Personal Protective Equipment

Introduction to Personal Protective Equipment

Personal Protective Equipment, commonly known as PPE, refers to equipment worn to minimize exposure to a variety of hazards. These hazards can range from physical and chemical to biological and radiological agents. The fundamental purpose of PPE is to place a barrier between the wearer and the hazardous environment, thereby reducing the risk of injury, illness, or even death. While often associated with occupational settings like construction sites or hospitals, PPE also plays a crucial role in public health scenarios and even during certain recreational activities. Understanding PPE is the first step toward appreciating its significance in safeguarding well-being across diverse contexts.

The world of PPE is dynamic and offers intriguing avenues for those interested in safety, health, and innovation. One engaging aspect is the constant evolution of materials and design, driven by the need for enhanced protection and user comfort. Another exciting facet is the direct impact one can have on preventing harm and promoting safer environments, whether in a specific workplace or for the broader public. Furthermore, the field is increasingly intersecting with technology, leading to the development of "smart" PPE that can monitor a worker's environment or physiological state in real-time. These advancements highlight the critical and ever-evolving nature of personal protection.

Introduction to Personal Protective Equipment

This section will lay the groundwork for understanding what Personal Protective Equipment encompasses, its historical roots, fundamental types, and its indispensable role in both workplace safety and public health. The aim is to provide a clear and accessible overview, particularly for those new to the concept.

Defining Personal Protective Equipment and Its Primary Role

Personal Protective Equipment (PPE) is defined as equipment, appliances, or clothing designed to protect the wearer from injury or infection. The primary purpose of PPE is to act as a barrier against workplace hazards that can cause harm through contact, inhalation, or absorption. It's a critical line of defense when other control measures, such as engineering controls (e.g., modifying equipment) or administrative controls (e.g., changing work practices), are not feasible or sufficient to eliminate the risks.

The core idea behind PPE is risk reduction. By wearing appropriate gear, individuals can significantly lessen their exposure to potential dangers. This could involve anything from a construction worker wearing a hard hat to prevent head injuries, a healthcare professional using gloves and masks to avoid pathogen transmission, or a laboratory technician donning safety goggles to protect their eyes from chemical splashes. The effectiveness of PPE hinges on its correct selection for the specific hazard, proper fit, consistent use, and regular maintenance.

It's important to understand that PPE is generally considered the last resort in the hierarchy of hazard controls. This means that employers should first attempt to eliminate or reduce hazards at their source. However, in many situations, hazards cannot be completely eliminated, making PPE an essential component of a comprehensive safety program. The selection and use of PPE are often guided by risk assessments that identify the specific dangers present in a particular environment.

A Brief Look at the History of PPE

The concept of personal protection against hazards is not new; it has evolved over centuries, driven by human experience and technological advancements. Early forms of PPE were rudimentary, often consisting of natural materials like animal hides for protection against the elements or basic metal armor for combat. As industries developed, so did the understanding of occupational hazards and the need for more specialized protection.

The Industrial Revolution, for instance, brought about new dangers in factories and mines, leading to early innovations in respiratory protection and headgear. Significant advancements in PPE often followed major incidents or periods of increased risk, such as wars or pandemics, which highlighted the need for better protective measures for both workers and the general public. The 20th century saw a more formalized approach to occupational safety, with governments and organizations establishing standards and regulations for PPE. This period also witnessed significant developments in materials science, leading to the creation of more effective and comfortable protective equipment.

The COVID-19 pandemic dramatically underscored the importance of PPE, particularly in healthcare settings and for the general public, leading to a surge in demand and innovation. This recent global event has further accelerated research and development in areas like antimicrobial fabrics and advanced filtration technologies, pushing the boundaries of what PPE can achieve. The history of PPE is a testament to the ongoing effort to safeguard human health and safety in the face of evolving risks.

Fundamental Categories of PPE

Personal Protective Equipment can be broadly categorized based on the part of the body it protects or the type of hazard it mitigates. Understanding these basic categories is essential for selecting the appropriate PPE for a given situation. Some of the most common categories include respiratory protection, eye and face protection, and hand protection.

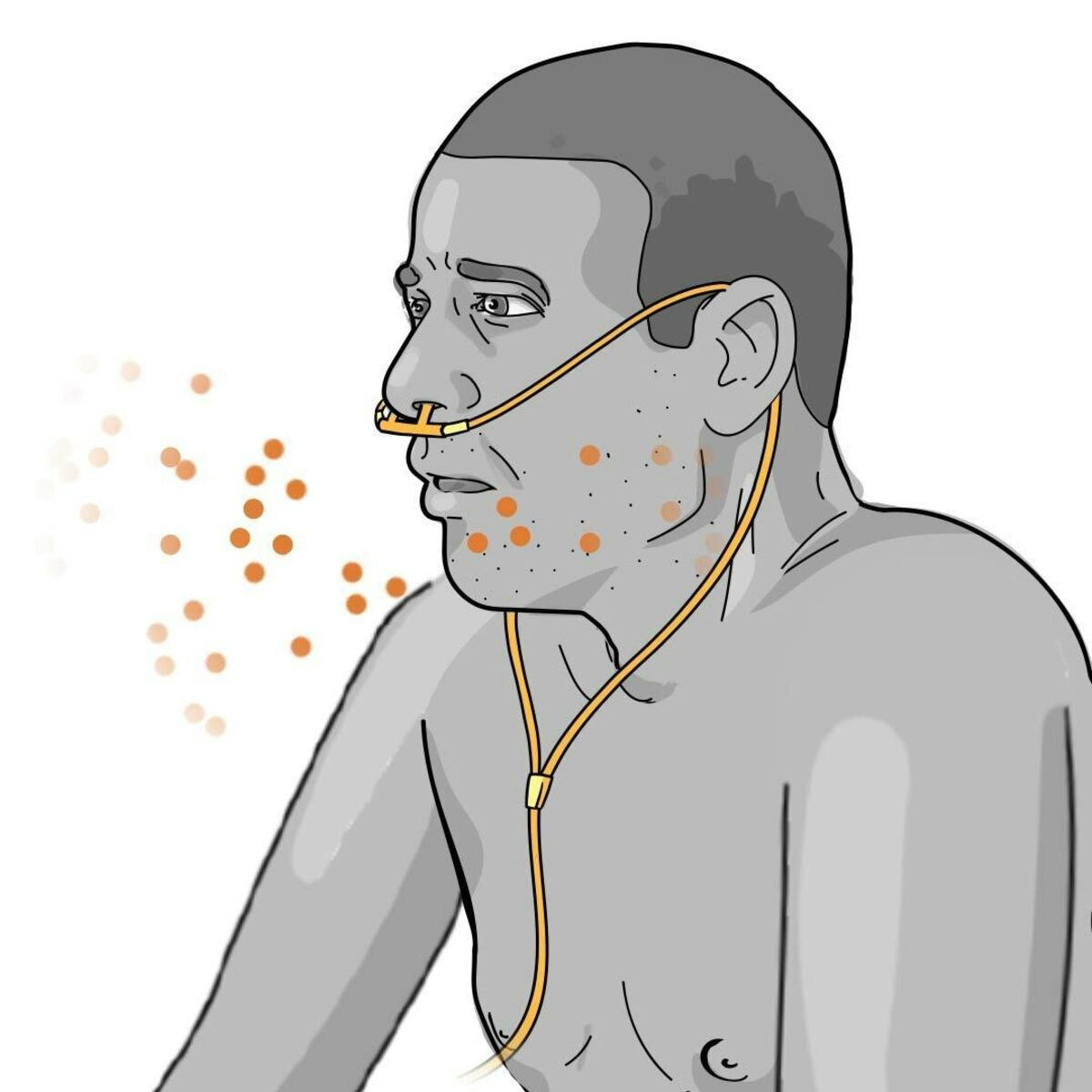

Respiratory Protection: This category includes devices like masks and respirators designed to protect the wearer from inhaling hazardous substances such as dust, fumes, vapors, gases, or infectious airborne particles. Examples range from simple disposable dust masks to more complex powered air-purifying respirators (PAPRs) and self-contained breathing apparatus (SCBA) used in highly contaminated environments. The selection of respiratory protection depends on the nature and concentration of the airborne contaminant.

Eye and Face Protection: This type of PPE is designed to shield the eyes and face from hazards like flying particles, chemical splashes, molten metal, intense light, and infectious droplets. Common examples include safety glasses, goggles, face shields, and welding helmets. The choice of eye and face protection is determined by the specific risks present, such as impact, chemical exposure, or radiation.

Hand Protection: Gloves are the most common form of hand protection, safeguarding against a wide array of hazards including cuts, abrasions, punctures, chemical burns, thermal burns, and biological contamination. Gloves are made from various materials, such as latex, nitrile, vinyl, leather, and specialized chemical-resistant polymers, each suited for different types of hazards and tasks. The hand protection segment represents a significant portion of the PPE market due to its widespread use across numerous industries.

Other important categories of PPE include head protection (e.g., hard hats), foot protection (e.g., safety shoes and boots), hearing protection (e.g., earplugs and earmuffs), and protective clothing (e.g., coveralls, aprons, and full-body suits) designed to protect against chemical, thermal, or biological hazards.

The Vital Role of PPE in Workplace Safety and Public Health

Personal Protective Equipment plays an indispensable role in maintaining safety in the workplace and protecting public health. In occupational settings, employers have a responsibility to provide a safe working environment, and PPE is a critical component of this responsibility, especially when hazards cannot be eliminated through other means. Proper use of PPE can significantly reduce the incidence of workplace injuries and illnesses, leading to a healthier and more productive workforce.

The importance of PPE extends beyond traditional industrial or healthcare workplaces. For instance, in public health crises, such as pandemics, PPE like face masks becomes crucial for limiting the spread of infectious diseases within communities. The effectiveness of PPE in these situations relies on widespread adoption, correct usage, and adequate supply. The COVID-19 pandemic highlighted global vulnerabilities in PPE supply chains and spurred efforts to increase manufacturing capacity and ensure equitable access.

Furthermore, PPE is vital in emergency response situations, protecting first responders like firefighters, paramedics, and law enforcement officers from the unique hazards they face. The ongoing development of PPE, driven by research and technological advancements, continues to enhance its protective capabilities and user comfort, reinforcing its critical role in safeguarding individuals in a multitude of environments. The increasing awareness of workplace safety and public health concerns is a major driver for the growth of the PPE market globally.

These courses offer a solid introduction to health and safety principles, including the importance and use of PPE in various settings.

For foundational knowledge, these books provide comprehensive insights into PPE and general safety practices.

Exploring these topics can provide a broader understanding of the contexts in which PPE is crucial.

Core Components of Personal Protective Equipment

Delving deeper, this section explores the technical aspects of PPE. It will cover the science behind the materials used, the importance of ergonomic design for user comfort and effectiveness, the standards that dictate protection levels, and how PPE integrates with broader safety systems. This part of the article is geared towards those seeking a more in-depth understanding, such as industry practitioners and researchers.

The Science Behind PPE Materials

The effectiveness of Personal Protective Equipment is fundamentally linked to the materials used in its construction. Material science plays a pivotal role in developing PPE that can withstand specific hazards while being as lightweight, durable, and comfortable as possible. For instance, resistance to chemical permeation, physical tearing, or pathogen penetration are critical properties determined by the material's composition and structure.

Common materials include specialized polymers like polyethylene, polypropylene, and polyvinyl chloride (PVC) for chemical resistance and barrier protection in items like gloves and gowns. Advances in textile technology have led to the development of non-woven fabrics with excellent filtration capabilities, crucial for respiratory masks. For impact protection, such as in hard hats or safety eyewear, materials like high-density polyethylene (HDPE) or polycarbonate are often employed due to their strength-to-weight ratio.

Ongoing research focuses on creating "smart" materials that can, for example, change properties in response to environmental conditions or indicate exposure to a hazard. Nanotechnology is also being explored to enhance material properties, such as creating surfaces that are inherently antimicrobial or self-decontaminating. The selection of materials is a complex process involving trade-offs between protection level, durability, cost, and user comfort.

Ergonomic Design: Marrying Safety with Comfort and Usability

While the primary function of PPE is protection, its ergonomic design is equally critical for ensuring it is worn correctly and consistently. If PPE is uncomfortable, cumbersome, or interferes with a worker's ability to perform tasks, compliance rates will likely be low, thereby reducing its effectiveness. Ergonomics in PPE design considers factors such as fit, weight, breathability, and freedom of movement.

A well-designed piece of PPE should integrate seamlessly with the user's body and their work activities. For example, safety harnesses must distribute forces evenly in the event of a fall without causing secondary injury. Respirators need to form a tight seal with the face without being overly restrictive or causing discomfort during prolonged use. The development of gender-inclusive PPE and a wider range of sizes addresses the diverse needs of the workforce, ensuring a proper fit for all individuals.

Manufacturers invest significantly in research and development to improve the ergonomic aspects of their products. This includes user trials, anthropometric studies (the study of human body measurements), and incorporating feedback from workers. The goal is to create PPE that workers are willing and able to wear for the duration of their exposure to hazards, without compromising their safety or productivity.

Understanding Protection Levels and Certification Standards

Personal Protective Equipment is often categorized by the level of protection it offers, and this is typically governed by rigorous certification standards. These standards, set by national and international bodies, ensure that PPE meets specific performance criteria before it can be marketed and sold. For example, organizations like the Occupational Safety and Health Administration (OSHA) in the United States and the European Committee for Standardization (CEN) in Europe establish such standards.

Certification involves testing PPE against specific hazards. For instance, a respirator might be tested for its filtration efficiency against particles of a certain size, while a pair of safety gloves might be rated for its resistance to specific chemicals or cut hazards. The results of these tests determine the protection level or classification of the PPE. This information is crucial for employers and users to select the appropriate equipment for the risks they face. Markings on the PPE, such as the CE mark in Europe, indicate compliance with relevant standards.

It is vital for users and procurement officers to understand these standards and protection levels to ensure that the selected PPE provides adequate protection. Using PPE that is not certified or that does not meet the required protection level for a specific hazard can provide a false sense of security and leave individuals vulnerable. Many online resources and training programs are available to help understand these complex but critical aspects of PPE selection.

These courses delve into specific areas of safety where PPE is critical, such as biocontainment and infection control, aligning with the need for understanding protection levels and standards.

These books provide in-depth knowledge about the technical aspects of PPE and safety standards in various work environments.

For those interested in the standards and best practices in specific high-risk areas, these topics offer further exploration.

Integration with Other Safety Systems and Protocols

Personal Protective Equipment does not operate in a vacuum; it is most effective when integrated into a comprehensive safety management system. This system includes other control measures such as engineering controls (e.g., ventilation systems, machine guarding), administrative controls (e.g., safe work procedures, training), and an overall culture of safety within an organization.

For example, in a chemical plant, respirators (PPE) might be used in conjunction with localized exhaust ventilation (engineering control) and strict protocols for handling hazardous materials (administrative control). Similarly, in a construction setting, fall arrest systems (PPE) are part of a broader fall protection plan that might include guardrails (engineering control) and worker training on working at heights (administrative control).

The integration also involves ensuring that the use of one type of PPE does not compromise the effectiveness of another or create new hazards. For instance, wearing certain types of respirators might interfere with the proper fit of safety glasses. Therefore, a holistic approach to hazard assessment and control is necessary to select compatible PPE and ensure all safety measures work harmoniously. Regular audits, inspections, and employee feedback are crucial for maintaining the effectiveness of the integrated safety system.

Regulatory Frameworks and Compliance

This section will navigate the complex landscape of PPE regulations. It will cover key global standards, the processes involved in getting PPE certified, the legal responsibilities of organizations, and how regulatory changes can impact the market. This is particularly relevant for those in compliance roles, procurement, and business analysis.

Navigating Key Global Standards (OSHA, EU Directives)

The regulation of Personal Protective Equipment is crucial for ensuring worker safety and product efficacy. Globally, several key regulatory bodies and standards frameworks govern the design, manufacture, and use of PPE. Prominent among these are the Occupational Safety and Health Administration (OSHA) in the United States and the European Union's PPE Regulation (EU) 2016/425.

OSHA, a U.S. Department of Labor agency, sets and enforces standards to ensure safe and healthful working conditions. OSHA's regulations cover various aspects of PPE, including hazard assessment, equipment selection, employee training, and program implementation. Specific standards address different types of PPE, such as respiratory protection (29 CFR 1910.134) and eye and face protection (29 CFR 1910.133). OSHA often requires PPE to meet or be equivalent to standards developed by organizations like the American National Standards Institute (ANSI).

In the European Union, Regulation (EU) 2016/425 lays down requirements for the design, manufacture, and marketing of PPE. This regulation aims to ensure that PPE placed on the EU market provides a high level of protection against risks. It categorizes PPE into three risk categories, with stricter conformity assessment procedures for higher-risk equipment. PPE that complies with the regulation bears the CE marking, indicating its conformity. Many other countries and regions also have their own specific PPE standards and regulatory bodies, often aligning with or drawing from these major frameworks.

Understanding these regulations is critical for manufacturers, importers, employers, and safety professionals to ensure compliance and protect workers effectively. For those interested in the specifics of OSHA standards, OpenCourser offers a variety of resources that can be found using a targeted search for OSHA standards.

The Ins and Outs of Certification Processes

Bringing Personal Protective Equipment to market involves rigorous certification processes to verify its safety and effectiveness. These processes are designed to ensure that PPE meets the specific performance requirements outlined in relevant standards before it can be sold and used. The complexity of the certification process often depends on the risk category of the PPE; equipment designed to protect against more severe hazards typically undergoes more stringent evaluation.

Manufacturers are generally responsible for ensuring their PPE complies with applicable standards. This often involves submitting product samples to accredited testing laboratories for independent evaluation. These laboratories conduct a series of tests based on the specific type of PPE and the hazards it is intended to protect against. For example, impact resistance for hard hats, filtration efficiency for respirators, or chemical permeation resistance for gloves would be assessed.

Once a product successfully passes these tests and meets all other regulatory requirements (such as technical documentation and quality control systems), it can be certified. In the European Union, for Category II and III PPE, a Notified Body (an organization designated by an EU country to assess conformity) must be involved in the conformity assessment procedure. The CE marking on PPE signifies that the manufacturer declares conformity with all legal requirements for CE marking and has gone through the necessary conformity assessment procedures. Maintaining certification often involves ongoing quality control and periodic re-testing to ensure continued compliance.

Legal Liabilities and Responsibilities for Organizations

Organizations, particularly employers, have significant legal liabilities and responsibilities concerning the provision and use of Personal Protective Equipment. These responsibilities are generally mandated by occupational health and safety laws and regulations in most jurisdictions. Failure to comply can result in penalties, fines, legal action, and, most importantly, preventable harm to employees.

A primary responsibility of employers is to conduct a thorough workplace hazard assessment to identify potential dangers that necessitate the use of PPE. Based on this assessment, employers must select and provide appropriate PPE to their employees at no cost. The selected PPE must be suitable for the identified hazards and must fit the employees properly. OSHA, for example, explicitly requires employers to ensure PPE is of safe design and construction and fits each affected employee.

Beyond providing the equipment, employers are also responsible for training employees on the proper use, care, maintenance, and limitations of the PPE. This includes demonstrating how to correctly put on, adjust, wear, and take off the equipment. Employers must also ensure that PPE is properly maintained, cleaned, and stored, and that damaged or defective equipment is replaced. Record-keeping related to hazard assessments, PPE selection, training, and equipment maintenance is often a legal requirement and good practice for demonstrating due diligence.

Market Implications of Regulatory Changes

Changes in Personal Protective Equipment regulations can have significant implications for the PPE market. These changes can be driven by new research on hazards, technological advancements in protective materials and design, major incidents that highlight gaps in existing standards, or evolving societal expectations regarding worker safety and public health. Regulatory updates can influence product development, manufacturing processes, market access, and overall market demand.

When new or stricter standards are introduced, manufacturers may need to redesign their products, invest in new testing procedures, and update their certification documentation to comply. This can lead to increased research and development costs but also drive innovation and the availability of more effective PPE. For instance, heightened awareness and regulatory focus on infectious diseases, especially after events like the COVID-19 pandemic, spurred innovation and demand for higher-quality respiratory protection and other medical PPE.

Regulatory changes can also impact market access. Products that do not meet new standards may be barred from sale, creating opportunities for compliant manufacturers and potentially shifting market share. Furthermore, increased regulatory scrutiny or awareness campaigns can lead to greater demand for PPE as more organizations and individuals recognize the importance of protection. The global PPE market is influenced by these regulatory dynamics, with stricter regulations generally contributing to market growth as businesses invest in compliant equipment to ensure worker safety and avoid penalties.

These courses offer valuable insights into regulatory compliance and safety management, which are crucial for understanding the market implications of PPE regulations.

For those who wish to delve deeper into regulatory frameworks, these topics are highly relevant.

Formal Education Pathways

For individuals considering a career related to Personal Protective Equipment, understanding the educational avenues is key. This section will outline relevant university degrees, postgraduate research opportunities, certification programs, and the interdisciplinary nature of the field, connecting to areas like engineering and public health. This is aimed at students and those contemplating a career shift into PPE-related roles.

Relevant Undergraduate Degrees (e.g., Occupational Health and Safety)

A foundational step towards a career in fields related to Personal Protective Equipment often involves pursuing a relevant undergraduate degree. Several academic disciplines provide the necessary knowledge and skills. One of the most direct routes is a bachelor's degree in Occupational Health and Safety (OHS). These programs typically cover topics such as hazard identification, risk assessment, safety regulations, industrial hygiene, and the principles of PPE selection and use.

Other related undergraduate degrees can also serve as strong foundations. For instance, degrees in Environmental Health focus on protecting human health from environmental hazards, which often involves the use and management of PPE. Engineering disciplines, particularly Industrial Engineering or Chemical Engineering, can be relevant, especially for those interested in the design, manufacturing, and testing of PPE materials and products. A background in Public Health can also be advantageous, particularly for roles involving PPE in community health settings or during public health emergencies.

Regardless of the specific degree, coursework in chemistry, biology, physics, and statistics provides a solid scientific underpinning. Strong communication and analytical skills are also highly valued in this field. Many universities offer specialized tracks or elective courses within broader degree programs that allow students to focus more specifically on safety management or industrial hygiene.

Graduate Research Opportunities in PPE

For those wishing to delve deeper into the science, technology, and policy surrounding Personal Protective Equipment, graduate research opportunities offer a path for advanced study and contribution to the field. Master's degrees or doctoral programs in areas like Occupational Health and Safety, Industrial Hygiene, Environmental Health Sciences, Materials Science and Engineering, or Public Health can provide platforms for specialized research in PPE.

Research at the graduate level might focus on a wide array of topics. This could include the development of novel materials with enhanced protective properties, such as self-decontaminating fabrics or materials with improved breathability and comfort. Other research areas involve studying the efficacy of different types of PPE against emerging hazards, improving the ergonomic design of equipment, or investigating the psychological and behavioral factors that influence PPE compliance. Research might also explore the lifecycle of PPE, including sustainable manufacturing and disposal methods.

Universities with strong engineering, public health, and materials science departments often have faculty conducting cutting-edge research related to PPE. These research endeavors are crucial for advancing the field, informing standards and regulations, and ultimately improving worker and public safety. Funding for such research often comes from government agencies, industry partnerships, and private foundations dedicated to occupational and environmental health.

Certification Programs and Apprenticeships

Beyond formal academic degrees, various certification programs and apprenticeships can provide specialized knowledge and practical skills relevant to Personal Protective Equipment. These programs are often geared towards specific job roles or industries and can be an excellent way for individuals to gain credentials and enhance their career prospects. Professional certifications demonstrate a level of competency and commitment to the field.

Several organizations offer certifications for safety professionals. For example, the Board of Certified Safety Professionals (BCSP) offers designations like the Certified Safety Professional (CSP) and the Associate Safety Professional (ASP), which are widely recognized in the industry. While these certifications cover a broad range of safety topics, knowledge of PPE is a core component. Specific training programs and certifications may also focus on particular types of PPE, such as respiratory protection fit testing or hazardous materials handling.

Apprenticeships, while perhaps less common for broadly defined "PPE professionals," can exist in skilled trades where PPE use is critical (e.g., construction, electrical work, welding). These programs combine on-the-job training with classroom instruction, ensuring that apprentices learn not only their trade but also how to work safely, including the correct selection and use of PPE. Some industries or large companies may also offer internal training and qualification programs related to specific PPE requirements for their operations.

These courses can complement formal education by providing specific certifications and foundational knowledge in health and safety, directly applicable to PPE-related careers.

For individuals seeking to deepen their understanding through established texts, these books are valuable resources.

Exploring these related topics can provide a broader context for the application of PPE knowledge.

Interdisciplinary Connections: Engineering, Public Health, and Beyond

The field of Personal Protective Equipment is inherently interdisciplinary, drawing knowledge and expertise from a variety of fields. Engineering plays a crucial role in the design, development, and testing of PPE. This includes Materials Science and Engineering for creating advanced protective materials, Mechanical Engineering for designing ergonomic and effective equipment, and Industrial Engineering for optimizing manufacturing processes and ensuring quality control.

Public Health is another closely related discipline. PPE is a cornerstone of infection control in healthcare settings and plays a vital role in protecting communities during outbreaks of infectious diseases. Public health professionals are involved in developing guidelines for PPE use, managing stockpiles, and educating the public on proper PPE practices. Epidemiology, the study of disease patterns, helps identify risks where PPE is needed.

Beyond these, fields like chemistry are essential for understanding chemical hazards and developing resistant materials. Physics informs our understanding of hazards like radiation and noise, and the design of corresponding PPE. Even psychology and behavioral sciences contribute by studying factors that influence PPE adherence and risk perception. This interdisciplinary nature makes the field of PPE dynamic and offers opportunities for individuals with diverse educational backgrounds to contribute to safety and health.

Skill Development Through Online Learning

The rise of online education has opened new doors for acquiring knowledge and skills in Personal Protective Equipment. This section will discuss the types of online courses available, how to validate practical skills learned online, the importance of integrating online learning with hands-on experience, and a realistic look at the costs and benefits of self-study. This is for those who prefer or require flexible learning options.

Exploring Fundamental vs. Specialized PPE Course Types

Online learning platforms offer a diverse range of courses related to Personal Protective Equipment, catering to various learning needs, from foundational knowledge to highly specialized skills. Fundamental courses typically provide an overview of occupational health and safety principles, introduce the different categories of PPE, explain how to conduct basic hazard assessments, and cover general guidelines for PPE selection and use. These courses are excellent starting points for individuals new to the field or those who need a general understanding of PPE for their work.

Specialized online courses delve into specific aspects of PPE or target particular industries. For example, one might find courses focused on respiratory protection programs, chemical protective clothing, electrical safety and PPE, or infection control and PPE in healthcare settings. These specialized courses often assume some foundational knowledge and are designed for professionals seeking to deepen their expertise in a particular niche. They might cover advanced topics like specific regulatory standards, complex selection criteria for high-risk environments, or techniques for managing comprehensive PPE programs.

When choosing an online course, it's important to consider your current knowledge level and your learning objectives. Reputable courses will clearly outline their target audience, learning outcomes, and any prerequisites. OpenCourser is a valuable resource for finding and comparing such courses, allowing learners to browse through thousands of options in health and medicine and related safety fields.

Methods for Validating Practical Skills Acquired Online

While online courses are effective for imparting theoretical knowledge about Personal Protective Equipment, validating the practical skills associated with its use can present a challenge. Simply understanding how a respirator works is different from being able to correctly don, doff, and perform a seal check. Therefore, supplementing online learning with methods for practical skill validation is crucial, especially for roles that require hands-on competency.

One common approach is through blended learning programs, where online theoretical components are combined with in-person practical sessions. These sessions allow learners to practice using different types of PPE under the guidance of a qualified instructor. Another method involves competency assessments, which can sometimes be proctored remotely or conducted by a qualified supervisor in the workplace. These assessments might require learners to demonstrate specific skills, such as selecting the appropriate PPE for a given scenario or inspecting equipment for damage.

Some online courses incorporate simulations or interactive case studies to help learners apply their knowledge in a virtual environment. While not a perfect substitute for hands-on experience, these tools can enhance practical understanding. For certain types of PPE, such as respiratory fit testing, certification often requires an in-person assessment by a qualified professional. Ultimately, the responsibility for ensuring practical competency often lies with employers, who must verify that their employees can use PPE safely and effectively in their specific work environment.

The Synergy of Online Learning and Hands-On Training

The most effective approach to developing comprehensive skills in Personal Protective Equipment often involves a synergistic combination of online learning and hands-on training. Online courses excel at delivering foundational knowledge, theoretical concepts, regulatory information, and standardized procedures in a flexible and accessible manner. Learners can study at their own pace and revisit materials as needed to ensure understanding.

However, the practical application of this knowledge – the "how-to" of using PPE – is best learned through hands-on experience. This is where in-person training, supervised practice, and real-world application become indispensable. Hands-on sessions allow individuals to become familiar with the feel and fit of different equipment, practice proper donning and doffing techniques, learn how to perform inspections and maintenance, and understand the limitations of PPE in realistic scenarios. This experiential learning helps to build muscle memory and confidence.

Employers and training providers are increasingly adopting blended learning models that leverage the strengths of both online and in-person modalities. For instance, employees might complete an online module on respiratory protection standards and then attend an in-person session for respirator fit testing and practical use exercises. This integrated approach optimizes learning efficiency, ensures theoretical understanding, and validates practical competence, leading to a more skilled and safer workforce.

These courses offer a blend of theoretical knowledge and practical considerations for workplace safety, including specialized areas like COVID-19 protocols and infection control, which can be effectively supplemented with hands-on training.

For those who prefer self-study through books, these selections provide comprehensive coverage of safety engineering and infection control, which benefit greatly from practical application.

Understanding these related topics can provide context for the practical application of PPE knowledge in various settings.

A Realistic Look at the Cost-Benefit Analysis of Self-Study in PPE

Embarking on self-study in Personal Protective Equipment through online courses can be a cost-effective and flexible way to gain knowledge and skills. However, it's important to conduct a realistic cost-benefit analysis. The "cost" component includes not only the direct expenses of course fees (though many introductory resources may be free or low-cost) but also the time investment required. Effective self-study demands discipline, motivation, and dedicated time, which can be a significant commitment, especially for working professionals.

The "benefit" side can be substantial. Acquiring knowledge in PPE can enhance job prospects, lead to career advancement, improve workplace safety, and contribute to a culture of health and safety within an organization. For individuals, it can mean increased confidence in handling hazardous situations and a better understanding of their rights and responsibilities regarding workplace safety. For businesses, investing in employee training on PPE (including supporting self-study initiatives) can lead to reduced accident rates, lower insurance premiums, and improved regulatory compliance.

When evaluating online courses, consider factors like the credibility of the provider, the expertise of the instructors, the relevance of the content to your goals, and whether the course offers any form of certification or credential upon completion. OpenCourser's Learner's Guide offers valuable articles on how to choose and make the most of online courses, including tips on creating a structured curriculum and staying disciplined. While self-study offers many advantages, it's crucial to be realistic about the effort required and to supplement online learning with practical experience where necessary, especially for safety-critical skills.

Career Progression in PPE Fields

Understanding potential career trajectories is crucial for anyone considering a future in Personal Protective Equipment. This section will map out typical entry-level positions, avenues for mid-career specialization, leadership roles in safety management, and the scope of global employment opportunities in this expanding field. This is designed to provide a roadmap for students and early-career professionals.

Entry-Level Roles: Safety Technician, Inspector, and More

Individuals starting their careers in fields related to Personal Protective Equipment can find a variety of entry-level roles across different industries. A common starting point is the role of a Safety Technician. Safety Technicians typically work under the supervision of experienced safety professionals, assisting with tasks such as conducting safety inspections, maintaining PPE inventories, delivering basic safety training, and helping to implement safety programs. This role provides excellent hands-on experience and exposure to various aspects of occupational safety.

Another accessible entry point is the position of a Safety Inspector or Health and Safety Inspector. These professionals are responsible for examining workplaces to ensure compliance with safety regulations, including those pertaining to PPE. They might identify hazards, investigate accidents, and recommend corrective actions. Government agencies and larger corporations often employ safety inspectors. Some individuals may start as PPE distributors or sales representatives, gaining product knowledge and industry connections.

Other entry-level opportunities can include roles like Environmental Health and Safety (EHS) Assistant, Occupational Health Technician, or Junior Industrial Hygienist. These positions often require an associate's degree or a bachelor's degree in occupational health and safety or a related field, along with strong attention to detail and good communication skills. Gaining certifications, even at an early career stage, can also enhance employability.

These careers represent common entry points and progression paths for individuals interested in safety and health, where PPE knowledge is fundamental.

Mid-Career Specialization Paths

As professionals gain experience in the PPE field, numerous opportunities for mid-career specialization emerge. These specialized paths allow individuals to develop deeper expertise in specific areas of safety and health, often leading to increased responsibility and higher earning potential. One common specialization is becoming an Industrial Hygienist. Industrial hygienists anticipate, recognize, evaluate, and control workplace conditions that may cause worker injury or illness. This often involves complex exposure assessments and the selection of highly specialized PPE.

Another specialization is in Risk Management, where professionals focus on identifying, assessing, and mitigating various operational risks, including those related to worker safety and PPE. Those with a healthcare background might specialize as an Infection Control Nurse or practitioner, focusing on preventing healthcare-associated infections, a role where PPE is paramount. Other specializations can include ergonomics, focusing on designing workplaces and equipment (including PPE) to optimize human well-being and overall system performance, or focusing on specific high-hazard industries like construction, oil and gas, or chemical manufacturing.

Pursuing advanced certifications, such as the Certified Industrial Hygienist (CIH) or specialized certifications in areas like construction safety or hazardous materials management, can facilitate these mid-career transitions. Continuous learning and staying abreast of new technologies and regulations are crucial for success in any specialized PPE-related role.

These careers represent specialized mid-career paths where expertise in PPE is critical.

Leadership Positions in Safety Management

With significant experience and a proven track record, professionals in the PPE field can advance to leadership positions in safety management. These roles involve overseeing comprehensive safety programs, developing safety policies and procedures, managing teams of safety professionals, and ensuring organizational compliance with all relevant health and safety regulations. A common leadership title is Safety Manager or Director of Environmental Health and Safety (EHS).

Safety Managers are responsible for creating and fostering a strong safety culture within an organization. They work closely with senior management to integrate safety into all aspects of business operations. Their responsibilities often include budget management for safety programs, liaising with regulatory agencies, overseeing accident investigations, and developing strategies for continuous improvement in safety performance. A deep understanding of PPE, from selection and procurement to training and program evaluation, is essential for these roles.

Other leadership positions might include roles like Corporate Safety Director, Regional Safety Manager, or Chief Safety Officer. These positions typically require a bachelor's or master's degree in a relevant field, extensive experience, and often advanced professional certifications like the CSP. Strong leadership, communication, strategic thinking, and problem-solving skills are paramount for success in these high-level safety management roles. Professionals in these positions play a critical role in protecting the workforce and ensuring the long-term sustainability of their organizations.

These courses are designed for individuals aiming for or currently in safety management roles, covering essential aspects of health, safety, and environmental management.

This career path is a common goal for those seeking leadership roles in the safety field.

This book offers valuable insights for those in or aspiring to leadership positions in safety engineering and management.

Global Employment Opportunities in the PPE Sector

The demand for expertise in Personal Protective Equipment is not confined to a single country or region; it is a global need. As industries expand worldwide and awareness of occupational and public health safety grows, so do the employment opportunities for PPE professionals. Developing economies, in particular, are seeing increased investment in infrastructure and manufacturing, which often correlates with a greater need for robust safety practices and, consequently, skilled safety personnel.

Multinational corporations often require safety professionals who can navigate international standards and manage safety programs across different cultural and regulatory contexts. There are also opportunities with international organizations, non-governmental organizations (NGOs), and consulting firms that work on global health and safety initiatives. The COVID-19 pandemic further highlighted the global interconnectedness of PPE supply chains and the universal need for expertise in pandemic preparedness and response, which heavily involves PPE.

For individuals considering a global career, language skills, cultural adaptability, and an understanding of international safety standards and regulations are highly advantageous. Professional certifications that are recognized internationally can also enhance global mobility. The field of PPE offers the potential for a truly international career, contributing to safety and well-being across diverse settings and populations. The World Bank and the World Health Organization (WHO) are examples of international bodies that often address issues related to PPE in global health and development contexts.

Emerging Technologies in Personal Protective Equipment

Innovation is a constant in the world of PPE. This section looks to the future, exploring cutting-edge developments like smart PPE integrated with the Internet of Things (IoT), advanced new filtration materials, and biometric monitoring systems. It will also touch upon market growth projections, offering insights for those interested in the technological frontier and investment landscape of PPE.

Smart PPE: The Role of IoT and Wearable Tech

The integration of smart technologies, particularly the Internet of Things (IoT) and wearable sensors, is revolutionizing Personal Protective Equipment. Smart PPE goes beyond passive protection by actively monitoring the wearer's environment, physiological status, or the equipment's integrity. This can provide real-time data and alerts, significantly enhancing worker safety and situational awareness.

Examples of smart PPE include helmets equipped with sensors that can detect impacts, falls, or exposure to hazardous gases. Smart vests or garments might incorporate GPS tracking, vital sign monitoring (heart rate, body temperature), and even communication capabilities. Some advanced respirators now feature sensors that monitor filter life or detect the presence of specific airborne contaminants. This data can be transmitted wirelessly to a central system or a supervisor's device, allowing for immediate intervention in case of an emergency or unsafe condition.

The implementation of smart PPE also presents challenges, including data privacy concerns, the need for robust connectivity in harsh environments, battery life limitations, and the cost of the technology. However, as the technology matures and becomes more cost-effective, smart PPE is expected to become increasingly prevalent, offering unprecedented levels of protection and data-driven safety management. OpenCourser users interested in this area can explore courses related to Internet of Things (IoT) and wearable technology to understand the underlying principles.

Breakthroughs in Advanced Filtration Materials

Respiratory protection is a critical area of PPE, and advancements in filtration materials are key to improving its effectiveness, comfort, and sustainability. Traditional filters, while effective, can sometimes lead to breathing resistance and may have a limited lifespan. Researchers are actively developing new materials and filter designs to overcome these limitations.

One area of innovation involves the use of nanofibers in filter media. Nanofiber-based filters can offer higher filtration efficiency for very small particles, including viruses, often with lower breathing resistance compared to conventional materials. These materials can also be engineered to have antimicrobial properties, actively neutralizing trapped pathogens. Another approach involves developing "rechargeable" or self-cleaning filter materials that could extend the life of respirators and reduce waste.

Researchers are also exploring bio-based and biodegradable materials for filters as a more sustainable alternative to petroleum-derived plastics. The goal is to create filters that are not only highly protective and comfortable but also have a reduced environmental impact. These advancements are crucial for addressing both everyday occupational hazards and public health challenges like pandemics, where effective respiratory protection is paramount.

Biometric Monitoring Systems Integrated into PPE

The integration of biometric monitoring systems into Personal Protective Equipment represents a significant leap forward in proactive safety management. These systems use sensors embedded in PPE to track a worker's physiological data in real-time, providing early warnings of potential health issues or overexertion. This is particularly valuable in demanding or hazardous environments where workers are at risk of heat stress, fatigue, or exposure to harmful substances.

Biometric sensors in smart helmets, vests, or even footwear can monitor vital signs such as heart rate, core body temperature, respiration rate, and activity levels. Some systems can also detect signs of fatigue or drowsiness. If a worker's biometric data exceeds pre-set safe thresholds, an alert can be sent to the worker and their supervisor, allowing for timely intervention, such as taking a break, rehydrating, or seeking medical attention.

This technology not only helps prevent acute incidents but can also contribute to long-term health and wellness by identifying patterns of strain or exposure. The data collected can inform work-rest schedules, task rotation, and other preventative measures. As with other smart PPE, considerations around data privacy, accuracy of sensors, and user acceptance are important factors in the successful implementation of biometric monitoring systems.

These books provide foundational knowledge relevant to understanding the advanced materials and health implications discussed in emerging PPE technologies.

Exploring these topics can provide deeper insights into the technological and health-related aspects of PPE advancements.

Market Growth Projections and Investment Opportunities

The global Personal Protective Equipment market has seen significant growth in recent years and is projected to continue its expansion. Several factors are driving this growth, including increasing awareness of workplace safety, stringent occupational health and safety regulations worldwide, and the ongoing industrialization in emerging economies. The COVID-19 pandemic also led to an unprecedented surge in demand for certain types of PPE, particularly in the healthcare sector, and has had a lasting impact on public and institutional awareness regarding the importance of protective equipment.

Market research reports from firms like Grand View Research and Fortune Business Insights indicate a positive growth trajectory for the PPE market. For example, one report noted the global PPE market size was over USD 79.53 billion in 2023 and is anticipated to grow at a CAGR of 7.2% from 2024 to 2030. Another report projected the market to grow from USD 87.69 billion in 2024 to USD 128.57 billion by 2032, at a CAGR of 4.9%. While specific figures may vary between reports, the overall trend points towards sustained market growth.

This growth presents investment opportunities across the PPE value chain, from raw material suppliers and manufacturers to distributors and technology developers. Innovations in smart PPE, sustainable materials, and advanced filtration technologies are particularly attractive areas for investment. As organizations and governments continue to prioritize safety and health, the demand for effective and innovative PPE solutions is expected to remain strong. For those interested in market trends, resources like Grand View Research and Fortune Business Insights offer detailed market analysis reports.

Ethical and Sustainability Challenges

The production, use, and disposal of Personal Protective Equipment are not without ethical and sustainability concerns. This section will address the environmental footprint of disposable PPE, the challenge of ensuring equitable access, the delicate balance between cost and protection, and emerging circular economy initiatives aimed at mitigating these issues. This is for those considering the broader societal and environmental impact of PPE.

Environmental Impact of Disposable PPE

The widespread use of disposable Personal Protective Equipment, particularly items like single-use masks, gloves, and gowns, has raised significant environmental concerns. Many of these products are made from petroleum-based plastics, such as polypropylene and polyethylene, which are not readily biodegradable. When discarded, this PPE contributes to the growing problem of plastic pollution in landfills and, unfortunately, in natural environments like oceans and waterways.

The COVID-19 pandemic dramatically amplified this issue, with billions of masks and gloves being used and discarded globally every month. This surge in PPE waste has put additional strain on waste management systems. Improperly discarded PPE can break down into microplastics, which can contaminate ecosystems and potentially enter the food chain. The manufacturing process for these plastics also consumes resources and contributes to greenhouse gas emissions.

Addressing the environmental impact of disposable PPE requires a multi-faceted approach. This includes exploring more sustainable materials, improving waste collection and recycling infrastructure for PPE, promoting the use of reusable PPE where appropriate and safe, and raising public awareness about responsible disposal practices. Research into biodegradable plastics and advanced recycling technologies for mixed-material PPE is ongoing, but scalable solutions are still needed.

Ensuring Equitable Access to PPE, Especially in Developing Regions

A significant ethical challenge related to Personal Protective Equipment is ensuring equitable access for all who need it, particularly in low- and middle-income countries and for vulnerable populations. During global health crises, such as the COVID-19 pandemic, demand for PPE can skyrocket, leading to supply shortages and price increases. This can disproportionately affect regions with fewer resources and less purchasing power, leaving frontline workers and communities at greater risk.

Even in non-pandemic times, access to appropriate and sufficient PPE can be a challenge in under-resourced settings due to cost, logistical issues, and lack of awareness or enforcement of safety standards. This can lead to higher rates of occupational injuries and illnesses in certain industries and regions. International organizations, governments, and NGOs play a crucial role in addressing these inequities through initiatives that support local manufacturing, bulk procurement, and distribution of PPE to areas in need.

Efforts to improve equitable access also involve promoting technology transfer and capacity building to enable developing regions to produce their own PPE. Furthermore, developing affordable and effective PPE solutions suitable for diverse climates and cultural contexts is important. The ethical imperative to protect all workers and communities, regardless of their geographic location or economic status, underscores the need for global cooperation and solidarity in ensuring access to essential protective equipment.

The Balancing Act: Cost vs. Protection Efficacy

A persistent challenge in the world of Personal Protective Equipment is striking the right balance between the cost of the equipment and the level of protection it provides. While the primary goal is always to ensure adequate safety, economic factors inevitably play a role in decision-making, both for individual users and for organizations responsible for procuring PPE.

Higher-specification PPE, offering greater protection or incorporating advanced features like smart technology, often comes at a higher price point. For businesses, especially small and medium-sized enterprises, or for individuals with limited budgets, the cost of providing or purchasing the most advanced PPE for all potential hazards might be prohibitive. This can lead to difficult choices and potential compromises, where less expensive but potentially less effective PPE is chosen, or where PPE is used beyond its recommended lifespan to save costs.

However, under-protecting workers can lead to far greater costs in the long run, including medical expenses, lost productivity, legal liabilities, and reputational damage. A thorough risk assessment is crucial for determining the minimum acceptable level of protection required for specific tasks and hazards. Regulations and standards provide a baseline, but organizations may choose to exceed these minimums. The decision-making process should involve a careful evaluation of the risks, the available PPE options, and the long-term benefits of investing in adequate protection. Educating stakeholders about the true cost of inadequate protection is also an important aspect of this balancing act.

These courses provide essential knowledge on infection prevention and control, directly addressing the balance between protection efficacy and practical implementation in healthcare and other settings.

This book provides a comprehensive overview of infection control, a field where the cost-versus-efficacy of PPE is a constant consideration.

These topics are central to understanding the challenges of balancing cost, protection, and accessibility in PPE.

Circular Economy Initiatives in the PPE Lifecycle

In response to the environmental challenges posed by disposable Personal Protective Equipment, there is a growing interest in applying circular economy principles to the PPE lifecycle. A circular economy aims to minimize waste and maximize resource utilization by keeping products and materials in use for as long as possible through strategies like reuse, repair, remanufacturing, and recycling.

For PPE, this can involve several approaches. One is the design and promotion of reusable PPE, such as washable gowns and respirators with replaceable filters, where feasible and safe. Companies like AmorSui are developing business models around reusable PPE, including laundry and tracking systems. Another focus is on developing innovative recycling technologies that can handle the complex materials often found in PPE, such as mixed plastics or textiles. Some research has explored chemical recycling processes or methods to convert PPE waste into other useful materials, like construction additives or fuel.

Circular economy initiatives also emphasize better design for disassembly and recyclability from the outset. This means choosing materials that are easier to separate and recycle and avoiding the use of problematic substances. Furthermore, robust collection and sorting systems are needed to ensure that used PPE is channeled into appropriate recycling streams rather than ending up in landfills. While the transition to a circular economy for PPE is still in its early stages and faces significant challenges (e.g., decontamination of potentially infectious waste), it holds considerable promise for reducing the environmental footprint of these essential products. The World Economic Forum has highlighted the need for such innovative solutions to combat PPE waste.

Frequently Asked Questions (Career Focus)

This section directly addresses common questions that career-focused individuals might have about the Personal Protective Equipment field. The answers aim to be data-driven and practical, providing realistic insights into certifications, career transitions, the impact of automation, salary expectations, global demand, and freelance opportunities.

What are the essential certifications for starting an entry-level role in a PPE-related field?

For many entry-level roles in areas related to Personal Protective Equipment, specific PPE certifications might not be an absolute prerequisite if you have a relevant degree (e.g., in Occupational Health and Safety). However, possessing certain foundational safety certifications can significantly enhance your resume and demonstrate a commitment to the field. For instance, certifications like the OSHA 10-hour or 30-hour Outreach Training Program (for various industries like construction or general industry) are widely recognized in the U.S. and provide a good baseline understanding of workplace safety, including PPE.

Some entry-level positions, particularly those involving direct PPE distribution, fitting, or highly specialized equipment use (like respiratory protection), might require or prefer candidates with specific manufacturer certifications or competency verifications (e.g., qualitative or quantitative fit testing for respirators). If you're aiming for a technician role, certifications related to specific equipment inspection (e.g., fall protection equipment inspector) can be beneficial. As you gain experience, pursuing broader certifications like the Associate Safety Professional (ASP) can be a valuable next step. Many employers also value first aid and CPR certifications as complementary skills for safety-focused roles.

It's always advisable to check the specific requirements listed in job postings for the types of roles and industries you are interested in. Online learning platforms and professional organizations often list relevant certifications that can help you get started. OpenCourser can help you find courses that prepare you for such certifications; for example, you can search for OSHA certification courses to build a strong foundation.

Is it possible to transition expertise in PPE across different industries (e.g., healthcare to construction)?

Yes, expertise in Personal Protective Equipment is often transferable across different industries, although some industry-specific knowledge and adaptation will likely be required. The fundamental principles of hazard assessment, PPE selection, fit, use, and maintenance are broadly applicable. For example, understanding how to manage a respiratory protection program or select appropriate chemical protective clothing involves core competencies that are valuable in healthcare, manufacturing, construction, and many other sectors.

However, each industry has its unique hazards, regulatory requirements, work environments, and types of PPE commonly used. Someone transitioning from healthcare (focused on infection control, sterile environments, and biological hazards) to construction (focused on physical hazards like impacts, falls, and noise) would need to learn the specific standards (e.g., OSHA construction standards vs. healthcare regulations), common hazards, and specialized PPE relevant to the new industry. For example, knowledge of fall arrest systems is critical in construction but less so in typical healthcare settings.

Professionals looking to make such a transition can benefit from targeted training, industry-specific certifications, networking with professionals in the new sector, and highlighting their transferable skills. Emphasizing a strong understanding of risk assessment methodologies, regulatory compliance frameworks, and training principles can demonstrate adaptability. Many safety professionals successfully move between industries by continuously learning and applying their core safety knowledge to new contexts.

How is automation and robotics impacting jobs related to PPE management and use?

Automation and robotics are beginning to influence various aspects of Personal Protective Equipment management and use, presenting both opportunities and shifts in job roles. On one hand, automation can reduce the need for humans to enter highly hazardous environments, thereby decreasing the reliance on certain types of PPE in those specific tasks. For instance, robots might be used for tasks like spray painting, welding, or handling highly toxic materials, minimizing direct human exposure.

However, automation also creates new needs. The maintenance and programming of these robotic systems may require specialized PPE for the technicians involved. Furthermore, automation can be integrated into PPE itself, as seen with smart PPE that uses sensors and data analytics to enhance safety. This creates demand for professionals skilled in managing and interpreting data from these smart systems, and in developing and implementing such technologies.

In terms of PPE management, automation can streamline processes like inventory control, distribution, and inspection. Automated vending machines for PPE or software for tracking PPE usage and maintenance are examples. While this might change some traditional logistical roles, it also creates needs for individuals who can manage and optimize these automated systems. Overall, while some manual tasks related to PPE might be reduced by automation, the need for skilled professionals to design, select, implement, and manage PPE programs, especially with the advent of more sophisticated and technologically advanced PPE, is likely to continue and evolve rather than diminish.

What are the general salary expectations at different stages of a career in PPE-related fields?

Salary expectations in Personal Protective Equipment-related fields vary widely based on factors such as experience, education, certifications, industry, geographic location, and the specific role. Generally, as professionals gain more experience and acquire advanced certifications, their earning potential increases.

Entry-Level (0-2 years experience): Individuals in roles like Safety Technician or Junior Safety Officer might expect salaries ranging from approximately $50,000 to $65,000 annually in the U.S., though this can be lower or higher depending on the factors mentioned. Some data suggests entry-level safety inspectors might start around $30,000-$40,000, but this can also vary greatly.

Mid-Career (3-10 years experience): Professionals with several years of experience, possibly in specialized roles like Industrial Hygienist or mid-level Safety Manager, or those with certifications like the CSP, could see salaries in the range of $60,000 to $90,000 or more. Those with 5-10 years of experience often earn in the $70,000-$100,000+ range depending on the specific role and industry (e.g., oil and gas or construction often pay more due to higher risks).

Senior/Leadership Roles (10+ years experience): Senior Safety Managers, Directors of EHS, or highly specialized consultants with extensive experience and advanced credentials can command salaries well over $100,000, sometimes exceeding $150,000, particularly in high-demand industries or large corporations. Composite salary data from some sources shows "Professional 3" roles (likely senior, non-managerial professionals) having midpoints around $88,000-$92,000, with ranges extending higher. It is advisable to research salary benchmarks for specific roles and locations using resources like the U.S. Bureau of Labor Statistics (BLS) or industry-specific salary surveys.

These careers offer a range of salary potentials depending on experience, specialization, and industry, all requiring a strong foundation in PPE knowledge.

Where is the global demand for PPE professionals most concentrated?

The global demand for Personal Protective Equipment professionals is widespread but tends to be more concentrated in regions and industries with significant industrial activity, stringent safety regulations, and a strong focus on public health. Historically, developed regions like North America and Europe have had robust demand due to well-established industrial sectors (manufacturing, construction, oil and gas, chemicals) and comprehensive occupational safety and health frameworks. North America, for instance, dominated the PPE market with a significant share in 2023. Europe also holds a substantial share of the global PPE market.

However, the Asia-Pacific region is experiencing rapid growth in demand for PPE professionals. This is driven by expanding manufacturing and construction sectors, increasing foreign investment, and a growing awareness of workplace safety standards. Countries with large industrial bases and growing economies are key hotspots. The healthcare sector globally also represents a major source of demand, particularly in light of recent pandemics and an ongoing focus on infection control.

Specific industries with inherently higher risks, such as mining, oil and gas exploration and production, chemical manufacturing, and heavy construction, consistently require a high number of safety professionals with PPE expertise. Furthermore, regions prone to natural disasters or with significant emergency response needs also generate demand for professionals skilled in PPE for disaster preparedness and relief efforts. The rise of new technologies and emerging industries may also create new pockets of demand in the future.

Are there freelance or consulting opportunities available for experienced PPE specialists?

Yes, there are certainly freelance and consulting opportunities available for experienced Personal Protective Equipment specialists. Many organizations, particularly small to medium-sized enterprises (SMEs) that may not have the resources to employ a full-time senior safety professional, often engage consultants for specific projects or expertise. Experienced specialists can offer a range of services, such as developing and auditing safety management systems, conducting comprehensive hazard assessments, providing specialized PPE training, advising on regulatory compliance, or investigating complex incidents.

Consultants might specialize in particular industries (e.g., construction safety consultant, healthcare infection control advisor) or specific types of hazards or PPE (e.g., respiratory protection program consultant, chemical safety expert). The ability to offer tailored solutions, stay updated on the latest regulations and technologies, and demonstrate a strong track record of success is crucial for building a successful consulting practice.

Networking through professional organizations, obtaining advanced certifications (like CSP or CIH), and developing a strong professional reputation are key to securing freelance and consulting work. The flexibility and autonomy of consulting can be appealing, but it also requires strong business development skills, self-motivation, and the ability to manage multiple clients and projects. As industries continue to evolve and face new safety challenges, the demand for specialized external expertise in PPE is likely to remain robust.

Useful Links and Resources

To further your exploration of Personal Protective Equipment, the following resources may be helpful. OpenCourser itself is a comprehensive platform to find online courses and books across a vast range of subjects, including those related to health, safety, and PPE. You can visit OpenCourser to begin your search or browse specific categories.

Key Regulatory and Information Bodies

Understanding the guidelines and standards set by official bodies is crucial in the field of PPE.

Occupational Safety and Health Administration (OSHA): A primary source for regulations and guidance on workplace safety in the United States, including extensive information on PPE. You can visit their section on Personal Protective Equipment for detailed standards and resources.

European Commission: Provides information on PPE regulations within the European Union, including Regulation (EU) 2016/425. Their page on Personal protective equipment (PPE) is a key resource.

National Institute for Occupational Safety and Health (NIOSH): A U.S. federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. NIOSH plays a significant role in PPE research and respirator certification. Their Personal Protective Technology Program is a valuable resource.

World Health Organization (WHO): Provides global guidance on public health matters, including the use of PPE in healthcare settings and during pandemics. Their website, who.int, contains numerous publications and updates.

Exploring Educational Resources on OpenCourser

OpenCourser offers a wealth of learning materials to deepen your understanding of PPE and related fields.

Browse Health and Medicine Courses: For courses specifically related to healthcare safety, infection control, and medical PPE, visit the Health & Medicine category.

Explore Engineering Topics: If you're interested in the design and materials science aspects of PPE, the Engineering category may have relevant courses.

Search for Specific Safety Training: Use the OpenCourser search function to find courses on specific topics like "OSHA training," "industrial hygiene," or "risk assessment." For example, a search for occupational safety courses will yield many relevant results.

Utilize the Learner's Guide: For tips on how to effectively learn online and make the most of your educational journey, check out the OpenCourser Learner's Guide.

The field of Personal Protective Equipment is multifaceted, offering diverse career paths and continuous opportunities for learning and innovation. Whether you are just beginning to explore this area or are looking to advance your expertise, a commitment to understanding the principles, practices, and evolving landscape of PPE is essential for contributing to a safer and healthier world. We encourage you to utilize the resources available on OpenCourser to further your knowledge and achieve your learning goals.