Production Engineer

Production Engineering: A Comprehensive Career Guide

Production engineering is a specialized branch of engineering focused on the efficiency and effectiveness of manufacturing and production processes. At its core, a production engineer works to design, optimize, and manage the systems that create goods, ensuring products are made reliably, cost-effectively, and to the required quality standards. They act as a crucial bridge, translating product designs into tangible realities on the factory floor or production line.

Working as a production engineer can be highly engaging. You might find excitement in troubleshooting complex production bottlenecks, implementing cutting-edge automation technologies, or seeing a process you designed significantly reduce waste and improve output. The role often involves a blend of hands-on problem-solving, data analysis, and collaboration across different teams, making it a dynamic field for those who enjoy tackling practical challenges within industrial environments.

Understanding the Role of a Production Engineer

Defining Production Engineering and its Goals

Production engineering centers on the 'how' of making things. Its primary objective is to streamline and improve manufacturing operations. This involves analyzing existing production lines, identifying areas for improvement, and implementing changes to enhance productivity, reduce costs, and maintain or improve product quality. Production engineers work across various stages, from initial process design to ongoing operational management.

The field draws heavily from principles found in industrial engineering, mechanical engineering, and materials science. Production engineers apply scientific and mathematical principles to optimize complex systems involving people, materials, information, equipment, and energy. Their ultimate goal is to create sustainable, safe, and economically viable production systems.

Consider a factory making smartphones. A production engineer might analyze the assembly line, timing each step. If installing the screen takes too long and creates a backlog, the engineer might redesign the workstation, introduce a new tool, or suggest a different sequence of assembly to speed up that specific step, thereby improving the entire line's output.

A Brief History of the Field

The roots of production engineering can be traced back to the Industrial Revolution, where the focus shifted towards mass production and factory systems. Early pioneers like Eli Whitney (interchangeable parts) and Henry Ford (assembly line) laid the groundwork by demonstrating the power of standardized processes and specialized labor.

The field evolved significantly throughout the 20th century, influenced by advancements in operations research during World War II, the rise of quality management philosophies from Japan (like Toyota Production System/Lean Manufacturing), and the increasing use of computers in design and manufacturing (CAD/CAM). The principles developed were initially applied in discrete manufacturing (like cars) but soon spread to process industries (chemicals, food) as well.

Today, production engineering incorporates concepts like automation, robotics, data analytics, and sustainability, reflecting the complexities of modern global manufacturing. It continues to adapt to new challenges, such as Industry 4.0 and the need for resilient supply chains.

Understanding the historical context helps appreciate the core principles that still drive production efficiency today.

Where Production Engineers Work

Production engineers are vital in nearly any industry that involves making physical products or processing materials. The automotive and aerospace industries are major employers, relying on engineers to optimize complex assembly lines and ensure stringent quality and safety standards. Electronics manufacturing, from semiconductors to consumer gadgets, heavily depends on production engineers to manage intricate processes and rapid product cycles.

The energy sector, particularly oil and gas, employs production engineers (often with a chemical or petroleum engineering background) to manage extraction, processing, and transportation operations efficiently and safely. Pharmaceuticals and medical device manufacturing require meticulous process control and validation, areas where production engineers excel. Consumer goods, food and beverage processing, and chemical production also offer numerous opportunities.

Essentially, anywhere goods are produced on a significant scale, production engineers play a role in making it happen effectively. Their skills are transferable across many sectors, offering diverse career possibilities.

For those interested in the energy sector, specific knowledge of hydrocarbon processes is essential. Online courses can provide foundational understanding in areas like OCTG or reservoir engineering.

These books offer in-depth knowledge for those specializing in petroleum production.

Economic Significance and Global Demand

Production engineering is fundamental to economic productivity and competitiveness. Efficient manufacturing processes lower production costs, making goods more affordable and enabling companies to compete globally. By improving quality and reliability, production engineers enhance product value and customer satisfaction, further boosting economic activity.

The demand for production engineers tends to follow global manufacturing trends. While automation may change the nature of some tasks, the need for engineers to design, implement, manage, and optimize these automated systems remains strong. Regions with significant manufacturing bases, such as parts of Asia, North America, and Europe, typically show consistent demand.

Furthermore, challenges like supply chain resilience, the push for sustainable manufacturing, and the adoption of Industry 4.0 technologies are creating new opportunities and demands for skilled production engineers. Their ability to integrate technology, manage complex systems, and drive efficiency makes them valuable assets in the modern economy.

Key Responsibilities of a Production Engineer

Optimizing Manufacturing Processes

A core responsibility of a production engineer is the continuous improvement of manufacturing processes. This involves detailed analysis of current operations to identify bottlenecks, inefficiencies, and areas of waste. They use tools like time studies, process mapping (value stream mapping), and simulation software to understand workflow dynamics.

Based on this analysis, engineers propose and implement solutions. This might involve redesigning factory layouts, introducing automation, optimizing machine settings, changing work procedures, or improving material flow. The goal is always to increase throughput, reduce cycle times, minimize downtime, and make the process more robust and repeatable.

Techniques like Lean Manufacturing are central to this effort, focusing on eliminating waste in all its forms (e.g., overproduction, waiting time, unnecessary transport, defects). Production engineers often lead lean initiatives within their organizations.

This course provides practical insights into lean techniques valuable for optimizing production.

This topic explores the broader systems involved in production.

Ensuring Quality Control and Cost-Efficiency

Maintaining product quality while managing costs is another critical function. Production engineers help establish quality standards and implement systems to monitor and control processes, ensuring products consistently meet specifications. This often involves statistical process control (SPC), quality inspections, and root cause analysis of defects.

They work to prevent defects from occurring in the first place by improving process capability and stability. When issues arise, they lead troubleshooting efforts to identify the cause and implement corrective actions. This focus on quality directly impacts customer satisfaction and reduces the costs associated with rework, scrap, and warranty claims.

Simultaneously, production engineers are constantly seeking ways to reduce production costs without compromising quality or safety. This includes optimizing material usage, reducing energy consumption, improving labor productivity, and minimizing equipment downtime. They perform cost-benefit analyses for proposed process changes to ensure investments yield positive returns.

Collaborating Across Departments

Production engineers rarely work in isolation. Effective collaboration with other departments is essential for success. They work closely with design engineers to provide feedback on manufacturability (Design for Manufacturing - DFM), ensuring new product designs can be produced efficiently and reliably.

Interaction with operations and maintenance teams is constant. Production engineers help implement new processes, train operators, troubleshoot issues on the floor, and work with maintenance to schedule upkeep and minimize equipment failures. They also liaise with supply chain and procurement teams regarding raw materials, components, and logistics.

Strong communication and teamwork skills are therefore crucial. Production engineers must be able to articulate technical concepts to diverse audiences, build consensus, and manage projects involving multiple stakeholders.

This book explores manufacturing processes from a design perspective, highlighting the interface where production engineers collaborate.

Maintaining Safety and Sustainability Standards

Ensuring a safe working environment is paramount. Production engineers are responsible for identifying potential hazards in production processes and implementing measures to mitigate risks. This includes designing safe workstations, ensuring proper machine guarding, implementing lockout/tagout procedures, and promoting a culture of safety awareness.

They must be knowledgeable about relevant occupational health and safety regulations (like OSHA in the US) and ensure processes comply with these standards. This involves regular safety audits, risk assessments, and incident investigations.

Sustainability is an increasingly important aspect of the role. Production engineers look for ways to reduce the environmental footprint of manufacturing operations. This includes minimizing waste generation, reducing energy and water consumption, selecting environmentally friendly materials, and designing processes that support recycling or reuse initiatives, aligning with principles of the circular economy.

Formal Education Pathways

Relevant Undergraduate Degrees

A bachelor's degree in engineering is typically the minimum requirement to enter the field. The most common degrees are Industrial Engineering, Mechanical Engineering, and Manufacturing Engineering. These programs provide a strong foundation in mathematics, physics, materials science, thermodynamics, and engineering design.

Industrial engineering programs often emphasize optimization, operations research, statistics, quality control, and supply chain management, which are directly applicable to production environments. Mechanical engineering programs provide depth in machine design, mechanics, and thermal systems, valuable for understanding production equipment. Manufacturing engineering programs specifically focus on production processes, automation, and manufacturing systems.

Depending on the industry, degrees in Chemical Engineering (for process industries like chemicals or oil and gas), Electrical Engineering (for electronics manufacturing or automation), or Materials Science and Engineering might also be relevant entry points. Core coursework across these programs usually includes calculus, differential equations, physics, chemistry, statics, dynamics, and computer programming basics.

Explore relevant programs within the broader field of Engineering or specifically Industrial Engineering on OpenCourser.

Graduate Programs for Specialization

While a bachelor's degree is sufficient for many entry-level roles, a master's degree can provide specialized knowledge and potentially accelerate career advancement. Master's programs allow students to focus on specific areas like Advanced Manufacturing, Robotics and Automation, Operations Management, Quality Engineering, or Supply Chain Management.

A Master of Science (MS) degree is typically research-oriented, culminating in a thesis, while a Master of Engineering (MEng) degree is often course-based and focused on professional practice. Some engineers pursue a Master of Business Administration (MBA) after gaining industry experience, particularly if they aim for management roles combining technical and business leadership.

Pursuing graduate studies can deepen technical expertise, enhance analytical skills, and open doors to roles requiring specialized knowledge or leadership responsibilities. It's often beneficial after gaining some practical experience to better identify areas of interest.

Importance of Accreditation

When choosing an engineering program, particularly at the undergraduate level, accreditation is an important factor to consider. In the United States, ABET (Accreditation Board for Engineering and Technology) is the primary accrediting body for engineering programs. Graduation from an ABET-accredited program is often a prerequisite for professional licensure (like becoming a Professional Engineer - PE) and may be preferred by employers.

Accreditation ensures that the program meets certain quality standards regarding curriculum, faculty qualifications, facilities, and student outcomes. While not always mandatory for employment, choosing an accredited program provides assurance of a rigorous and comprehensive education recognized within the profession.

You can verify program accreditation through organizations like ABET. Similar accrediting bodies exist in other countries, ensuring global standards in engineering education.

Research Opportunities in Doctoral Programs

For those interested in pursuing research, innovation, or an academic career, a Doctor of Philosophy (PhD) in Industrial Engineering, Mechanical Engineering, or a related field is the typical path. PhD programs involve advanced coursework and significant independent research culminating in a dissertation.

Research areas in production engineering are diverse and evolving. Current topics often include smart manufacturing and Industry 4.0, development of advanced materials and manufacturing processes (like additive manufacturing), sustainable and green manufacturing, supply chain optimization and resilience, human-robot collaboration, and the application of AI and machine learning to production systems.

A PhD prepares individuals for roles in university teaching and research, advanced research and development positions in industry, or high-level consulting. It requires a strong passion for inquiry and the ability to contribute original knowledge to the field.

This comprehensive textbook covers many foundational topics in manufacturing, relevant for both undergraduate and graduate studies.

Online and Self-Directed Learning

Acquiring Core Technical Skills Online

Online learning platforms offer accessible ways to acquire or enhance technical skills crucial for production engineers. Courses are available covering foundational topics like statistics, quality control methods (Six Sigma, SPC), and principles of lean manufacturing. More specialized skills, such as proficiency in CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) software, process simulation tools, and data analysis techniques using software like Excel or Python, can also be learned online.

These platforms allow learners to study at their own pace and often focus on practical application. For career changers or those needing to upskill, online courses provide a flexible route to gain specific competencies demanded by employers without committing to a full degree program initially. Many courses offer certificates upon completion, which can be highlighted on resumes.

OpenCourser aggregates thousands of courses, making it easy to find resources tailored to specific skill needs in production and manufacturing engineering. You can browse categories like Manufacturing or search for specific tools.

The Value of Project-Based Learning

Simply completing online courses is often not enough; applying the learned concepts through projects is crucial for solidifying understanding and demonstrating capability. Many online courses incorporate projects, but learners can also undertake independent projects relevant to production engineering.

Examples could include designing a small assembly fixture using CAD software, analyzing publicly available manufacturing data to identify trends, developing a simulation model for a simple production line, or applying lean principles to optimize a process in a personal or volunteer setting. Documenting these projects in a portfolio can be highly beneficial during job searches.

Project-based learning bridges the gap between theoretical knowledge and practical application, showcasing problem-solving skills and initiative to potential employers. It's an excellent way for self-directed learners to build tangible evidence of their abilities.

These courses include practical elements or focus on specific tools often used in projects.

Certifications Alongside or Instead of Degrees

While a degree is the traditional route, professional certifications can play a significant role, especially for career pivots or specialization. Certifications like Lean Six Sigma (Green Belt, Black Belt), Certified Quality Engineer (CQE), or Project Management Professional (PMP) demonstrate proficiency in specific methodologies highly valued in production environments.

For individuals transitioning from related technical fields or roles like technician or supervisor, certifications combined with relevant experience can sometimes open doors to engineering positions, although a full engineering degree often remains preferred for broader roles and advancement. Certifications are also valuable for degree holders seeking to specialize or validate specific skills.

The decision between pursuing certifications versus a degree depends on individual career goals, existing background, and industry requirements. Often, a combination of formal education, practical experience, and targeted certifications provides the strongest profile.

Using MOOCs to Supplement Formal Education

Massive Open Online Courses (MOOCs) and other online learning resources are excellent tools for supplementing formal university education or for continuous professional development. University students can use online courses to deepen their understanding of complex topics, learn specific software tools not covered extensively in their curriculum, or explore emerging areas.

Working professionals can leverage online learning to stay current with technological advancements, acquire new skills needed for promotion or a change in focus (e.g., moving into data analytics for manufacturing), or refresh foundational knowledge. Platforms like Coursera, edX, and Udemy, searchable via OpenCourser, offer courses from universities and industry experts worldwide.

Integrating online learning into one's educational journey provides flexibility and access to a vast range of knowledge. For tips on structuring your self-learning, check out the OpenCourser Learner's Guide.

Career Progression for Production Engineers

Entry-Level Positions

Graduates typically start in entry-level roles such as Junior Production Engineer, Process Engineer, Manufacturing Engineer Associate, or Production Coordinator. Initial responsibilities often involve supporting senior engineers, collecting and analyzing production data, monitoring process performance, assisting with troubleshooting, documenting procedures, and participating in continuous improvement projects.

These roles provide essential hands-on experience and exposure to real-world manufacturing environments. New engineers learn to apply theoretical knowledge, understand the practical constraints of production, and develop problem-solving skills under supervision. Building a strong foundation in data analysis, process understanding, and communication is key during this phase.

The title "Process Engineer" is a common starting point, focusing specifically on analyzing and improving individual processes within the larger production system.

Mid-Career Advancement and Management

With experience (typically 3-7 years), production engineers can advance to senior engineer roles with greater responsibility and autonomy. They may lead larger projects, mentor junior engineers, take ownership of specific production lines or areas, and develop specialized expertise. Technical leadership and complex problem-solving become more central to the role.

Further progression often involves moving into management. Opportunities include roles like Production Supervisor, managing a team of operators; Operations Manager, overseeing broader plant or departmental operations; or Engineering Manager, leading a team of engineers. These roles require strong leadership, communication, and decision-making skills, often supplementing technical expertise.

Some engineers transition into related areas like project management, supply chain management, quality assurance management, or technical sales, leveraging their understanding of production processes.

Paths for Specialization

Production engineering offers various paths for specialization based on interest and industry needs. One major area is automation and robotics, focusing on designing, implementing, and managing automated systems within manufacturing. Another is Lean Manufacturing or Continuous Improvement, becoming an expert in driving efficiency and waste reduction initiatives across an organization.

Quality Engineering is another specialization, focusing deeply on quality management systems, statistical analysis, and reliability. Engineers might also specialize in specific manufacturing technologies like additive manufacturing (3D printing), advanced materials processing, or specific industry sectors like pharmaceuticals or semiconductor manufacturing, requiring deep domain knowledge.

Some production engineers develop expertise in simulation and modeling, using software to predict and optimize process performance. Others might focus on the intersection with data science, applying advanced analytics to large datasets generated by modern manufacturing systems. Choosing a specialization can enhance career prospects and lead to expert roles.

This book explores the growing field of additive manufacturing, a potential specialization.

Salary Expectations

Salaries for production engineers vary based on factors like location, industry, company size, years of experience, education level, and specific responsibilities. Generally, engineering roles offer competitive compensation. Entry-level salaries typically align with those of other engineering disciplines like mechanical or industrial engineering.

Compensation tends to increase significantly with experience and assumption of greater responsibility or management roles. Industries like oil and gas, aerospace, pharmaceuticals, and high-tech electronics often offer higher salaries due to the complexity and criticality of their operations. Geographic location also plays a major role, with salaries generally higher in regions with a higher cost of living and strong demand for engineers.

According to the U.S. Bureau of Labor Statistics, industrial engineers (a category often encompassing production engineers) had a median annual wage of $99,780 in May 2023. However, it's essential to research salary benchmarks specific to your target industry and location using resources like BLS, salary survey sites, or industry reports.

Production Engineer Tools and Technologies

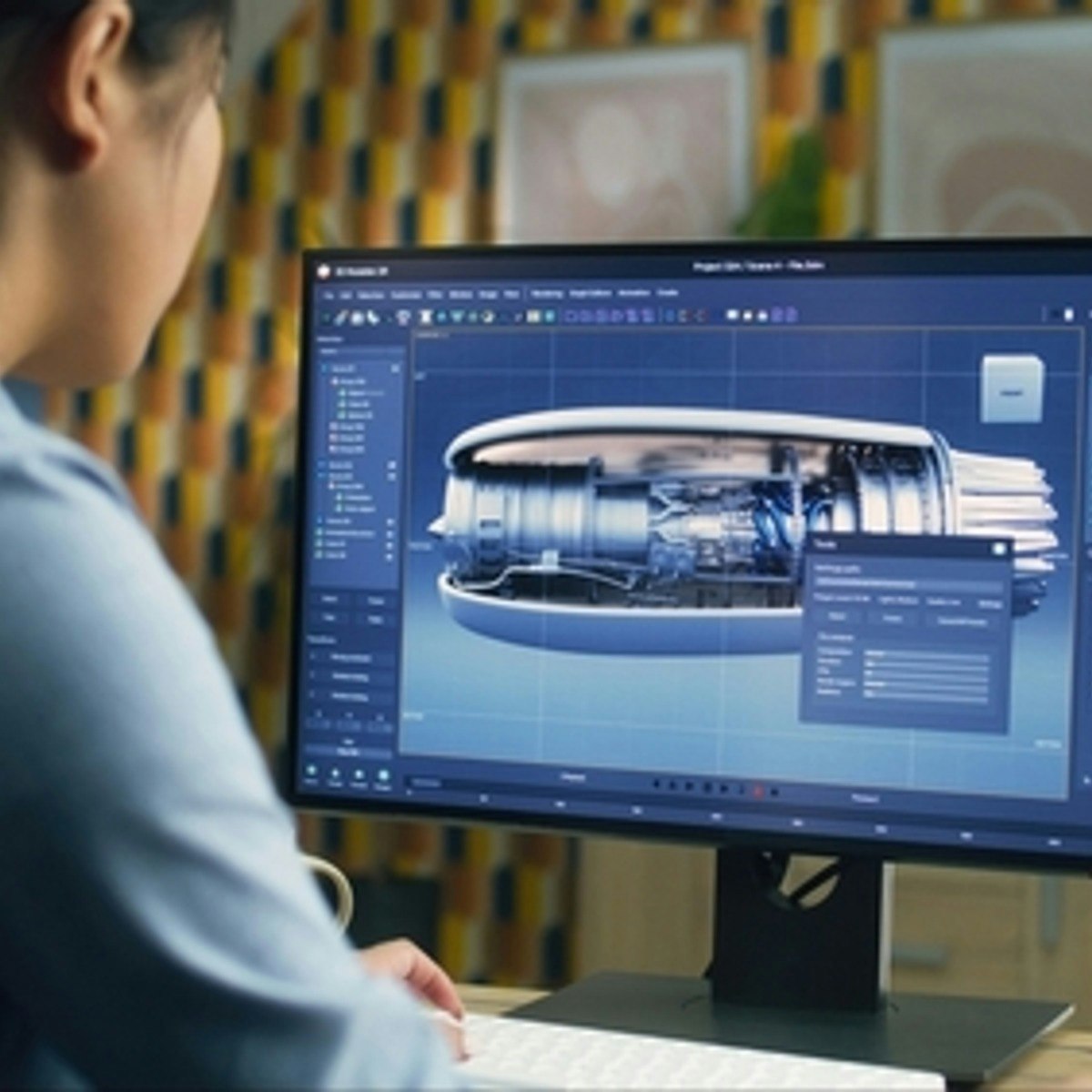

CAD/CAM Software Integration

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are fundamental tools for many production engineers. CAD software is used to create 2D drawings and 3D models of products and tooling. CAM software uses these designs to generate instructions for computer-controlled manufacturing equipment, such as CNC (Computer Numerical Control) machines.

Production engineers often use CAD to design jigs, fixtures, or modifications to production equipment. They work with CAM systems to optimize machining paths, select appropriate tools, and ensure efficient material removal or forming processes. Proficiency in major CAD/CAM platforms (e.g., SolidWorks, AutoCAD, CATIA, Siemens NX) is a valuable skill.

The integration of CAD and CAM allows for a seamless transition from design to production, reducing errors and lead times. Understanding these tools helps engineers optimize manufacturability early in the design process and manage automated production effectively. Search for CAD/CAM courses on OpenCourser to build proficiency.

This book delves into metal forming processes often managed using CAM software.

Industry 4.0 Technologies

The current era of manufacturing, often termed Industry 4.0, involves the integration of digital technologies into production processes. Production engineers are increasingly working with these technologies. The Internet of Things (IoT) involves connecting machines and sensors to collect real-time data on performance, condition, and environment.

Big Data analytics allows engineers to process and analyze the vast amounts of data generated by IoT devices to identify patterns, predict failures (predictive maintenance), and optimize processes. Digital twins—virtual replicas of physical assets or processes—enable simulation, testing, and optimization in a risk-free environment. Automation and Robotics continue to advance, requiring engineers to manage more sophisticated automated systems.

Familiarity with these Industry 4.0 concepts and technologies is becoming essential for modern production engineers. They need to understand how to leverage these tools to create smarter, more flexible, and more efficient factories. Explore topics like Artificial Intelligence which powers many of these advancements.

Data Analytics and Simulation Platforms

Data analysis is a critical skill for production engineers. They use various tools to analyze production data, identify trends, perform statistical analysis, and make data-driven decisions. Common tools range from spreadsheet software like Microsoft Excel for basic analysis and visualization to specialized statistical software like Minitab for quality control and process improvement.

Process simulation software (e.g., Arena, AnyLogic, or industry-specific tools like Aspen HYSYS for chemical processes) allows engineers to model manufacturing systems or processes virtually. This enables them to test different scenarios, predict performance, identify bottlenecks, and optimize designs before implementing changes in the real world, saving time and resources.

Increasingly, programming skills in languages like Python or R are becoming valuable for handling larger datasets and performing more complex analyses or custom simulations. Browse Data Science courses for relevant skills.

These courses focus on simulation tools used in specific industries, demonstrating the practical application of these platforms.

Emerging Tools in Sustainable Manufacturing

As sustainability becomes a greater focus, new tools and technologies are emerging to support environmentally conscious production. Life Cycle Assessment (LCA) software helps engineers evaluate the environmental impact of a product or process throughout its entire lifecycle, from raw material extraction to disposal.

Energy management systems provide real-time monitoring and control of energy consumption within a facility, helping to identify savings opportunities. Advanced materials with lower environmental impact or improved recyclability are constantly being developed. Technologies supporting the circular economy, such as advanced sorting and recycling processes or platforms for tracking material flows, are also gaining traction.

Production engineers play a key role in identifying, evaluating, and implementing these sustainable technologies and practices. Staying informed about advancements in green manufacturing is becoming increasingly important. Explore related topics in Sustainability and Environmental Sciences.

Additive manufacturing is one area with potential implications for sustainability, enabling localized production and potentially reducing material waste.

Global Opportunities and Challenges

Variations in Regional Demand

The demand for production engineers is not uniform globally; it mirrors the distribution of manufacturing activity. Major manufacturing hubs in East Asia (China, Japan, South Korea), Southeast Asia, North America (USA, Mexico, Canada), and Europe (Germany, Italy) typically have strong and consistent demand for these skills.

Emerging economies investing heavily in industrial development also present growing opportunities. However, the specific industries dominating in each region will influence the type of production engineering expertise needed. For instance, demand might be higher for electronics manufacturing engineers in parts of Asia, while automotive or chemical process engineers might be more sought after in other regions.

Economic conditions, technological shifts, and government policies supporting manufacturing significantly impact regional demand. Aspiring engineers should research the industrial landscape of regions they are interested in working in.

Impact of Offshoring and Reshoring Trends

Global manufacturing strategies, including decisions about where to locate production facilities (offshoring vs. reshoring), directly affect production engineers. Historically, offshoring to lower-cost regions led to job growth there but sometimes reduced opportunities in higher-cost countries, shifting the focus towards higher-value activities like R&D, automation management, and complex manufacturing.

More recently, factors like rising global labor costs, supply chain disruptions (highlighted by the pandemic), geopolitical tensions, and the push for faster R&D-to-market cycles have led some companies to reconsider their manufacturing footprint, resulting in reshoring or near-shoring initiatives. These trends can create new demands for production engineers in regions experiencing renewed manufacturing investment.

Production engineers need to be adaptable and understand the global dynamics influencing manufacturing location decisions. Skills in automation, advanced manufacturing, and supply chain resilience are valuable regardless of these shifts.

Navigating Regulatory Differences

Operating in a globalized economy means production engineers, especially those working for multinational corporations or with international supply chains, must navigate differing regulatory landscapes. Standards related to workplace safety, environmental protection, product quality, and labor practices can vary significantly from one country to another.

Engineers involved in designing or managing processes for global markets must ensure compliance with all relevant regulations in the locations where products are manufactured and sold. This requires ongoing learning and awareness of international standards (like ISO standards) and country-specific legal requirements.

Failure to comply can lead to legal penalties, reputational damage, and operational disruptions. Therefore, understanding and adhering to diverse regulatory frameworks is a critical aspect of production engineering in a global context.

The Need for Cultural Adaptability

Working in international teams, managing global supply chains, or relocating for overseas assignments requires strong cross-cultural communication skills and adaptability. Different cultures may have varying approaches to work styles, communication norms, hierarchy, and decision-making.

Production engineers interacting with colleagues, suppliers, or customers from different cultural backgrounds need to be sensitive to these differences to build effective working relationships. Misunderstandings can arise from communication barriers or differing expectations, potentially hindering project success.

Developing cultural intelligence—the ability to relate and work effectively across cultures—is a valuable asset for engineers in today's interconnected world. It enhances collaboration, facilitates smoother project execution, and fosters a more inclusive work environment.

Ethical Considerations in Production Engineering

Mitigating Environmental Impact

Production engineers have a significant ethical responsibility regarding the environmental impact of manufacturing activities. Processes they design and manage consume resources (energy, water, raw materials) and generate waste (emissions, solid waste, wastewater). Engineers must strive to minimize these impacts.

This involves designing processes for energy efficiency, reducing material waste through optimization and recycling, selecting less hazardous materials, implementing pollution control technologies, and ensuring compliance with environmental regulations. It goes beyond mere compliance towards proactively seeking sustainable solutions.

The ethical dimension lies in balancing economic objectives with environmental stewardship, considering the long-term health of the planet and communities affected by industrial operations. Prioritizing sustainability is increasingly seen not just as an ethical imperative but also as crucial for long-term business viability.

Labor Practices in Global Supply Chains

Many production systems rely on complex global supply chains, often involving manufacturing facilities in different countries with varying labor laws and practices. Production engineers, particularly those involved in sourcing or managing suppliers, face ethical considerations related to working conditions, fair wages, and worker safety throughout the supply chain.

While direct control may be limited, engineers have a role in supplier selection and evaluation, potentially influencing adherence to ethical labor standards. They should be aware of potential risks like child labor, forced labor, unsafe working conditions, and unfair wages within the supply chain and support initiatives promoting ethical sourcing.

Ensuring that efficiency and cost-reduction efforts do not come at the expense of worker well-being is a critical ethical responsibility. Promoting fair and safe labor practices aligns with corporate social responsibility principles.

Ethics of AI and Automation

The increasing use of Artificial Intelligence (AI) and automation in production raises new ethical questions. Engineers involved in implementing these technologies must consider their impact on the workforce. Automation can displace workers, creating an ethical obligation to consider retraining programs or strategies for managing this transition responsibly.

Bias in AI algorithms used for quality control or predictive maintenance is another concern. If AI systems are trained on biased data, they might perpetuate or even amplify inequalities. Engineers must work to ensure fairness, transparency, and accountability in the AI systems they deploy.

Furthermore, decisions regarding the balance between human oversight and autonomous operation, especially in safety-critical systems, involve ethical judgments about risk and responsibility. Thoughtful consideration of these issues is essential as automation becomes more pervasive.

Importance of Whistleblower Protections

Engineers may sometimes encounter situations where company practices conflict with safety regulations, environmental laws, or ethical standards. Professional codes of ethics often obligate engineers to prioritize public safety and welfare. In such cases, internal reporting mechanisms are the first recourse.

However, if internal channels fail or if there is fear of reprisal, whistleblower protections become crucial. These legal and organizational safeguards allow individuals to report wrongdoing without facing retaliation. While not unique to production engineering, the potential for significant safety or environmental incidents in manufacturing makes robust whistleblower policies particularly important.

An ethical organizational culture encourages reporting concerns internally, but strong external protections are necessary as a fallback to ensure accountability and protect those who speak up about potential harm.

Future of Production Engineering

Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are poised to further transform production engineering. These technologies will enable more sophisticated process optimization, predictive maintenance that anticipates equipment failures with greater accuracy, and AI-powered quality control systems capable of detecting subtle defects.

Production engineers will increasingly work alongside AI systems, leveraging them as powerful tools for analysis and decision-making. The role may shift towards designing, training, managing, and interpreting the outputs of these intelligent systems, rather than performing routine analysis tasks manually. Understanding the fundamentals of AI/ML and their applications in manufacturing will become increasingly vital.

This integration promises significant gains in efficiency, flexibility, and responsiveness, but also requires engineers to develop new skill sets combining domain expertise with data literacy. Explore AI concepts on OpenCourser.

Adoption of the Circular Economy

The shift towards a circular economy—where resources are kept in use for as long as possible, extracting maximum value and then recovering and regenerating products and materials—will profoundly impact production engineering. Engineers will need to design products for durability, repairability, and disassembly.

Manufacturing processes will need to accommodate recycled materials, minimize waste generation, and potentially incorporate remanufacturing or refurbishment operations. This requires a systems-thinking approach, considering the entire product lifecycle from design through end-of-life management.

Production engineers will be key players in developing and implementing the technologies and processes needed to make the circular economy a reality, contributing to both environmental sustainability and new business models.

Workforce Reskilling and Upskilling

As technology evolves, particularly with automation and digitalization, the skills required for production engineers and the broader manufacturing workforce are changing. There is a growing need for skills in data analysis, software development (especially for automation integration), cybersecurity for connected systems, and managing human-robot collaboration.

Continuous learning will be essential for production engineers to remain effective. Companies and educational institutions face the challenge of providing accessible training and reskilling programs to help the workforce adapt. Engineers themselves must take initiative in upskilling through online courses, certifications, and on-the-job learning.

The future production engineer will likely be more digitally savvy, adept at working with data and automated systems, while retaining core problem-solving and process optimization skills. Embracing lifelong learning is crucial for navigating this transition.

Innovations in Post-Pandemic Supply Chains

The COVID-19 pandemic exposed vulnerabilities in global supply chains, accelerating trends towards greater resilience, agility, and transparency. Production engineers are involved in implementing solutions to address these challenges.

This includes diversifying supplier bases, exploring regionalization or localization of production (reshoring/near-shoring), investing in digital supply chain technologies for better visibility and tracking, and developing more flexible manufacturing systems capable of adapting quickly to disruptions or changes in demand. Concepts like additive manufacturing for on-demand parts production also play a role.

Designing and managing production systems that are robust against future disruptions is now a key consideration. This focus on resilience, often enabled by digital technologies, is shaping the future of production and supply chain management, as highlighted in industry analyses like those from McKinsey.

Frequently Asked Questions

Can I become a production engineer without an engineering degree?

While a formal engineering degree (Industrial, Mechanical, Manufacturing) is the most direct and common pathway, it's sometimes possible to enter the field through alternative routes, though often more challenging. Individuals with degrees in related fields like Physics, Mathematics, or Technology Management, combined with significant relevant experience (e.g., as a senior technician, process specialist) and targeted certifications (like Lean Six Sigma), might transition into certain production engineering roles.

Some companies offer internal development programs or apprenticeships. However, for roles requiring professional licensure (PE) or for broader career advancement opportunities, an accredited engineering degree typically remains essential. It provides the foundational theoretical knowledge and analytical rigor expected in the profession.

Making the transition without a degree often requires demonstrating exceptional practical skills, continuous self-learning, and potentially starting in more operational or technician roles before moving into engineering functions.

How does this role differ from manufacturing engineering?

The terms "Production Engineer" and "Manufacturing Engineer" are often used interchangeably, and the roles can have significant overlap depending on the company and industry. However, subtle distinctions sometimes exist. Manufacturing Engineering might be considered slightly broader, potentially encompassing the entire product realization process from design through production, including tooling and equipment design.

Production Engineering often places a stronger emphasis on optimizing the *efficiency*, *flow*, and *output* of existing production lines and systems. They might focus more heavily on operations management, work-study, process improvement methodologies (Lean, Six Sigma), and managing day-to-day production challenges.

In practice, the specific responsibilities defined by the employer are more important than the exact title. Both roles require a strong understanding of manufacturing processes, materials, quality control, and optimization techniques.

What industries typically offer the highest salaries for production engineers?

Salaries can vary widely, but certain industries tend to offer higher compensation for production engineers due to factors like high-profit margins, complexity of operations, or demand for specialized skills. The Oil and Gas industry, dealing with complex extraction and processing operations and high-value commodities, is often among the highest paying.

Aerospace and Defense, requiring stringent quality, safety standards, and advanced manufacturing techniques, also typically offers competitive salaries. The Pharmaceutical and Biotechnology industries, with their regulated environments and high R&D investment, are generally well-paying sectors. High-tech industries like Semiconductor Manufacturing and advanced Electronics also tend to compensate production engineers well due to the precision and complexity involved.

Compensation in industries like Automotive or Consumer Goods manufacturing can also be competitive, particularly in management roles or for engineers with specialized expertise in automation or advanced materials. Remember that experience level and geographic location remain major factors influencing salary within any industry.

Is programming knowledge required for a production engineer?

While not always a mandatory requirement for every production engineering role, programming knowledge is becoming increasingly valuable. Basic scripting skills can be helpful for automating data analysis tasks or customizing reports. Proficiency in languages like Python or R is particularly useful for engineers involved in data analytics, simulation, or working with AI/ML applications in manufacturing.

Knowledge of languages used in industrial automation, such as those for Programmable Logic Controllers (PLCs) or robotics, is essential for engineers specializing in automation. Familiarity with database query languages like SQL can also be beneficial for accessing and manipulating production data stored in manufacturing execution systems (MES).

While core engineering principles remain paramount, adding programming skills to your toolkit can enhance your capabilities, make you more competitive in the job market, and open doors to roles involving more advanced digital manufacturing technologies. Explore Programming courses to get started.

How vulnerable is this career to automation?

Like many professions, production engineering is affected by automation, but the role itself is not easily automated away. While routine tasks like data collection or basic process monitoring might become more automated, the core responsibilities of a production engineer—designing systems, analyzing complex problems, implementing improvements, managing projects, and collaborating with diverse teams—require critical thinking, creativity, and human judgment.

Automation is often a tool *used* by production engineers, rather than a replacement *for* them. The focus of the role may shift towards designing, implementing, managing, and optimizing these automated systems, requiring new skills related to robotics, data science, and systems integration. Engineers who adapt and embrace these new technologies are likely to remain in high demand.

The ability to understand the bigger picture, solve non-routine problems, and manage the human aspects of production processes ensures the continued relevance of production engineers, even in highly automated environments.

What are typical internship-to-hire conversion rates?

Internship-to-hire conversion rates for engineering roles, including production engineering, are generally considered favorable, though specific rates vary significantly by company, industry, economic conditions, and individual intern performance. Many companies use internships as a primary pipeline for recruiting entry-level talent, viewing them as extended interviews.

Successful internships allow students to gain practical experience and demonstrate their skills, while enabling employers to assess potential hires in a real-world setting. Strong performance during an internship, coupled with a good cultural fit, often leads to a full-time job offer upon graduation. Engineering disciplines often report relatively high conversion rates compared to some other fields.

Securing relevant internships during university is therefore highly recommended for aspiring production engineers. It not only provides valuable experience but also significantly increases the chances of landing a desirable entry-level position after graduation.

Production engineering is a challenging yet rewarding field that plays a vital role in modern industry. It requires a blend of technical knowledge, analytical skills, practical problem-solving abilities, and strong collaboration skills. From optimizing assembly lines to implementing cutting-edge sustainable technologies, production engineers are at the forefront of making manufacturing more efficient, effective, and responsible. If you enjoy tackling complex systems, driving tangible improvements, and working in dynamic industrial environments, a career in production engineering could be a fulfilling path. Explore the resources on OpenCourser to start building the skills you need for this exciting career.