Manufacturing Engineer

Manufacturing Engineer: Designing the Future of Production

Manufacturing Engineers are the architects behind the production processes that bring products to life. They design, develop, implement, and optimize the systems used to make everything from cars and smartphones to medical devices and consumer goods. This branch of engineering focuses on turning raw materials, individual parts, and sub-assemblies into finished products efficiently, cost-effectively, and with high quality.

Working as a Manufacturing Engineer can be incredibly engaging. You get to see designs transform into tangible products and play a crucial role in making production faster, safer, and more sustainable. It’s a field where problem-solving meets practical application, requiring a blend of technical knowledge, creativity, and management skills to keep production lines running smoothly and competitively.

Introduction to Manufacturing Engineering

This section introduces the foundational concepts of manufacturing engineering, its historical context, and its widespread application across various industries. It's designed to be accessible for those new to the field, including students exploring potential career paths.

What is Manufacturing Engineering?

Manufacturing Engineering is a specialized field dedicated to optimizing how products are made. Professionals in this area apply engineering principles, materials science, and mathematical analysis to create efficient and cost-effective manufacturing systems. They focus on the entire production journey, from initial design feasibility to final assembly and quality checks.

Think of it like designing the most efficient kitchen and cooking process for a restaurant. A manufacturing engineer figures out the best layout for the equipment (ovens, prep stations), the sequence of steps for preparing dishes, the tools needed, and how to ensure every meal comes out perfectly and quickly. They are constantly looking for ways to improve the "recipe" for making things.

This discipline involves designing new production systems, identifying weaknesses in existing processes, creating prototypes, managing inventory, and ensuring compliance with safety and quality standards. Manufacturing engineers often work hands-on with machinery and technology on the factory floor, solving problems and implementing improvements.

For those interested in the fundamental principles behind making things, exploring topics like

The Evolution of Manufacturing

Manufacturing engineering has evolved significantly over time. Early manufacturing relied heavily on manual labor and basic tools. The Industrial Revolution introduced mechanization and assembly lines, dramatically increasing production speed and volume. Engineers focused on standardizing parts and optimizing workflows, laying the groundwork for modern manufacturing.

The 20th century brought automation, computer control, and concepts like Lean manufacturing and Six Sigma, which emphasize waste reduction and quality improvement. Manufacturing engineers became key players in implementing these methodologies, using data and statistical analysis to refine processes.

Today, the field is undergoing another transformation known as Industry 4.0 or

Key Industries Employing Manufacturing Engineers

Manufacturing engineers are essential across a vast array of industries responsible for producing physical goods. Their skills in process optimization, quality control, and system design are universally valuable wherever products are made.

Major sectors include automotive, aerospace, and transportation equipment manufacturing, where efficiency, precision, and safety are paramount. Electronics and computer manufacturing rely heavily on manufacturing engineers to manage complex assembly processes and rapidly evolving technologies. Other significant employers include manufacturers of industrial machinery, chemical products, plastics, medical devices, and consumer goods.

According to the Institute for Supply Management®, there are numerous manufacturing industries in the United States, including textiles, metal products, and more, all requiring manufacturing engineering expertise to maintain productivity and profitability. The skills of a manufacturing engineer are transferable, offering opportunities to work in diverse settings and contribute to the production of a wide range of essential and innovative products.

Core Responsibilities of a Manufacturing Engineer

This section details the typical day-to-day tasks and core functions of a manufacturing engineer, providing a clearer picture of the career's realities for students, career changers, and current practitioners.

Designing and Optimizing Production Processes

A primary responsibility of manufacturing engineers is designing the systems and workflows used to produce goods. This involves analyzing product requirements, selecting appropriate manufacturing methods (like machining, molding, or assembly), and planning the sequence of operations.

They determine the most efficient layout for equipment and workstations within a factory, aiming to minimize material handling, reduce bottlenecks, and ensure a smooth flow of production. This often involves using tools like Computer-Aided Design (CAD) software to model factory layouts and simulate production scenarios.

Optimization is an ongoing task. Manufacturing engineers continually analyze production data, conduct time studies, and identify opportunities to improve efficiency, reduce costs, and enhance product quality. They might implement changes to workflows, introduce new machinery, or refine existing processes based on their findings.

These courses offer insights into analyzing and improving manufacturing systems.

Ensuring Quality and Applying Lean Principles

Maintaining high product quality is a critical function. Manufacturing engineers develop and implement quality control systems and procedures. This includes setting quality standards, performing inspections, and using statistical methods like

When defects or issues arise, manufacturing engineers lead root cause analysis efforts to understand why the problem occurred and implement corrective actions to prevent recurrence. They play a key role in ensuring products meet specifications and customer expectations.

Many manufacturing engineers apply principles of

These courses provide comprehensive training in Lean and Six Sigma methodologies, essential for quality control and process improvement.

Collaborating Across Functions

Manufacturing engineers rarely work in isolation. Effective collaboration with various teams is essential for success. They work closely with product design engineers to ensure new products are designed for manufacturability (DFM) – meaning they can be produced efficiently and cost-effectively.

Collaboration extends to supply chain and procurement teams to ensure timely availability of materials and components. They also work with maintenance teams to schedule equipment upkeep and address breakdowns, and with production staff on the factory floor to provide technical support, training, and troubleshoot issues.

Strong communication and interpersonal skills are vital for coordinating efforts, resolving conflicts, and ensuring alignment across different departments towards common production goals. This cross-functional nature makes the role dynamic and requires a holistic view of the business.

This book offers insights into leadership challenges that often involve cross-functional collaboration.

Driving Sustainability in Production

Increasingly, manufacturing engineers are tasked with incorporating sustainability into production systems. This involves finding ways to reduce environmental impact, conserve resources, and minimize waste throughout the manufacturing lifecycle.

Activities might include optimizing processes to reduce energy consumption, selecting more sustainable materials, implementing recycling programs for production waste, and ensuring compliance with environmental regulations like emissions standards. They might explore and implement principles of the circular economy, designing processes where materials can be reused or repurposed.

As sustainability becomes a higher priority for businesses and consumers, manufacturing engineers play a crucial role in developing greener production practices. This focus area is expected to grow, creating more opportunities for engineers skilled in sustainable manufacturing techniques.

According to a Forbes article on manufacturing trends, software is playing a pivotal role in helping manufacturers achieve carbon neutrality, reduce waste, and optimize energy consumption through real-time data tracking.

Formal Education Pathways

This section outlines the typical educational journey for aspiring manufacturing engineers, from high school preparation through postgraduate studies, focusing on building the necessary competencies.

Preparing in High School

A strong foundation in science, technology, engineering, and mathematics (STEM) during high school is crucial preparation for a career in manufacturing engineering. Courses in physics, chemistry, and especially mathematics (including algebra, geometry, trigonometry, and calculus) are essential.

Developing strong analytical and problem-solving skills is also important. Engaging in extracurricular activities like robotics clubs, science fairs, or coding competitions can provide valuable hands-on experience and demonstrate initiative.

Taking courses in computer science or drafting can provide an early introduction to tools like CAD, which are widely used in the field. Strong communication skills, both written and verbal, are also beneficial, as engineers need to collaborate effectively and document their work clearly.

Undergraduate Degree Options

A bachelor's degree is typically the minimum educational requirement for entry-level manufacturing engineering positions. Common degree paths include a Bachelor of Science in Manufacturing Engineering,

Coursework generally includes foundational engineering topics like thermodynamics, mechanics of materials, fluid mechanics, and electrical circuits, alongside specialized subjects such as manufacturing processes, quality control, automation, robotics, materials science, and factory layout/design. Many programs also incorporate training in CAD/CAM software and simulation tools.

Internships or co-op programs completed during undergraduate studies provide invaluable real-world experience and can significantly enhance job prospects upon graduation. These experiences allow students to apply classroom knowledge in an industrial setting and build professional networks.

Online courses can supplement a traditional degree, offering specialized knowledge or foundational understanding in key areas.

Graduate Programs and Specialization

While a bachelor's degree is sufficient for many roles, a Master's or Ph.D. in Manufacturing Engineering or a related field can open doors to advanced research, specialized technical roles, or leadership positions. Graduate programs allow for deeper specialization in areas like automation, robotics, additive manufacturing, advanced materials, supply chain management, or manufacturing systems optimization.

A master's degree often focuses on advanced coursework and project-based learning, preparing graduates for complex engineering challenges in industry. A Ph.D. is typically research-oriented, training individuals for careers in academia or high-level industrial research and development (R&D).

Pursuing advanced degrees can lead to higher earning potential and opportunities to work on cutting-edge technologies and innovations shaping the future of manufacturing. Online graduate programs and certificates also offer flexible options for working professionals seeking to advance their expertise.

Consider these books for foundational and advanced knowledge relevant to graduate studies.

Accreditation Standards

When choosing an engineering program, accreditation is an important consideration. In the United States, ABET (Accreditation Board for Engineering and Technology) is the primary accrediting body for engineering and technology programs.

Graduating from an ABET-accredited program ensures that the education meets rigorous quality standards set by the engineering profession. This accreditation is often a prerequisite for obtaining a Professional Engineer (PE) license and can be preferred or required by some employers.

Accreditation signifies that the program has appropriate course content, qualified faculty, adequate facilities, and institutional support. While not always mandatory for employment, choosing an ABET-accredited program provides a strong validation of the quality of your education.

Career Progression in Manufacturing Engineering

This section maps out the typical career trajectory for manufacturing engineers, from initial roles to potential leadership positions and specialization pathways.

Entry-Level Roles and Early Career

Graduates typically begin their careers in entry-level positions such as Junior Manufacturing Engineer, Process Engineer, or Production Engineer. In these roles, the focus is often on applying foundational knowledge, learning specific company processes, and supporting senior engineers.

Daily tasks might include monitoring production lines, troubleshooting minor issues, collecting and analyzing process data, assisting with process improvements, maintaining documentation, and learning industry standards and quality control procedures. This stage is crucial for building practical skills and understanding the realities of a manufacturing environment.

With a few years of experience (typically 2-5 years), engineers gain more responsibility, tackle more complex problems, and may begin to lead smaller projects or improvement initiatives. They develop expertise in specific processes or technologies used within their company.

Paths to Specialization

As manufacturing engineers gain experience, they often choose to specialize in specific areas based on their interests and industry needs. Common specialization paths include automation and robotics, focusing on designing and implementing automated systems to improve efficiency and reduce labor costs.

Another path is quality engineering, specializing in developing and managing quality control systems, implementing methodologies like Six Sigma, and ensuring products meet stringent standards. Materials science is another area, focusing on selecting, testing, and developing new materials for manufacturing processes.

Other specializations can include additive manufacturing (3D printing), lean manufacturing implementation, supply chain logistics related to production, or focusing on specific manufacturing processes like welding, casting, or machining. Specialization often involves further training, certifications, or even advanced degrees.

These courses explore common specialization areas like automation, quality, and specific processes.

Transitioning into Leadership and Management

Experienced manufacturing engineers with strong technical skills and demonstrated leadership capabilities can transition into management roles. This might start with supervising a small team of engineers or technicians, leading larger projects, or managing specific production areas.

Further progression can lead to roles like Manufacturing Manager,

An MBA or advanced training in management and leadership can be beneficial for those aiming for senior leadership positions. Strong project management skills and business acumen become increasingly important at this level.

Global Opportunities and Mobility

Manufacturing is a global industry, offering opportunities for engineers to work internationally. Many large corporations have manufacturing facilities spread across different countries, creating possibilities for assignments abroad.

Working internationally can provide valuable experience with different manufacturing practices, cultures, and regulatory environments. It can broaden an engineer's perspective and enhance their career profile. Skills in languages and cross-cultural communication can be advantageous for those seeking global roles.

Mobility within the field is also common. Engineers might move between different industries (e.g., from automotive to aerospace) or transition into related roles such as supply chain management, technical sales, or consulting, leveraging their manufacturing expertise.

Essential Technical Skills for Modern Manufacturing Engineers

This section highlights the critical technical competencies required for success in today's evolving manufacturing landscape, covering both foundational and cutting-edge skills.

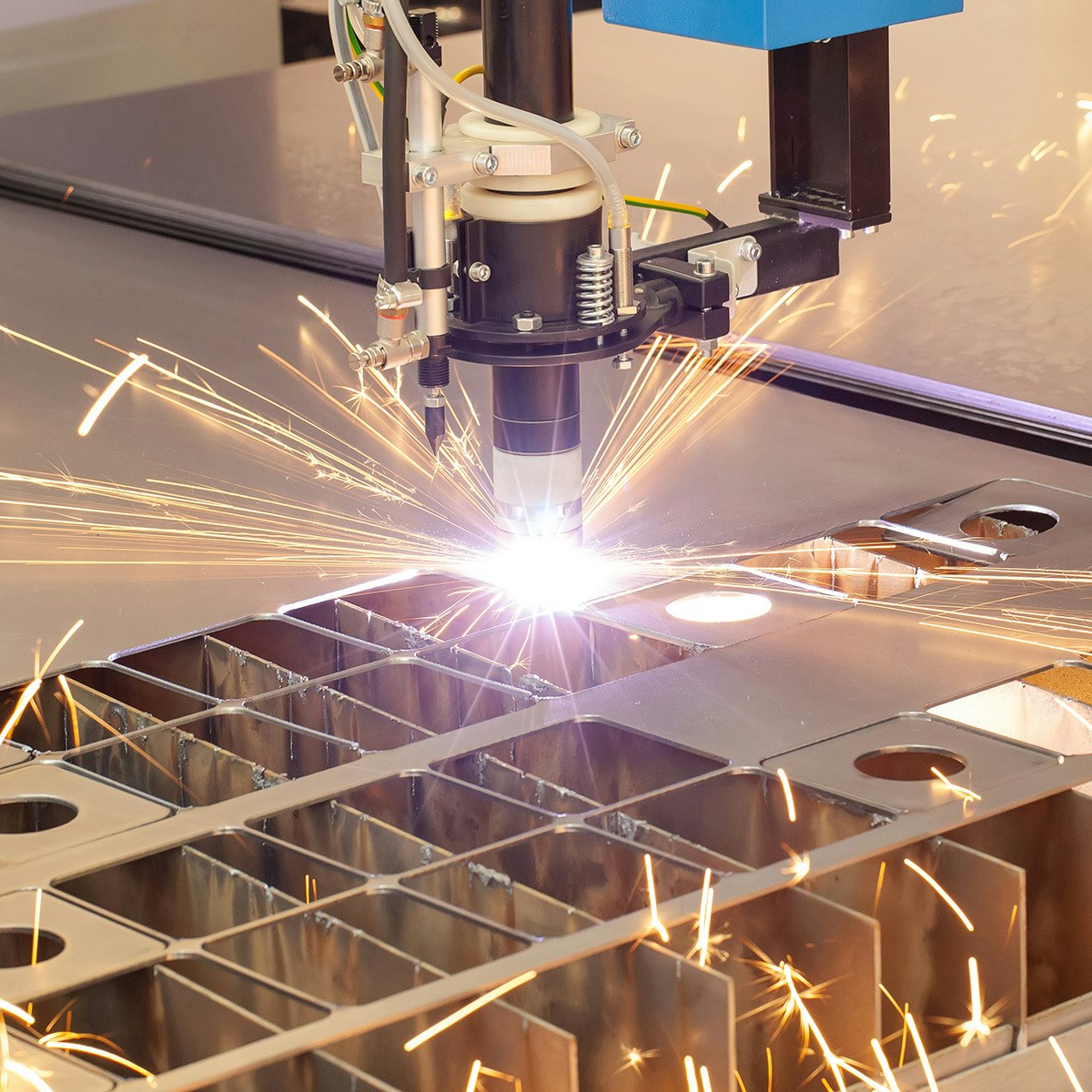

Proficiency in CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are fundamental tools for manufacturing engineers. CAD software is used to create 2D drawings and 3D models of products, tools, and factory layouts. Proficiency allows engineers to visualize designs, analyze feasibility, and communicate specifications accurately.

CAM software uses these CAD models to generate instructions (like G-code) for computer-controlled machinery, such as

Familiarity with popular software packages like

These courses cover essential CAD/CAM software and CNC programming, crucial for modern manufacturing.

Understanding Industry 4.0 Technologies

Industry 4.0 represents the digitalization of manufacturing. Manufacturing engineers need to understand and leverage these technologies. This includes the Internet of Things (IoT), where sensors embedded in equipment collect real-time data on performance and conditions.

Understanding data analytics allows engineers to interpret this IoT data to optimize processes, predict maintenance needs (predictive maintenance), and improve decision-making. Familiarity with cloud computing is also important, as it often underpins data storage and analysis for smart manufacturing systems.

Other key Industry 4.0 technologies include robotics and automation for increased efficiency and precision, digital twins (virtual replicas of physical systems for simulation and analysis), and cybersecurity measures to protect interconnected systems. Staying updated on these rapidly evolving technologies is crucial for competitiveness.

These courses provide insights into digital manufacturing and Industry 4.0 concepts.

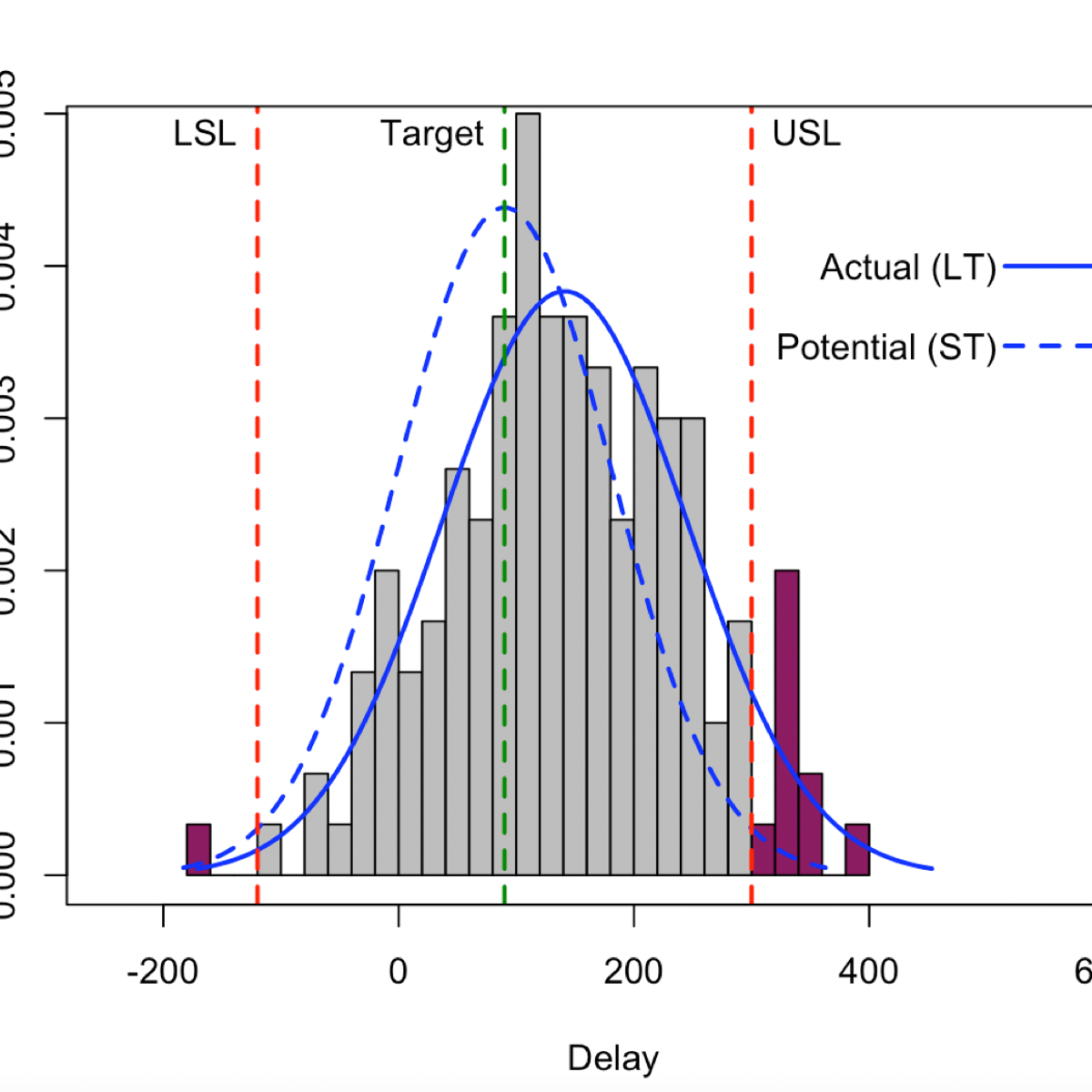

Applying Statistical Process Control (SPC)

Statistical Process Control (SPC) involves using statistical methods to monitor and control manufacturing processes. Manufacturing engineers use SPC charts (like control charts) to track process performance over time, distinguish between normal process variation and special causes of variation, and ensure processes remain stable and capable.

Understanding SPC allows engineers to make data-driven decisions about process adjustments, identify when intervention is needed, and maintain consistent product quality. It's a core tool for quality improvement and defect prevention.

Knowledge of basic statistics, probability, and different types of control charts is necessary. Software tools like Minitab or even advanced features in Excel are often used to perform SPC analysis and create charts.

These resources cover SPC and related statistical methods essential for quality engineering.

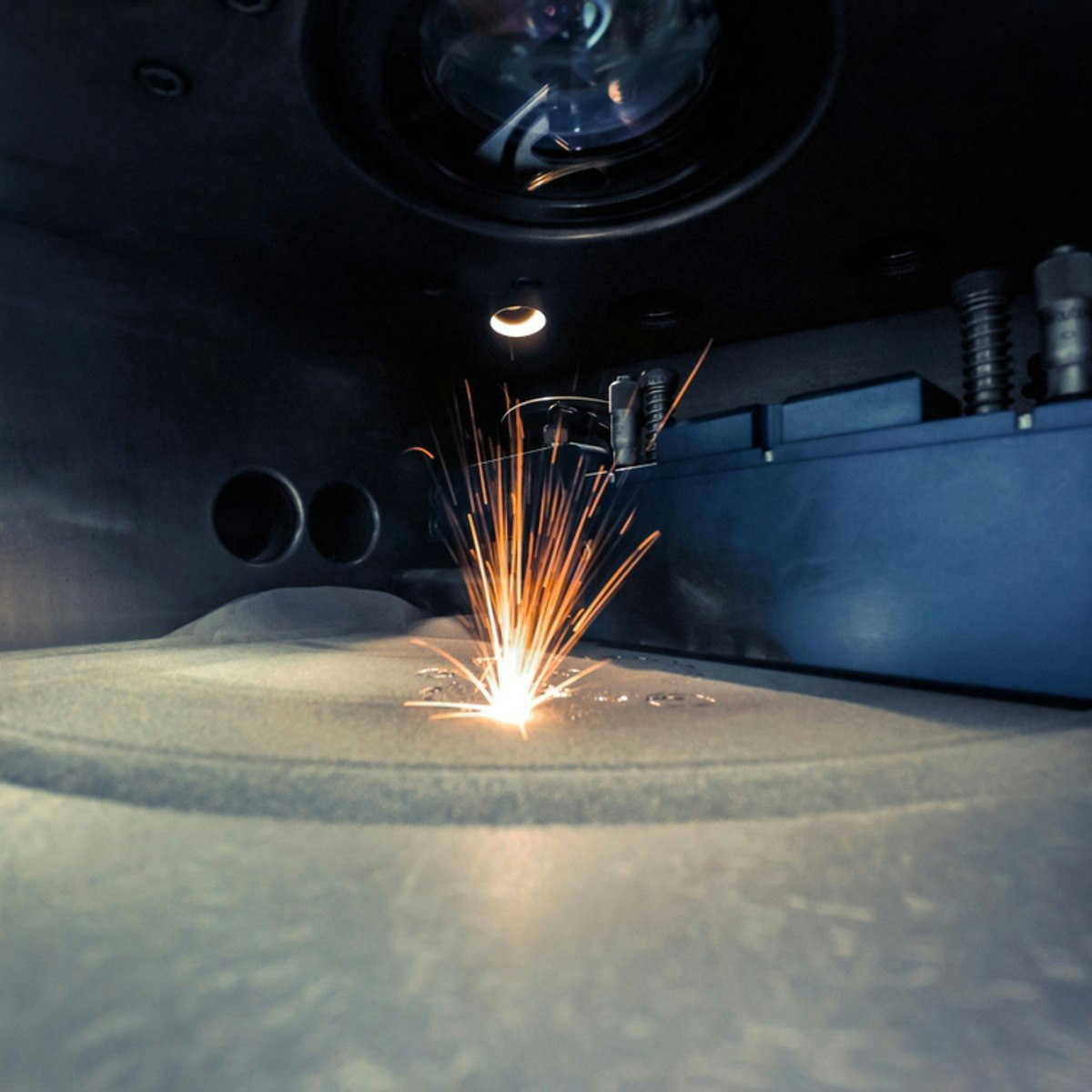

Expertise in Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is rapidly transforming product development and production. Manufacturing engineers increasingly need expertise in this area. This involves understanding different additive processes (like Fused Deposition Modeling, Stereolithography, Selective Laser Sintering), their capabilities, and limitations.

Engineers need to know how to design parts specifically for additive manufacturing (DfAM), considering factors like material properties, support structures, and post-processing requirements. They may be involved in selecting the right additive technology for specific applications, operating 3D printers, or integrating additive manufacturing into existing production workflows.

As the technology matures and finds wider industrial application, particularly for rapid prototyping, custom tooling, and even direct part production, expertise in additive manufacturing is becoming a highly valuable skill.

These courses cover the fundamentals and applications of 3D printing.

Manufacturing Engineer's Role in Global Supply Chains

This section explores how manufacturing engineers contribute to the broader context of global supply chains, addressing risks, strategic decisions, and resilience planning.

Managing Risks in Production

Manufacturing engineers play a role in identifying and mitigating risks within the production process that could impact the supply chain. This includes risks related to equipment failure, quality defects, process variability, and workforce availability.

By designing robust processes, implementing effective quality control measures, and ensuring proper equipment maintenance schedules, they help minimize disruptions that could lead to delays or shortages downstream in the supply chain. They might use tools like Failure Mode and Effects Analysis (FMEA) to proactively identify potential failure points and implement preventative measures.

Their understanding of process capabilities and limitations helps inform realistic production planning and scheduling, contributing to more reliable supply chain performance. Ensuring safety protocols are followed also mitigates risks related to workplace accidents, which can halt production.

Navigating Localization vs. Globalization

Manufacturing engineers provide critical input into strategic decisions about where to locate production facilities – whether to centralize globally or localize regionally. Their expertise helps evaluate the technical feasibility, costs, and quality implications of different manufacturing locations.

They assess factors like local infrastructure, availability of skilled labor, material sourcing options, and the suitability of different locations for specific manufacturing processes or technologies. They might be involved in setting up new production lines or transferring technology between facilities in different regions.

Understanding the trade-offs between economies of scale offered by globalization and the potential benefits of localization (like shorter lead times, reduced transportation costs, and potentially greater resilience) is important. Engineers contribute data and analysis to help businesses make informed decisions about their manufacturing footprint.

Adapting to Trade Policies and Regulations

Changes in international trade policies, tariffs, and regulations can significantly impact manufacturing operations and supply chains. Manufacturing engineers may need to adapt processes or sourcing strategies in response to these external factors.

For example, new tariffs might make imported components more expensive, prompting engineers to find alternative domestic suppliers or redesign processes to use different materials. Changes in environmental or safety regulations in different markets may require modifications to manufacturing processes or product designs to ensure compliance.

Staying informed about relevant policies and regulations and understanding their potential impact on production costs, lead times, and market access is part of navigating the complexities of global manufacturing.

Building Resilient Production Systems

Recent global events have highlighted the importance of supply chain resilience. Manufacturing engineers contribute to building more resilient production systems that can withstand disruptions, whether from natural disasters, geopolitical events, pandemics, or supplier issues.

This might involve designing flexible manufacturing systems that can quickly adapt to changes in demand or switch between different products. It could also involve diversifying suppliers for critical components or materials, or developing contingency plans for potential equipment failures or labor shortages.

By focusing on process robustness, implementing backup systems, and utilizing technologies like digital twins for predictive analysis, manufacturing engineers help create production operations that are less vulnerable to unexpected shocks, thereby strengthening the overall supply chain.

Ethical Challenges in Manufacturing Engineering

This section addresses some of the unique ethical considerations and moral dimensions inherent in the field of manufacturing engineering, relevant for deeper reflection.

Reducing Environmental Impact

Manufacturing processes inevitably consume energy and resources and generate waste and emissions. Manufacturing engineers face the ethical challenge of minimizing this environmental footprint. This involves designing processes that are energy-efficient, reduce material waste, limit pollution, and utilize sustainable resources where possible.

Engineers must balance the pressure for cost-effectiveness and production speed with the responsibility to protect the environment. Decisions about technology selection, process design, and material choices all have environmental consequences that require careful ethical consideration.

Promoting a culture of sustainability within the organization and advocating for environmentally responsible practices, even when they might involve higher initial costs, is an important ethical dimension of the role.

Labor Practices and Worker Well-being

In a globalized manufacturing landscape, engineers may work with or design processes for facilities in regions with varying labor laws and standards. Ethical challenges arise concerning fair wages, safe working conditions, reasonable working hours, and the treatment of workers.

Engineers designing production lines and workstations have a responsibility to consider ergonomics and worker safety to prevent injuries and promote well-being. Decisions about automation also have ethical implications, potentially displacing workers and requiring consideration of retraining or support programs.

Ensuring that efficiency and cost-reduction efforts do not come at the expense of worker safety or fair labor practices is a critical ethical responsibility for manufacturing engineers.

Accountability for Product Safety

Manufacturing engineers play a role in ensuring that products are manufactured safely and reliably. Defects introduced during the manufacturing process can lead to product failures, potentially causing harm to consumers.

Engineers have an ethical obligation to design and implement robust quality control systems, ensure processes are capable of meeting safety-critical specifications, and address any potential safety concerns identified during production. This includes resisting pressure to cut corners on quality or testing procedures for the sake of speed or cost.

Transparency and honesty in reporting quality issues and potential safety risks are paramount. The ultimate responsibility for the safety and reliability of the manufactured product rests, in part, with the engineers who design and oversee its production.

Impacts of AI and Automation

The increasing use of artificial intelligence and automation in manufacturing presents new ethical challenges. While these technologies can enhance efficiency and safety, they also raise concerns about job displacement and the future of the workforce.

Manufacturing engineers involved in implementing AI and automation need to consider the societal impacts of their work. This includes thinking about how to manage the transition for affected workers, the potential for bias in AI algorithms used in quality control or decision-making, and ensuring that automated systems operate safely and reliably.

Balancing the benefits of technological advancement with the ethical responsibility towards the workforce and society requires careful consideration and proactive planning.

Future Trends Shaping Manufacturing Engineering

This section looks ahead at key trends and developments that are expected to influence the field of manufacturing engineering, helping readers prepare for the industry's evolution.

Adoption of the Circular Economy

The shift towards a circular economy, focused on minimizing waste and maximizing resource utilization, is a major trend impacting manufacturing. Engineers will increasingly focus on designing products and processes for durability, repairability, reuse, and recycling.

This involves selecting materials that can be easily recycled or composted, designing products for disassembly, and developing remanufacturing processes. Manufacturing engineers will play a key role in creating closed-loop systems where resources are kept in use for as long as possible, reducing reliance on virgin materials and minimizing environmental impact.

Expertise in life cycle assessment, sustainable materials, and reverse logistics will become more valuable as companies embrace circular economy principles.

AI-Driven Predictive Maintenance

Artificial intelligence (AI) is poised to revolutionize equipment maintenance. By analyzing real-time data from sensors on machinery (via IoT), AI algorithms can predict potential failures before they occur. This allows for proactive maintenance scheduling, reducing unexpected downtime and optimizing maintenance resources.

Manufacturing engineers will need skills in interpreting AI-driven insights and integrating predictive maintenance strategies into overall production planning. This trend promises significant improvements in operational efficiency and equipment reliability.

According to a Deloitte survey mentioned by Forbes, 93% of manufacturers see AI as pivotal for growth and innovation by 2025, with significant application in smart production.

Addressing the Skills Gap

The rapid pace of technological change, particularly with Industry 4.0, is creating a skills gap in manufacturing. There is a growing need for engineers proficient in digital technologies, data analytics, automation, and advanced manufacturing processes.

Educational institutions and companies are working to address this gap through updated curricula, training programs, and apprenticeships. Manufacturing engineers themselves will need to engage in continuous learning to keep their skills relevant. Online courses and professional certifications offer accessible ways to upskill and adapt to evolving industry demands.

A report highlighted by the University of Wisconsin-Madison suggests this skills shortage could lead to millions of unfilled jobs by 2030, emphasizing the need for workforce development.

Staying competitive requires continuous learning. OpenCourser offers a vast catalog of online courses across Engineering and Technology to help professionals bridge skills gaps.

Navigating Regulatory Changes

Regulations concerning environmental protection, product safety, data privacy, and cybersecurity are constantly evolving and becoming more stringent globally. Manufacturing engineers must stay informed about these changes and ensure their processes and products comply.

For instance, stricter emissions standards may necessitate process modifications or investments in new pollution control technologies. Increased focus on data security requires robust measures to protect sensitive production data in interconnected smart factories. Adapting to new regulations requires diligence, foresight, and often, innovative engineering solutions.

Understanding the regulatory landscape in different markets is crucial for companies operating globally, and manufacturing engineers play a key role in ensuring compliance.

Frequently Asked Questions (Career Focus)

This section addresses common questions potential and current manufacturing engineers might have about the career path, qualifications, and industry landscape.

Manufacturing Engineering vs. Industrial Engineering: What's the Difference?

While there's overlap, the focus differs. Manufacturing Engineers primarily concentrate on the design, development, and optimization of the *physical production processes* and equipment used to make products. They deal more directly with the machinery, tooling, automation, and specific steps involved in transforming materials into finished goods.

Industrial Engineers often take a broader view, focusing on optimizing *complex systems and processes* involving people, materials, information, equipment, and energy. They analyze workflows, improve efficiency across the organization, manage supply chains, optimize plant layouts for overall flow, and apply statistical analysis to improve overall productivity and quality, often with more emphasis on the human element and organizational structure.

Think of it this way: a manufacturing engineer might design the specific robot and process for welding a car chassis, while an industrial engineer might optimize the entire assembly line layout, including how workers interact with the robots and how materials flow to the line, to maximize overall throughput.

How Valuable Are Certifications (e.g., Six Sigma, PE)?

Certifications can be quite valuable. Six Sigma certifications (Green Belt, Black Belt) demonstrate expertise in data-driven quality improvement methodologies (like

A Professional Engineer (PE) license, while not always mandatory in manufacturing (unlike in civil engineering, for example), signifies a high level of competence and ethical commitment. It can be advantageous for career advancement, especially for roles involving public safety or consulting.

Other certifications, like the Certified Manufacturing Engineer (CMfgE) offered by SME (Society of Manufacturing Engineers), can also validate specific knowledge and skills relevant to the field. The value often depends on the specific industry, company culture, and career goals.

These courses prepare learners for valuable Six Sigma certifications.

Is Remote Work Possible for Manufacturing Engineers?

Manufacturing engineering has traditionally been a hands-on role requiring significant time on the factory floor. However, the landscape is changing. While direct oversight of physical production lines and equipment troubleshooting often requires an on-site presence, some aspects of the job can be done remotely.

Tasks like process design using CAD software, data analysis, simulation, documentation, project planning, and virtual collaboration with teams can potentially be performed remotely, at least part-time. The rise of digital twins and remote monitoring tools (IoT) may further increase remote work possibilities.

However, fully remote roles are still less common than in purely software-based engineering fields. The feasibility depends heavily on the specific company, role responsibilities, and the level of automation and digital infrastructure in place. Hybrid arrangements are becoming more common.

Which Industry Sectors Show the Highest Growth Potential?

Growth potential exists across various manufacturing sectors, driven by technological advancements and market demands. Industries heavily investing in Industry 4.0, automation, and smart manufacturing technologies (like automotive, aerospace, electronics, and medical devices) often offer strong prospects.

Sectors focused on sustainability and renewable energy (e.g., electric vehicle manufacturing, battery production, renewable energy equipment) are experiencing significant growth. Additive manufacturing continues to expand its applications, creating demand in related roles.

Additionally, reshoring initiatives and investments aimed at strengthening domestic supply chains in areas like semiconductors and pharmaceuticals could also boost demand for manufacturing engineers in specific regions or industries.

What Are Typical Salary Ranges?

Salaries for manufacturing engineers vary based on experience, education level, industry, company size, and geographic location. According to the U.S. Bureau of Labor Statistics (BLS), the broader category of industrial engineers (which often includes manufacturing engineers) had a median annual wage of $99,380 in May 2023. The lowest 10% earned less than $65,320, and the highest 10% earned more than $142,220.

Payscale.com, as of May 2024, reported a mean annual salary specifically for manufacturing engineers around $76,726, while Michigan Tech University data cites Payscale figures indicating a mean entry-level salary around $67,220 and a higher mean around $101,000 possibly reflecting more experienced roles. Entry-level positions typically start lower, while senior engineers and managers can earn significantly more, often well into six figures, especially in high-demand industries or locations.

Can I Transition from Other Engineering Disciplines?

Yes, transitioning into manufacturing engineering from other engineering disciplines, particularly mechanical, electrical, or industrial engineering, is common and often feasible. These fields share foundational engineering principles and coursework.

Engineers looking to pivot may need to acquire specific knowledge or skills relevant to manufacturing, such as expertise in specific production processes (e.g., machining, injection molding), quality control methodologies (Lean, Six Sigma), CAD/CAM software, or automation technologies.

Online courses, certifications, or even a focused master's degree can help bridge knowledge gaps. Emphasizing transferable skills like problem-solving, project management, and analytical abilities during the job search is also key. Networking within the manufacturing industry and seeking roles that leverage existing expertise while allowing for growth into manufacturing-specific tasks can facilitate a successful transition.

Making a career change can feel daunting, but your existing engineering foundation provides a strong starting point. Focus on identifying the specific manufacturing skills you need, utilize resources like online courses on OpenCourser to learn them, and highlight how your background brings unique value.

This book provides a general overview of manufacturing processes, useful for those transitioning.

Manufacturing engineering offers a dynamic and impactful career path for those interested in how things are made. It's a field constantly evolving with technology, providing opportunities to innovate, improve efficiency, and contribute to the production of essential goods across diverse industries. With strong projected job growth and the increasing importance of smart and sustainable manufacturing, it represents a compelling choice for aspiring and established engineers.