Production Manager

A Comprehensive Guide to the Production Manager Career

A Production Manager plays a crucial role in the world of manufacturing and production. At its core, this position involves overseeing the entire production process, ensuring efficiency, quality, and safety from start to finish. Think of them as the conductors of an orchestra, coordinating various sections – machinery, materials, and personnel – to create a harmonious and productive output, whether it's producing consumer goods, industrial equipment, or even digital media.

What makes this role particularly engaging is its dynamic nature. Production Managers constantly tackle challenges, optimize workflows, and lead teams to achieve targets. They are problem-solvers, strategists, and leaders rolled into one, operating at the heart of where value is created. The satisfaction comes from seeing tangible results: improved efficiency, higher quality products, and a well-run, motivated team contributing to the organization's success.

What Does a Production Manager Do?

Understanding the day-to-day responsibilities provides a clearer picture of the Production Manager role. It's a multifaceted job requiring a blend of technical knowledge, management skills, and strategic thinking.

Overseeing Manufacturing Processes and Workflows

Production Managers are responsible for the smooth execution of manufacturing operations. This involves planning production schedules, monitoring the workflow, and ensuring that processes run efficiently and effectively. They analyze current procedures to identify bottlenecks or areas for improvement, implementing changes to enhance productivity.

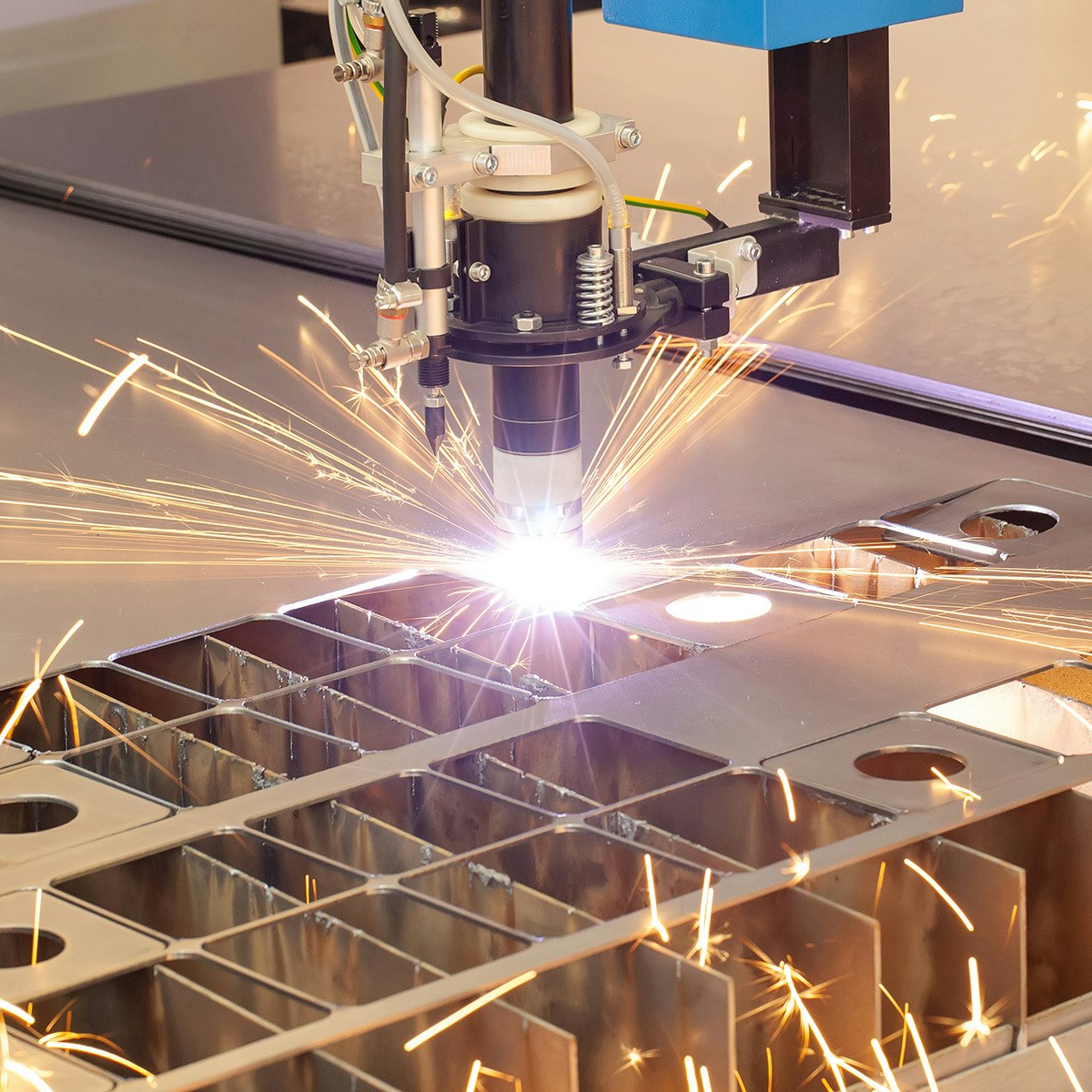

They work closely with engineers, technicians, and shop floor staff to ensure that production targets are met without compromising quality. This requires a deep understanding of the specific manufacturing techniques and technologies used within their industry, from traditional methods to modern automated systems.

Adapting workflows to changing demands, material availability, or unexpected disruptions is a constant challenge. Production Managers must be adept at quick decision-making to keep production lines moving and minimize downtime.

These courses offer insights into optimizing production workflows and understanding operational fundamentals.

Resource Allocation and Budget Management

Effective resource management is critical. Production Managers allocate resources like raw materials, equipment, and personnel optimally to meet production goals. This involves careful planning and forecasting to ensure that necessary inputs are available when needed, avoiding shortages or excess inventory.

Budgeting is another key aspect. They are often responsible for managing the production budget, which includes costs related to materials, labor, energy, and maintenance. Monitoring expenditures against the budget and finding ways to reduce costs without sacrificing quality or safety are essential parts of the job.

Strategic decisions about investments in new machinery or technology also fall under their purview, requiring them to build business cases based on potential ROI and efficiency gains. Balancing short-term production needs with long-term investment strategies is crucial.

Explore inventory management techniques further with this resource.

Quality Control and Compliance

Maintaining high standards of quality is paramount. Production Managers implement and oversee quality control systems, ensuring that products meet specified standards and customer expectations. This involves setting quality benchmarks, conducting inspections, and analyzing quality data to identify and address defects.

Compliance with industry regulations and safety standards is non-negotiable. Production Managers ensure that all production activities adhere to legal requirements and company policies, particularly concerning workplace safety and environmental protection. They are responsible for creating a safe working environment and implementing procedures to prevent accidents.

Regular audits, training programs for staff on quality and safety protocols, and continuous improvement initiatives are typical activities managed by the Production Manager to uphold these standards.

Understanding quality control and process improvement is vital. These courses delve into quality management and process follow-up.

Team Coordination and Performance Monitoring

Production Managers lead and motivate teams of supervisors, technicians, and production workers. Effective leadership involves clear communication, setting performance expectations, providing feedback, and resolving conflicts. Building a cohesive and productive team culture is essential for achieving operational goals.

Monitoring team performance and individual contributions is crucial. This includes tracking key performance indicators (KPIs) related to productivity, quality, and safety. Performance data helps identify training needs, recognize high performers, and address areas where improvement is needed.

They collaborate with Human Resources for recruitment, training, and development of production staff. Ensuring the team has the necessary skills and resources to perform their jobs effectively is a continuous responsibility.

Developing strong leadership and team management skills is crucial for success in this role.

Essential Skills for Production Managers

Success as a Production Manager hinges on a combination of technical expertise, leadership qualities, and analytical abilities. Developing these skills is key for anyone aspiring to enter or advance in this field.

Technical Proficiency

A strong foundation in manufacturing processes and technologies relevant to the specific industry is crucial. This includes understanding machinery operation, maintenance principles, and production techniques. Familiarity with concepts like Lean Manufacturing and Six Sigma is highly valued for process optimization and waste reduction.

Proficiency with Enterprise Resource Planning (ERP systems) is often required for managing resources, scheduling, and tracking production data. Depending on the industry, knowledge of specific software for Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), or production simulation might also be necessary.

Staying updated with technological advancements, such as automation, robotics, and the Industrial Internet of Things (IIoT), is increasingly important for modern Production Managers.

These courses cover Lean principles and essential manufacturing techniques.

These books provide deep dives into Lean methodologies and the influential Toyota Production System.

Leadership and Interpersonal Skills

Production Managers must effectively lead and motivate diverse teams. This requires strong communication skills to convey instructions clearly, provide constructive feedback, and foster collaboration. Conflict resolution skills are essential for addressing disagreements and maintaining a positive work environment.

Decision-making ability, often under pressure, is critical. Managers need to assess situations quickly, weigh options, and make informed choices that impact production outcomes. Delegating tasks effectively empowers team members and ensures efficient workflow distribution.

Building trust and rapport with team members, peers, and upper management is key. Empathy and the ability to understand different perspectives contribute to effective leadership and team cohesion.

Analytical and Problem-Solving Skills

The role demands strong analytical skills to interpret production data, identify trends, and diagnose problems. Production Managers use data to track KPIs, measure performance against targets, and make data-driven decisions for process improvements.

Problem-solving is a daily activity. Whether it's addressing equipment breakdowns, material shortages, or quality issues, managers need a systematic approach to identify root causes and implement effective solutions. Critical thinking helps in evaluating complex situations and developing innovative strategies.

Skills in statistical process control (SPC) and root cause analysis techniques are valuable assets for maintaining quality and efficiency.

These courses focus on problem-solving within operations and analytical tools like Root Cause Analysis.

Adaptability and Time Management

Manufacturing environments are often fast-paced and subject to change. Production Managers must be adaptable, able to adjust plans quickly in response to unforeseen events or shifting priorities. Resilience in handling stress and maintaining composure during challenging situations is crucial.

Excellent time management and organizational skills are needed to juggle multiple tasks, manage deadlines, and prioritize activities effectively. Planning and scheduling abilities ensure that production runs smoothly and targets are met consistently.

A proactive approach to anticipating potential issues and developing contingency plans helps minimize disruptions and maintain operational continuity.

Career Path in Production Management

The journey to becoming a Production Manager often involves starting in related roles and gaining experience. Understanding the typical progression can help aspiring professionals plan their careers effectively.

Entry-Level and Foundational Roles

Many Production Managers start their careers in entry-level positions within manufacturing or operations. Roles like Production Supervisor, Team Lead, or Production Coordinator provide foundational experience in overseeing specific aspects of the production floor, managing small teams, and learning operational processes firsthand.

Other entry points might include roles in quality control, process engineering, or supply chain coordination. These positions offer valuable insights into different facets of the production ecosystem, building a well-rounded understanding necessary for management.

Gaining hands-on experience and demonstrating competence in these roles is crucial for advancing towards a management position. Pursuing relevant certifications or additional training can also accelerate this progression.

Mid-Career Advancement

With proven experience and leadership capabilities, individuals can advance to Assistant Production Manager or shift Production Manager roles. At this stage, responsibilities expand to include overseeing larger teams, managing more complex processes, and contributing to strategic planning.

Specialization within a particular area, such as lean manufacturing implementation, quality systems management, or specific production technologies, can enhance career prospects. Taking on challenging projects and demonstrating measurable results are key factors for promotion.

Networking within the industry and continuous professional development, perhaps through advanced coursework or workshops, can open doors to greater responsibilities and opportunities.

This book provides practical tools for continuous improvement, a key skill for advancement.

Senior Leadership Opportunities

Experienced Production Managers can aspire to senior leadership positions. Roles like Plant Manager, Director of Operations, or VP of Manufacturing involve overseeing entire facilities or multiple production sites, setting strategic direction, and managing significant budgets and resources.

At this level, the focus shifts towards broader business strategy, long-term planning, driving major operational improvements, and representing the production function at the executive level. Strong business acumen and strategic vision are essential.

An MBA or advanced degree in engineering or management can be beneficial, though not always required, for reaching these top-tier positions. A track record of significant achievements and impactful leadership is paramount.

Lateral Moves and Related Roles

The skills and experience gained as a Production Manager are highly transferable. Professionals may choose to move laterally into related fields such as Supply Chain Management, Logistics, Quality Assurance Management, or Operations Consulting.

Some may transition into roles focused on process improvement, becoming Lean Specialists or Six Sigma Black Belts. Others might leverage their technical expertise in roles like Manufacturing Engineering or Industrial Engineering.

The broad operational knowledge acquired provides a solid foundation for various roles focused on efficiency, quality, and system optimization across different industries.

Educational Pathways to Production Management

While practical experience is invaluable, a solid educational foundation is often the starting point for a career in Production Management. Various pathways exist, catering to different learning styles and career goals.

Relevant Bachelor's Degrees

A bachelor's degree is typically considered the minimum educational requirement for many Production Manager roles, especially in larger organizations or technical industries. Common fields of study include Industrial Engineering, Mechanical Engineering, Operations Management, Business Administration, or Supply Chain Management.

These programs provide essential knowledge in areas like production planning, process analysis, quality control, logistics, and management principles. Coursework often includes mathematics, statistics, economics, and specialized technical subjects relevant to manufacturing.

Internships or co-op programs integrated into degree studies offer valuable hands-on experience and industry exposure, significantly enhancing employability upon graduation.

Consider exploring foundational topics through Industrial Engineering or Management courses available online.

Advanced Degrees and Specializations

For those seeking senior leadership roles or specialized positions, a Master's degree can be advantageous. An MBA (Master of Business Administration) with a concentration in Operations Management or Supply Chain Management provides advanced business acumen and strategic perspectives.

Master's degrees in Industrial Engineering or Manufacturing Systems Engineering offer deeper technical expertise. These programs often involve research or project work focused on advanced production technologies, optimization techniques, or systems analysis.

While not always mandatory, an advanced degree can differentiate candidates and potentially accelerate career progression, particularly in competitive environments or highly technical fields.

Vocational Training and Certifications

Vocational training programs and technical schools offer practical, hands-on training focused on specific manufacturing skills and technologies. These can be excellent entry points into production roles, particularly for positions like technician or supervisor.

Professional certifications can significantly boost a Production Manager's credentials and demonstrate expertise in specific areas. Certifications like Certified Supply Chain Professional (CSCP), Certified in Production and Inventory Management (CPIM) from APICS, or Lean Six Sigma certifications (Green Belt, Black Belt) are highly respected in the industry.

These certifications often require passing an exam and may have prerequisites related to education or work experience. They signal a commitment to professional development and mastery of industry best practices.

This course can help prepare for the CSCP certification exam.

This book offers a comprehensive overview useful for those managing supply chains.

Leveraging Online Learning for Skill Development

In today's digital age, online learning offers flexible and accessible pathways to acquire the knowledge and skills needed for a Production Management career. Whether supplementing formal education or upskilling for career advancement, online resources are invaluable.

Online Courses in Operations and Manufacturing

Numerous online platforms offer courses covering all aspects of operations management, production planning, supply chain logistics, quality control, and lean manufacturing. These courses range from introductory overviews to advanced specializations, often taught by university professors or industry experts.

OpenCourser provides a vast catalog where you can search and compare courses on topics like Manufacturing and Logistics from various providers. Features like summarized reviews and syllabi comparison help learners choose the best fit for their needs and goals.

Online learning allows professionals to study at their own pace, fitting education around work schedules. Many courses offer certificates upon completion, which can be added to resumes and professional profiles to showcase acquired skills.

These online courses provide comprehensive introductions or specialized knowledge in manufacturing systems and operations management.

Micro-credentials and Specialized Skills

For targeting specific technical skills, micro-credentials or specialized online courses are highly effective. Learners can focus on areas like ERP software proficiency, specific quality standards (e.g., ISO 9001), data analysis for production, or emerging technologies like additive manufacturing or robotics process automation (RPA).

These focused learning modules allow for rapid skill acquisition in high-demand areas. Platforms often offer badges or certificates for completing these programs, providing verifiable proof of competency.

Building a portfolio of these specialized skills through online learning can make a candidate more attractive for specific roles or promotions within the production management field.

Explore specialized topics like additive manufacturing, RPA, and CNC programming with these courses.

These books delve into the specifics of additive manufacturing technologies.

Virtual Simulations and Hands-On Projects

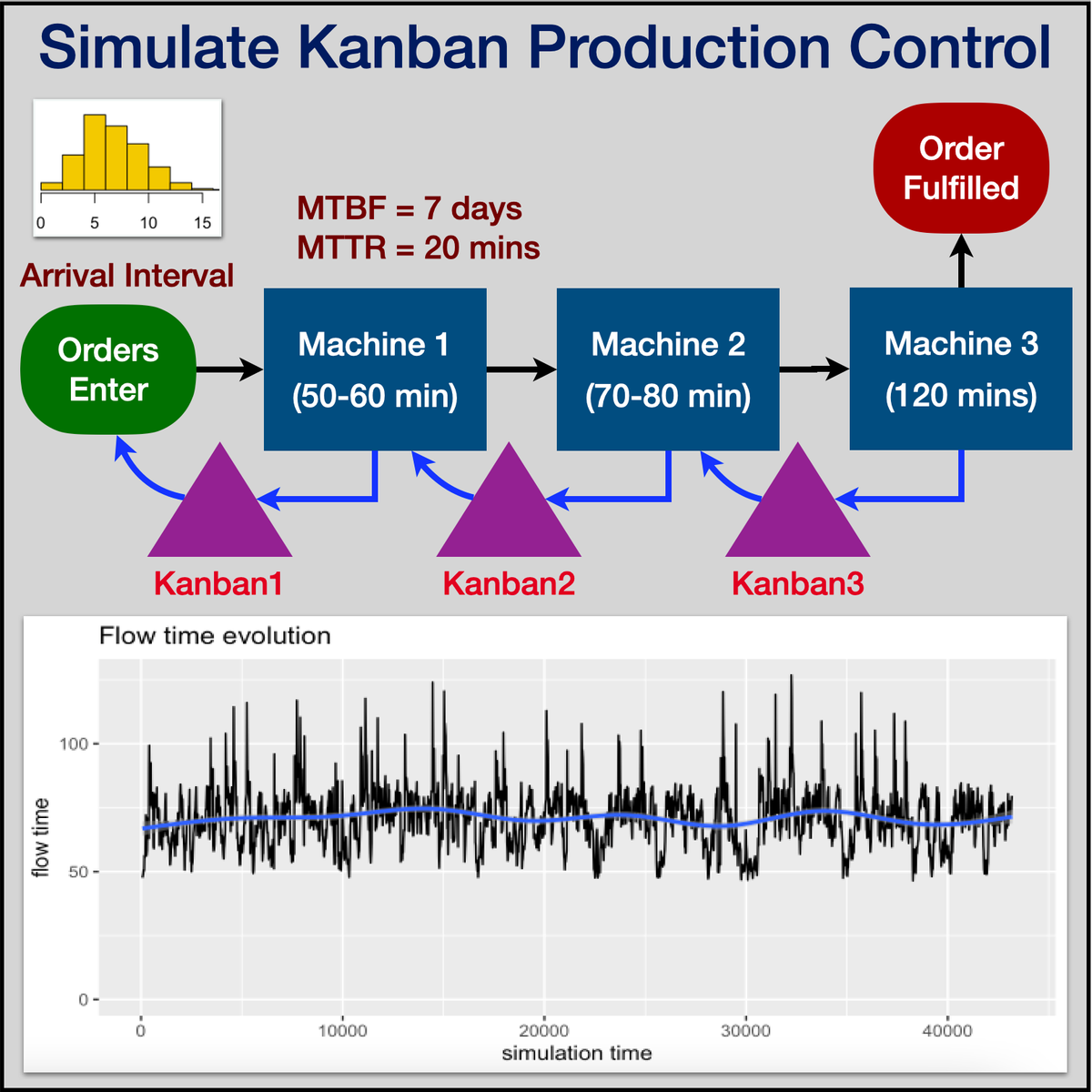

Some online courses incorporate virtual simulations that allow learners to practice managing production processes, optimizing layouts, or responding to supply chain disruptions in a risk-free environment. These simulations bridge the gap between theoretical knowledge and practical application.

Blending online coursework with hands-on projects, either personal or through work, reinforces learning. Applying concepts like value stream mapping or implementing a Kanban system in a real or simulated setting solidifies understanding and builds practical experience.

Documenting these projects and their outcomes can serve as tangible evidence of skills and initiative during job applications or performance reviews. The OpenCourser Learner's Guide offers tips on structuring self-learning paths and documenting progress.

These courses offer insights into manufacturing systems and simulation techniques.

The Evolving Landscape of Production Management

The field of production management is constantly evolving, shaped by technological advancements, shifting economic priorities, and global challenges. Staying informed about these trends is crucial for long-term career success.

Impact of Industry 4.0 and Automation

Industry 4.0, characterized by the integration of digital technologies like IoT, AI, big data analytics, and automation into manufacturing, is transforming production environments. Production Managers increasingly need to understand and leverage these technologies to improve efficiency, flexibility, and decision-making.

Automation, including robotics and automated workflows, is changing the nature of tasks on the production floor. While it can enhance productivity and consistency, it also requires managers to oversee human-machine collaboration and manage workforce transitions. According to research by the World Economic Forum, automation is expected to shift task allocation between humans and machines, requiring new skill sets.

Familiarity with smart factory concepts, predictive maintenance based on sensor data, and cybersecurity in manufacturing environments are becoming essential competencies.

These courses explore the future of production and the role of digital technologies.

Sustainability and Circular Economy

Growing environmental concerns and regulatory pressures are pushing manufacturers towards more sustainable practices. Production Managers play a key role in implementing strategies to reduce waste, conserve energy and water, minimize environmental footprint, and comply with environmental regulations.

The concept of the circular economy – designing products and processes for reuse, remanufacturing, and recycling – is gaining traction. Production Managers may be involved in redesigning production systems to support circularity, managing reverse logistics, and tracking environmental performance metrics.

Understanding sustainable materials, eco-design principles, and life cycle assessment methodologies is becoming increasingly important in many industries.

Global Supply Chain Dynamics

Recent global events have highlighted the complexities and vulnerabilities of international supply chains. Production Managers must navigate challenges related to sourcing materials globally, managing logistics disruptions, and ensuring supply chain resilience.

Strategies like diversifying suppliers, near-shoring or re-shoring production, and improving supply chain visibility through technology are becoming more common. Production Managers contribute to these strategic decisions and manage their operational implementation.

Understanding global trade dynamics, geopolitical risks, and cross-cultural communication is vital for managers operating in companies with international operations or supply chains. Data from organizations like the World Bank often highlight trends in global trade and logistics performance.

These courses touch upon supply chain strategy and global procurement challenges.

Navigating Ethical Considerations

Production Management involves decisions that have significant ethical implications. Awareness and responsible handling of these challenges are integral to the role, impacting reputation, compliance, and social responsibility.

Environmental Responsibility

Production processes inevitably impact the environment through resource consumption, emissions, and waste generation. Managers face ethical dilemmas regarding balancing production targets with environmental protection. This includes decisions about investing in cleaner technologies, managing hazardous materials responsibly, and ensuring compliance with environmental laws, which can sometimes conflict with short-term cost-saving goals.

Transparency in reporting environmental performance and actively seeking ways to minimize harm are ethical obligations. Engaging stakeholders and adopting sustainable practices go beyond mere compliance and reflect a commitment to corporate social responsibility.

Exploring topics like Sustainability can provide valuable context for environmentally conscious management.

Labor Practices and Worker Welfare

In global manufacturing, particularly in regions with varying labor regulations, Production Managers may encounter ethical challenges related to worker rights, fair wages, working hours, and workplace safety. Ensuring ethical treatment of employees throughout the supply chain is crucial.

Decisions regarding automation can also raise ethical questions about job displacement and the need for workforce retraining and support. Balancing efficiency gains with the impact on employees requires careful consideration and ethical leadership.

Promoting a culture of safety, respect, and fairness within the production facility is a fundamental ethical responsibility. Adherence to codes of conduct and international labor standards is essential.

Ethical Sourcing and Supply Chain Integrity

Ensuring that raw materials and components are sourced ethically is a growing concern. Production Managers may need to verify that suppliers adhere to standards regarding labor practices, environmental impact, and human rights, avoiding involvement with conflict minerals or exploitative sources.

Maintaining transparency and traceability within the supply chain helps ensure ethical sourcing. This requires robust supplier vetting processes and potentially audits to confirm compliance.

Balancing cost considerations with ethical sourcing principles can present dilemmas, requiring managers to advocate for responsible practices within their organizations.

Data Privacy in Smart Factories

As factories become more digitized (Smart Manufacturing), vast amounts of data are collected, including potentially sensitive information about employee performance or operational processes. Production Managers must ensure this data is handled ethically and securely.

This involves complying with data privacy regulations (like GDPR), implementing robust cybersecurity measures to prevent breaches, and using data in ways that respect employee privacy and fairness.

Transparency about data collection practices and ensuring data is used primarily for legitimate operational improvement and safety purposes are key ethical considerations in the era of Industry 4.0.

This course touches upon the crucial aspect of cybersecurity in modern manufacturing.

Frequently Asked Questions about Production Management

Here are answers to some common questions individuals explore when considering a career as a Production Manager.

How does Production Management differ from Operations Management?

While related and often overlapping, Production Management typically focuses specifically on the manufacturing process itself – overseeing the transformation of raw materials into finished goods. Operations Management often has a broader scope, encompassing the entire system of producing and delivering goods or services, which can include logistics, supply chain management, service delivery, and overall business process optimization, not just manufacturing.

In smaller companies, one person might handle both roles. In larger organizations, Production Management might be a specialized function within the broader Operations department.

Which industries have the highest demand for Production Managers?

Demand is strong across various manufacturing sectors. Industries like automotive, aerospace, electronics, pharmaceuticals, food and beverage, consumer goods, chemicals, and industrial machinery consistently require skilled Production Managers. The specific demand can fluctuate based on economic conditions and technological shifts within each sector.

Emerging fields like additive manufacturing (3D printing) and renewable energy technology production are also creating new opportunities. Checking resources like the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook can provide insights into employment trends, although specific industry demand might vary regionally.

Is an MBA necessary for advancement?

An MBA is not strictly necessary for advancement, especially in the early to mid-career stages where practical experience and demonstrated results often carry more weight. Many successful senior Production Managers and Plant Managers have bachelor's degrees in engineering or related fields combined with extensive experience.

However, an MBA, particularly one with an operations or supply chain focus, can be beneficial for those aiming for top executive positions (e.g., VP of Operations, Chief Operating Officer). It provides broader business knowledge, strategic thinking skills, and valuable networking opportunities that can accelerate advancement to senior leadership.

The decision often depends on individual career goals, the specific company culture, and the industry.

How does automation affect job security for Production Managers?

Automation is changing the role, not necessarily eliminating it. While automation takes over certain manual tasks, it creates new demands for managers who can oversee automated systems, manage human-robot collaboration, analyze data generated by smart machines, and implement new technologies.

The focus of the role may shift from direct supervision of manual labor towards managing complex technological systems, optimizing automated workflows, and ensuring cybersecurity. Managers who adapt and develop skills related to Industry 4.0 technologies are likely to remain in high demand.

Job security depends more on adaptability and continuous learning rather than automation itself posing a direct threat to the management role, which requires strategic oversight and human judgment.

What is the typical salary progression?

Salary progression varies significantly based on industry, location, company size, experience level, education, and certifications. Entry-level roles like Production Supervisor typically offer lower salaries, while experienced Production Managers earn substantially more. Senior roles like Plant Manager or Director of Operations command significantly higher compensation packages.

General salary data can be found on sites like the BLS or through industry-specific salary surveys. Progression usually involves steady increases with experience, demonstrated performance (meeting production targets, implementing cost savings), and assumption of greater responsibilities. Earning relevant certifications can also positively impact earning potential.

It's important to research salary benchmarks specific to your target industry and geographic location for accurate expectations.

What are critical certifications for international roles?

For international roles, globally recognized certifications are particularly valuable. Certifications from APICS (now part of ASCM - Association for Supply Chain Management), such as CPIM (Certified in Production and Inventory Management) and CSCP (Certified Supply Chain Professional), are widely respected worldwide.

Lean Six Sigma certifications (Green Belt, Black Belt, Master Black Belt) from reputable organizations also have international recognition and demonstrate expertise in process improvement methodologies applicable across borders.

Depending on the industry, certifications related to specific quality standards (e.g., ISO standards) or safety regulations relevant to the target region might also be critical. Language proficiency and cross-cultural communication skills are equally important for success in international roles.

Concluding Thoughts

Embarking on a career as a Production Manager offers a challenging yet rewarding path for individuals interested in the tangible world of making things. It requires a blend of technical knowledge, leadership acumen, and problem-solving skills, placing you at the operational heart of an organization. While the journey demands continuous learning and adaptation, especially with evolving technologies and global dynamics, the opportunities for impact and growth are substantial.

Whether you are just starting to explore this field, considering a career pivot, or seeking to advance within it, focusing on building relevant skills through education, experience, and continuous learning is key. Resources like online courses found via OpenCourser Browse and professional certifications can significantly aid your development. With dedication and the right preparation, a fulfilling career managing the engine of production awaits.