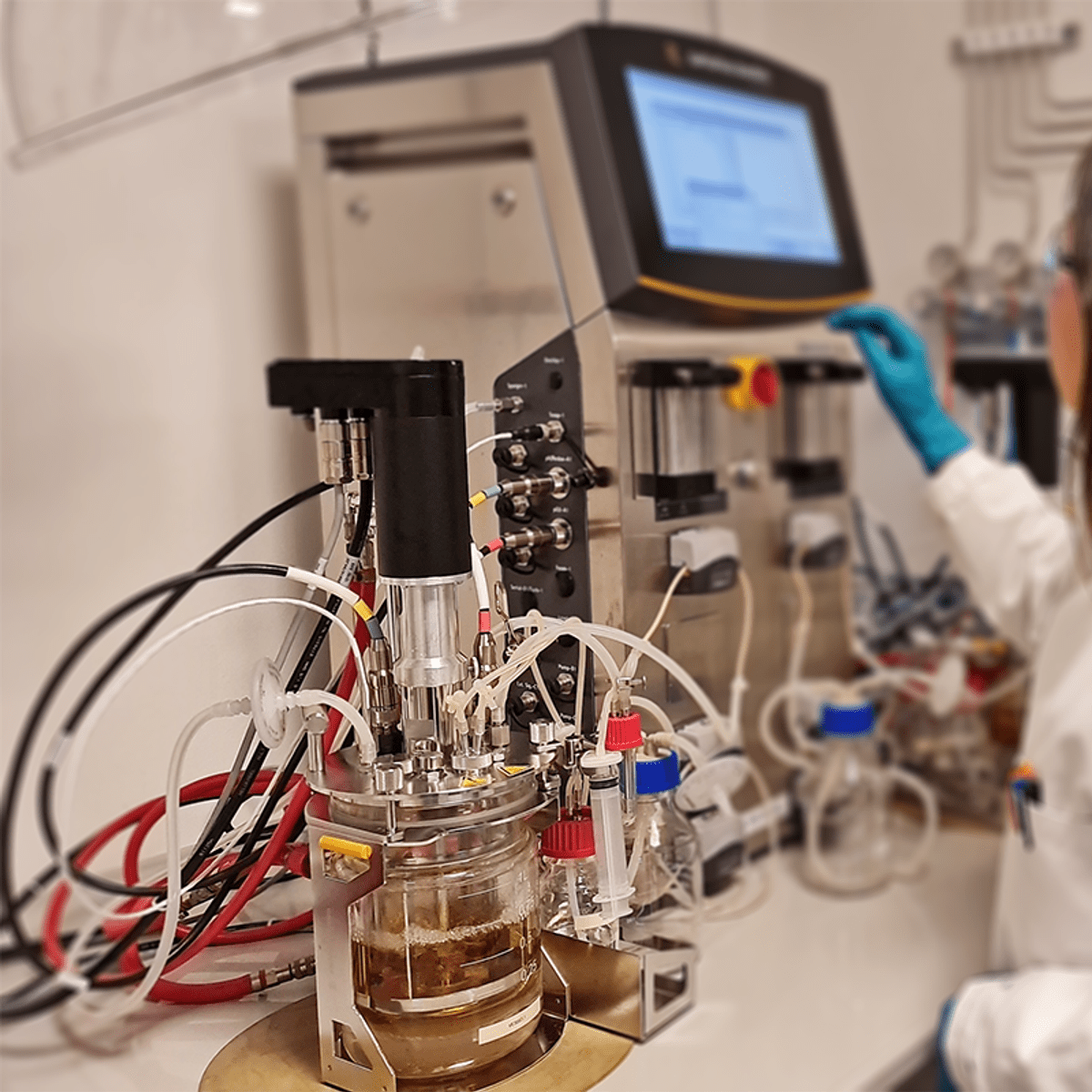

Bioprocesses make use of microorganisms, animal cells, or enzymes to manufacture new products or complete a chemical transformation. Since ancient days, humans have been using microorganisms to transform biological materials for the production of alcoholic beverages and other fermented foods. Since then, bioprocesses have been developed for an enormous range of commercial products, from relatively cheap products such as organic solvents and industrial alcohol, to expensive specialty chemicals such as therapeutic proteins, antibiotics, and vaccines. Nowadays, the development of bioprocesses is an essential part of a large number of chemical, food, and pharmaceutical industries.

Read more

Bioprocesses make use of microorganisms, animal cells, or enzymes to manufacture new products or complete a chemical transformation. Since ancient days, humans have been using microorganisms to transform biological materials for the production of alcoholic beverages and other fermented foods. Since then, bioprocesses have been developed for an enormous range of commercial products, from relatively cheap products such as organic solvents and industrial alcohol, to expensive specialty chemicals such as therapeutic proteins, antibiotics, and vaccines. Nowadays, the development of bioprocesses is an essential part of a large number of chemical, food, and pharmaceutical industries.

Bioprocesses make use of microorganisms, animal cells, or enzymes to manufacture new products or complete a chemical transformation. Since ancient days, humans have been using microorganisms to transform biological materials for the production of alcoholic beverages and other fermented foods. Since then, bioprocesses have been developed for an enormous range of commercial products, from relatively cheap products such as organic solvents and industrial alcohol, to expensive specialty chemicals such as therapeutic proteins, antibiotics, and vaccines. Nowadays, the development of bioprocesses is an essential part of a large number of chemical, food, and pharmaceutical industries.

The main purpose of the course “Introduction to Industrial Bioprocess Development” is to provide an overview of the common stages involved in this type of processes.

The course is primarily aimed at students, researchers, and professionals with an interest in bioprocessing, biomanufacturing, or fermentation technology. Some knowledge of biology, biotechnology and/or biochemical engineering will be advantageous, but not mandatory.

The course begins with a brief description of some basic properties of microorganisms and general aspects related to their use in bioprocesses at industrial scale. Following this, the kinetic bases for cell growth, substrate utilization and product formation during batch, continuous and fed-batch cultures are discussed. In addition, the course includes a group of lectures dedicated to some stages that precede fermentation; specifically, media formulation, sterilization, preservation of microorganisms and inoculum preparation. The main characteristics of predominant types of industrial bioreactors along with process parameters that need to be controlled in stirred tank reactors are also covered in one of the modules of the course. Since the expansion of a bioprocess from a lab scale to an industrial scale is of considerable importance, an additional lecture dedicated to this topic is presented. The last part of the course provides a general overview of downstream processing, addressing processes used for the removal of cells from the culture medium, methods for the disruption of cells, and isolation of the target bioproduct.

By the end of the course, you should:

# Be able to identify the fundamental difference between the two basic cell types: eukaryotic and prokaryotic cells

# Distinguish the main steps of the brewing process

# Identify some important steps in recombinant protein production

# Define the different stages of the industrial production of bioethanol

# Distinguish the main characteristics of the three fermentation modes: batch, continuous and fed-batch

# Define important parameters of the continuous fermentation mode

# Identify bioprocesses where fed-batch fermenters are used and for how long can a fed-batch process be run

# Identify how defined and undefined fermentation media are formulated

# Discuss the role that key components of culture media play in bioconversion processes

# Recognize the importance in avoiding microbial contamination

# Describe chemical and physical sterilization methods

# Distinguish the main characteristics of common techniques of cell preservation

# Recognize factors that are commonly considered to obtain an inoculum suitable for fermentation at industrial scale

# Define what a bioreactor is and in which industrial bioprocesses are commonly used

# Identify the main parameters that need to be controlled during microbial conversions in STRs

# List relevant parameters that are considered for scale-up purposes

# Define the sequential steps of downstream processing

# Distinguish different methods for biomass removal or cell harvesting

# Select common unit operations used for primary isolation

What's inside

Syllabus

Module 1 - Fundamentals of Microbial Bioreaction Design

In Module 1 you will find an introduction to some properties of microorganisms. Microorganisms are essential for the development of industrial bioprocesses. You will learn how they are used in fermentation processes for conversion of sugars into ethanol, e.g., for beer or vinegar production. Major discoveries during the 19th and 20th centuries that led to the bioproduction of antibiotics and chemicals on an industrial scale are also covered in this Module. A discussion on the use of recombinant proteins, metabolic engineering and commercial production of bioethanol is presented in the last part of the Module.

Read more

Syllabus

Good to know

Save this course

Activities

Compile a list of resources on bioprocessing

Show steps

Compiling a list of resources on bioprocessing will help you stay up-to-date on the latest developments in the field.

Show steps

-

Search for resources on bioprocessing online and in libraries.

-

Create a list of the most relevant and useful resources.

-

Organize the list by topic or type of resource.

Review molecular biology concepts

Show steps

Reviewing molecular biology concepts will help you understand the fundamentals of bioprocessing.

Browse courses on

Molecular Biology

Show steps

-

Read textbooks and articles on molecular biology.

-

Attend review sessions or workshops on molecular biology.

-

Take practice quizzes or exams on molecular biology.

Brush up on your microbiology skills

Show steps

Brushing up on your microbiology skills will help you understand the role of microorganisms in bioprocessing.

Browse courses on

Microbiology

Show steps

-

Review your microbiology notes or textbooks.

-

Take practice quizzes or exams on microbiology.

-

Attend a microbiology workshop or seminar.

Six other activities

Expand to see all activities and additional details

Show all nine activities

Read 'Bioprocess Engineering: Principles, Modeling, and Design'

Show steps

This book provides a comprehensive overview of bioprocess engineering principles and applications.

View

Bioprocess Engineering

on Amazon

Show steps

-

Read the book thoroughly.

-

Take notes and highlight important concepts.

-

Complete the practice problems at the end of each chapter.

Solve bioprocess engineering problems

Show steps

Solving bioprocess engineering problems will help you develop your problem-solving skills and apply your knowledge to practical scenarios.

Show steps

-

Find bioprocess engineering problems online or in textbooks.

-

Attempt to solve the problems on your own.

-

Check your solutions against the provided answer key or ask for help from a tutor or instructor.

-

Review your mistakes and identify areas where you need improvement.

Follow video tutorials on bioprocess design

Show steps

Following video tutorials on bioprocess design will provide you with visual demonstrations and practical insights into the design process.

Show steps

-

Search for video tutorials on bioprocess design online.

-

Watch the tutorials carefully and take notes.

-

Try to apply the concepts you learn to your own bioprocess design projects.

Design a bioprocess for a specific product

Show steps

Designing a bioprocess for a specific product will allow you to apply your knowledge and skills to a real-world scenario.

Show steps

-

Identify the product you want to produce.

-

Research the different bioprocesses that can be used to produce the product.

-

Design a bioprocess that meets your specific requirements.

-

Write a report that describes your design.

Mentor other students in bioprocessing

Show steps

Mentoring other students in bioprocessing will help you solidify your own understanding of the subject.

Show steps

-

Identify students who need help with bioprocessing.

-

Offer your help and schedule regular meetings.

-

Provide guidance and support on bioprocess engineering concepts and techniques.

Contribute to open-source bioprocessing projects

Show steps

Contributing to open-source bioprocessing projects will allow you to learn from and collaborate with others in the field.

Show steps

-

Identify open-source bioprocessing projects that align with your interests.

-

Join the project community and introduce yourself.

-

Find a task that you can contribute to and start working on it.

Compile a list of resources on bioprocessing

Show steps

Compiling a list of resources on bioprocessing will help you stay up-to-date on the latest developments in the field.

Show steps

- Search for resources on bioprocessing online and in libraries.

- Create a list of the most relevant and useful resources.

- Organize the list by topic or type of resource.

Review molecular biology concepts

Show steps

Reviewing molecular biology concepts will help you understand the fundamentals of bioprocessing.

Browse courses on

Molecular Biology

Show steps

- Read textbooks and articles on molecular biology.

- Attend review sessions or workshops on molecular biology.

- Take practice quizzes or exams on molecular biology.

Brush up on your microbiology skills

Show steps

Brushing up on your microbiology skills will help you understand the role of microorganisms in bioprocessing.

Browse courses on

Microbiology

Show steps

- Review your microbiology notes or textbooks.

- Take practice quizzes or exams on microbiology.

- Attend a microbiology workshop or seminar.

Read 'Bioprocess Engineering: Principles, Modeling, and Design'

Show steps

This book provides a comprehensive overview of bioprocess engineering principles and applications.

View

Bioprocess Engineering

on Amazon

Show steps

- Read the book thoroughly.

- Take notes and highlight important concepts.

- Complete the practice problems at the end of each chapter.

Solve bioprocess engineering problems

Show steps

Solving bioprocess engineering problems will help you develop your problem-solving skills and apply your knowledge to practical scenarios.

Show steps

- Find bioprocess engineering problems online or in textbooks.

- Attempt to solve the problems on your own.

- Check your solutions against the provided answer key or ask for help from a tutor or instructor.

- Review your mistakes and identify areas where you need improvement.

Follow video tutorials on bioprocess design

Show steps

Following video tutorials on bioprocess design will provide you with visual demonstrations and practical insights into the design process.

Show steps

- Search for video tutorials on bioprocess design online.

- Watch the tutorials carefully and take notes.

- Try to apply the concepts you learn to your own bioprocess design projects.

Design a bioprocess for a specific product

Show steps

Designing a bioprocess for a specific product will allow you to apply your knowledge and skills to a real-world scenario.

Show steps

- Identify the product you want to produce.

- Research the different bioprocesses that can be used to produce the product.

- Design a bioprocess that meets your specific requirements.

- Write a report that describes your design.

Mentor other students in bioprocessing

Show steps

Mentoring other students in bioprocessing will help you solidify your own understanding of the subject.

Show steps

- Identify students who need help with bioprocessing.

- Offer your help and schedule regular meetings.

- Provide guidance and support on bioprocess engineering concepts and techniques.

Contribute to open-source bioprocessing projects

Show steps

Contributing to open-source bioprocessing projects will allow you to learn from and collaborate with others in the field.

Show steps

- Identify open-source bioprocessing projects that align with your interests.

- Join the project community and introduce yourself.

- Find a task that you can contribute to and start working on it.

Career center

Biomanufacturing Scientist

Fermentation Scientist

Bioprocess Engineer

Bioprocess Technician

Biomanufacturing Operator

Regulatory Affairs Specialist

Quality Control Analyst

Project Manager

Business Development Manager

Sales and Marketing Specialist

Patent Attorney

Science Writer

Policy Analyst

Consultant

Research Scientist

Reading list

Share

Similar courses

OpenCourser helps millions of learners each year. People visit us to learn workspace skills, ace their exams, and nurture their curiosity.

Our extensive catalog contains over 50,000 courses and twice as many books. Browse by search, by topic, or even by career interests. We'll match you to the right resources quickly.

Find this site helpful? Tell a friend about us.

We're supported by our community of learners. When you purchase or subscribe to courses and programs or purchase books, we may earn a commission from our partners.

Your purchases help us maintain our catalog and keep our servers humming without ads.

Thank you for supporting OpenCourser.