Petroleum Engineer

A Comprehensive Guide to a Career as a Petroleum Engineer

Petroleum engineers are central figures in the global energy sector, specializing in the exploration, extraction, and production of hydrocarbons like crude oil and natural gas. They apply principles from geology, physics, chemistry, and engineering to locate and recover these resources from subsurface reservoirs. Working in the upstream sector of the oil and gas industry, they collaborate closely with earth scientists to understand underground formations and devise strategies for efficient and economical resource recovery.

This career offers intellectually stimulating challenges, combining detailed analysis with practical problem-solving. Petroleum engineers design complex drilling operations, develop innovative extraction techniques, and manage sophisticated production systems. The field often involves leveraging advanced technologies, including reservoir simulation software and data analytics, to optimize resource extraction while considering environmental and safety factors. For those interested in a technical career with global relevance and significant impact, petroleum engineering presents compelling opportunities.

Introduction to Petroleum Engineering

What is Petroleum Engineering?

Petroleum engineering is a specialized field focused on activities related to discovering and producing hydrocarbons—primarily crude oil and natural gas. It involves understanding the complex underground rock formations, known as reservoirs, where these resources accumulate. Engineers in this field use scientific principles and technology to determine the most effective methods for drilling wells and extracting the oil and gas.

The scope of petroleum engineering covers the entire lifecycle of an oil or gas field, from initial exploration support to production management and eventual site abandonment. It requires a deep understanding of subsurface geology, fluid mechanics, thermodynamics, and materials science. Petroleum engineers work to maximize the amount of recoverable resources while ensuring operations are safe, cost-effective, and environmentally responsible.

This field is a crucial part of the global energy industry. Petroleum engineers work alongside geoscientists to evaluate potential drilling sites and analyze geological data. Their primary goal is to design and implement strategies that efficiently bring energy resources to the surface, meeting worldwide demand for fuel and other petroleum-based products.

A Brief History

The origins of petroleum engineering trace back to the late 19th and early 20th centuries, coinciding with the rise of the modern oil industry. Early efforts focused primarily on drilling techniques and basic production methods. As the demand for petroleum grew, the need for more sophisticated engineering approaches became apparent, leading to the formalization of petroleum engineering as a distinct discipline.

Significant advancements occurred throughout the 20th century, driven by technological innovation and a deeper understanding of reservoir behavior. Techniques like secondary and tertiary recovery methods (e.g., water or gas injection) were developed to extract more oil from existing fields. The advent of offshore drilling opened up vast new reserves, presenting unique engineering challenges.

In recent decades, the field has been shaped by digital technology, including advanced simulation software and data analytics, allowing for more precise reservoir modeling and production optimization. There's also been an increasing focus on environmental stewardship and safety, leading to stricter regulations and the development of cleaner extraction technologies. The history of petroleum engineering reflects a continuous effort to innovate and adapt to changing energy needs and societal expectations.

To understand the historical context and economic forces shaping the industry, certain texts offer valuable insights. These books provide a comprehensive look at the evolution of the oil and gas sector.

Core Objectives and Global Relevance

The fundamental objective of petroleum engineering is the safe, efficient, and economical extraction of oil and natural gas resources. Engineers strive to maximize recovery from subsurface reservoirs while minimizing environmental impact and operational costs. This involves designing optimal drilling plans, selecting appropriate extraction technologies, and managing production processes throughout the life of a well.

Petroleum engineers play a critical role in meeting global energy demand. Despite the growth of renewable energy sources, oil and natural gas remain vital components of the world's energy mix, powering transportation, heating homes, and serving as feedstocks for countless industrial products. Engineers in this field ensure a stable supply of these essential resources.

The profession has significant global relevance, impacting economies and international relations. Petroleum engineers work worldwide, often in diverse and challenging environments, from deep offshore platforms to remote onshore locations. Their expertise is crucial for developing energy resources responsibly and sustainably, navigating both technical complexities and geopolitical factors that influence the oil and gas industry.

Key Responsibilities of a Petroleum Engineer

Reservoir Analysis and Management

Reservoir analysis is a core responsibility, involving the evaluation of subsurface rock formations to estimate the quantity and accessibility of oil and gas. Petroleum engineers, particularly reservoir engineers, use geological data, well logs, and fluid samples to build detailed models of these underground reservoirs. These models help predict how fluids will flow within the rock and how much resource can be economically recovered.

Understanding reservoir behavior is crucial for effective management. Engineers analyze pressure, temperature, and fluid properties to develop strategies for maximizing production over the reservoir's lifespan. This often involves using sophisticated reservoir simulation software to test different production scenarios and optimize well placement and extraction rates.

Effective reservoir management also includes planning for enhanced oil recovery (EOR) techniques. As natural pressure declines, engineers might design methods like injecting water, gas, or chemicals to maintain pressure and sweep more oil towards production wells. Continuous monitoring and data analysis allow engineers to adapt strategies and ensure long-term productivity.

These courses provide foundational and advanced knowledge in reservoir characterization and management techniques.

For those seeking a deeper dive into the properties of reservoir fluids, this book is a standard reference.

Drilling Optimization Techniques

Drilling engineers specialize in planning and supervising the complex process of drilling wells to access oil and gas reservoirs. They design the well trajectory, select appropriate drilling equipment and fluids (drilling mud), and manage the technical aspects of the operation. Optimization involves balancing speed, cost, safety, and environmental considerations.

A key aspect is selecting the right drilling technology for the geological conditions. This might involve directional or horizontal drilling to access reservoirs more effectively or using specialized tools for challenging environments like deepwater or unconventional shale formations. Engineers monitor drilling parameters in real-time to make adjustments and prevent problems.

Continuous improvement is central to drilling optimization. Engineers analyze data from past drilling operations to refine techniques, improve equipment performance, and reduce non-productive time. Emerging technologies like drilling automation and advanced data analytics are increasingly used to enhance efficiency and safety.

These courses offer introductions to the principles and practices of oil and gas drilling.

This book delves into the specifics of horizontal drilling, a key technique in modern petroleum engineering.

Designing Extraction and Production Systems

Once a well is drilled, petroleum engineers design and implement systems to bring hydrocarbons to the surface efficiently and safely. This includes selecting and installing downhole equipment like tubing, packers, and safety valves, a process known as well completion. The design must account for reservoir pressure, fluid properties, and potential issues like sand production.

Production engineers focus on managing the interface between the reservoir and the wellbore. They design artificial lift systems, such as submersible pumps or gas lift, when reservoir pressure isn't sufficient to push fluids to the surface. They also manage fluid behavior, addressing challenges like corrosion, scaling, or wax deposition that can impede flow.

Optimizing surface facilities is another critical aspect. Engineers design separation equipment to separate oil, gas, and water produced from the well. They also plan pipelines and storage facilities, ensuring that the entire production system operates efficiently and meets regulatory standards for safety and environmental protection.

These courses cover essential aspects of well completion, production operations, and the equipment involved.

For detailed insights into well completion and production systems design, these books are valuable resources.

Environmental and Safety Compliance

Ensuring environmental protection and operational safety is a paramount responsibility for petroleum engineers. They must design and operate facilities in compliance with stringent environmental regulations, aiming to minimize impacts on air, water, and land. This includes managing drilling waste, preventing spills, and reducing emissions.

Safety management involves identifying potential hazards and implementing robust safety protocols throughout all phases of exploration, drilling, and production. Engineers work to prevent accidents like blowouts, fires, or equipment failures by ensuring proper design, maintenance, and operational procedures are followed. They often collaborate with safety specialists and regulatory agencies.

Petroleum engineers are increasingly involved in managing the carbon footprint of operations. This includes efforts to reduce methane leaks, improve energy efficiency, and explore technologies like carbon capture, utilization, and storage (CCUS). Adherence to ethical standards and community engagement are also crucial aspects of responsible resource development.

Understanding the environmental context and ethical dimensions is crucial for modern engineers.

Formal Education Pathways

High School Prerequisites

Aspiring petroleum engineers should focus on building a strong foundation in science, technology, engineering, and mathematics (STEM) during high school. Courses in physics, chemistry, and advanced mathematics (including calculus, if available) are essential. These subjects provide the fundamental principles needed for engineering studies.

Developing strong analytical and problem-solving skills is also crucial. Engaging in science fairs, math competitions, or robotics clubs can help cultivate these abilities. Computer science courses are beneficial, as modern engineering relies heavily on software tools and data analysis.

Beyond academics, good communication skills, both written and verbal, are important, as engineers often work in teams and need to present complex information clearly. Taking courses in English, technical writing, or public speaking can be advantageous. Exploring geology or earth science can also provide relevant background knowledge.

Undergraduate Degrees

The most direct educational path is a bachelor's degree in petroleum engineering. These programs, typically four years long, provide specialized knowledge in areas like reservoir mechanics, drilling engineering, production operations, and petroleum geology. Curricula often blend classroom learning with laboratory work and field studies.

Many petroleum engineers also enter the field with bachelor's degrees in related engineering disciplines, such as chemical engineering, mechanical engineering, or civil engineering. These programs provide a strong grounding in fundamental engineering principles applicable to the oil and gas industry. Graduates with these degrees may need additional specialized training or coursework upon entering the field.

Employers often prefer candidates who have graduated from programs accredited by organizations like ABET (Accreditation Board for Engineering and Technology). Accreditation ensures the program meets rigorous quality standards. Practical experience through internships or co-op programs during undergraduate studies is highly valued and can significantly improve job prospects.

These courses cover foundational engineering principles relevant to petroleum engineering.

This introductory book provides a broad overview of the field for those starting their journey.

Graduate Programs and Research Opportunities

While a bachelor's degree is the typical entry requirement, pursuing a master's or Ph.D. in petroleum engineering can offer significant advantages. Graduate programs allow for deeper specialization in areas like reservoir simulation, enhanced oil recovery, drilling technology, or unconventional resources. Advanced degrees often lead to roles in research, academia, or specialized technical positions within companies.

A master's degree, often requiring one to two years of study, can enhance technical expertise and leadership potential. Some employers prefer candidates with a master's degree, particularly for roles involving complex analysis or project leadership. Some universities offer integrated five-year programs leading to both a bachelor's and master's degree.

A Ph.D. program is primarily focused on research and is essential for careers in academia or advanced research and development within industry or government labs. Doctoral candidates contribute original research to the field, pushing the boundaries of knowledge and technology in petroleum extraction and related energy fields like geothermal energy or carbon sequestration.

These courses delve into more advanced topics often covered in graduate studies.

Licensing and Certification Requirements

Licensure as a Professional Engineer (PE) is not typically required for entry-level petroleum engineering positions. However, obtaining a PE license can be crucial for career advancement, particularly for roles involving significant responsibility, supervising other engineers, or offering services directly to the public.

The requirements for PE licensure vary by state in the US (and by jurisdiction internationally) but generally include several key components. First, candidates need a bachelor's degree in engineering from an ABET-accredited program. Second, they must pass the Fundamentals of Engineering (FE) exam, often taken near graduation, to become an Engineer-in-Training (EIT) or Engineer Intern (EI).

After passing the FE exam, candidates typically need around four years of progressive engineering experience working under the supervision of a licensed PE. Finally, they must pass the Principles and Practice of Engineering (PE) exam specific to petroleum engineering. Many jurisdictions also require continuing education to maintain the license. The Society of Petroleum Engineers (SPE) also offers a voluntary certification program for members who meet specific experience requirements and pass an exam, which can sometimes waive the PE exam requirement depending on the licensing board.

Career Progression in Petroleum Engineering

Entry-Level Roles

Graduates typically begin their careers in entry-level positions, often working under the supervision of experienced engineers. Common starting roles include Field Engineer, Junior Reservoir Engineer, Junior Drilling Engineer, or Junior Production Engineer. These positions provide essential hands-on experience and exposure to the practical aspects of the industry.

Field engineers often work directly at drilling or production sites, overseeing operations, troubleshooting equipment, and collecting data. This provides invaluable practical knowledge of equipment and field procedures. Junior engineers in office-based roles might assist with data analysis, well planning, simulation model updates, or permit applications.

The initial years focus on developing technical competence and understanding company operations. Strong performance, a willingness to learn, and good communication skills are key to progressing. Many companies have structured training programs for new engineers to rotate through different departments or functions.

Mid-Career Specializations

After gaining several years of experience, petroleum engineers often specialize in a particular area. Common specializations include Reservoir Engineering, Drilling Engineering, Production Engineering, and Completions Engineering. Specialization allows engineers to develop deep expertise in a specific domain.

Reservoir engineers focus on understanding and managing underground reservoirs to maximize recovery. Drilling engineers concentrate on the technical aspects of designing and executing well drilling operations. Production engineers manage the well-reservoir interface and optimize hydrocarbon flow to the surface, including artificial lift systems.

Completions engineers design and oversee the final stages of well construction to prepare it for production. Other specializations might include petrophysics (analyzing rock properties), well logging, or focusing on specific types of resources like unconventional shale gas or deepwater reserves. Mid-career often involves taking on more complex projects and mentoring junior engineers.

Senior and Management Positions

With significant experience and demonstrated expertise, petroleum engineers can advance to senior technical roles or move into management. Senior technical positions might involve leading complex projects, serving as an internal expert consultant, or focusing on research and development of new technologies.

Management paths often involve supervising teams of engineers, managing departmental budgets, and making strategic decisions related to asset development or operations. Roles like Reservoir Engineering Manager, Drilling Superintendent, or Production Manager require strong leadership, communication, and business acumen in addition to technical knowledge.

Further advancement can lead to executive positions within oil and gas companies, overseeing entire business units or regions. Some experienced engineers transition into consulting, offering their expertise to various clients, or start their own service companies. Obtaining a PE license or an advanced degree (like an MBA) can facilitate progression into higher management levels.

Transition Opportunities to Adjacent Industries

The skills developed by petroleum engineers are transferable to other industries, particularly those involving subsurface resources or fluid flow. The growing fields of geothermal energy extraction and carbon capture, utilization, and storage (CCUS) heavily rely on expertise in reservoir analysis, drilling, and fluid injection – core competencies of petroleum engineers.

Engineers may also find opportunities in environmental consulting, particularly related to groundwater management or remediation of contaminated sites. Their understanding of subsurface geology and fluid movement is valuable in these areas. Some transition into roles in finance or investment banking, focusing on the energy sector, leveraging their technical knowledge to evaluate projects and companies.

The strong analytical, problem-solving, and project management skills honed in petroleum engineering are applicable across various engineering and technical fields. With additional training or education, transitions into areas like mining engineering, civil engineering (especially geotechnics), or even data science focused on energy applications are possible.

Tools and Technologies in Petroleum Engineering

Simulation Software

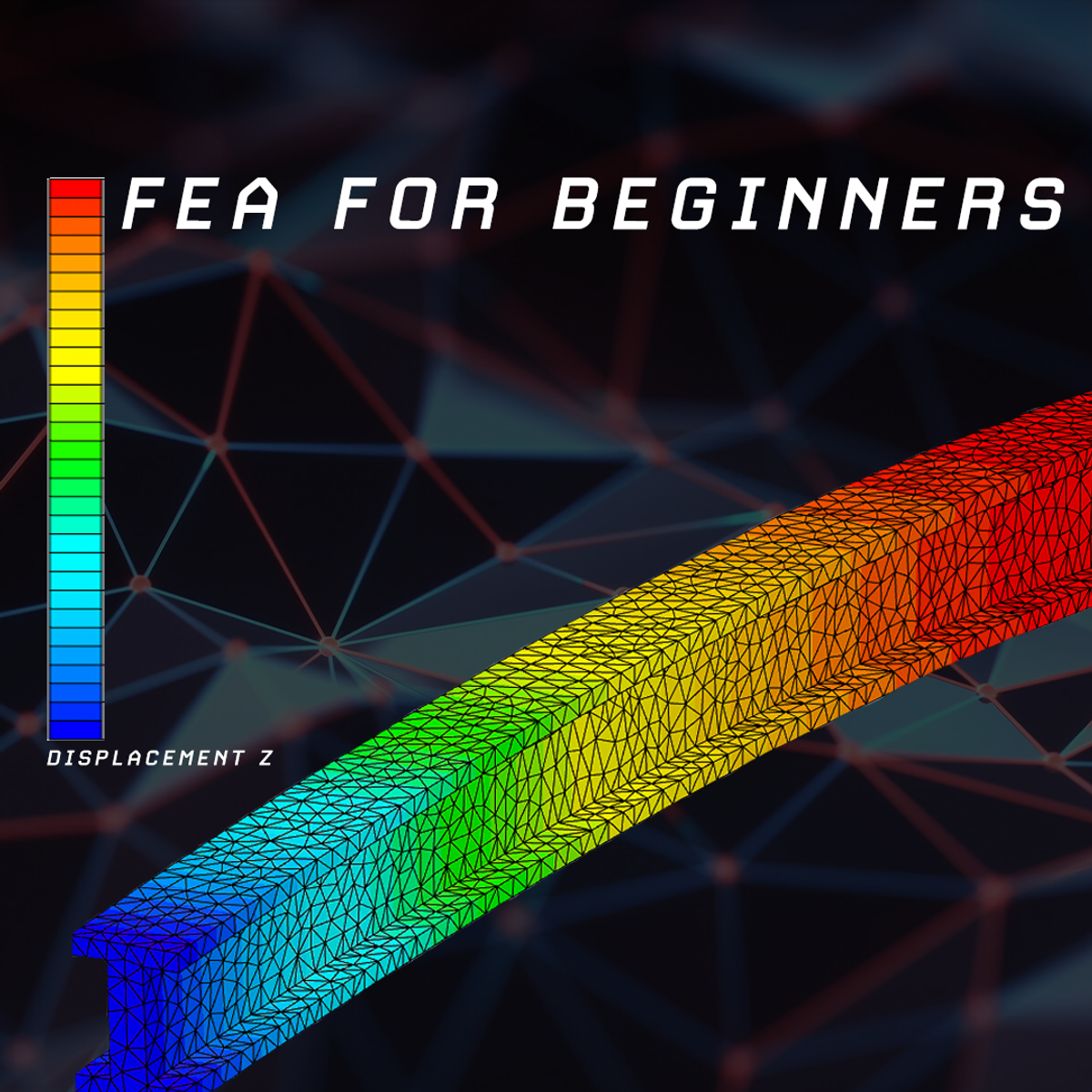

Computer simulation is an indispensable tool in modern petroleum engineering. Reservoir simulation software allows engineers to build detailed 3D models of underground reservoirs based on geological and geophysical data. These models simulate the complex flow of oil, gas, and water through porous rock over time.

Engineers use these simulations to predict reservoir performance under different production scenarios, test the effectiveness of various well placements or EOR techniques, and forecast ultimate resource recovery. Software packages like Petrel, Eclipse (from Schlumberger), or Aspen HYSYS (often used for process simulation) are industry standards. Proficiency in using these tools is a highly valued skill.

Process simulation software is also used to model and optimize surface facilities, such as separation plants, pipelines, and processing units. These tools help engineers design efficient systems, troubleshoot operational problems, and ensure safety and environmental compliance for the entire production chain.

Developing proficiency in industry-standard software is crucial. These courses provide hands-on training with popular simulation tools.

Drilling Automation Systems

Automation is increasingly transforming drilling operations, enhancing efficiency, safety, and precision. Automated drilling systems can control parameters like weight on bit, rotational speed, and mud circulation more consistently than manual methods. This leads to faster drilling rates, longer equipment life, and reduced risk of human error.

Advanced systems incorporate real-time data from downhole sensors (Measurement While Drilling - MWD, and Logging While Drilling - LWD) to make automatic adjustments to the drilling process. This allows for more accurate wellbore placement, particularly in complex directional or horizontal drilling scenarios. Robotics are also being introduced for tasks like pipe handling on the rig floor, further reducing human exposure to hazardous environments.

Petroleum engineers involved in drilling work closely with these automation technologies. They are responsible for planning drilling programs that leverage automation capabilities, monitoring system performance, and interpreting the vast amounts of data generated to optimize operations further.

Understanding the mechanics and control systems involved is important.

Data Analytics in Resource Estimation

The oil and gas industry generates massive amounts of data from seismic surveys, well logs, production monitoring, and sensor networks. Petroleum engineers increasingly use data analytics techniques to extract valuable insights from this information, leading to better resource estimation and decision-making.

Statistical analysis and machine learning algorithms can help identify complex patterns in geological and production data that might be missed by traditional methods. This can lead to more accurate predictions of reservoir size and characteristics, better identification of sweet spots for drilling, and improved forecasting of well performance.

Data analytics is also used to optimize drilling and production operations in real time. By analyzing sensor data from equipment, engineers can predict potential failures, optimize maintenance schedules (predictive maintenance), and fine-tune operating parameters for maximum efficiency and safety.

Emerging AI Applications

Artificial intelligence (AI) is beginning to find applications across the petroleum engineering workflow. Machine learning models are being developed to accelerate tasks like seismic interpretation, reservoir characterization, and production forecasting, often performing these tasks faster and sometimes more accurately than conventional approaches.

AI can assist in optimizing complex operational decisions, such as real-time drilling parameter adjustments or scheduling interventions for production wells. AI-powered systems can analyze vast datasets to identify subtle correlations and recommend optimal strategies that might not be apparent to human operators.

While still an emerging area, AI holds significant potential to further enhance efficiency, reduce costs, and improve safety in the oil and gas industry. Petroleum engineers who understand AI principles and can work alongside these technologies will be increasingly valuable in the future.

Petroleum Engineer in the Energy Transition

Role in Decarbonization Efforts

While often associated with fossil fuels, petroleum engineers possess skills crucial for the global transition to a lower-carbon energy system. Their expertise in subsurface engineering – understanding fluid flow through porous rock – is directly applicable to Carbon Capture, Utilization, and Storage (CCUS) projects. CCUS involves capturing CO2 emissions from industrial sources and injecting them deep underground for permanent storage, a key strategy for decarbonization.

Petroleum engineers design and manage the injection wells, monitor the underground storage sites to ensure containment, and model the long-term behavior of the stored CO2. Their knowledge of reservoir mechanics, geomechanics, and well integrity is vital for the safe and effective deployment of CCUS technology.

Furthermore, optimizing the efficiency of existing oil and gas operations helps reduce their carbon intensity. Engineers work to minimize methane leaks (a potent greenhouse gas) from pipelines and facilities, improve energy efficiency in extraction and processing, and sometimes integrate renewable energy sources to power field operations.

Hydrocarbon vs. Renewable Energy Dynamics

The global energy landscape is shifting, with renewable energy sources like solar and wind experiencing rapid growth. However, the transition away from hydrocarbons is complex and expected to take decades. According to organizations like the International Energy Agency (IEA), oil and gas will likely remain significant parts of the energy mix for the foreseeable future, particularly for sectors like heavy industry, aviation, and petrochemicals.

Petroleum engineers navigate this dynamic environment. They continue to work on extracting existing resources efficiently and safely, while also applying their skills to new energy frontiers. Their expertise in subsurface management is valuable for geothermal energy projects, which tap into the Earth's heat, and potentially for large-scale energy storage solutions underground.

The skills required for managing large, complex energy projects, assessing geological risks, and handling fluid flow under pressure are transferable. While the specific resource may change, the underlying engineering principles often remain relevant, positioning petroleum engineers to contribute across the evolving energy spectrum.

Carbon Capture and Storage Innovations

Innovation in Carbon Capture, Utilization, and Storage (CCUS) is a critical area where petroleum engineers contribute significantly. This involves developing more efficient and cost-effective methods for capturing CO2 from sources like power plants or industrial facilities. Research focuses on new solvents, membranes, or sorbents for CO2 separation.

On the storage side, engineers work on identifying suitable geological formations (like depleted oil and gas reservoirs or deep saline aquifers), assessing their storage capacity and integrity, and designing optimal injection strategies. Innovations include advanced monitoring techniques using fiber optics or seismic methods to track the underground CO2 plume and ensure long-term security.

Utilization (the 'U' in CCUS) involves finding ways to use captured CO2, for example, in enhanced oil recovery (where CO2 is injected to produce more oil) or as a feedstock for creating chemicals, fuels, or building materials. Petroleum engineers collaborate with chemists and material scientists to develop and scale up these utilization pathways, potentially creating value from captured carbon.

This course offers insights into the broader context of sustainability efforts.

Market Volatility and Geopolitical Factors

The oil and gas industry is inherently subject to market volatility, with prices fluctuating based on global supply and demand dynamics, economic growth, and geopolitical events. These fluctuations directly impact investment decisions, project viability, and employment levels within the sector. Petroleum engineers must often navigate cycles of boom and bust.

Geopolitical factors play a significant role. Conflicts, political instability in major producing regions, trade disputes, and government policies (like sanctions or production quotas set by groups like OPEC+) can disrupt supply chains and influence prices. Engineers working on international projects must be aware of these risks.

The ongoing energy transition adds another layer of complexity. Policy decisions aimed at reducing carbon emissions, promoting renewable energy, and phasing out fossil fuel subsidies impact long-term demand forecasts and investment strategies. Petroleum engineers need to stay informed about these evolving market and political landscapes. Reliable data and analysis from sources like the U.S. Energy Information Administration (EIA) and the IEA's Oil Market Report help navigate this uncertainty.

Online Learning and Skill Development

Core Technical Skills Achievable Remotely

Online learning offers powerful avenues for acquiring foundational knowledge and technical skills relevant to petroleum engineering. Many core concepts, such as thermodynamics, fluid mechanics, geology, and engineering mathematics, can be effectively learned through online courses offered by universities and specialized platforms. These courses often include video lectures, readings, simulations, and assessments.

Furthermore, proficiency in essential software tools used in the industry, like reservoir simulation packages (e.g., Petrel, Eclipse) or process simulators (e.g., Aspen HYSYS), can often be developed through online training modules and tutorials. Data analysis and programming skills (like Python), which are increasingly important, are also readily learnable online.

Platforms like OpenCourser aggregate thousands of courses, allowing learners to browse engineering topics, compare options, and find resources covering specific technical areas. This accessibility makes it easier for individuals to build a strong theoretical base or upskill in specific software or analytical techniques from anywhere.

These online courses cover fundamental and applied topics accessible remotely.

Project-Based Learning for Portfolio Building

While online courses provide knowledge, applying that knowledge through projects is crucial for demonstrating competence. Many online platforms incorporate project-based assignments where learners tackle realistic engineering problems. This might involve analyzing well data, designing a simple production system using simulation software, or developing a basic reservoir model.

Completing such projects allows learners to solidify their understanding and build a portfolio of work that can be showcased to potential employers. This is particularly valuable for career changers or those supplementing formal education, as it provides tangible evidence of practical skills beyond theoretical knowledge.

Individuals can also undertake self-directed projects, perhaps using publicly available datasets or open-source software, to explore areas of interest. Documenting these projects clearly, outlining the problem, methodology, and results, creates compelling portfolio pieces demonstrating initiative and problem-solving ability.

These courses include practical components or focus on skills applicable to project work.

Bridging Knowledge Gaps Alongside Formal Education

Online courses are excellent resources for students currently enrolled in formal engineering programs or professionals looking to pivot into petroleum engineering. They can be used to reinforce concepts learned in class, explore topics not covered in the curriculum, or get ahead in specific areas like software proficiency or data analysis.

For those transitioning from related fields like chemical or mechanical engineering, online courses offer a structured way to learn petroleum-specific topics such as reservoir engineering or drilling techniques. This targeted learning can help bridge knowledge gaps and make candidates more competitive for petroleum engineering roles.

Working professionals can use online learning to stay updated on the latest technologies, industry trends, or regulatory changes without needing extended time off work. Platforms like OpenCourser allow users to save courses to a list, making it easy to plan and track their continuous professional development.

These courses cover specific petroleum industry processes and products.

This book offers a comprehensive overview of refining processes.

Limitations of Online Training for Fieldwork

It is crucial to recognize the limitations of online learning, particularly concerning the hands-on aspects of petroleum engineering. While theoretical knowledge and software skills can be acquired remotely, the practical experience gained from fieldwork cannot be fully replicated online.

Working on a drilling rig, participating in wellsite operations, handling physical equipment, and experiencing the real-world conditions of an operational site provide invaluable learning that virtual environments cannot capture. Safety procedures, teamwork dynamics in the field, and troubleshooting physical systems often require direct, in-person experience.

Therefore, while online learning is a powerful tool for building foundational knowledge and specific technical skills, it should ideally be complemented by practical experience through internships, co-op programs, or entry-level field positions. Employers highly value candidates who combine strong theoretical understanding with hands-on capabilities.

Ethical and Environmental Considerations

Climate Impact of Extraction Processes

The extraction and combustion of oil and gas are significant contributors to global greenhouse gas emissions, primarily carbon dioxide (CO2) and methane (CH4). Petroleum engineers operate within an industry facing increasing scrutiny regarding its climate impact. Ethical considerations require engineers to understand and work towards minimizing these impacts.

Direct emissions occur during extraction, processing, and transportation, including methane leaks from equipment and pipelines, and CO2 released from flaring (burning excess gas) or energy used in operations. Indirect emissions result from the end-use combustion of the produced fuels. Engineers play a role in measuring, reporting, and reducing these emissions through better design, maintenance, and operational practices.

Developing and implementing technologies to mitigate climate impact, such as methane detection and repair programs, electrifying operations with renewable energy, and advancing CCUS, are increasingly part of the engineer's responsibilities. Balancing the world's energy needs with the imperative to address climate change is a central ethical challenge for the profession.

Community Engagement in Resource-Rich Regions

Oil and gas operations often take place in or near communities, and responsible development requires meaningful engagement with local stakeholders. Petroleum engineers may be involved in communicating project plans, addressing community concerns, and ensuring operations minimize local disruptions related to noise, traffic, or land use.

Ethical practice involves respecting local cultures, land rights (particularly Indigenous rights), and contributing positively to the local economy through employment or infrastructure development where appropriate. Transparency about potential risks and environmental impacts, along with robust emergency response planning, is crucial for building trust.

Failure to engage effectively can lead to social conflict, project delays, and reputational damage. Engineers need cultural sensitivity and strong communication skills to navigate these complex social dynamics and ensure projects proceed with community support or acceptance.

Regulatory Compliance Frameworks

The oil and gas industry operates under extensive regulatory frameworks governing environmental protection, worker safety, resource conservation, and financial reporting. Petroleum engineers must have a thorough understanding of the applicable laws and regulations in the jurisdictions where they work and ensure their designs and operations comply.

This includes regulations related to air and water quality, waste disposal, well integrity standards, offshore safety protocols, and emissions reporting. Compliance often involves detailed documentation, obtaining permits, undergoing inspections, and implementing specific technologies or procedures mandated by regulators.

Staying abreast of evolving regulations, which increasingly incorporate climate change considerations, is essential. Non-compliance can result in significant fines, legal liabilities, operational shutdowns, and damage to the company's reputation. Ethical engineering practice demands strict adherence to legal and regulatory requirements.

This book touches upon the legal aspects pertinent to the industry.

Industry Sustainability Initiatives

In response to environmental pressures and societal expectations, the oil and gas industry is undertaking various sustainability initiatives. Many companies are setting targets to reduce their greenhouse gas emissions, improve energy efficiency, and minimize environmental footprints. Petroleum engineers are often key players in implementing these initiatives.

Examples include investing in methane leak detection and repair (LDAR) programs, reducing flaring, using recycled water in operations, developing less invasive drilling techniques, and restoring sites after operations cease. Some companies are also investing in renewable energy projects or CCUS as part of their long-term strategy.

Industry associations like the Ipieca (formerly the International Petroleum Industry Environmental Conservation Association) and SPE promote best practices and collaborative efforts on sustainability. Engineers contribute by developing innovative solutions, sharing knowledge, and integrating sustainability considerations into daily decision-making, aligning operations with broader goals like the UN Sustainable Development Goals.

Global Opportunities for Petroleum Engineers

Major Oil-Producing Regions and Employers

Petroleum engineering is a global profession, with opportunities concentrated in regions rich in oil and gas reserves. Major hubs include North America (USA, Canada), the Middle East (Saudi Arabia, UAE, Qatar, Kuwait, Iraq), Russia, Latin America (Brazil, Mexico, Venezuela), Africa (Nigeria, Angola, Algeria), and parts of Asia-Pacific (China, Australia, Malaysia).

Key employers range from large multinational corporations (often called "supermajors" like ExxonMobil, Shell, BP, Chevron, TotalEnergies) and national oil companies (NOCs like Saudi Aramco, Petrobras, Gazprom) to smaller independent exploration and production companies and numerous oilfield service companies (like Schlumberger, Halliburton, Baker Hughes) that provide specialized technical services and equipment.

Opportunities also exist with consulting firms, government regulatory agencies, financial institutions involved in energy investments, and research institutions or universities. The geographic distribution of jobs can shift based on exploration success, geopolitical stability, and oil price fluctuations.

Expatriate Assignments and Cultural Challenges

Given the global nature of the industry, many petroleum engineers undertake expatriate assignments, working outside their home country for extended periods. These assignments can offer unique professional experiences, exposure to different technologies and operating environments, and often come with attractive compensation packages.

However, working abroad involves navigating cultural differences, language barriers, and adapting to new living and working environments. Engineers may work in remote locations with limited amenities or in regions with different safety standards or political climates. Success requires adaptability, cultural sensitivity, and resilience.

Families accompanying engineers on expatriate assignments face their own adjustments related to schooling, healthcare, and social integration. Companies often provide support services, such as relocation assistance, cross-cultural training, and housing allowances, to help ease the transition for employees and their families.

Salary Benchmarks by Experience Level

Petroleum engineering is consistently ranked among the highest-paying engineering disciplines. Salaries vary significantly based on experience, location, company size, specialization, and prevailing market conditions (especially oil prices).

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for petroleum engineers in the United States was $135,690 in May 2023. Entry-level engineers typically earn less, while experienced senior engineers, specialists, or managers can earn substantially more, often exceeding $200,000 annually. Data suggests that salaries can vary widely by state and metropolitan area, not always aligning directly with production volume.

International salaries also vary greatly. Assignments in challenging locations or high-demand regions often command premium pay and comprehensive benefits packages, including housing, transportation, and international school allowances for families. Bonuses tied to project success or company performance are also common.

For the latest salary data, consult resources like the U.S. Bureau of Labor Statistics Occupational Outlook Handbook.

Impact of Energy Policies on Job Markets

Government energy policies significantly influence the job market for petroleum engineers. Policies related to exploration leasing, environmental regulations, taxation, subsidies for fossil fuels or renewables, and climate change targets all shape investment decisions and operational activities in the oil and gas sector.

For example, stricter environmental regulations might increase demand for engineers specializing in compliance or emissions reduction technologies. Policies promoting domestic energy production could boost exploration and drilling activity. Conversely, policies accelerating the transition to renewable energy might temper long-term demand for traditional petroleum engineers while increasing opportunities in related fields like geothermal or CCUS.

International agreements and geopolitical dynamics also play a role. Trade policies, sanctions, and global climate agreements can alter energy flows and investment climates, impacting job opportunities in different regions. Staying informed about evolving energy policies is crucial for navigating career prospects in this field.

Frequently Asked Questions

Is petroleum engineering becoming obsolete?

While the global energy system is transitioning towards lower-carbon sources, petroleum engineering is not becoming obsolete in the near term. Oil and natural gas are projected to remain significant components of the global energy mix for decades, requiring engineers to manage existing production and develop remaining resources efficiently and responsibly.

Furthermore, the core skills of petroleum engineers – subsurface analysis, fluid mechanics, drilling technology, project management – are transferable and increasingly in demand for energy transition activities. These include geothermal energy extraction, carbon capture and storage (CCS), and potentially hydrogen storage underground.

The role is evolving, with a greater emphasis on environmental performance, digital technology, and contributing to lower-carbon energy solutions. While the long-term trajectory might see a shift in focus, the demand for the expertise held by petroleum engineers is expected to persist through the energy transition. The BLS projects slower-than-average growth (2% from 2023-2033), but still anticipates around 1,200 openings per year, mostly due to retirements and transfers.

Can I transition to renewables later?

Yes, transitioning from petroleum engineering to the renewable energy sector is feasible, particularly into areas that leverage similar skill sets. Geothermal energy development heavily relies on expertise in drilling, reservoir characterization, and fluid flow, making it a natural transition path.

Skills in managing large-scale projects, assessing geological risks, and understanding subsurface environments are also valuable for offshore wind farm development (foundation design, site assessment) and large-scale energy storage projects, including underground hydrogen storage or compressed air energy storage.

The rapidly growing field of Carbon Capture, Utilization, and Storage (CCUS) directly utilizes the core competencies of petroleum engineers for CO2 injection, reservoir management, and long-term monitoring. While some additional training or upskilling might be necessary depending on the specific role, the foundational knowledge from petroleum engineering provides a strong basis for contributing to various parts of the renewable and low-carbon energy sector.

Fieldwork vs office-based roles?

Petroleum engineering offers a mix of fieldwork and office-based roles, and the balance often changes throughout a career. Entry-level positions, particularly for field engineers or drilling supervisors, frequently involve significant time spent at drilling rigs or production sites, which can be onshore or offshore, sometimes in remote locations.

These field roles provide invaluable hands-on experience but often require working long shifts (e.g., 12 hours), being away from home for extended periods (e.g., weeks on an offshore rotation), and adapting to challenging physical environments. Office-based roles typically involve reservoir modeling, well planning, data analysis, project management, and design work.

Many engineers transition from predominantly field-based roles to more office-centric positions as they gain experience and seniority. However, even office-based engineers often make periodic visits to field sites. Roles in consulting, research, or management are generally more office-based but may still require travel.

Typical career lifespan in the industry?

The career lifespan for a petroleum engineer can be long and rewarding, often spanning several decades until retirement. The industry values experience, and engineers typically progress through various technical and managerial roles over their careers. Continuous learning and adaptation are key, especially given the industry's cyclical nature and technological advancements.

While concerns about the long-term future of fossil fuels exist, the skills acquired are transferable, and the transition itself creates new opportunities. Many engineers work well into their 50s and 60s, often moving into senior advisory, consulting, or management roles later in their careers.

The industry has faced periods of downturn leading to layoffs, which can impact career longevity for some. However, the fundamental need for energy and the specialized skills of petroleum engineers suggest continued demand for the profession, albeit with an evolving focus, for the foreseeable future.

Gender diversity statistics?

Historically, petroleum engineering, like many engineering fields, has been male-dominated. While progress has been made, women remain underrepresented in the industry. Statistics vary by region and company, but women often constitute a minority of petroleum engineering students and professionals.

Organizations like the Society of Petroleum Engineers (SPE) and the Society of Women Engineers (SWE) actively work to promote diversity and inclusion within the field. Initiatives include mentoring programs, networking events, and scholarships aimed at encouraging more women and individuals from diverse backgrounds to pursue careers in engineering.

Many major companies have also implemented diversity and inclusion programs to attract, retain, and promote female engineers. While challenges remain, there is a growing recognition of the benefits of a diverse workforce, and efforts are ongoing to improve representation at all levels of the industry.

Impact of automation on job security?

Automation and digitalization are transforming the oil and gas industry, leading to increased efficiency and safety, but also raising questions about job security. Automation can perform certain tasks previously done by humans, particularly routine monitoring, data collection, and some operational controls.

However, automation is more likely to augment the role of petroleum engineers rather than replace them entirely. Engineers will increasingly work alongside automated systems, using AI and data analytics to interpret complex data, make higher-level decisions, and focus on problem-solving and innovation. Tasks requiring critical thinking, creativity, complex judgment, and human interaction are less susceptible to automation.

While the nature of the job may change, requiring new skills in data science and digital tools, the need for engineers to design, oversee, and interpret the results from these systems remains. Some estimates suggest only a fraction of current tasks are fully automatable, with the larger impact being increased productivity and a shift in required skill sets.

Helpful Resources

To further explore the field of petroleum engineering, consider these resources:

- Society of Petroleum Engineers (SPE): The primary international professional society for petroleum engineers, offering technical resources, publications, conferences, training, and networking opportunities.

- U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook: Provides detailed information on job duties, education requirements, salary data, and job outlook for petroleum engineers in the United States.

- U.S. Energy Information Administration (EIA): Offers extensive data, analysis, and forecasts on energy production, consumption, and markets, including petroleum and natural gas.

- International Energy Agency (IEA): Provides global energy statistics, market analysis, policy recommendations, and forecasts, including regular reports on the oil market.

- OpenCourser - Engineering Category: Browse a wide range of online courses related to petroleum engineering and other engineering disciplines.

- ABET (Accreditation Board for Engineering and Technology): Find accredited engineering programs in the United States and internationally.

Embarking on a career as a petroleum engineer requires a strong technical foundation, adaptability, and a commitment to continuous learning. While the energy landscape is evolving, the skills and knowledge of petroleum engineers remain critical for meeting global energy demands and contributing to a sustainable energy future. Whether managing traditional resources or pioneering new energy technologies, this challenging field offers significant opportunities for those willing to engage with its complexities.