Quality Control Manager

Navigating a Career as a Quality Control Manager

A Quality Control (QC) Manager plays a pivotal role in ensuring that products, services, and processes meet established standards of quality. They are the guardians of consistency, reliability, and customer satisfaction, overseeing systems designed to detect and correct deviations from desired specifications. This involves a blend of technical knowledge, analytical skill, and leadership.

Working as a Quality Control Manager can be deeply engaging. You might find satisfaction in solving complex problems that improve product safety and performance. The role often involves collaborating across different departments, offering a broad view of business operations. Furthermore, implementing successful quality initiatives provides tangible results and contributes directly to a company's reputation and success.

Introduction to Quality Control Management

This section provides a foundational understanding of the Quality Control Manager role, its historical roots, and its relevance across various industries.

Defining the Quality Control Manager

At its core, a Quality Control Manager is responsible for implementing and managing the quality control system within an organization. Their primary objective is to ensure that products or services meet specific requirements and standards before reaching the customer. This involves monitoring, testing, and inspecting processes and outputs.

They establish quality procedures, standards, and specifications for the company and often for its suppliers. They work closely with operations staff to ensure production processes comply with these standards. Ultimately, their work minimizes waste, ensures compliance, and upholds the organization's commitment to quality.

This role requires a keen eye for detail, strong analytical abilities, and excellent problem-solving skills. Effective communication and leadership are also crucial for managing teams and liaising with other departments like production, engineering, and supply chain management.

The Evolution of Quality Control

Quality control is not a new concept, but its formalization as a distinct management discipline evolved significantly over the past century. Early efforts focused primarily on inspection – sorting good products from bad after production. Pioneers like Walter Shewhart introduced statistical methods in the 1920s, shifting the focus towards process control to prevent defects rather than just detect them.

Post-World War II Japan saw figures like W. Edwards Deming and Joseph Juran championing concepts of Total Quality Management (TQM), integrating quality responsibility throughout the organization, not just within a specific department. This era emphasized continuous improvement (Kaizen) and customer focus.

Today, quality control incorporates methodologies like Six Sigma and Lean Manufacturing, leveraging data and sophisticated tools to optimize processes and minimize variability. The field continues to adapt, incorporating advancements in technology and addressing globalized supply chains and increasing customer expectations.

Key Industries Employing Quality Control Managers

Quality Control Managers are essential in nearly every industry where products or services are created. Manufacturing is a major sector, including automotive, aerospace, electronics, consumer goods, and pharmaceuticals. In these fields, ensuring product safety, reliability, and regulatory compliance is paramount.

The food and beverage industry relies heavily on QC Managers to guarantee safety, taste consistency, and adherence to health regulations. This involves meticulous monitoring from raw ingredients to final packaging. You can explore related topics in Food Sciences on OpenCourser.

Other significant sectors include construction, where quality control ensures structural integrity and safety standards are met, and software development, where Quality Assurance (a related field) focuses on bug detection and software performance. Healthcare also employs QC professionals to maintain standards in labs, equipment, and patient care processes.

These courses provide insights into quality control within specific manufacturing contexts.

Key Responsibilities of a Quality Control Manager

This section details the day-to-day tasks and strategic functions that define the role of a Quality Control Manager.

Oversight of Production Processes and Compliance Standards

A primary responsibility is monitoring production processes to ensure they operate within established parameters. This involves understanding the intricacies of how products are made or services delivered. Managers work to identify potential areas where quality could falter.

They are also responsible for ensuring adherence to internal standards and external regulations. This might include industry-specific guidelines (like FDA regulations in pharmaceuticals or food) or international standards such as those set by the International Organization for Standardization (ISO). Maintaining compliance is critical for legal operation and market access.

This often involves setting up checkpoints, conducting regular process audits, and working with production teams to implement corrective actions when deviations occur. Their goal is proactive prevention rather than reactive correction.

This course introduces operational processes relevant to quality oversight.

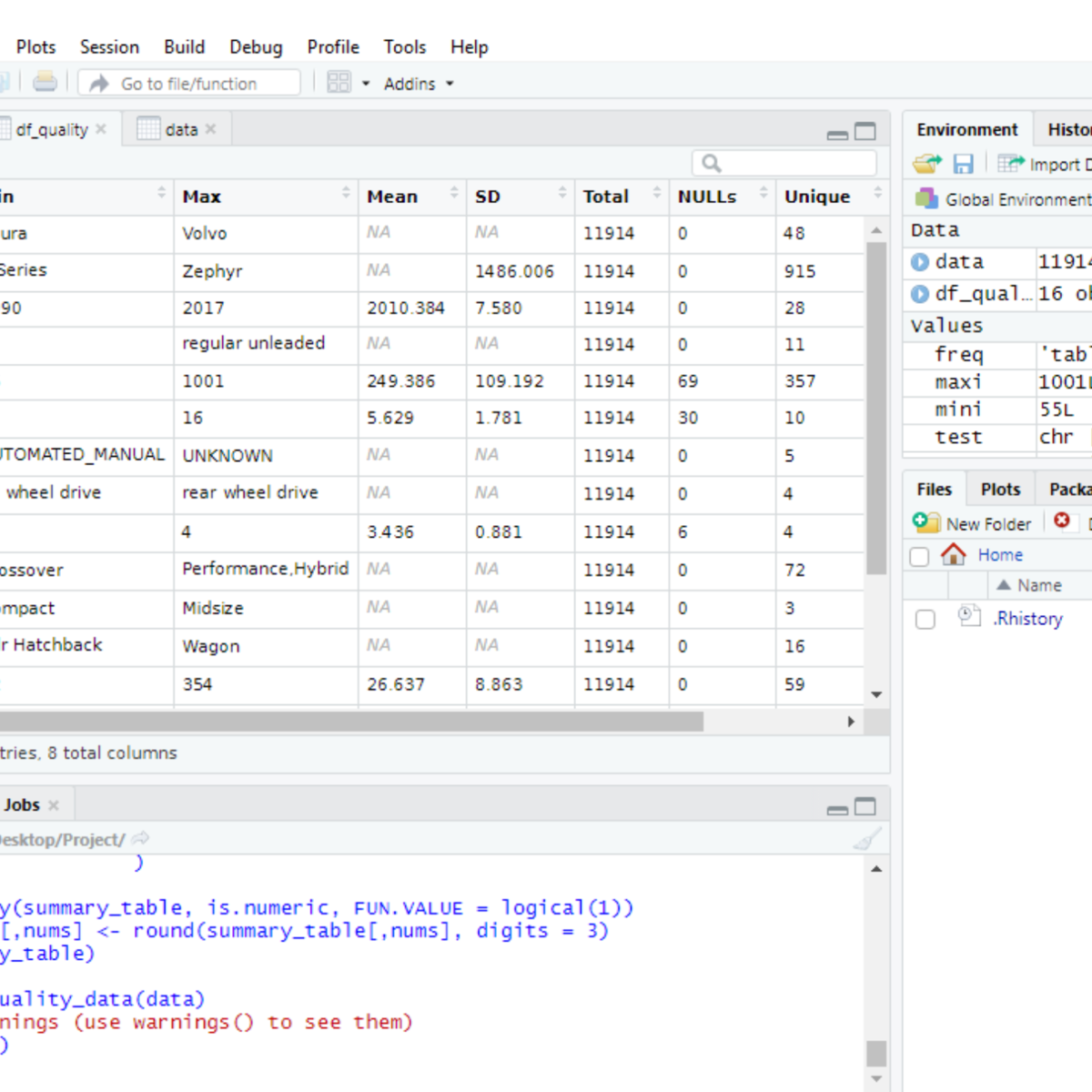

Data Analysis for Defect Prevention

Modern quality control relies heavily on data. QC Managers collect and analyze data from inspections, tests, customer feedback, and process monitoring. Statistical tools are used to identify trends, pinpoint root causes of defects, and measure process capability.

Statistical Process Control (SPC) charts, histograms, and Pareto analysis are common techniques used to understand variation and prioritize improvement efforts. The aim is to move beyond simple pass/fail checks towards understanding and controlling the factors that influence quality outcomes.

By analyzing data proactively, managers can anticipate potential problems and implement preventative measures before defects occur. This data-driven approach is fundamental to continuous improvement cycles like Plan-Do-Check-Act (PDCA).

These resources cover fundamental quality tools and statistical methods essential for data analysis in QC.

Team Management and Cross-Department Collaboration

Quality Control Managers typically lead a team of inspectors, technicians, or analysts. This involves hiring, training, mentoring, and evaluating staff performance. Building a skilled and motivated team is essential for effective quality monitoring and improvement.

Effective leadership fosters a culture where quality is everyone's responsibility. Managers must communicate quality standards clearly and empower their team to identify and address issues. Setting clear goals and providing constructive feedback are key aspects of managing the QC department.

Collaboration extends beyond the QC team. Managers work closely with engineering on product design, with purchasing on supplier quality, with production on process improvements, and with sales/marketing on customer feedback. Strong interpersonal skills are needed to navigate these cross-functional relationships effectively.

This course touches upon lean leadership, a valuable skill for QC Managers.

Regulatory Documentation and Audit Preparation

Maintaining meticulous records is a critical function. QC Managers ensure that all tests, inspections, process changes, and corrective actions are properly documented according to internal procedures and regulatory requirements. This documentation provides traceability and evidence of compliance.

This paperwork is essential during internal and external audits. QC Managers are often the primary point of contact during audits conducted by regulatory agencies (like the FDA or EPA), certification bodies (like ISO auditors), or major customers.

Preparing for audits involves organizing documentation, ensuring procedures are up-to-date and followed, and training staff on audit protocols. Successfully navigating audits demonstrates the effectiveness of the quality management system.

This book provides insights into managing microbiological testing, often subject to regulatory scrutiny.

Quality Control Manager Career Path

Understanding the typical progression can help aspiring professionals plan their journey towards becoming a Quality Control Manager.

Starting Your Journey: Entry-Level Roles

Most individuals don't start directly as QC Managers. Common entry points include roles like Quality Control Inspector, Quality Technician, or Lab Analyst. These positions provide hands-on experience with testing procedures, inspection methods, and quality documentation.

Other related starting points might be in production or process engineering roles, providing a strong understanding of the operations being monitored. Early career professionals focus on mastering technical skills, understanding industry standards, and developing attention to detail.

Building a solid foundation in these initial roles is crucial. Seek opportunities to learn about different aspects of the quality system, participate in problem-solving teams, and understand the 'why' behind the procedures you follow. This foundational knowledge is invaluable for future advancement.

Advancing to Management

Transitioning from a technical role to a Quality Control Manager typically requires several years of experience, demonstrated leadership potential, and a deeper understanding of quality management systems. Strong analytical skills and the ability to interpret data for process improvement become increasingly important.

Employers often look for candidates who have experience leading small projects or teams, contributing to audits, and implementing corrective actions. Pursuing relevant certifications can also strengthen a candidate's profile for management roles.

The timeline varies significantly based on industry, company size, and individual performance, but progressing to a management position often takes 5-10 years. Developing soft skills, such as communication, conflict resolution, and strategic thinking, is just as important as technical expertise.

Specialization and Growth Opportunities

Quality Control offers diverse specialization paths. Managers might focus on specific industries like pharmaceuticals, food safety, automotive, or software, each with unique standards and challenges. Specialization deepens expertise and can increase marketability.

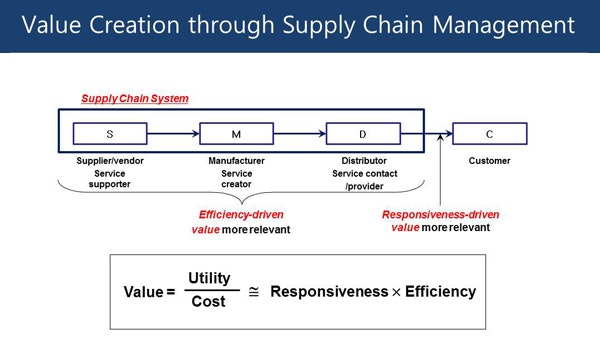

Beyond managing a specific plant or department's QC function, experienced managers can move into broader roles. This could involve overseeing quality across multiple sites, developing corporate quality strategy, or transitioning into related fields like Operations Management or Supply Chain Management.

Further growth might lead to roles like Director of Quality, Vice President of Operations, or specialized consulting positions. Continuous learning and adapting to new methodologies and technologies are key to long-term career growth in the quality field.

Formal Education Requirements

While experience is crucial, formal education provides the theoretical knowledge and analytical skills needed for a career in Quality Control Management.

Relevant Bachelor's Degrees

A bachelor's degree is often the minimum educational requirement for entering the quality field, especially for roles with advancement potential. Degrees in technical fields are highly relevant. Engineering disciplines, particularly Industrial Engineering, Mechanical Engineering, or Chemical Engineering, provide strong foundations.

Degrees in hard sciences like Chemistry or Biology are common, especially in industries like pharmaceuticals, food science, and environmental testing. Business degrees with a focus on Operations Management or Supply Chain Management can also be suitable pathways.

Some universities may offer specific programs or concentrations in Quality Management or Quality Assurance. Regardless of the major, coursework in statistics, process analysis, and technical writing is highly beneficial.

Graduate Studies and Certifications

While not always required, a master's degree (e.g., MBA with an operations focus, MS in Quality Assurance, or a specialized engineering master's) can accelerate career progression, particularly for higher-level management or strategic roles. Graduate studies offer deeper dives into statistical methods, quality systems design, and leadership.

Professional certifications are highly valued in the quality field. Organizations like the American Society for Quality (ASQ) offer certifications such as Certified Quality Manager (CQM/OE), Certified Quality Engineer (CQE), and Six Sigma belts (Green Belt, Black Belt). These credentials demonstrate expertise and commitment to the profession.

Choosing between graduate studies and certifications often depends on career goals. Certifications tend to be more focused on practical application, while degrees offer broader theoretical knowledge. Many professionals pursue both over their careers.

These courses cover methodologies often associated with advanced roles and certifications.

This handbook is a common resource for those pursuing ASQ Black Belt certification.

Industry-Specific Accreditation and Research

Certain industries have specific regulatory bodies or standards organizations that influence quality practices and sometimes require specific training or accreditation. For example, familiarity with Good Manufacturing Practices (GMP) is essential in pharmaceuticals and food production.

Staying current involves engaging with industry publications, attending conferences, and participating in professional organizations. These venues often discuss emerging trends, new regulations, and advancements in quality methodologies.

For those interested in pushing the boundaries of the field, research opportunities exist in universities and specialized institutes. Research focuses on developing new quality tools, refining statistical techniques, exploring AI applications in quality, or studying the impact of quality management on business performance.

Digital Learning Pathways for Quality Control

Online education offers flexible and accessible ways to acquire the knowledge and skills needed for a career in quality control, whether you're starting out or looking to advance.

Building Foundational Skills Online

Online courses are well-suited for learning the core concepts of quality control. Platforms like OpenCourser offer courses covering topics such as statistical process control, quality management systems (like ISO 9001), lean principles, and specific quality tools. These courses provide the theoretical underpinnings necessary for the field.

You can start with introductory courses on operations management or supply chain fundamentals to understand the broader context where quality control operates. Specialized courses can then delve into specific techniques or industry requirements.

Many online courses are designed by universities or industry experts, offering high-quality instruction. The flexibility allows learners to study at their own pace, making it ideal for working professionals seeking to upskill or individuals exploring a career change.

These courses provide broad overviews relevant to quality and operations.

Bridging Theory and Practice Virtually

A common concern with online learning is the lack of hands-on experience. However, many courses incorporate practical elements. This might include case studies, data analysis exercises using real-world scenarios, or simulations of quality control processes.

Some platforms offer project-based courses where learners apply concepts to solve a specific problem, such as designing a quality control plan or analyzing a dataset for defects. Building a portfolio of these projects can demonstrate practical application of learned skills to potential employers.

OpenCourser's "Activities" section on course pages can suggest supplementary projects or readings to deepen understanding. Learners can also seek out virtual internship opportunities or volunteer projects that allow them to apply quality principles in a real-world context, even remotely.

This course focuses on applying lean principles for continuous improvement, a practical skill.

Gaining Recognition with Online Credentials

Certificates earned from reputable online courses can enhance your resume and LinkedIn profile. They demonstrate initiative and a commitment to continuous learning. While they may not replace a traditional degree or extensive experience, they can be valuable supplements.

Employers increasingly recognize the value of skills gained through online education, especially for specific technical competencies. When choosing online courses, consider the reputation of the provider institution or instructor. Look for courses that offer assessments or projects to validate learning.

Effectively showcasing your online learning is key. OpenCourser's Learner's Guide offers tips on how to add certificates to your professional profiles. Clearly articulate the skills gained and how they apply to the Quality Control Manager role during job applications and interviews.

This course focuses on delivering quality work, a core competency.

Technological Tools for Modern Quality Control Managers

Technology is rapidly transforming the field of quality control, providing powerful tools for analysis, monitoring, and process improvement.

Statistical Process Control (SPC) Software

While manual charting is foundational, modern QC relies heavily on specialized software for Statistical Process Control (SPC). This software automates the collection, analysis, and visualization of process data, making it easier to monitor performance in real-time.

SPC software can generate various control charts (Xbar-R, p-charts, c-charts, etc.), calculate process capability indices (Cpk, Ppk), and perform statistical tests. This allows managers to quickly identify out-of-control conditions or shifts in process performance.

Integration with manufacturing execution systems (MES) or enterprise resource planning (ERP) systems allows for seamless data flow. Choosing and implementing the right SPC software, and training teams to use it effectively, are key responsibilities for a modern QC Manager.

These books cover statistical quality control methods often implemented using software.

AI and Machine Learning in Defect Prediction

Artificial Intelligence (AI) and Machine Learning (ML) are increasingly used for predictive quality analytics. By analyzing vast datasets from sensors, production logs, and even images, ML algorithms can identify complex patterns that precede defects.

This allows for proactive intervention before non-conforming products are even made. For example, AI-powered visual inspection systems can detect subtle flaws missed by human inspectors, and predictive maintenance algorithms can signal when equipment needs servicing to prevent quality issues.

While requiring specialized skills or collaboration with data scientists, understanding the potential and limitations of AI/ML is becoming important for QC Managers looking to leverage cutting-edge techniques for quality improvement.

This course touches upon advanced AI techniques in a related field.

IoT Integration in Real-Time Quality Monitoring

The Internet of Things (IoT) enables the connection of sensors and devices throughout the production process. These sensors can continuously monitor critical parameters like temperature, pressure, vibration, or chemical composition in real-time.

Data streamed from IoT devices provides an unprecedented level of visibility into process conditions. QC Managers can use this data to ensure processes remain within specification moment-to-moment, triggering alerts if parameters drift outside acceptable ranges.

Implementing IoT solutions requires careful planning regarding sensor selection, data security, and integration with existing systems. However, the potential for real-time control and richer data insights makes it a significant trend in modern quality management.

Blockchain for Supply Chain Quality Assurance

Blockchain technology offers potential applications in enhancing traceability and transparency within complex supply chains. By creating an immutable, shared ledger, blockchain can track products and components from source to final delivery.

This can improve quality assurance by verifying the authenticity of materials, tracking environmental conditions during transport (e.g., temperature for perishable goods), and providing a transparent record for audits and recalls.

While still an emerging application, understanding how blockchain can secure supply chain data and enhance quality verification is becoming relevant for QC Managers, especially in industries like pharmaceuticals, food, and high-value goods where provenance and traceability are critical.

Global Market Trends Impacting Quality Control Managers

The role of a Quality Control Manager is influenced by broader economic, technological, and societal trends shaping the global marketplace.

Impact of Globalization on Quality Standards

Globalization has led to complex, international supply chains. This increases the challenge of maintaining consistent quality across different suppliers, manufacturing locations, and regulatory environments. QC Managers need to navigate diverse cultural contexts and varying national standards.

There is a growing push towards harmonization of international standards, such as ISO 9001, to facilitate global trade and ensure baseline quality levels. QC Managers often play a role in implementing these global standards within their organizations and ensuring compliance across their supply networks.

Understanding international regulations, managing supplier quality globally, and adapting quality systems for diverse markets are increasingly important skills for professionals in this field.

Automation's Dual Effect on QC Job Markets

Automation presents both challenges and opportunities for quality control. Automated inspection systems (like machine vision) and robotic testing can perform certain QC tasks faster, more consistently, and sometimes more accurately than humans. This may reduce demand for some manual inspection roles.

However, automation also creates new needs. QC professionals are required to program, calibrate, maintain, and interpret the data from these automated systems. The focus shifts from manual inspection to managing quality systems, analyzing complex data sets generated by automation, and overseeing process control.

The U.S. Bureau of Labor Statistics provides outlook data for related fields. For example, the outlook for Industrial Production Managers, a field QC Managers might progress into, can offer insights, though specific QC data might vary. You can explore occupational outlooks on the BLS website.

This book discusses the broader impact of technology on work.

Emerging Markets with Growing QC Demand

As economies develop and industrialize, the demand for robust quality control systems increases. Emerging markets often represent growth opportunities for companies, but also require establishing quality standards and practices, sometimes from the ground up.

QC Managers with experience setting up quality systems, training local teams, and adapting standards to new environments may find opportunities in these growing regions. Understanding the specific challenges and regulatory landscapes of emerging markets is key.

Companies expanding globally need skilled professionals to ensure their brand reputation for quality is maintained consistently across all markets, driving demand for experienced QC personnel.

Sustainability-Driven Quality Requirements

Increasingly, quality is being linked to sustainability. Customers and regulators are demanding products that are not only high-quality but also produced in an environmentally and socially responsible manner. This adds new dimensions to the QC role.

QC Managers may become involved in verifying the sourcing of sustainable materials, monitoring environmental compliance in production processes, reducing waste through process optimization (a core tenet of Lean), and ensuring products meet eco-labeling standards.

Integrating sustainability metrics into the quality management system and reporting on environmental performance are becoming part of the expanded scope for quality professionals in many industries.

This course explores sustainable supply chains, an area intersecting with quality control.

Ethical Challenges in Quality Control Management

Quality Control Managers often face situations where ethical considerations are paramount. Navigating these challenges requires integrity and a strong commitment to quality principles.

Balancing Production Targets with Quality Standards

A common ethical tension arises between meeting production quotas or deadlines and upholding quality standards. Pressure from management or sales to ship products quickly can conflict with the need for thorough testing or addressing identified quality issues.

QC Managers must advocate for quality, clearly communicating the risks associated with compromising standards (e.g., safety issues, customer dissatisfaction, recalls, reputational damage). This requires courage and strong communication skills to influence decision-making based on data and potential consequences.

Establishing clear protocols for handling non-conforming products and empowering the QC team to halt production or shipments when necessary are crucial elements of an ethical quality system.

Whistleblowing Scenarios in Regulated Industries

In highly regulated industries like pharmaceuticals or aerospace, QC professionals may uncover serious compliance failures or safety risks. Deciding whether and how to report these issues internally or externally (whistleblowing) presents a significant ethical dilemma.

Organizations should have clear internal channels for reporting concerns without fear of retribution. However, if internal channels fail or the issue poses a significant public risk, external reporting might become an ethical obligation, despite potential personal or professional repercussions.

Understanding regulatory reporting requirements and company policies on ethical conduct is essential. Seeking guidance from professional organizations or legal counsel may be necessary in complex situations.

Cultural Differences in Quality Perception

In global operations, differing cultural perspectives can influence perceptions of quality and approaches to problem-solving. What constitutes acceptable quality or an effective corrective action might vary across regions or teams.

QC Managers working internationally need cultural sensitivity and adaptability. They must establish clear, objective quality standards while respecting local work practices where possible. Building trust and open communication across diverse teams is key to implementing a consistent global quality culture.

Misunderstandings can arise from communication styles or differing interpretations of procedures. Effective cross-cultural training and standardized documentation can help mitigate these challenges.

Data Integrity in Automated Reporting Systems

As quality control becomes more reliant on automated data collection and reporting, ensuring data integrity is a critical ethical responsibility. There can be temptations to manipulate data or reporting parameters to present a more favorable picture of quality performance.

QC Managers must ensure that data systems are secure, validated, and free from bias. They must foster a culture where accurate reporting is valued, even when the data indicates problems. Procedures for data verification, audit trails, and access control are essential.

Maintaining the trustworthiness of quality data is fundamental to the credibility of the QC function and the entire quality management system. Compromising data integrity undermines the basis for sound decision-making and continuous improvement.

Frequently Asked Questions (Career Focus)

Here are answers to some common questions individuals have when considering a career as a Quality Control Manager.

Can quality control experience transition to operations management?

Yes, definitely. Quality Control provides a deep understanding of production processes, problem-solving, data analysis, and team leadership – skills highly valuable in operations management. Many QC Managers transition into broader operational roles, leveraging their expertise in process improvement and efficiency.

How critical are Six Sigma certifications today?

Six Sigma certifications (Green Belt, Black Belt) remain highly regarded in many industries, particularly manufacturing and service sectors focused on process improvement. They demonstrate proficiency in a structured, data-driven methodology for reducing defects and variation. While not always mandatory, they can significantly enhance career prospects.

Is remote work feasible for QC Managers?

This depends heavily on the industry and specific role. While some aspects like data analysis, documentation review, and team coordination can be done remotely, direct oversight of physical production processes, hands-on inspections, and lab work often require an on-site presence. Hybrid arrangements are becoming more common, but fully remote QC Manager roles are less typical in manufacturing settings.

Which industry sectors have the highest demand for QC Managers?

Demand is strong across manufacturing (especially pharmaceuticals, medical devices, automotive, aerospace, electronics), food and beverage production, and construction. The increasing complexity of products, stringent regulations, and global supply chains continue to drive the need for skilled quality professionals in these areas.

How might AI impact the long-term career prospects for QC Managers?

AI is likely to automate some routine inspection and data analysis tasks, shifting the QC Manager's focus towards higher-level activities. This includes interpreting complex AI-driven insights, managing integrated quality systems, strategic planning, problem-solving complex issues identified by AI, and ensuring the ethical use of these technologies. Adaptability and a willingness to embrace new tools will be key.

Are there entrepreneurial paths leveraging QC expertise?

Yes. Experienced QC professionals can start consulting businesses, helping companies implement or improve their quality management systems. Others might develop specialized training programs or even launch businesses focused on specific quality-related products or services (e.g., calibration services, specialized testing labs).

Exploring a career as a Quality Control Manager means entering a field dedicated to excellence and continuous improvement. It demands technical skill, analytical thinking, and strong leadership. While challenging, it offers the reward of making tangible contributions to product safety, customer satisfaction, and organizational success. Whether you are starting your career journey or considering a pivot, the path offers diverse opportunities for growth and specialization. Utilize resources like OpenCourser's extensive catalog to find courses that can help build the necessary skills and knowledge for this vital profession.