools and find relevant courses to master them.

These courses offer training in specific, widely used CFD software packages.

Connecting with Peers: Conference Participation

Attending and participating in conferences, workshops, and seminars is an excellent way for Computational Fluid Dynamics professionals to stay abreast of the latest advancements in the field, learn about new techniques and applications, and network with peers from academia and industry. These events provide a platform for sharing research findings, discussing challenges, and fostering collaborations.

Major international conferences dedicated to CFD or with significant CFD tracks are organized by professional societies like the American Institute of Aeronautics and Astronautics (AIAA), the American Society of Mechanical Engineers (ASME), and various international organizations. These conferences often feature keynote presentations by leading experts, technical paper sessions, poster presentations, and exhibitions by software vendors and hardware manufacturers.

For early-career professionals, presenting their work at a conference can be a valuable experience, providing an opportunity to receive feedback from experts and gain visibility within the community. Even attending without presenting can be highly beneficial for learning and networking. Many conferences also offer short courses or tutorials on specific CFD topics. Actively participating in the CFD community through such events can significantly contribute to one's professional growth and career development.

Guidance and Growth: Mentorship Opportunities

Mentorship can play a crucial role in the professional development of Computational Fluid Dynamics engineers, especially those in the early stages of their careers. A mentor, typically a more experienced professional in the field, can provide guidance, advice, and support, helping the mentee navigate career challenges, develop new skills, and expand their professional network.

Finding a mentor can happen through various channels. Within an academic setting, professors or senior researchers can serve as mentors. In an industrial environment, a senior colleague or manager might take on a mentorship role. Professional organizations and alumni networks can also be good resources for finding mentors. Some companies have formal mentorship programs, while in other cases, mentorship relationships develop more informally.

A good mentor can offer insights into industry trends, share experiences from their own career path, provide feedback on technical work, help identify areas for skill development, and offer advice on career advancement. For those considering a career transition into CFD, a mentor who has made a similar switch can be particularly valuable. Building a strong mentorship relationship requires effort from both the mentor and the mentee, based on trust, open communication, and a shared commitment to the mentee's growth.

Ethical and Regulatory Considerations

As with any powerful technology, the application of Computational Fluid Dynamics comes with ethical and regulatory considerations that practitioners, policymakers, and society at large must address. While CFD offers immense benefits in terms of design optimization, scientific understanding, and problem-solving, its use also raises questions related to the responsible application of the technology, potential environmental impacts, data privacy, and the need for standardized validation practices.

Ensuring that CFD is used in a manner that is safe, ethical, and beneficial to society requires ongoing dialogue and the development of appropriate guidelines and regulations. This section touches upon some of the key ethical and regulatory aspects pertinent to the field of Computational Fluid Dynamics.

The Dual-Use Dilemma: Military Applications Oversight

Computational Fluid Dynamics has significant applications in the defense and military sectors, contributing to the design and analysis of military aircraft, missiles, naval vessels, and other weapons systems. This dual-use nature of CFD – its applicability for both civilian and military purposes – raises important ethical questions and necessitates careful oversight.

The development of advanced military technologies often relies on sophisticated CFD simulations to optimize performance, stealth, and destructive capabilities. While these applications may be deemed necessary for national security by some, they also contribute to the global arms race and can have profound humanitarian consequences if deployed in conflict. Ethical considerations revolve around the role of CFD engineers and scientists in developing such technologies and the potential for their work to be used in ways that cause harm.

Oversight mechanisms, including national export controls, international treaties, and ethical guidelines within professional organizations, aim to manage the proliferation of sensitive military technologies, including those heavily reliant on CFD. Transparency and public discourse regarding the military applications of CFD are important for ensuring accountability and for fostering a responsible approach to its development and use in this domain.

The Environmental Footprint: Computational Resource Impact

Running complex Computational Fluid Dynamics simulations, especially those requiring High-Performance Computing (HPC) clusters, consumes a significant amount of electrical energy. This energy consumption, in turn, contributes to a carbon footprint, particularly if the electricity is generated from fossil fuels. As the scale and frequency of CFD simulations continue to grow, the environmental impact of the computational resources they rely on is becoming an increasingly important consideration.

Researchers and practitioners are beginning to explore ways to quantify and mitigate the carbon footprint of CFD. This includes developing more energy-efficient HPC hardware and cooling systems, optimizing CFD algorithms to reduce computational cost without sacrificing accuracy, and utilizing renewable energy sources to power computing centers. There is also a growing interest in "green computing" practices within the broader scientific computing community.

While the direct environmental impact of running simulations is a concern, it's also important to note that CFD itself can be a powerful tool for environmental protection and sustainability. For example, CFD is used to design more fuel-efficient vehicles, optimize renewable energy systems like wind turbines, model pollutant dispersion to improve air quality, and develop carbon capture technologies. Therefore, a holistic view considers both the energy consumed by CFD and its role in creating more environmentally friendly solutions.

Collaboration and Confidentiality: Data Privacy in Projects

Computational Fluid Dynamics projects, particularly those in industrial settings or involving sensitive research, often deal with proprietary or confidential data. This can include detailed design specifications, experimental data used for validation, or novel simulation methodologies. When multiple organizations or individuals collaborate on CFD projects, ensuring data privacy and protecting intellectual property become critical concerns.

Clear agreements regarding data ownership, access rights, and confidentiality should be established at the outset of any collaborative project. Non-disclosure agreements (NDAs) are commonly used to protect sensitive information shared between parties. Secure data storage and transfer protocols are also essential to prevent unauthorized access or data breaches.

In the context of cloud-based CFD, where data is stored and processed on third-party servers, data privacy and security are particularly important considerations. Users need to be aware of the cloud provider's security measures and data handling policies. As CFD becomes more data-intensive and collaborative, robust frameworks for managing data privacy and ensuring the ethical handling of sensitive information will be increasingly vital.

Ensuring Reliability: Standardization of Validation Protocols

The credibility of Computational Fluid Dynamics simulations hinges on their accuracy and reliability. Validation, the process of determining the degree to which a model is an accurate representation of the real world from the perspective of the intended uses of the model, is a critical step in any CFD analysis. It typically involves comparing simulation results with experimental data or analytical solutions.

However, the process of validation itself can be complex and subject to variability. There is a growing recognition within the CFD community of the need for standardized validation protocols and best practice guidelines. Standardization helps ensure that CFD studies are conducted rigorously, that results are reported transparently, and that the level of accuracy and uncertainty is clearly communicated. This is particularly important when CFD results are used to make critical engineering decisions or for regulatory compliance.

Organizations like the American Society of Mechanical Engineers (ASME) and the European Research Community on Flow, Turbulence and Combustion (ERCOFTAC) have been active in developing best practice guidelines and standards for verification (ensuring the code correctly solves the mathematical equations) and validation in CFD. Adherence to such standards promotes confidence in CFD results and fosters a culture of quality and rigor within the field. The Nuclear Regulatory Commission, for example, also outlines best practices for specific applications like dry cask simulations.

Emerging Frontiers

Computational Fluid Dynamics is far from a static field; it is continuously evolving, driven by advances in computing technology, numerical algorithms, and our understanding of fluid physics. Researchers and engineers are constantly pushing the boundaries of what can be simulated and how CFD can be applied to solve new and complex challenges. This section explores some of the exciting emerging frontiers in CFD, highlighting trends that are shaping the future of the discipline.

From the integration of artificial intelligence and machine learning to the potential applications of quantum computing and the development of real-time simulation capabilities, these cutting-edge developments promise to make CFD even more powerful, versatile, and impactful in the years to come. Staying aware of these emerging frontiers is important for both seasoned professionals and those just entering the field, as they represent the future direction of CFD research and application.

Smarter Simulations: Machine Learning-Enhanced Turbulence Models

One of the most exciting frontiers in Computational Fluid Dynamics is the integration of Artificial Intelligence (AI) and Machine Learning (ML) techniques, particularly in the challenging area of turbulence modeling. Traditional turbulence models, while widely used, often involve simplifications and empirical correlations that may not be accurate for all flow conditions. ML offers a new paradigm for developing more accurate and robust turbulence models by learning from data.

Researchers are exploring various ways to use ML to enhance turbulence modeling. This includes using ML algorithms to improve the predictive capabilities of existing RANS models by correcting discrepancies or by learning optimal model parameters from high-fidelity simulation data (like DNS or LES) or experimental measurements. Another approach involves developing entirely new turbulence models, or components of models, using techniques like neural networks or genetic programming. These data-driven models have the potential to capture complex turbulence physics that are difficult to represent with traditional approaches.

While ML-enhanced turbulence modeling is still an active area of research, it holds significant promise for improving the accuracy and efficiency of CFD simulations, especially for complex turbulent flows encountered in aerospace, energy, and industrial applications. The ability of ML to identify patterns and relationships in large datasets makes it a powerful tool for tackling the inherent complexity of turbulence.

These courses introduce the intersection of CFD with machine learning and AI, a rapidly advancing area.

For a deeper understanding of how AI is revolutionizing fluid dynamics, consider exploring resources from institutions like the Journal of Artificial Intelligence in Fluid Dynamics, which publishes cutting-edge research in this domain.

The Quantum Leap: Potential Quantum Computing Applications

Quantum computing, while still in its nascent stages, holds the long-term potential to revolutionize many fields of science and engineering, including Computational Fluid Dynamics. Quantum computers leverage the principles of quantum mechanics to perform calculations that are intractable for even the most powerful classical computers. For CFD, this could eventually mean the ability to solve fluid dynamics problems with unprecedented speed and accuracy.

Potential applications of quantum computing in CFD are still largely theoretical and exploratory. One area of interest is the development of quantum algorithms for solving systems of linear equations, which are a core component of many CFD solvers. Quantum algorithms could potentially offer exponential speedups for these tasks. Another possibility is using quantum computers to directly simulate certain aspects of quantum fluid dynamics or to tackle highly complex turbulence problems that are beyond the reach of classical simulation methods.

However, significant challenges remain before quantum computing can become a practical tool for mainstream CFD. These include building stable, large-scale quantum computers, developing robust quantum algorithms specifically tailored for fluid dynamics problems, and finding ways to efficiently input classical flow data into a quantum computer and extract the results. Despite these hurdles, the long-term transformative potential of quantum computing makes it an intriguing frontier for the CFD community to watch.

Real-Time Reactions: CFD for Autonomous Systems

The increasing prevalence of autonomous systems, such as self-driving cars, drones, and autonomous underwater vehicles (AUVs), is creating a demand for real-time or near real-time Computational Fluid Dynamics capabilities. For these systems to operate safely and efficiently, they often need to sense and respond to their fluid dynamic environment in real time. For example, a drone might need to adjust its flight path based on sudden wind gusts, or an AUV might need to optimize its trajectory based on ocean currents.

Traditional CFD simulations are typically too computationally expensive to run in real time on board an autonomous system. However, researchers are exploring several approaches to enable faster, more responsive CFD. This includes developing highly optimized, reduced-order models (ROMs) that capture the essential flow physics with much lower computational cost. Machine learning techniques are also being used to create fast surrogate models that can predict flow behavior based on sensor inputs.

The integration of such rapid CFD capabilities into the control systems of autonomous vehicles could lead to significantly improved performance, safety, and adaptability. For instance, real-time aerodynamic analysis could help a self-driving truck optimize its shape or speed to minimize fuel consumption in varying wind conditions. While significant challenges remain in achieving true real-time CFD for complex scenarios, this is a rapidly advancing area with substantial potential impact.

The Digital Twin: Integrating Simulations with Physical Assets

The concept of the "digital twin" is another exciting frontier where Computational Fluid Dynamics plays a crucial role. A digital twin is a virtual representation of a physical asset or system that is continuously updated with real-world data from sensors. This allows for the simulation, prediction, and optimization of the physical asset's performance throughout its lifecycle.

In the context of CFD, a digital twin might involve creating a high-fidelity CFD model of, for example, a gas turbine, a wind farm, or a chemical reactor. This model would be linked to sensors on the actual physical asset that provide real-time operational data (e.g., temperatures, pressures, flow rates). The CFD model can then be used to monitor the asset's health, predict potential failures, optimize operating parameters for efficiency or longevity, and test the impact of proposed modifications before they are implemented on the physical system.

The integration of CFD into digital twin frameworks enables a much deeper understanding of how physical assets behave under real-world operating conditions. It allows for proactive maintenance, improved operational efficiency, and data-driven decision-making. As sensor technology, IoT (Internet of Things) connectivity, and computational power continue to advance, the use of CFD-enabled digital twins is expected to become increasingly prevalent across various industries, from manufacturing and energy to aerospace and infrastructure.

Career Development FAQ

Embarking on or advancing a career in Computational Fluid Dynamics can be both exciting and challenging. As a specialized and technically demanding field, it often raises many questions for job seekers, students, and those considering a career change. This FAQ section aims to address some of the common practical concerns related to career development in CFD, offering insights and actionable advice.

From the essential skills and tools to industry demand and long-term prospects, understanding these aspects can help you make informed decisions and strategically plan your career path in the dynamic world of Computational Fluid Dynamics.

What programming languages are essential for CFD roles?

While many Computational Fluid Dynamics roles involve using commercial or open-source CFD software packages with graphical user interfaces, proficiency in certain programming languages can be highly beneficial, and sometimes essential, depending on the specific role. For tasks like automating simulation workflows, pre-processing data, post-processing results, developing custom solvers or models, or working with open-source CFD codes, programming skills are invaluable.

Python has become increasingly popular in the scientific computing community, including CFD, due to its ease of use, extensive libraries for numerical computation (like NumPy and SciPy), data analysis (Pandas), and visualization (Matplotlib, ParaView scripting). It's often used for scripting, automation, and developing utility tools. Fortran and C++ have traditionally been the workhorses for developing high-performance CFD solvers due to their efficiency in handling computationally intensive tasks. Many legacy and cutting-edge CFD codes are written in these languages. Familiarity with C++ is particularly useful for working with object-oriented CFD codes like OpenFOAM.

MATLAB is another tool frequently used for numerical computation, algorithm development, and data visualization in academic and research settings. For those working with HPC clusters, scripting languages like Bash or Perl can be useful for managing jobs and files. The specific languages required will vary by job, but a good foundation in Python and some exposure to C++ or Fortran would generally be a strong asset for a CFD professional.

How can I build a strong portfolio for CFD jobs?

A strong portfolio showcasing your skills and experience is crucial when applying for Computational Fluid Dynamics jobs, especially for entry-level positions or when transitioning into the field. Since CFD is a highly practical discipline, employers want to see evidence that you can apply your knowledge to solve real problems. Your portfolio should highlight relevant projects, technical skills, and problem-solving abilities.

Include detailed descriptions of CFD projects you've completed, whether as part of your academic coursework, research, internships, or personal initiatives. For each project, describe the problem you were trying to solve, the CFD tools and methods you used (software, mesh generation techniques, turbulence models, etc.), the challenges you faced, and the results you achieved. Use visuals like mesh images, contour plots, and graphs to illustrate your work. If possible, quantify the impact of your work (e.g., "achieved a 10% reduction in drag" or "validated simulation results within 5% of experimental data").

Highlight your proficiency in specific CFD software packages and programming languages. If you have experience with scripting, automation, or developing custom tools, showcase these skills. Contributions to open-source CFD projects or participation in CFD-related competitions can also be valuable additions. Consider creating an online portfolio (e.g., a personal website or a GitHub repository) to make your work easily accessible to potential employers. Remember to only include work that you are permitted to share publicly, especially if it involved proprietary or confidential information from previous employment or research.

What are the industry demand trends for CFD professionals by region?

The demand for Computational Fluid Dynamics professionals tends to be concentrated in regions with strong industrial and research sectors that heavily utilize simulation technologies. North America, particularly the United States, has a high demand for CFD expertise, driven by its large aerospace, automotive, defense, and energy industries, as well as numerous research institutions and tech companies. Major hubs often align with centers for these industries.

Europe also has a robust CFD market, with countries like Germany, the UK, and France having significant aerospace, automotive, and manufacturing sectors that employ CFD engineers. The European Union's focus on research and development, particularly in areas like renewable energy and sustainable transportation, further fuels demand.

The Asia-Pacific region is experiencing rapid growth in the CFD market, with countries like China, India, Japan, and South Korea showing increasing adoption of CFD solutions in their expanding automotive, electronics, manufacturing, and aerospace sectors. Government investments in research and development and a growing manufacturing base contribute to this trend. While specific demand can fluctuate based on economic conditions and industry-specific trends, the overall outlook for skilled CFD professionals remains positive as industries continue to rely on simulation for innovation and efficiency. According to one market report, the global CFD market was valued at $2.6 billion in 2023 and is projected to reach $5.3 billion by 2033, growing at a CAGR of 7.2%. Another report projects the market to reach USD 6,427 Million by 2035, registering a CAGR of 8.3%.

Is remote work feasible for CFD roles?

The feasibility of remote work for Computational Fluid Dynamics roles has increased significantly in recent years, accelerated by advancements in collaboration tools, cloud computing, and shifting work culture. However, whether a specific CFD role can be fully remote depends on several factors, including the nature of the work, company policy, and the available infrastructure.

Many aspects of CFD work, such as pre-processing (geometry and mesh generation), setting up and running simulations, post-processing results, and report writing, can often be performed remotely, provided there is access to the necessary software and computational resources (which could be cloud-based or accessed via remote connections to on-premises HPC clusters). For roles that are primarily software-based and involve individual analytical work, remote arrangements are often quite feasible.

However, some CFD roles may require a physical presence. For example, if the role involves close collaboration with experimental teams, hands-on work with physical prototypes for validation, or access to secure on-site computing facilities that cannot be accessed remotely, then a hybrid or fully on-site arrangement might be necessary. Company culture and IT infrastructure also play a significant role. Some organizations are fully equipped for remote work, while others may prefer or require on-site presence for collaboration and security reasons. As you explore job opportunities, it's advisable to clarify the company's stance on remote work for the specific role.

What is the career longevity like, especially with AI augmenting CFD?

The field of Computational Fluid Dynamics offers strong prospects for career longevity, and the advent of Artificial Intelligence (AI) is more likely to augment and evolve the role of CFD professionals rather than replace them. While AI and machine learning are indeed automating certain aspects of the CFD workflow and enhancing capabilities (e.g., in turbulence modeling, mesh generation, or post-processing), the fundamental need for human expertise in understanding fluid mechanics, interpreting results, and making critical engineering judgments remains.

AI tools can free up CFD engineers from repetitive tasks, allowing them to focus on more complex problem-solving, innovation, and higher-level analysis. The future CFD engineer will likely need to be proficient in using these AI-augmented tools and understanding their capabilities and limitations. This means that continuous learning and adaptation will be key to long-term career success. Those who embrace new technologies and develop skills at the intersection of CFD and AI/ML will likely find themselves in high demand.

Furthermore, the core principles of fluid dynamics and the ability to critically assess simulation results will always be valuable. As industries continue to push for greater efficiency, performance, and sustainability, the demand for skilled professionals who can leverage CFD (including its AI-enhanced forms) to solve complex engineering challenges is expected to remain strong. The ability to adapt and integrate new tools and methodologies will be a hallmark of a long and successful career in this evolving field.

These career paths are central to the field of Computational Fluid Dynamics.

Are there entrepreneurial opportunities in CFD consulting?

Yes, there are certainly entrepreneurial opportunities for Computational Fluid Dynamics professionals in the realm of consulting. Many industries rely on CFD analysis but may not have the in-house expertise or resources to perform these simulations themselves. This creates a demand for specialized CFD consultants who can provide expert services on a project basis.

CFD consultants can offer a range of services, including performing specific simulation projects for clients, providing expert advice on CFD methodology and best practices, developing custom CFD tools or workflows, and offering specialized training. Niche areas, such as expertise in a particular industry (e.g., renewable energy, biomedical devices) or a specific type of analysis (e.g., multiphase flow, combustion, aeroacoustics), can help a consultant differentiate themselves.

Starting a CFD consulting business requires not only strong technical skills in CFD but also business acumen, including marketing, client management, project management, and financial planning. Building a reputation for delivering high-quality work and reliable results is crucial for success. Networking within relevant industries and staying current with the latest CFD technologies and software are also important. While challenging, a successful CFD consulting practice can offer a rewarding career path with a high degree of autonomy and the opportunity to work on diverse and interesting projects. The rise of cloud-based CFD solutions can also lower the initial barrier to entry in terms of computational hardware costs.

Useful Links and Resources

To further your exploration of Computational Fluid Dynamics and the learning opportunities available, here are some helpful resources from OpenCourser:

- Discover a wide array of online courses and books on OpenCourser's main page: OpenCourser Home

- Stay updated with the latest in online learning through our blog: OpenCourser Notes

- Find guidance on how to make the most of your online learning journey: OpenCourser Learner's Guide

- Browse courses specifically in the Engineering category to find CFD-related and other engineering topics.

- Explore the fundamentals of Physics, a core component of CFD.

- Delve into Mathematics courses, essential for understanding the underpinnings of CFD.

Additionally, for those looking to connect with the broader scientific community or find regulatory information, resources from organizations such as the American Institute of Aeronautics and Astronautics (AIAA) or specific governmental bodies like the U.S. Nuclear Regulatory Commission can provide valuable context and standards relevant to CFD applications.

Computational Fluid Dynamics is a challenging yet profoundly rewarding field that sits at the confluence of physics, mathematics, and computer science. It offers the opportunity to unravel the complexities of fluid flow and apply this understanding to solve critical problems across a vast spectrum of industries. Whether you are designing the next generation of aircraft, optimizing clean energy solutions, or pioneering new medical treatments, CFD provides a powerful lens through which to view and shape the world around us. The path to mastering CFD requires dedication and continuous learning, but the intellectual stimulation and the potential to make a tangible impact are immense. As technology continues to advance, particularly with the integration of AI and more powerful computing resources, the frontiers of CFD will only expand, offering even more exciting avenues for exploration and innovation for those who choose to embark on this journey.