Serial Communication

Comprehensive Guide to Serial Communication

Serial communication is a fundamental concept in the world of digital electronics and data transmission. At its core, it is the process of sending data one bit at a time, sequentially, over a communication channel or computer bus. This method is ubiquitous, forming the backbone of how many electronic devices, from simple microcontrollers to complex computer networks, exchange information. Understanding serial communication opens doors to a wide array of technological fields, including embedded systems, robotics, and the Internet of Things (IoT).

Working with serial communication can be quite engaging. Imagine designing a system where a sensor transmits temperature data to a microcontroller, which then displays it on an LCD screen – this often involves serial communication. Or picture yourself debugging data flowing between two devices, meticulously ensuring each bit arrives correctly. The ability to make different electronic components "talk" to each other is a powerful and rewarding skill. Furthermore, as technology evolves, the applications of serial communication continue to expand, offering continuous learning and innovation opportunities.

What is Serial Communication?

This section delves into the foundational knowledge of serial communication, helping you understand its core principles and relevance in modern technology.

Defining Serial Communication and Its Core Principles

Serial communication, in essence, is the method of transmitting data one single bit at a time over a communication channel. Think of it like a single-lane road where cars (bits of data) travel one after another. This sequential transmission typically requires only a few wires, often just two: one for transmitting (TX) and one for receiving (RX).

Several core principles govern how serial communication works. Baud rate is a crucial concept, representing the speed at which data bits are transmitted, measured in bits per second (bps). Both the sending and receiving devices must agree on the same baud rate for successful communication. Data is often organized into packets or frames, which include not only the actual data bits but also control bits like a start bit (signaling the beginning of a data packet) and a stop bit (signaling the end). Some protocols also include a parity bit for basic error checking.

Serial communication can be asynchronous, meaning there's no shared clock signal between the transmitter and receiver; timing is established using the start and stop bits within each data packet. Alternatively, it can be synchronous, where a separate clock line synchronizes the data transfer between devices.

Serial vs. Parallel Communication: A Comparative Look

To better understand serial communication, it's helpful to compare it with its counterpart: parallel communication. While serial communication sends data one bit at a time, parallel communication transmits multiple bits simultaneously over multiple channels (wires). Imagine a multi-lane highway where several cars can travel side-by-side – that's akin to parallel data transmission.

Historically, parallel communication offered faster data transfer rates because more data could be sent in the same amount of time. This made it suitable for short-distance applications like connecting printers to computers. However, parallel communication requires more wires, which increases cost, complexity, and the potential for signal interference (crosstalk) over longer distances.

Serial communication, on the other hand, uses fewer wires, making it more cost-effective, less susceptible to interference over long distances, and simpler to implement in terms of hardware. While traditionally slower, advancements in serial technology have led to very high-speed serial interfaces (like USB and Ethernet) that now often surpass the speeds of older parallel interfaces for many applications. This is why serial communication is dominant in long-haul communication and most computer networks.

A Brief History: The Evolution of Serial Communication

The roots of serial communication can be traced back to early telegraphy systems in the 19th century, which sent messages bit by bit over long wires. The concept evolved with the advent of teletypewriters and early computer systems. One of the most influential early standards for serial communication was RS-232, introduced in 1960. RS-232 defined the electrical characteristics, signal timing, and mechanical connectors for communication between Data Terminal Equipment (DTE), like computers or terminals, and Data Circuit-Terminating Equipment (DCE), like modems. For many years, RS-232 serial ports were a standard feature on personal computers, used for connecting to modems, printers, mice, and other peripherals.

Over time, other serial protocols emerged to address different needs. For instance, within electronic devices and for communication between integrated circuits (ICs) on the same circuit board, protocols like SPI (Serial Peripheral Interface) and I2C (Inter-Integrated Circuit) became popular. These protocols are designed for short-distance communication and are widely used in embedded systems.

While dedicated serial ports like RS-232 have become less common on consumer PCs, largely replaced by USB (Universal Serial Bus) and Ethernet (which are themselves forms of serial communication), the underlying principles of serial data transfer remain fundamental to modern technology. USB, for example, sends data serially but at much higher speeds and with more sophisticated protocols than traditional RS-232.

Ubiquitous Applications: Serial Communication in the Modern World

Serial communication is deeply embedded in a vast range of modern technologies, often working silently in the background. Many consumer electronics still rely on it internally. For instance, microcontrollers in appliances, toys, and automotive systems frequently use serial protocols like UART, SPI, or I2C to communicate with sensors, displays, and other peripheral components.

In industrial settings, serial communication remains crucial. Industrial automation systems often use RS-485, a robust serial standard suitable for noisy environments and longer distances, to connect PLCs (Programmable Logic Controllers), sensors, and actuators. Scientific instruments and point-of-sale systems also frequently utilize serial interfaces.

The Internet of Things (IoT) heavily relies on various forms of serial communication. Low-power wireless communication protocols, which are essential for many IoT devices, often transmit data serially. Even wired connections between IoT modules and sensors commonly employ serial interfaces. Furthermore, networking hardware like routers and switches often have serial console ports for configuration and diagnostics.

You can explore introductory courses on platforms like OpenCourser in the Computer Science category to find resources that touch upon these fundamental communication principles.

Technical Standards and Protocols

This section provides an overview of key serial communication standards and protocols, essential for anyone looking to implement or work with serial systems.

Key Protocols: RS-232, UART, SPI, and I2C

Several standard protocols define how serial communication is implemented. Understanding these is crucial for anyone working with hardware and embedded systems.

RS-232 (Recommended Standard 232) is one of the oldest and most well-known serial communication standards. It defines the voltage levels, signal timing, and pinouts for communication, typically between a DTE (Data Terminal Equipment, e.g., a computer) and a DCE (Data Circuit-Terminating Equipment, e.g., a modem). RS-232 uses relatively large voltage swings (e.g., +3V to +15V for a logic 0 and -3V to -15V for a logic 1), which can make it robust over short to moderate distances but also limits its maximum speed and cable length. While less common on modern consumer PCs, it's still found in industrial equipment and legacy systems.

UART (Universal Asynchronous Receiver/Transmitter) is not a communication protocol in the same way as RS-232, but rather a piece of hardware (an integrated circuit or part of a microcontroller) that implements asynchronous serial communication. UARTs handle the conversion of parallel data from a CPU into a serial stream for transmission and convert incoming serial streams back into parallel data. They manage the addition of start, stop, and optional parity bits. The actual electrical signaling levels (e.g., TTL or RS-232 levels) are determined by other circuitry connected to the UART. Many microcontrollers have built-in UARTs for serial communication.

SPI (Serial Peripheral Interface) is a synchronous serial communication interface used for short-distance communication, primarily in embedded systems. It uses a master-slave architecture where a single master device controls one or more slave devices. SPI typically requires four wires: SCLK (Serial Clock, generated by the master), MOSI (Master Out Slave In, for data from master to slave), MISO (Master In Slave Out, for data from slave to master), and SS (Slave Select, for the master to select a specific slave). SPI is full-duplex, meaning data can be sent and received simultaneously, and can achieve high data rates.

I2C (Inter-Integrated Circuit), often pronounced "I-squared-C," is another synchronous serial protocol designed for communication between ICs on a single board. It uses only two wires: SDA (Serial Data) and SCL (Serial Clock). I2C supports multiple masters and multiple slaves on the same bus, and each device has a unique address. Data rates are generally slower than SPI but faster than standard UART speeds. I2C is widely used for connecting lower-speed peripherals like sensors, real-time clocks, and EEPROMs to microcontrollers.

These courses can help build a foundation in understanding and working with these common protocols:

The following book offers a good introduction to the broader field where these protocols are often applied:

Signal Timing and Voltage Specifications

Signal timing and voltage levels are fundamental aspects that define how bits are represented and interpreted in serial communication. Different standards have different specifications.

In asynchronous communication (like that handled by a UART), timing is critical. Since there's no shared clock line, both devices rely on the agreed-upon baud rate and the start/stop bits to synchronize. The start bit signals the receiver to start sampling the incoming data bits at intervals determined by the baud rate. The stop bit signals the end of the frame. If the clocks of the transmitter and receiver drift too much relative to each other, errors can occur.

In synchronous communication (like SPI and I2C), a dedicated clock line (SCLK or SCL) dictates when data bits are transmitted and sampled. For SPI, the master generates the clock signal. The clock polarity (CPOL) and clock phase (CPHA) are configurable settings that determine whether data is sampled on the rising or falling edge of the clock and the idle state of the clock. For I2C, the master also generates the clock, but slaves can perform "clock stretching" by holding the SCL line low to indicate they need more time before the next bit is transferred.

Voltage specifications also vary. TTL (Transistor-Transistor Logic) levels are common in microcontroller-to-microcontroller or IC-to-IC communication. A logic '0' is typically represented by a voltage close to 0V (GND), and a logic '1' by a voltage close to the microcontroller's supply voltage (e.g., 3.3V or 5V).

RS-232, as mentioned, uses higher and bipolar voltage levels. A logic '1' (mark state) is a negative voltage (typically -3V to -15V), and a logic '0' (space state) is a positive voltage (typically +3V to +15V). The range between -3V and +3V is undefined. This larger voltage swing provides better noise immunity but requires specific driver and receiver ICs (like MAX232) to interface with TTL-level devices.

I2C typically uses voltage levels determined by pull-up resistors connected to the SDA and SCL lines. The lines are pulled high to the supply voltage, and devices pull them low to transmit a '0'. This open-drain configuration allows multiple devices to share the bus.

Detecting and Correcting Errors

Data transmitted over any communication channel can be susceptible to errors due to noise or other forms of interference. Serial communication protocols often include mechanisms for error detection, and some advanced systems might implement error correction.

A common and simple form of error detection is the parity bit. During configuration, "even parity" or "odd parity" is chosen. For even parity, the parity bit is set to make the total number of '1's in the data bits (plus the parity bit itself) an even number. For odd parity, it's set to make the total number of '1's odd. The receiver checks the parity. If it doesn't match the expected parity, an error is detected. However, parity checking can only detect an odd number of bit errors; an even number of bit errors might go undetected. It also cannot correct errors.

Checksums are another error detection method. The sender calculates a checksum value based on the data being sent (e.g., by summing the data bytes) and transmits this checksum along with the data. The receiver performs the same calculation on the received data and compares its result with the received checksum. If they don't match, an error has occurred. Checksums are more robust than simple parity bits and can detect more types of errors.

Cyclic Redundancy Check (CRC) is a more powerful error detection technique. It treats the block of data bits as a binary polynomial and performs a polynomial division with a predefined generator polynomial. The remainder of this division is the CRC, which is appended to the data and transmitted. The receiver performs the same division. If the remainder is zero (or matches an expected value), the data is likely error-free. CRCs are very effective at detecting common types of transmission errors, including burst errors (multiple consecutive bit errors).

While these methods primarily detect errors, error correction is more complex. Some advanced coding schemes, like Hamming codes, can not only detect but also correct a certain number of bit errors by adding more redundant bits. In many serial communication systems, if an error is detected, the common approach is to request a retransmission of the data (Automatic Repeat reQuest, ARQ).

Choosing the Right Protocol for the Job

Selecting the appropriate serial communication protocol depends heavily on the specific requirements of the application. There's no one-size-fits-all solution.

Consider the number of devices involved. If you need to connect many peripheral devices to a single master, I2C might be a good choice due to its addressing scheme and use of only two wires. SPI can also support multiple slaves, but each slave typically requires a separate chip select line from the master, which can consume more I/O pins on the master device if many slaves are present. UART is primarily for point-to-point communication between two devices.

Data transfer speed is another critical factor. SPI is generally the fastest of the common microcontroller-level protocols, making it suitable for applications requiring high throughput, such as interfacing with displays or high-speed ADCs. I2C speeds are moderate, typically up to 400kHz or 1MHz, with some newer modes going faster. Standard UART speeds can vary widely but are often lower than SPI or I2C, though high-speed UARTs exist.

The distance of communication plays a role. RS-232 can cover moderate distances (e.g., up to 15 meters or more depending on baud rate and cabling). RS-485 (another serial standard, not detailed here but related) is designed for longer distances and more robust communication in noisy industrial environments. SPI and I2C are intended for short-distance communication, typically on the same PCB or between closely connected boards.

Number of wires/pins required is often a constraint, especially in pin-limited microcontrollers. I2C shines here with only two wires. UART typically uses two data wires (TX and RX). SPI needs at least three (SCLK, MOSI, MISO) plus one for each slave (SS).

Communication complexity and software overhead are also considerations. UART is relatively simple to implement. SPI and I2C involve more complex state machines and addressing (for I2C).

Finally, consider whether full-duplex (simultaneous send and receive) or half-duplex (devices take turns sending and receiving) communication is needed. SPI is full-duplex. I2C is half-duplex. Standard UART communication with separate TX and RX lines is full-duplex.

Hardware Implementation

This section explores the practical aspects of building serial communication interfaces, including circuit design, components, and troubleshooting.

Designing Circuits for Serial Interfaces

Designing circuits for serial interfaces involves selecting appropriate components and ensuring proper connections based on the chosen protocol and voltage levels. For basic TTL-level serial communication (common with UARTs on microcontrollers), the design can be straightforward. The TX pin of one device connects to the RX pin of the other, and vice-versa. A common ground connection is also essential.

When interfacing with RS-232 devices, level shifter ICs like the MAX232 or similar are necessary if your microcontroller operates at TTL levels (e.g., 3.3V or 5V). These ICs convert the microcontroller's TTL signals to the higher positive and negative voltage levels required by RS-232 and vice-versa. The circuit will typically include capacitors required by the charge pump within the level shifter IC to generate the RS-232 voltages.

For I2C, the circuit requires pull-up resistors on both the SDA (data) and SCL (clock) lines. These resistors pull the lines high when no device is actively pulling them low. The value of these resistors (typically in the range of 1 kΩ to 10 kΩ) depends on the bus capacitance and the desired speed. Both lines are connected to all devices (master and slaves) on the I2C bus.

SPI circuit design involves connecting the SCLK, MOSI, and MISO lines between the master and all slaves. Each slave also needs a dedicated SS (Slave Select) line from the master. When the master wants to communicate with a specific slave, it asserts (usually pulls low) that slave's SS line.

For those interested in the practical side of connecting devices, courses focusing on platforms like Arduino and Raspberry Pi often cover serial communication implementations.

Key Components: Transceivers and Wiring

The term transceiver is a portmanteau of transmitter and receiver. In the context of serial communication, a transceiver is a device or circuit that can both send and receive serial data. UARTs themselves are often referred to as transceivers because they have separate transmit and receive functionalities. For protocols like RS-232, RS-422, or RS-485, dedicated transceiver ICs are used. These chips handle the electrical characteristics of the bus, such as converting logic levels and providing the necessary drive current.

Wiring is a critical aspect. As mentioned, for simple UART communication, a crossover connection is used: TX of device A to RX of device B, and RX of device A to TX of device B. A shared ground is also vital. Incorrect wiring (e.g., TX to TX) will prevent communication and could potentially damage devices in some cases, though many modern devices have protection circuitry.

For I2C, both SDA and SCL lines are shared among all devices on the bus. The pull-up resistors are typically placed once per bus. For SPI, SCLK, MOSI, and MISO are shared, while SS lines are individual to each slave.

Connectors also play a role. While direct wiring is common on PCBs, external serial connections use various connectors. The DB9 (9-pin D-subminiature) connector was very common for RS-232 ports on PCs. Industrial systems might use terminal blocks for more robust connections. Modern devices often use USB connectors, which carry serial data according to the USB protocol. Internally, many development boards and modules use simple header pins for accessing UART, SPI, or I2C interfaces.

Understanding the pinouts of microcontrollers is fundamental for wiring serial interfaces. These courses provide detailed insights into specific microcontroller families:

Ensuring Signal Integrity

Signal integrity refers to the quality of an electrical signal as it travels from a transmitter to a receiver. Poor signal integrity can lead to data errors. Several factors can affect signal integrity in serial communication.

Noise is a major culprit. Electromagnetic Interference (EMI) from nearby sources (motors, power lines, other electronic devices) can corrupt signals. Using shielded cables can help reduce EMI. Proper grounding techniques are also essential to minimize noise.

Cable length and quality are important. Longer cables have higher resistance and capacitance, which can degrade signals, especially at higher baud rates or clock frequencies. The RS-232 standard, for example, specifies a maximum capacitive load rather than a fixed maximum cable length, recognizing that cable characteristics vary. Using appropriate quality cables designed for the specific communication standard and speed is recommended.

Impedance matching can be crucial for high-speed serial links, though it's less of a concern for lower-speed protocols like standard UART or I2C on a PCB. If the impedance of the transmission line (cable) doesn't match the impedance of the transmitter and receiver, signal reflections can occur, distorting the signal.

Termination resistors are sometimes used, particularly in longer or higher-speed buses like RS-485 or high-speed CAN bus, to prevent signal reflections from the ends of the bus. For I2C, the pull-up resistors also serve a role in defining the line impedance and ensuring proper signal levels.

Crosstalk can occur when signals in adjacent wires interfere with each other. This is more of a concern in parallel buses with many closely packed wires but can also affect serial cables if not properly designed or shielded, especially at high frequencies.

Careful PCB layout is also vital for maintaining signal integrity for on-board serial communication. This includes keeping trace lengths short, avoiding sharp bends in traces, providing a solid ground plane, and routing sensitive signal lines away from noisy components.

Troubleshooting Common Hardware Issues

When serial communication isn't working, hardware issues are often the first place to check. A systematic approach to troubleshooting can save a lot of time.

Check Wiring: This is the most common source of problems.

- Are TX and RX lines correctly connected (TX to RX, RX to TX for UART)?

- Is there a solid common ground connection between the devices?

- For I2C, are pull-up resistors present and correctly valued/connected?

- For SPI, are MOSI, MISO, SCLK, and SS lines all correctly wired?

- Are there any loose connections, broken wires, or bad solder joints?

Verify Voltage Levels: Ensure that the voltage levels are compatible between the communicating devices.

- If one device is 3.3V and the other is 5V, is level shifting being used where necessary? Direct connection can damage the lower voltage device or simply not work.

- For RS-232, are the correct positive and negative voltage swings present on the lines? A multimeter or oscilloscope can verify this.

Use an Oscilloscope or Logic Analyzer: These tools are invaluable for debugging serial communication.

- An oscilloscope can show you the actual waveforms on the TX, RX, SCL, or SDA lines. You can see if signals are present, if their voltage levels are correct, and if the timing looks reasonable (e.g., baud rate).

- A logic analyzer can capture and decode the digital data being transmitted, showing you the start bits, data bits, stop bits, and any addresses or control information for protocols like I2C and SPI. This can quickly reveal if data is being sent at all, if it's corrupted, or if protocol violations are occurring.

Check for Component Failure: While less common, ICs like UARTs, level shifters, or transceivers can fail. If you suspect a component, try replacing it if possible. Static discharge can damage these components, so proper handling is important.

Simplify the System: If you have multiple devices on a bus (like I2C or SPI with multiple slaves), try communicating with just one device first to isolate the problem.

Power Supply Issues: Ensure all devices have a stable and adequate power supply. Noise or fluctuations on the power lines can interfere with communication.

For practical experience, consider courses that involve hands-on hardware projects:

Software Development for Serial Systems

Effective serial communication relies not just on hardware but also on well-crafted software to manage data transmission, reception, and processing. This section delves into the software aspects.

Leveraging Serial Communication Libraries and APIs

Most programming languages and development environments used for embedded systems or PC applications offer libraries or Application Programming Interfaces (APIs) to simplify serial communication. These libraries abstract away many of the low-level hardware details, allowing developers to focus on sending and receiving data.

For microcontroller development (e.g., using C or C++ for Arduino, ARM microcontrollers, etc.), manufacturers often provide Hardware Abstraction Layers (HALs) or specific driver libraries for on-chip UART, SPI, and I2C peripherals. These libraries typically provide functions to:

- Initialize the serial port (set baud rate, data bits, parity, stop bits for UART; configure clock speed, mode for SPI/I2C).

- Send data (a single byte, an array of bytes, or a string).

- Receive data (check if data is available, read a byte, read a block of data).

- Handle interrupts for received data, allowing the system to perform other tasks while waiting for incoming communication.

On desktop operating systems (like Windows, macOS, or Linux), programming languages such as Python, Java, C#, and C++ have libraries for accessing serial ports (often appearing as COM ports on Windows or /dev/tty devices on Linux/macOS). Python's `pySerial` library is a popular choice for its ease of use in scripting and testing serial devices. These libraries allow applications to open a serial port, configure its parameters, and then read from or write to it as if it were a file stream.

Using these libraries correctly involves understanding their specific functions, error handling mechanisms, and how they manage buffers for incoming and outgoing data. The documentation for the chosen library or HAL is an essential resource.

Many online courses introduce programming with a focus on hardware interaction, where serial communication is a common topic.

To get a grasp of programming languages often used in this domain, you might find these resources useful:

Configuring Baud Rate and Flow Control

Proper configuration of baud rate and flow control is essential for reliable asynchronous serial communication (typically via UART).

Baud Rate: As discussed earlier, the baud rate is the speed of data transmission in bits per second. Both the transmitting and receiving devices must be configured to use the same baud rate. If there's a mismatch, the receiver will misinterpret the timing of the bits, leading to garbled data or complete communication failure. Common baud rates include 9600, 19200, 38400, 57600, and 115200 bps, but many others are possible. The choice of baud rate depends on the capabilities of the devices and the required data throughput.

Data Bits, Parity, and Stop Bits: Besides the baud rate, other parameters of the serial frame must match:

- Data Bits: The number of actual data bits in each frame (commonly 7 or 8).

- Parity: The type of error checking used (None, Even, or Odd).

- Stop Bits: The number of bits signaling the end of a frame (commonly 1 or 2).

A common configuration is "8N1" (8 data bits, No parity, 1 stop bit). All these settings must be identical on both ends of the communication link.

Flow Control: Flow control mechanisms prevent the sender from overwhelming the receiver with data faster than it can process. If the receiver's input buffer fills up, incoming data can be lost.

- Software Flow Control (XON/XOFF): This method uses special control characters (XON and XOFF) sent over the data lines themselves. If the receiver's buffer is getting full, it sends an XOFF character to the transmitter to pause sending. When the buffer has space again, it sends an XON character to resume. This method consumes some of the data bandwidth for control characters.

- Hardware Flow Control (RTS/CTS): This method uses separate hardware lines, typically Request to Send (RTS) and Clear to Send (CTS). When the receiver is ready for data, it asserts its CTS line. The transmitter will only send data if its RTS line is asserted (indicating it wants to send) and it sees CTS asserted by the receiver. This is generally more reliable than software flow control but requires extra wires.

Not all devices or serial interfaces support flow control, or they may support only one type. If flow control is used, it must be enabled and configured correctly on both devices.

Navigating Cross-Platform Development Challenges

Developing software for serial communication that needs to run on different operating systems or hardware platforms can present challenges. While the underlying serial protocols (like RS-232, SPI, I2C) are standards, the way they are accessed and managed at the software level can vary significantly.

Serial Port Naming Conventions: Operating systems use different names for serial ports. Windows uses "COM1", "COM2", etc. Linux and macOS use file-like paths in the /dev directory, such as "/dev/ttyS0" (for hardware UARTs) or "/dev/ttyUSB0" (for USB-to-serial adapters). Software that needs to be cross-platform must be able to detect or allow configuration of the correct port name for the target system.

Driver Availability and Compatibility: USB-to-serial adapter chips (e.g., from FTDI, Prolific, Silicon Labs) are common, but they require drivers. While modern OSes often have built-in drivers for many common chips, sometimes specific drivers need to be installed, or older chips may not be supported on newer OS versions. This can be a source of frustration for end-users.

API Differences: The system calls and library functions for accessing serial ports differ between operating systems. For example, on POSIX-compliant systems (like Linux and macOS), serial ports are often treated like files, and functions like `open()`, `read()`, `write()`, and `ioctl()` (for configuring parameters) are used. Windows has its own set of API functions (e.g., `CreateFile()`, `ReadFile()`, `WriteFile()`, `SetCommState()`). Cross-platform libraries (like Python's `pySerial` or QtSerialPort for C++) help abstract these differences but may not always expose every platform-specific feature.

Timing and Buffering Behavior: The way operating systems buffer serial data and the timing precision of serial operations can vary. This might affect applications that are highly sensitive to latency or require precise timing for sending or receiving data. Real-time operating systems (RTOS) used in embedded systems often provide more deterministic behavior for serial I/O compared to general-purpose OSes.

Hardware Access for SPI/I2C: When developing on a general-purpose computer (like a PC or Raspberry Pi) to communicate with SPI or I2C devices, you're typically going through the OS's driver model. On Linux, for instance, I2C devices appear as `/dev/i2c-N` and SPI devices as `/dev/spidevX.Y`. Accessing these requires appropriate permissions and using specific `ioctl` calls. This is different from direct register access on a microcontroller.

Developing robust cross-platform serial communication software often involves using higher-level libraries that handle these platform-specific details or writing conditional compilation code (#ifdefs in C/C++) to use the correct APIs for each target platform.

Techniques for Real-Time Data Processing

Many applications involving serial communication require processing data in real-time or near real-time. This is especially true in control systems, data acquisition, and robotics. Several techniques are employed to handle this efficiently.

Interrupt-Driven I/O: Instead of constantly polling the serial port to see if new data has arrived (which wastes CPU cycles), interrupt-driven I/O is preferred. When a byte or a predefined amount of data arrives at the UART, it generates an interrupt. The CPU then temporarily suspends its current task and executes an Interrupt Service Routine (ISR). The ISR typically reads the incoming data from the UART's hardware buffer and places it into a software buffer (e.g., a circular buffer or FIFO) for the main application to process later. This ensures that incoming data is captured promptly without the main program having to wait for it.

Buffering: Software buffers are crucial. Incoming data from the serial port is stored in a buffer until the main application is ready to process it. This decouples the timing of data arrival from the timing of data processing. Circular buffers are commonly used because they efficiently manage a fixed-size memory space for streaming data.

Non-Blocking I/O: When the main application needs to read data from the buffer, it can use non-blocking read operations. This means the read function checks if data is available and returns immediately, either with the available data or an indication that no data is present. This prevents the main application from getting stuck waiting for serial data if none has arrived.

Dedicated Threads or Tasks: In more complex applications, especially those running on an OS or RTOS, a dedicated thread or task might be responsible for handling serial communication. This thread can block (wait) for incoming data without affecting the responsiveness of other parts of the system (like a user interface or control loops). When data arrives, this thread processes it or passes it to other threads/tasks via inter-process communication mechanisms (queues, semaphores, etc.).

Data Framing and Parsing: Often, the raw serial data stream needs to be parsed to extract meaningful messages or data packets. This might involve looking for specific start and end markers, checking checksums or CRCs, and then converting the payload into the appropriate data types. Efficient parsing algorithms are important, especially for high-speed data streams.

Direct Memory Access (DMA): For very high-speed serial communication, DMA can be used. DMA allows the serial peripheral (e.g., UART, SPI) to transfer data directly to or from memory without involving the CPU for each byte. This significantly reduces CPU overhead and is common in applications like streaming audio or video data or high-frequency sensor readings.

These techniques help ensure that serial data is handled promptly and efficiently, which is vital for applications where timely responses or continuous data logging are critical.

Education Pathways

For those interested in pursuing expertise in serial communication, often as part of a broader education in electronics or computing, several educational pathways exist.

University Programs in Electrical and Computer Engineering

A traditional route to gaining a deep understanding of serial communication and the systems that use it is through university programs in Electrical Engineering (EE) or Computer Engineering (CE). These degree programs typically provide a strong theoretical foundation in electronics, digital logic, computer architecture, and embedded systems, all of which are relevant to serial communication.

Core courses in an EE or CE curriculum that would cover aspects of serial communication include:

- Digital Logic Design: Understanding gates, flip-flops, and the building blocks of digital circuits, which form the basis of how UARTs, SPI, and I2C controllers are constructed.

- Microprocessor/Microcontroller Systems: Learning about the architecture of microcontrollers, their peripheral interfaces (including serial ports), and how to program them. This is where students often get their first hands-on experience with UART, SPI, and I2C.

- Embedded Systems Design: Courses focusing on the design and implementation of systems built around microcontrollers, where communication between components is a key aspect.

- Computer Networks/Data Communications: While often focused on higher-level networking, these courses cover fundamental principles of data transmission, encoding, error detection, and protocols, many of which apply to serial communication at a lower level.

- Computer Architecture: Understanding how different parts of a computer system communicate, including I/O interfaces. You can find related courses on OpenCourser's Computer Science section.

Many university programs also offer specializations or elective courses in areas like VLSI design (for those interested in designing the ICs themselves), communication systems, or robotics, all of which heavily utilize serial communication principles.

The following topics are closely related and often studied in conjunction with serial communication in university settings:

Specialized Certifications in Embedded Systems

Beyond traditional university degrees, specialized certifications can demonstrate proficiency in embedded systems, an area where serial communication skills are paramount. While not always a strict requirement for employment, certifications can enhance a resume and validate specific knowledge and skills, which can be particularly helpful for career changers or those looking to specialize.

Several organizations and companies offer certifications related to embedded systems or specific microcontroller architectures (e.g., ARM, Microchip PIC, etc.). These certification programs often involve training courses and exams that cover topics like:

- Microcontroller architecture and programming.

- Interfacing with peripherals, including extensive work with serial communication protocols like UART, SPI, and I2C.

- Real-time operating systems (RTOS).

- Debugging and testing embedded systems.

- Low-level driver development.

Some certifications might focus on particular industries, such as automotive embedded systems or IoT device development. Researching certifications relevant to your specific career interests in the embedded field is advisable. While OpenCourser primarily focuses on courses and books, professional organizations in electrical engineering or embedded systems often list or endorse relevant certification programs.

For those looking to solidify their understanding, particularly in the realm of microcontrollers which are central to embedded systems, these courses could be beneficial:

The Importance of Hands-On Lab Work

Theoretical knowledge of serial communication is important, but practical, hands-on experience is indispensable. Lab work provides the opportunity to apply concepts, troubleshoot real-world problems, and develop a deeper intuition for how these systems work.

In university EE/CE programs, labs are an integral part of courses on microcontrollers and embedded systems. Students typically work with development boards (like those based on Arduino, Raspberry Pi, STM32, PIC, etc.), sensors, actuators, and displays. Lab assignments often involve:

- Configuring UART peripherals to send and receive data between a microcontroller and a PC or another microcontroller.

- Implementing SPI communication to interface with devices like EEPROMs, ADCs/DACs, or sensor modules.

- Setting up an I2C bus to communicate with multiple sensors or real-time clocks.

- Using an oscilloscope or logic analyzer to observe serial signals, verify timing, and debug communication issues.

- Writing firmware to handle data packets, implement simple protocols, and manage communication flow.

These practical exercises are where students truly learn the nuances of baud rate settings, voltage level compatibility, noise issues, protocol-specific timings (like I2C acknowledgments or SPI chip selects), and the art of debugging when things don't work as expected. This hands-on experience is highly valued by employers.

Even for self-learners, engaging in projects with affordable development kits is crucial for building practical skills. Many online tutorials and project guides are available to facilitate this.

Integration with IoT and Robotics Curricula

Serial communication is a cornerstone technology in the rapidly growing fields of the Internet of Things (IoT) and Robotics. As such, curricula focused on these areas heavily integrate the study and application of serial protocols.

In IoT curricula:

- Understanding how sensors (temperature, humidity, motion, GPS, etc.) communicate their data to microcontrollers or single-board computers is fundamental. Many of these sensors use I2C or SPI for low-power, short-distance communication.

- UART communication is often used for debugging (e.g., printing status messages to a serial console) or for connecting to cellular, Wi-Fi, or Bluetooth modules that bridge the IoT device to a network.

- Low-power wide-area network (LPWAN) technologies like LoRaWAN and NB-IoT, while wireless, often involve microcontrollers communicating with the radio transceivers via serial interfaces (UART or SPI) to send and receive data packets.

In Robotics curricula:

- Robots are complex systems of interconnected components: motors, sensors (LIDAR, cameras, encoders, IMUs), controllers, and actuators. Serial communication is extensively used for these interconnections.

- Microcontrollers controlling motors often receive commands (e.g., speed, direction) via UART or CAN bus (another serial protocol common in automotive and robotics).

- Sensors provide data to the main robot controller using SPI, I2C, or UART. For example, an Inertial Measurement Unit (IMU) might send orientation data over I2C or SPI.

- Communication between different processing units within a robot (e.g., a main computer and specialized motor controllers) might also use serial links.

Therefore, students specializing in IoT or robotics will inevitably spend significant time learning about and implementing various serial communication methods. The skills gained are directly transferable to designing and building functional IoT devices and robotic systems.

The following topics are highly relevant to these fields and build upon a strong understanding of serial communication:

This course offers a practical look at combining popular platforms used in IoT and robotics:

Online Learning Resources

For those who prefer self-paced learning or wish to supplement formal education, a wealth of online resources is available to master serial communication. These platforms and tools empower learners to gain practical skills independently.

Experimenting with Open-Source Hardware Platforms

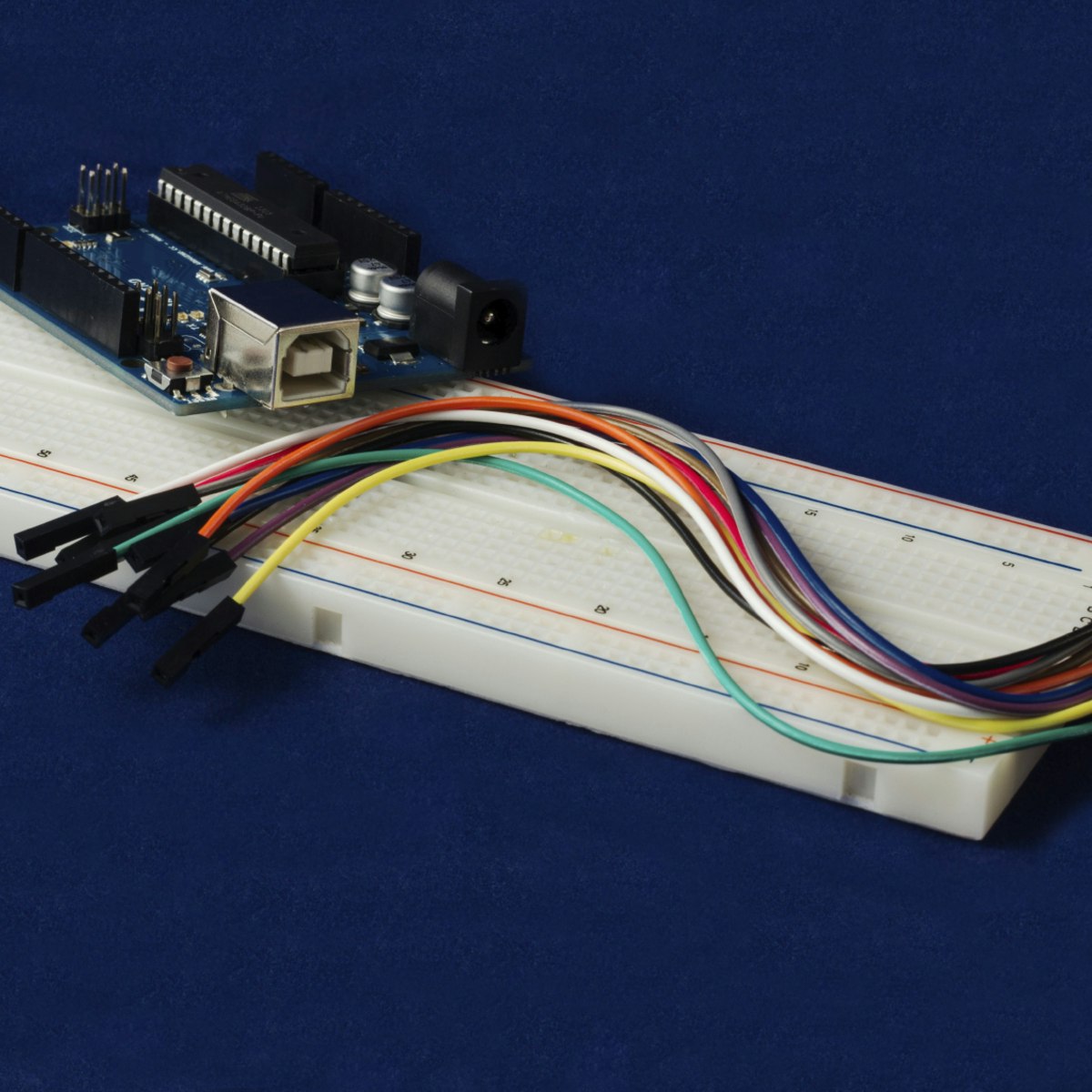

Open-source hardware platforms like Arduino and Raspberry Pi have revolutionized electronics education and hobbyist projects. They are excellent tools for learning serial communication because they are affordable, well-documented, and supported by large online communities.

Arduino boards are microcontrollers that are easy to program using the Arduino IDE and a simplified version of C++. They have built-in support for UART (via the `Serial` object), I2C (via the `Wire` library), and SPI (via the `SPI` library). Countless tutorials and projects demonstrate how to connect various sensors, displays, and modules to Arduino using these serial protocols. This hands-on experience is invaluable for understanding the practicalities of wiring, coding, and debugging serial interfaces.

Raspberry Pi is a series of small single-board computers that typically run a Linux-based operating system. They offer more processing power than Arduinos and can be programmed in languages like Python. Raspberry Pi boards also have GPIO (General Purpose Input/Output) pins that support UART, I2C, and SPI communication. Libraries in Python (like `pySerial` for UART, `smbus` for I2C, and `spidev` for SPI) make it relatively easy to interact with serial devices. The combination of Linux and Python on a Raspberry Pi provides a powerful platform for more complex projects involving serial communication, data logging, and network connectivity.

Many other open-source hardware platforms exist, catering to different needs and experience levels. Experimenting with these platforms allows learners to directly apply theoretical knowledge, see immediate results, and build a portfolio of projects.

These courses are excellent starting points for working with such platforms:

This book can also guide you through interesting projects:

Utilizing Simulation Tools for Protocol Analysis

While physical hardware experimentation is crucial, simulation tools can also be powerful aids for learning and debugging serial communication, especially for understanding protocol behavior without needing immediate access to all physical components.

Circuit Simulators: Software like Proteus, Tinkercad Circuits (which simulates Arduino), LTspice, and others allow you to design and simulate electronic circuits, including those with microcontrollers and serial peripherals. You can often model UART, SPI, or I2C communication between virtual components. Some simulators even have virtual logic analyzers or oscilloscopes to inspect the simulated signals. This can be useful for testing code logic and understanding how protocols should behave before deploying to real hardware.

Logic Analyzer Software: Many affordable USB-based logic analyzers come with software that can capture and decode various serial protocols (UART, I2C, SPI, CAN, etc.). While this requires some hardware (the logic analyzer itself), the software component is key for visualizing the data streams, timings, and protocol events. This is extremely helpful for debugging why communication between two physical devices is failing. Seeing the actual bits on the wire, along with decoded protocol information, can quickly pinpoint issues like incorrect baud rates, wrong slave addresses in I2C, or incorrect SPI modes.

Serial Terminal Emulators: For UART communication, serial terminal programs (like PuTTY, Tera Term, RealTerm on Windows, or `minicom` and `screen` on Linux/macOS) are essential. These tools allow your PC to act as a serial device, sending and receiving data via a COM port (physical or USB-to-serial adapter). You can use them to communicate with microcontrollers, view debug messages, and test basic serial connectivity. Many of these terminals also allow logging of serial data, which is useful for analysis.

Some Integrated Development Environments (IDEs) for microcontrollers also include simulators or debugging tools that can help analyze serial communication behavior at the firmware level.

Adopting Project-Based Learning Approaches

Project-based learning is a highly effective way to master serial communication. Instead of just reading about protocols, you apply them to build something tangible. This approach fosters deeper understanding and problem-solving skills.

Start with simple projects and gradually increase complexity:

- Basic UART: Make two Arduinos (or an Arduino and a PC) exchange simple text messages or sensor readings. Control an LED on one Arduino from another via serial commands.

- I2C Exploration: Connect an I2C sensor (like a temperature/humidity sensor, accelerometer, or real-time clock) to a microcontroller and display its readings on an LCD or a serial terminal. Try adding multiple I2C devices to the same bus.

- SPI Interfacing: Interface with an SPI device like an SD card module (for data logging), an SPI-based display, or a digital potentiometer.

- Combined Systems: Design a system where different components communicate using various serial protocols. For example, a Raspberry Pi (master) might use I2C to talk to sensors and SPI to talk to a display controller, while also providing a UART interface for debugging or remote commands.

Numerous online resources (project websites, forums, YouTube channels) offer step-by-step guides for such projects. When you encounter problems (and you will!), the process of diagnosing and fixing them is where much of the learning happens. Documenting your projects, perhaps in a blog or a GitHub repository, can also solidify your understanding and showcase your skills.

OpenCourser's extensive catalog, which can be explored via the browse page, contains many courses that are project-oriented, particularly in areas like Robotics and IoT (though a direct IoT browse link isn't provided, you can search for it).

These courses emphasize project-based learning:

Engaging with Community-Driven Knowledge Sharing Platforms

The online community around electronics, microcontrollers, and embedded systems is vast and incredibly supportive. Engaging with these communities can accelerate your learning and provide help when you're stuck.

Forums and Q&A Sites: Websites like Stack Exchange (especially Electrical Engineering Stack Exchange and Stack Overflow for programming questions), Reddit communities (e.g., r/arduino, r/raspberry_pi, r/embedded), and specific product forums (e.g., for microcontroller brands or development tools) are invaluable. You can search for answers to common problems, ask your own questions, and learn from the experiences of others.

Manufacturer Communities: Many semiconductor manufacturers (e.g., Microchip, STMicroelectronics, NXP, Texas Instruments) host official forums where users can discuss their products, share solutions, and get help from company engineers and other community members.

Project Sharing Sites: Platforms like GitHub, Instructables, Hackaday.io, and others host a multitude of open-source hardware and software projects involving serial communication. Exploring these projects can provide inspiration, code examples, and design ideas. Contributing to open-source projects is also a great way to learn and collaborate.

Online Course Platforms: Websites like OpenCourser aggregate courses from various providers, many of which have their own discussion forums or communities associated with specific courses. Engaging with fellow learners and instructors can enhance the learning experience.

Social Media and Blogs: Many experts and enthusiasts share their knowledge through blogs, YouTube channels, and social media. Following these can keep you updated on new technologies, project ideas, and best practices.

Don't be afraid to ask questions (after doing your own research first), and also try to help others when you can. Teaching or explaining a concept to someone else is one of the best ways to solidify your own understanding.

Career Development

A strong grasp of serial communication is a valuable asset for various careers in technology. This section outlines potential roles, skill progression, and industry trends.

Roles in Embedded Systems and IoT Industries

Expertise in serial communication is highly sought after in the embedded systems and Internet of Things (IoT) industries. These fields involve creating smart devices that interact with the physical world, and serial protocols are the lifelines that enable this interaction.

Common job titles include:

- Embedded Systems Engineer: Designs, develops, and tests firmware and hardware for embedded systems. This role heavily involves working with microcontrollers and interfacing with sensors, actuators, and other peripherals using UART, SPI, I2C, CAN, etc. [osiyvn]

- Firmware Engineer: Specializes in writing the low-level software that runs on embedded devices. A deep understanding of serial communication protocols and how to implement them efficiently in code is crucial.

- IoT Engineer/Developer: Focuses on building and deploying IoT solutions. This can involve selecting appropriate sensors, communication modules (Wi-Fi, Bluetooth, LoRa, etc., which often interface via serial), and developing the software to collect, transmit, and process data from IoT devices.

- Hardware Engineer (with embedded focus): Designs the electronic circuits for embedded devices, including the selection and implementation of serial interfaces.

- Test Engineer (Embedded/IoT): Develops and executes test plans for embedded systems and IoT devices, which often includes verifying the correctness and reliability of serial communication links.

- Robotics Engineer: Develops robots, which involves integrating various sensors, motors, and controllers, many of which communicate serially. [05la3w]

- Industrial Automation Engineer: Works with PLCs and industrial control systems, where serial protocols like RS-485 and Modbus (often over serial) are common. [lznycz]

These roles can be found in diverse industries, including consumer electronics, automotive, medical devices, aerospace, industrial manufacturing, and telecommunications. The ability to debug communication issues between different hardware components is a key skill in all these roles.

You may wish to explore these related career paths:

This book may also be of interest for those looking into security aspects of embedded systems:

Skill Progression: From Junior to Senior Engineer

Career progression in fields utilizing serial communication typically follows a path of increasing complexity, responsibility, and leadership.

Junior Engineer:

- Focuses on implementing and testing specific modules or features involving serial communication under supervision.

- Writes firmware to read from sensors via I2C/SPI or send debug data over UART.

- Helps troubleshoot basic communication issues using tools like oscilloscopes or logic analyzers.

- Learns about the specific hardware platforms and software tools used by the team.

- Develops a foundational understanding of different serial protocols and their practical application.

Mid-Level Engineer:

- Takes ownership of designing and implementing more complex serial communication interfaces.

- Develops custom communication protocols or adapts existing ones for specific needs.

- Optimizes serial communication for performance, power consumption, or reliability.

- Mentors junior engineers and assists with more challenging debugging tasks.

- May be involved in selecting components and making design decisions related to serial interfaces.

- Contributes to system architecture discussions regarding inter-component communication.

Senior Engineer/Lead Engineer:

- Architects complex embedded systems, making high-level decisions about communication strategies between multiple subsystems.

- Leads teams of engineers, providing technical guidance and project management.

- Solves the most challenging technical problems related to serial communication, signal integrity, and protocol interoperability.

- Stays abreast of new serial communication technologies and standards and evaluates their applicability.

- May be involved in research and development of novel communication solutions.

- Often responsible for ensuring overall system reliability and performance, where robust communication is key.

- Interacts with other teams (e.g., hardware, software, QA) and potentially clients or vendors.

Throughout this progression, continuous learning is essential. This includes mastering new microcontrollers, development tools, communication protocols, and debugging techniques. Strong problem-solving skills, attention to detail, and good communication abilities are also vital for advancement.

The Impact of Industry Certifications

Industry certifications, while not always mandatory, can play a role in career development, especially in specialized fields like embedded systems.

Validation of Skills: Certifications can provide a formal validation of your knowledge and skills in specific areas related to serial communication, such as proficiency with a particular microcontroller family's peripherals or expertise in certain embedded operating systems that manage serial I/O. This can be particularly useful for individuals transitioning into the field or those without extensive on-the-job experience.

Enhanced Credibility: Holding a recognized certification can enhance your credibility with employers and clients. It demonstrates a commitment to professional development and a certain level of expertise.

Career Advancement: Some companies may value or even prefer candidates with specific certifications for certain roles, potentially leading to better job opportunities or faster career progression. In some cases, certifications might be tied to pay grades or promotions.

Staying Current: Preparing for and obtaining certifications often requires studying the latest technologies and best practices, helping you stay current in a rapidly evolving field.

However, it's important to remember that practical experience and a strong portfolio of projects are often weighed more heavily by employers than certifications alone. Certifications are best viewed as a supplement to, rather than a replacement for, hands-on skills and a solid educational foundation. Research the most respected and relevant certifications for your specific career goals within the embedded systems or IoT landscape.

Emerging Specializations in Wireless Serial Technologies

While traditional wired serial communication remains fundamental, the principles of serial data transfer are also at the heart of many wireless technologies. As wireless connectivity becomes ubiquitous, specializations in wireless serial technologies are emerging and growing in demand.

Bluetooth and BLE (Bluetooth Low Energy): Bluetooth uses serial communication principles (often emulating a serial port via profiles like SPP - Serial Port Profile) to enable short-range wireless data exchange between devices. BLE is optimized for low power consumption and is widely used in wearables, beacons, and IoT sensors. Engineers specializing in BLE often work on firmware that manages GATT services and characteristics, which essentially define how data (often serial in nature) is structured and exchanged.

Wi-Fi based Serial Communication: While Wi-Fi is a network protocol, it's often used to extend serial communication over a wireless link. For example, "Serial-to-Wi-Fi" converters allow legacy serial devices to connect to a TCP/IP network. IoT devices frequently use Wi-Fi modules (which themselves often interface with a host microcontroller via SPI or UART) to transmit sensor data serially encapsulated in network packets.

Zigbee, Z-Wave, and Thread: These are low-power, mesh networking protocols designed for home automation and IoT. Devices in these networks often have microcontrollers that use internal serial communication to talk to the radio transceivers. Understanding how to efficiently package and transmit serial data over these wireless links is key.

LPWAN (Low-Power Wide-Area Network) Technologies: Protocols like LoRaWAN and NB-IoT are designed for long-range, low-bandwidth communication for IoT devices. End-nodes typically collect sensor data (often via I2C/SPI from sensors to a microcontroller) and then use a LoRa or NB-IoT modem (interfaced via UART or SPI) to transmit this data serially (though packaged according to the LPWAN protocol) to a gateway.

Near Field Communication (NFC): NFC is a very short-range wireless technology. While it has its own distinct protocols, the underlying data exchange often involves serial streams of information.

Specializing in these wireless technologies requires not only understanding the wireless protocols themselves but also how they interface with embedded systems at the serial level, how to manage power consumption for battery-operated wireless devices, and the security implications of wireless data transmission. This is a dynamic and evolving area with significant career opportunities.

This topic is relevant to wireless specializations:

Industry Challenges and Innovations

The field of serial communication, while mature in many respects, continues to face challenges and drive innovation, particularly as it intersects with modern technological demands like higher bandwidth, security, and the rise of new interface standards.

Addressing Bandwidth Limitations in Legacy Systems

Many legacy industrial, medical, and scientific systems rely on older serial communication standards like RS-232, which were designed for much lower data rates than what modern applications often demand. The inherent bandwidth limitations of these protocols (e.g., RS-232 typically topping out around 20 kbps to 115.2 kbps effectively, though the standard allows for higher theoretical rates that are rarely practical over distance) can become a bottleneck when trying to integrate these systems with newer technologies or when needing to transfer larger amounts of data.

Challenges include:

- Slow Data Transfer: Transmitting large data files, high-resolution sensor readings, or detailed diagnostic information over slow serial links can be time-consuming and inefficient.

- Limited Real-time Capability: For control systems requiring rapid feedback or a high volume of real-time data, legacy serial speeds may not suffice.

- Difficulty in Upgrading: Replacing embedded serial hardware in long-lifespan industrial or medical equipment can be costly and disruptive.

Innovations and approaches to address these limitations include:

- Data Compression: Implementing compression algorithms on the data before transmission can reduce the amount of data that needs to be sent, effectively increasing throughput over the limited bandwidth.

- Protocol Converters/Gateways: Devices that convert legacy serial protocols to modern network protocols (like Ethernet or Wi-Fi) can allow older equipment to be integrated into higher-bandwidth networks. For instance, a serial-to-Ethernet converter allows a device with only an RS-232 port to communicate over a TCP/IP network.

- Edge Computing: Processing data closer to the source (at the "edge") can reduce the need to transmit large volumes of raw data over slow serial links. Only processed results or critical alerts might be sent.

- Incremental Upgrades: Where possible, components within a legacy system might be upgraded to support faster serial interfaces or alternative communication methods, without a full system replacement.

- Optimized Software: Carefully designed software that minimizes data overhead and efficiently manages the serial link can help maximize the use of available bandwidth.

Tackling Security Vulnerabilities in Serial Interfaces

Historically, serial interfaces like RS-232, SPI, and I2C were often designed for communication within a trusted, physically contained system and therefore lacked robust built-in security features. [6nb8t5] As devices become more interconnected, especially in IoT and industrial control systems (ICS), these vulnerabilities can be exploited.

Common vulnerabilities include:

- Lack of Authentication: Many serial protocols have no mechanism to verify the identity of the devices communicating. An attacker with physical access (or sometimes even remote access via a compromised connected system) could potentially connect an unauthorized device to a serial bus and inject malicious commands or intercept data.

- Lack of Encryption: Data transmitted over traditional serial links is typically in plain text. This means anyone who can tap into the communication lines (e.g., using a logic analyzer or serial monitor) can read the data. This is a concern if sensitive information is being exchanged.

- Susceptibility to Physical Attacks: Since these are often direct hardware interfaces, an attacker with physical access to a device can easily connect probes to I2C or SPI lines on a PCB to read firmware, extract keys, or manipulate communication.

- Firmware Manipulation: Serial interfaces are often used for firmware updates. If this process is not secured, an attacker could potentially load malicious firmware onto a device.

Innovations and mitigation strategies include:

- Implementing Security at Higher Layers: While the base serial protocol might be insecure, security can be added at the application layer. This can involve encrypting data before sending it over the serial link and authenticating messages using cryptographic techniques.

- Secure Boot and Signed Firmware: Ensuring that devices only load and execute firmware that has been cryptographically signed by a trusted source can prevent malicious firmware updates via serial (or other) interfaces.

- Physical Security: Protecting physical access to devices and circuit boards is a fundamental security measure. Tamper-evident enclosures or potting compounds can make it harder to access internal serial buses.

- Use of Secure Elements/TPMs: Integrating dedicated secure hardware (like a Trusted Platform Module or a secure microcontroller) can provide a protected environment for storing cryptographic keys and performing sensitive operations, even if the main communication lines are not inherently secure.

- Network Segmentation and Firewalls: For devices where serial communication is bridged to a network (e.g., via serial-to-Ethernet converters), network security measures like firewalls and segmentation can help protect the serial devices from broader network attacks.

- Purpose-Built Secure Serial Protocols: In some specialized applications, custom or proprietary serial protocols with built-in security features might be developed, though this is less common than securing at higher layers.

A deeper dive into embedded security can be found in this book:

The Transition to USB and Wireless Alternatives

While traditional serial ports like RS-232 have largely disappeared from consumer PCs, replaced by USB (Universal Serial Bus) and various wireless technologies, the principles of serial data transmission are still very much alive and have evolved within these newer standards.

USB: USB is a serial bus, but it's far more complex and capable than older serial ports. It offers much higher speeds, plug-and-play capability, and power delivery. Many devices that previously used RS-232 (like printers, external modems, data acquisition devices) now use USB. For developers, USB often involves more complex driver and software stacks. However, many USB devices implement a "virtual COM port" class, which allows them to appear to the operating system and applications as a traditional serial port, simplifying the transition for some legacy software. USB-to-serial adapter cables are also widely used to connect older RS-232 devices to modern PCs that lack built-in serial ports.

Wireless Alternatives:

- Bluetooth: As mentioned, Bluetooth often uses a Serial Port Profile (SPP) to emulate serial communication wirelessly, making it a convenient replacement for short-range cable connections.

- Wi-Fi: Used for higher-bandwidth wireless networking, Wi-Fi can also carry serial data encapsulated in TCP/IP packets, often via serial-to-Wi-Fi converters or by microcontrollers with built-in Wi-Fi capabilities.

- Zigbee, Z-Wave, LoRaWAN, etc.: These and other IoT-focused wireless protocols transmit data serially over the air, designed for specific needs like low power, mesh networking, or long range.

This transition brings both benefits and challenges:

- Benefits: Higher speeds (USB, Wi-Fi), greater convenience (plug-and-play for USB, no cables for wireless), new capabilities (power delivery over USB, mesh networking with Zigbee).

- Challenges: Increased complexity in hardware and software (especially for USB drivers and wireless protocol stacks), power consumption concerns for battery-operated wireless devices, security considerations for wireless transmission, and potential interoperability issues between different wireless standards or USB versions.

Despite these transitions for external connectivity, internal serial protocols like I2C and SPI remain dominant for on-board communication between ICs in all sorts of devices, from simple gadgets to complex computers and wireless modules themselves.

This book provides a look at system administration which can involve managing various types of ports and connections:

And for a broader view of data transmission systems:

Role in Industry 4.0 and Smart Manufacturing

Serial communication, in both its traditional and evolved forms, plays a significant role in Industry 4.0 and smart manufacturing initiatives. Industry 4.0 refers to the fourth industrial revolution, characterized by the increasing automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of Things (IoT), cloud computing, and cognitive computing.

Connecting Legacy Equipment: Many factories still operate with older machinery that relies on traditional serial interfaces like RS-232 or RS-485 for control and data acquisition. Integrating these legacy systems into modern smart factory networks is a key challenge. Serial-to-Ethernet converters, gateways, and edge computing devices are crucial for bridging this gap, allowing data from older machines to be collected, analyzed, and used for process optimization, predictive maintenance, and overall equipment effectiveness (OEE) calculations.

Industrial IoT (IIoT): Sensors are fundamental to smart manufacturing, providing data on machine health, environmental conditions, production status, and quality control. Many industrial sensors communicate using serial protocols (e.g., Modbus RTU over RS-485, IO-Link which has a serial component, or direct I2C/SPI for embedded sensors). This data is then fed into IIoT platforms for analysis and action.

Robotics and Automated Guided Vehicles (AGVs): Robots and AGVs are central to automated manufacturing. As discussed, serial communication (including CAN bus, Ethernet-based serial, and internal SPI/I2C) is used extensively within these systems for controlling motors, processing sensor data, and coordinating actions.

Real-time Control and Monitoring: While Ethernet-based industrial protocols (like EtherNet/IP, PROFINET) are gaining traction for high-speed control, many control loops and monitoring tasks still effectively use robust serial communication, especially where deterministic behavior and noise immunity are critical (e.g., RS-485).

Data Logging and Traceability: Serial interfaces are often used to log production data, machine parameters, and quality metrics. This information is vital for traceability, compliance, and continuous improvement efforts in smart manufacturing.

The reliability and simplicity of certain serial protocols make them well-suited for the harsh environments often found in manufacturing. As factories become "smarter," the need to reliably extract data from and send commands to a diverse range of equipment—both old and new—ensures that skills in serial communication remain highly relevant.

This topic directly relates to this area:

Ethical and Safety Considerations

Implementing serial communication, especially in industrial, medical, or critical systems, involves important ethical and safety considerations. Ensuring the reliability, security, and proper functioning of these communication links is paramount to prevent harm, data breaches, or operational failures.

EMI/EMC Compliance Requirements

Electromagnetic Interference (EMI) refers to the unwanted effects of electromagnetic energy on electronic devices. Electromagnetic Compatibility (EMC) is the ability of a device to function correctly in its electromagnetic environment without introducing intolerable electromagnetic disturbances to other equipment in that environment.

Serial communication lines, like any electrical conductor, can both radiate EMI and be susceptible to it. Poorly shielded cables or improperly designed circuits can lead to:

- Data Corruption: EMI can induce noise on serial lines, causing bit errors and corrupting the transmitted data. This can lead to incorrect operation of machinery, false readings from sensors, or system failures.

- Interference with Other Devices: A serial communication system that radiates excessive EMI can interfere with the operation of other nearby sensitive electronic equipment, such as medical devices, radio communication systems, or precision instruments.

Most countries and regions have regulatory standards for EMC (e.g., FCC Part 15 in the USA, CE marking requirements in Europe which include EMC directives). Products must typically be tested and certified to meet these standards before they can be sold. This involves testing for both radiated and conducted emissions (the EMI the device produces) and for immunity (the device's ability to withstand EMI from external sources).

Design considerations for EMI/EMC compliance in serial communication systems include:

- Shielded Cables: Using properly grounded shielded cables can significantly reduce both radiation and susceptibility to EMI.

- Filtering: Adding filters (e.g., ferrite beads, capacitors, inductors) to serial lines can help suppress high-frequency noise.

- Proper Grounding and PCB Layout: Good grounding practices and careful PCB layout (e.g., using ground planes, separating analog and digital grounds where appropriate, keeping trace lengths short) are crucial for minimizing EMI.

- Enclosure Design: Using metallic or conductive-coated enclosures can provide shielding for the internal electronics.

Ensuring EMI/EMC compliance is not just a regulatory hurdle; it's essential for the safety and reliability of systems that depend on serial communication.

Safety Protocols in Industrial Implementations

In industrial environments, failures in serial communication can have severe safety consequences, potentially leading to equipment damage, production stoppages, or, most critically, injury to personnel. Therefore, robust safety protocols and design practices are essential when implementing serial communication in industrial control systems.

Key considerations include:

- Fail-Safe Design: Systems should be designed to enter a safe state in the event of communication failure. For example, if a control signal from a PLC to a motor is lost, the motor should default to a safe condition (e.g., stop) rather than continuing to operate erratically or in an uncontrolled manner.

- Redundancy: For critical communication links, redundancy might be implemented. This could involve having a backup serial communication path or using protocols that support redundant controllers or media.

- Error Detection and Handling: Robust error detection (like CRC) is vital. The system must have a clear strategy for how to respond when communication errors are detected (e.g., request retransmission, trigger an alarm, shut down a process safely).

- Watchdog Timers: Watchdog timers can be used to detect if a device (e.g., a sensor or actuator connected via serial) has stopped communicating or become unresponsive. If the watchdog timer expires without receiving a "heartbeat" signal, the system can take corrective action.

- Physical Protection of Cables and Connectors: In harsh industrial environments, serial cables and connectors must be protected from physical damage, moisture, chemicals, and extreme temperatures. Using industrial-grade connectors and conduits is often necessary.

- Proper Isolation: Electrical isolation (e.g., using optocouplers or isolated transceivers) can protect devices from ground loops, voltage surges, and other electrical hazards that might propagate over serial lines.

- Adherence to Safety Standards: Many industries (e.g., process industries, machine safety) have specific safety standards (like IEC 61508 for functional safety) that dictate requirements for control systems, including their communication links.

- Regular Maintenance and Testing: Serial communication links should be part of regular maintenance schedules to check for cable wear, loose connections, and proper functioning. Periodic testing of safety interlocks that rely on serial communication is also crucial.

Safety in industrial implementations requires a holistic approach, considering both the hardware and software aspects of the serial communication system within the broader context of the industrial process and its potential hazards.

Ensuring Data Privacy in Serial-Connected Systems

While often overlooked because serial communication frequently occurs within a physically contained system, data privacy can become a concern, especially when serial devices are connected to networks or when they handle sensitive information.

As discussed under security vulnerabilities, traditional serial protocols like RS-232, SPI, and I2C do not typically offer built-in encryption. [6nb8t5] This means data transmitted over these links is often in plain text. If this data includes personally identifiable information (PII), financial details, confidential business information, or sensitive medical data, its interception could lead to a privacy breach.

Considerations for data privacy include:

- Data Minimization: Only transmit the data that is strictly necessary over the serial link. Avoid sending sensitive information if it's not required for the system's operation.

- Application-Layer Encryption: If sensitive data must be transmitted serially, implement encryption at the application layer before the data is passed to the serial transmission functions. The receiving end would then decrypt the data after it's received from the serial port. This protects the data even if the serial link itself is tapped.

- Secure Storage: If data received via a serial port is stored, ensure that the storage medium is secure and that access controls are in place, especially if it contains private information.