Maintenance Technician

The Essential Role of the Maintenance Technician

A Maintenance Technician is a skilled professional dedicated to the upkeep, repair, and optimal functioning of machinery, equipment, and physical structures. These individuals are the backbone of many industries, ensuring that operations run smoothly, safely, and efficiently. They are hands-on problem-solvers, adept at diagnosing issues and implementing effective solutions across a wide range of mechanical, electrical, and structural systems. The role often involves a blend of preventive actions to avert problems and reactive measures to address them when they arise, all with the goal of minimizing downtime and maximizing productivity.

Working as a Maintenance Technician can be engaging due to the variety of tasks and challenges encountered daily. One day might involve troubleshooting a complex piece of automated machinery in a manufacturing plant, while the next could focus on ensuring the climate control systems in a large commercial building are operating perfectly. This career offers the satisfaction of directly contributing to an organization's success by keeping its essential assets in prime condition and ensuring a safe environment for everyone.

Introduction to Maintenance Technician Roles

Understanding the full scope of a Maintenance Technician's duties provides a clear picture of their importance. These professionals are integral to the operational stability of numerous sectors, applying a diverse skill set to maintain the systems that keep businesses and services running.

What is a Maintenance Technician?

A Maintenance Technician is a professional responsible for ensuring that machinery, equipment, systems, and buildings are in good operational condition. Their work involves a broad spectrum of tasks, including inspection, preventive maintenance, troubleshooting, and repair. They are the troubleshooters and fixers who keep the physical assets of an organization functioning correctly, preventing costly breakdowns and ensuring safety.

The scope of their work can be vast, ranging from simple repairs like fixing a leaky faucet in a residential complex to complex tasks like diagnosing and repairing sophisticated production machinery in a factory. They might work on electrical systems, mechanical equipment, hydraulic and pneumatic systems, plumbing, and HVAC (Heating, Ventilation, and Air Conditioning) systems. Essentially, if something needs to be kept in working order or fixed, a Maintenance Technician is often the one to call.

These technicians are not just "fix-it" people; they are proactive in their approach. A significant part of their role involves preventive maintenance—performing regular checks and servicing to identify and address potential issues before they escalate into major problems. This foresight helps organizations avoid unexpected downtime, extend the lifespan of their equipment, and maintain a safe working environment.

Where Do Maintenance Technicians Work?

Maintenance Technicians are in demand across a multitude of industries because nearly every organization relies on physical equipment or facilities that require upkeep. Manufacturing is a major employer, where technicians maintain and repair production machinery, automated systems, and facility infrastructure. In this setting, minimizing downtime is critical to production targets.

Healthcare facilities, such as hospitals and clinics, also heavily depend on Maintenance Technicians. They ensure that essential systems like HVAC, electrical power, and medical gas lines are functioning reliably, which is vital for patient care and safety. Commercial and residential properties, including office buildings, apartment complexes, and retail centers, employ technicians for general building upkeep, encompassing plumbing, electrical work, and appliance repair. Other sectors include transportation (maintaining fleet vehicles or infrastructure), energy and utilities (power plants, water treatment facilities), and even hospitality (hotels and resorts).

The diversity of industries means that Maintenance Technicians can find work in various environments, from large industrial plants and bustling commercial centers to quieter residential settings. This variety also allows for specialization in particular types of equipment or systems, depending on the industry. For individuals seeking a career with broad applicability and consistent demand, the wide array of industries employing Maintenance Technicians is a significant advantage.

OpenCourser offers a broad selection of courses relevant to various industries. You can easily browse through thousands of courses to find those that align with specific sectors such as Manufacturing or Engineering.

Core Duties and Goals

The primary responsibilities of a Maintenance Technician revolve around ensuring the reliability, safety, and efficiency of equipment and facilities. A core duty is performing preventive maintenance, which involves scheduled inspections, lubrication, cleaning, and replacement of worn parts to prevent breakdowns. This proactive approach is crucial for minimizing unexpected failures and extending the operational life of assets.

Troubleshooting and repair are also central to the role. When equipment malfunctions or systems fail, technicians must diagnose the root cause of the problem and execute effective repairs. This can involve interpreting technical manuals, reading blueprints and schematics, and using diagnostic tools. Their ability to quickly and accurately resolve issues is vital for restoring operations and preventing further disruptions.

Beyond these hands-on tasks, Maintenance Technicians are often responsible for maintaining records of their work, including completed repairs, parts used, and maintenance schedules, often using a Computerized Maintenance Management System (CMMS). Adherence to safety protocols is paramount in all their activities to protect themselves and others from potential hazards. The overarching goals are to maximize equipment uptime, ensure a safe working environment, control maintenance costs, and support the overall operational objectives of their organization.

Maintenance Technician: Daily Tasks and Work Environment

Grasping the day-to-day realities of a Maintenance Technician role, including common activities and the typical settings, helps prospective individuals assess if this career aligns with their expectations and preferences.

A Day in the Life

A typical day for a Maintenance Technician is often dynamic and rarely predictable, though some routine tasks are always part of the schedule. The day might begin with reviewing scheduled preventive maintenance tasks or outstanding work orders. This could involve inspecting specific machinery, lubricating components, changing filters, or testing safety systems.

Throughout the day, technicians respond to calls for unexpected breakdowns or malfunctions. This requires them to shift priorities, quickly assess the situation, diagnose the problem, and perform necessary repairs. They might need to consult technical manuals, order spare parts, or even fabricate a temporary solution to get critical equipment back online. Problem-solving is a constant element of their work.

Documentation is another key daily activity. Technicians meticulously record the maintenance and repair work performed, parts used, and time spent on each task, often using a CMMS. This record-keeping is essential for tracking equipment history, managing inventory, and planning future maintenance. Communication with supervisors, colleagues, and sometimes equipment operators is also frequent to coordinate work and report on progress.

The Demands of the Job

The role of a Maintenance Technician comes with a unique set of physical and technical demands. Physically, the job often requires standing for extended periods, lifting and carrying tools or equipment, and working in various positions, including kneeling, crouching, or reaching overhead. Technicians may need to work in confined spaces, at heights on ladders or lifts, or in environments with fluctuating temperatures. Good physical stamina and dexterity are therefore beneficial.

Technically, the demands are equally significant. A solid understanding of mechanical principles, electrical theory, and often hydraulic and pneumatic systems is crucial. Technicians must be proficient in reading and interpreting blueprints, electrical schematics, and technical manuals. The ability to use a variety of hand and power tools, as well as diagnostic equipment like multimeters and calibration tools, is essential.

Strong analytical and problem-solving skills are perhaps the most critical mental demands. Technicians must be able to systematically diagnose complex issues, identify root causes, and implement effective solutions, sometimes under pressure to minimize downtime. Continuous learning is also a key aspect, as technology and equipment are constantly evolving.

Work Settings and Conditions

Maintenance Technicians can find themselves working in a wide array of settings. In manufacturing plants, this might mean working on a factory floor amidst operating machinery, which can be noisy and require adherence to strict safety protocols. They might encounter various environmental conditions, from the heat of a boiler room to the chill of a refrigerated area.

In commercial or residential buildings, the work environment can be more varied, ranging from office spaces and apartment units to utility rooms and rooftops. Technicians in these roles might interact more frequently with tenants or building occupants. Healthcare settings, like hospitals, require technicians to work in and around patient care areas, necessitating a high degree of care and adherence to hygiene standards.

Work schedules can also vary. While many Maintenance Technicians work standard daytime hours, shift work, including evenings, nights, weekends, and holidays, is common, especially in facilities that operate 24/7. On-call duties for emergency repairs are also a possibility in many positions. Regardless of the setting, safety is a constant consideration, and technicians are typically required to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, hard hats, and sometimes respirators.

Formal Education Pathways

For those planning a career as a Maintenance Technician, several formal educational routes can provide the necessary knowledge and skills. These pathways range from foundational high school coursework to specialized vocational training and associate degrees.

Building a Foundation in High School

Aspiring Maintenance Technicians can begin laying the groundwork for their careers while still in high school. Courses in mathematics, particularly algebra and geometry, are valuable as they develop problem-solving abilities and an understanding of measurements and spatial relationships, which are frequently used in the trades. Taking science courses, especially physics, helps in understanding fundamental principles of mechanics, electricity, and energy transfer – all relevant to maintenance work.

Beyond core academics, participation in vocational or technical education classes can be highly beneficial. Subjects like woodworking, metal shop, electronics, or automotive technology offer hands-on experience with tools and machinery, and introduce basic repair and troubleshooting concepts. These practical skills not only build confidence but can also provide a significant advantage when applying for apprenticeships or further technical training.

Developing good communication and teamwork skills through extracurricular activities or part-time jobs can also be an asset. Maintenance Technicians often work as part of a team and need to communicate effectively with colleagues and supervisors. A strong foundation in these areas during high school can smooth the transition into more specialized training and the workforce.

Vocational Training and Apprenticeships

Vocational training programs, often offered at technical colleges or trade schools, provide focused, hands-on instruction in specific maintenance disciplines. These programs typically cover areas like industrial mechanics, electrical systems, HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration), welding, or general building maintenance. The curriculum is designed to impart practical skills and theoretical knowledge directly applicable to the job. Graduates of these programs often earn a certificate or diploma, signaling to employers that they have received specialized training.

Apprenticeships are another excellent pathway, combining structured on-the-job training with related classroom instruction. As an apprentice, an individual works under the guidance of experienced technicians, learning the trade through practical application in a real-world setting. Apprenticeships are often sponsored by employers or labor unions and typically last several years. This "earn while you learn" model is attractive as apprentices receive wages that increase as their skills develop.

Both vocational training and apprenticeships emphasize the development of tangible skills and a deep understanding of maintenance practices. They offer a direct route into the profession, often with strong job placement rates due to the practical experience gained. For individuals who prefer hands-on learning and want to enter the workforce relatively quickly, these pathways are compelling options. Some high schools may even offer pre-apprenticeship programs that can provide a head start.

To further explore foundational skills, consider courses that cover basic mechanical or electrical concepts. These courses can provide a good starting point before committing to a full vocational program or apprenticeship.

Earning an Associate Degree

An Associate of Applied Science (A.A.S.) degree in a field like Industrial Maintenance Technology, Mechatronics, or Electrical Technology can provide a more comprehensive educational foundation for a Maintenance Technician. These two-year programs, typically offered at community colleges and technical colleges, blend theoretical coursework with hands-on laboratory experience.

The curriculum in these programs often includes subjects such as AC/DC electricity, motor controls, programmable logic controllers (PLCs), hydraulics and pneumatics, mechanical drive systems, blueprint reading, and welding. Students also typically take general education courses in math, communication, and science, which enhance their analytical and problem-solving abilities. Some programs may offer specialization tracks, allowing students to focus on areas like electrical maintenance, mechanical maintenance, or automation.

An associate degree can enhance a technician's career prospects by providing a broader understanding of industrial systems and emerging technologies. It can lead to more specialized roles, higher earning potential, and opportunities for advancement into supervisory or management positions. For individuals seeking a deeper theoretical understanding alongside practical skills, and for those who may wish to pursue further education later, an associate degree is a valuable investment.

These books provide in-depth knowledge about the core principles and practices in maintenance engineering, which can be very helpful for students pursuing an associate degree or looking to deepen their understanding of the field.

Online and Independent Learning for Aspiring Technicians

In today's digital age, online learning and independent study offer flexible and accessible avenues for acquiring knowledge and skills relevant to a Maintenance Technician career. These approaches can be particularly beneficial for self-directed learners, career pivoters, or those looking to supplement traditional education or on-the-job training.

Can Technical Skills Be Learned Online?

Online courses can be highly effective for learning the theoretical foundations of many technical skills required by Maintenance Technicians. Topics like electrical theory, principles of mechanical systems, understanding schematics and blueprints, and safety regulations are well-suited for online delivery. Many platforms offer engaging content, including video lectures, simulations, and interactive quizzes, which can help solidify understanding.

However, it's important to recognize that a Maintenance Technician role is inherently hands-on. While online learning can provide crucial knowledge, it typically cannot fully replicate the practical experience gained from working with actual tools and equipment. Therefore, online learning is often most powerful when used as a component of a broader learning strategy that also includes opportunities for hands-on practice, whether through labs, workshops, personal projects, or entry-level work.

OpenCourser is an excellent resource for discovering a wide variety of online courses related to maintenance and technical skills. The platform allows learners to easily search and compare courses from different providers, read reviews, and find options that fit their learning style and budget. Exploring the Technical Training category can be a great starting point.

Key Technical Topics for Self-Study

For individuals pursuing independent learning, focusing on key technical topics can build a strong foundation. Understanding basic electrical principles, including AC/DC circuits, Ohm's Law, and electrical safety, is fundamental for many maintenance roles. Familiarity with mechanical systems, such as gears, bearings, pumps, and power transmission, is also vital.

Learning to read and interpret technical drawings, including blueprints and schematics (electrical, hydraulic, pneumatic), is a critical skill. An introduction to HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) systems can be beneficial, as these are common in many facilities. Additionally, basic knowledge of fluid power (hydraulics and pneumatics) and an understanding of different types of fasteners and materials can be very useful.

Many online courses delve into these specific areas. For example, courses on electrical troubleshooting, motor controls, or welding basics can provide targeted knowledge. Aspiring technicians might also explore introductory materials on Programmable Logic Controllers (PLCs), as these are increasingly common in automated industrial environments.

These online courses offer a good starting point for understanding core electrical systems, a crucial area for Maintenance Technicians. They cover maintenance, troubleshooting, and the fundamentals of industrial controls.

This book offers practical guidance on troubleshooting electrical systems, which is a key skill for self-study.

Blending Online Learning with Practical Experience

The most effective approach to using online learning for a technical career like a Maintenance Technician often involves blending digital coursework with tangible, hands-on experience. Online courses can provide the theoretical knowledge and understanding of concepts, which then makes practical application more meaningful and effective. For instance, learning about electrical circuit theory online can prepare someone to then safely and more competently wire a circuit in a lab or workshop setting.

Aspiring technicians can seek out opportunities for hands-on practice to complement their online studies. This might include personal projects, such as repairing household appliances or working on a car. Volunteering for organizations that require facility upkeep or joining a makerspace can also provide valuable experience. Some online courses may include kits for hands-on experiments or access to simulation software that mimics real-world equipment.

For those transitioning careers or just starting, an entry-level position as a maintenance helper or assistant, even if part-time, can offer invaluable on-the-job training that reinforces online learning. OpenCourser's Learner's Guide offers many articles and resources on how to structure self-learning paths and effectively combine different learning modalities to achieve career goals. This resource can be particularly helpful for those crafting their own educational journey towards becoming a Maintenance Technician.

These courses focus on practical skills that can be learned online and then practiced, such as home repair, pneumatics, and an introduction to CNC, which are all valuable for a well-rounded technician.

Career Progression and Advancement

A career as a Maintenance Technician offers various pathways for growth and advancement. With experience, additional training, and a strong work ethic, technicians can move into more specialized roles, supervisory positions, or even related technical fields.

Starting Out: Entry-Level Positions

Most individuals begin their maintenance careers in entry-level roles such as Maintenance Helper, Maintenance Assistant, or Apprentice Technician. In these positions, the primary focus is on learning the fundamentals of maintenance work under the supervision of more experienced technicians. Daily tasks might include assisting with basic repairs, performing routine preventive maintenance, retrieving tools and parts, and maintaining cleanliness in work areas.

This initial phase is crucial for gaining hands-on experience with various types of equipment and systems. It's an opportunity to develop practical skills, become familiar with safety procedures, and understand the operational flow of the facility. A willingness to learn, a strong work ethic, attention to detail, and good communication skills are highly valued at this stage.

Successfully navigating an entry-level role often involves asking questions, seeking feedback, and demonstrating reliability. Employers look for individuals who are proactive and show initiative. This period builds the foundational experience necessary for taking on more responsibility and advancing to more specialized or independent technician roles.

Developing Specializations

As Maintenance Technicians gain experience and identify areas of interest, they often choose to specialize. One common path is becoming an Electrical Maintenance Technician, focusing on installing, maintaining, and repairing electrical systems, wiring, motors, and control devices. This requires a deep understanding of electrical theory, codes, and safety practices.

Another specialization is Mechanical Maintenance Technician, which involves working with machinery, including engines, pumps, conveyor systems, and hydraulic and pneumatic equipment. These technicians are experts in mechanical principles, alignment, lubrication, and component replacement. Some may further specialize as Millwrights, who install, dismantle, and move heavy industrial machinery.

Facilities Maintenance Technicians often have a broader scope, responsible for the overall upkeep of a building, including HVAC systems, plumbing, carpentry, and general repairs. In increasingly automated environments, technicians might specialize as PLC (Programmable Logic Controller) Technicians or Automation Technicians, focusing on the complex control systems that run modern manufacturing and industrial processes. Developing a specialization typically involves targeted training, certifications, and extensive hands-on experience in the chosen area.

These courses can help individuals looking to specialize in areas like electrical systems, PLC programming, or general facility systems like plumbing and HVAC.

Moving into Leadership Roles

With significant experience and demonstrated expertise, Maintenance Technicians can advance into leadership positions. Common supervisory roles include Maintenance Supervisor, Lead Technician, or Maintenance Team Leader. In these capacities, individuals are responsible for overseeing a team of technicians, assigning work orders, scheduling maintenance activities, and ensuring that work is completed safely and efficiently.

Advancement to a Maintenance Manager or Facilities Manager role typically involves greater responsibility for strategic planning, budgeting, managing vendor contracts, and overseeing the entire maintenance department or facility operations. These positions require strong leadership, organizational, communication, and financial management skills, in addition to extensive technical knowledge.

Further education, such as a bachelor's degree in engineering or management, and professional certifications (like Certified Maintenance & Reliability Professional - CMRP) can be beneficial for those aspiring to higher-level management roles. The ability to motivate a team, implement continuous improvement initiatives, and effectively manage resources are key attributes for success in these leadership positions. OpenCourser's resources in Management and Career Development can provide valuable insights for those aiming for such advancement.

These books offer comprehensive knowledge crucial for technicians aiming for supervisory or management roles, covering planning, scheduling, and overall maintenance excellence.

Industry Trends Impacting Maintenance Technicians

The field of maintenance is continuously evolving, influenced by technological advancements and shifting industry priorities. Staying aware of these trends is crucial for Maintenance Technicians to remain effective and adapt their skills accordingly.

The Rise of Automation and Predictive Maintenance

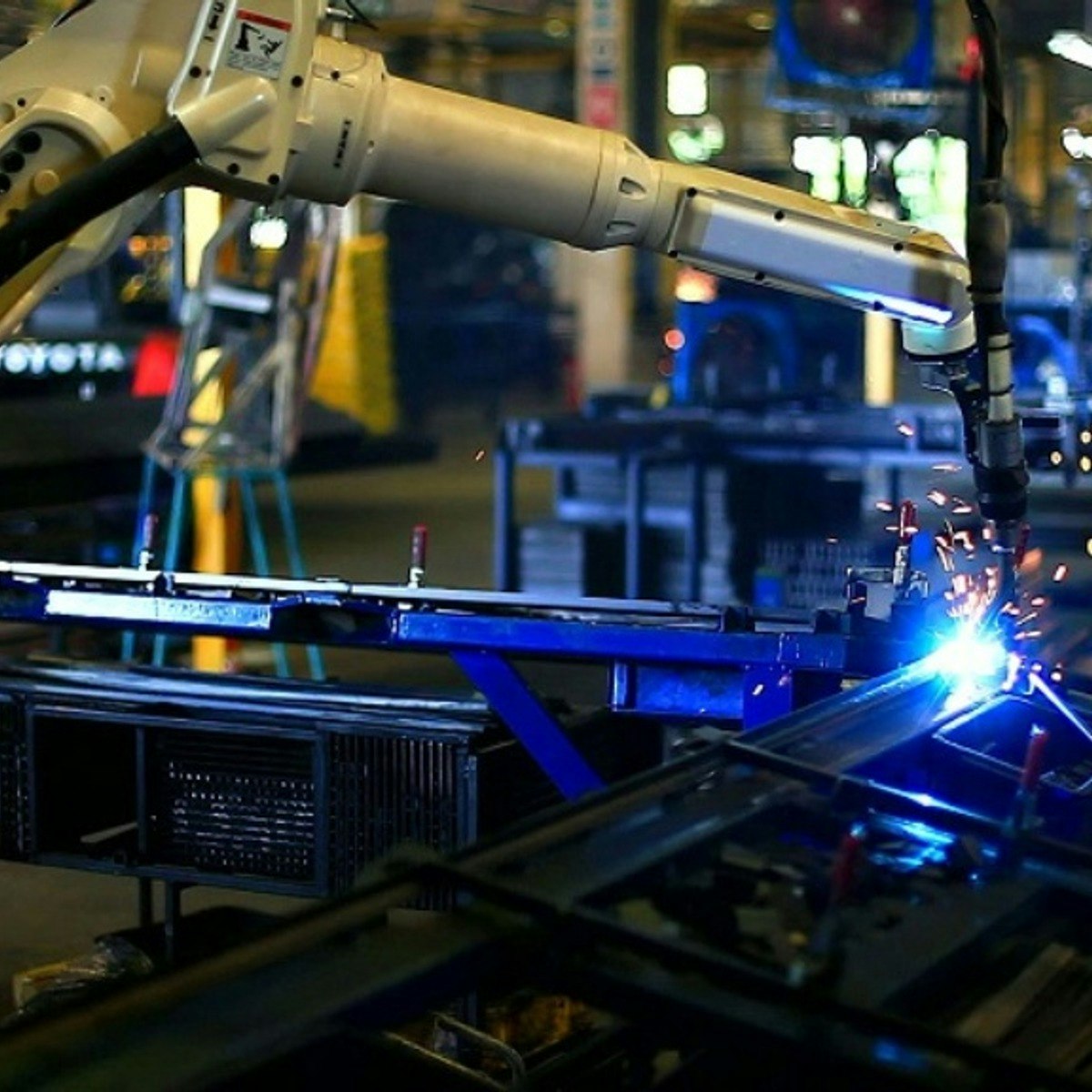

Automation is significantly transforming the landscape of industrial operations, and maintenance is no exception. As factories and facilities increasingly adopt robotic systems and automated processes, Maintenance Technicians need skills to install, maintain, and troubleshoot this sophisticated equipment. This often involves understanding PLC programming, robotics, and sensor technology.

Alongside automation, Predictive Maintenance (PdM) is becoming a prominent trend. PdM utilizes sensors and data analytics to monitor equipment condition in real-time and predict potential failures before they occur. This data-driven approach allows maintenance to be scheduled proactively, minimizing unplanned downtime and optimizing resource allocation. Technicians working with PdM systems need to be comfortable with data interpretation and may require training in using specialized diagnostic tools and software.

The U.S. Bureau of Labor Statistics (BLS) projects that overall employment in installation, maintenance, and repair occupations is projected to grow about as fast as the average for all occupations from 2023 to 2033. The BLS notes that the increasing adoption of sophisticated manufacturing machinery will require more mechanics and technicians to keep them in good working order. For more detailed information, you can explore the Occupational Outlook Handbook for various maintenance roles on the BLS website.

These courses introduce concepts related to modern manufacturing and automation, which are key trends in the maintenance field.

This book provides an introduction to predictive maintenance, a critical trend in the industry.

Sustainability and Green Initiatives

Sustainability has become a major focus across industries, and Maintenance Technicians play a vital role in supporting green initiatives. This includes maintaining equipment for optimal energy efficiency, reducing waste, and ensuring compliance with environmental regulations. For example, technicians might be responsible for fine-tuning HVAC systems to minimize energy consumption or repairing leaks to prevent water loss.

There is also a growing emphasis on maintaining and repairing environmentally friendly equipment, such as solar panels, wind turbines, or energy-efficient lighting systems. Technicians may be involved in implementing green building standards or retrofitting older facilities with more sustainable technologies. Understanding principles of energy conservation and waste management is becoming increasingly important.

This shift towards sustainability requires technicians to be knowledgeable about new "green" technologies and practices. Training in areas like renewable energy systems or environmentally safe disposal of materials can enhance a technician's value and contribute to an organization's environmental goals. Organizations like the U.S. Green Building Council (USGBC) offer resources and certifications related to green building practices, which can be relevant for facilities maintenance professionals.

The Internet of Things (IoT) in Equipment Monitoring

The Internet of Things (IoT) is revolutionizing equipment monitoring and maintenance. IoT involves embedding sensors and connectivity into machinery and systems, allowing them to collect and transmit real-time operational data. This data can provide valuable insights into equipment health, performance, and potential issues.

For Maintenance Technicians, IoT enables more proactive and precise maintenance. Instead of relying solely on scheduled preventive maintenance or waiting for a breakdown, technicians can use IoT data to identify subtle anomalies or trends that indicate an impending problem. This allows for targeted interventions before a failure occurs, reducing downtime and repair costs.

Working with IoT-enabled equipment requires technicians to develop new skills. This includes understanding how these sensor networks operate, interpreting the data they generate, and potentially using specialized software platforms for diagnostics and analysis. Basic networking knowledge and an aptitude for data-driven decision-making are becoming increasingly valuable assets in this evolving landscape.

These courses touch upon aspects of industrial automation and control systems, which are increasingly incorporating IoT technologies.

Challenges and Risks in the Role

While rewarding, a career as a Maintenance Technician also presents certain challenges and inherent risks. Understanding these aspects is important for individuals considering this path, as it allows for realistic expectations and preparation.

Navigating Physical Hazards and Prioritizing Safety

Maintenance Technicians often work in environments with potential physical hazards. These can include risks of electrical shock when working with live circuits, falls from ladders or elevated platforms, and injuries from working with heavy machinery or power tools. Exposure to chemicals, solvents, dust, or extreme temperatures can also occur depending on the specific job and industry.

Due to these risks, a strong emphasis is placed on safety. Technicians must diligently follow established safety protocols and procedures, including lockout/tagout procedures to de-energize equipment before servicing. The use of Personal Protective Equipment (PPE) such as safety glasses, gloves, hard hats, respirators, and fall protection harnesses is often mandatory and crucial for preventing injuries.

Comprehensive safety training, such as OSHA (Occupational Safety and Health Administration) courses, is typically required and highly recommended. A constant awareness of potential hazards and a commitment to safe work practices are essential for a long and healthy career in maintenance.

These courses focus on safety aspects, which are critical for Maintenance Technicians. OSHA certification is a widely recognized safety credential.

Handling Emergency Repairs and Time Constraints

One of the significant challenges for Maintenance Technicians is dealing with emergency repairs, often under tight time constraints. When critical equipment breaks down unexpectedly, the pressure to restore it to operation quickly can be intense, as downtime can lead to significant production losses or disruptions to essential services.

This requires technicians to think on their feet, troubleshoot effectively under pressure, and make sound decisions in urgent situations. They may need to work long or irregular hours to resolve an emergency. The ability to remain calm, focused, and methodical while facing a crisis is a valuable trait.

Managing these situations often involves not only technical skill but also strong problem-solving and communication abilities. Technicians might need to coordinate with other team members, communicate updates to management, and quickly source necessary parts or resources. While challenging, successfully resolving an emergency and getting operations back on track can also be a highly rewarding aspect of the job.

The Need for Continuous Learning

The field of maintenance is not static; technology, equipment, and processes are constantly evolving. New machinery is introduced, existing systems are upgraded, and new diagnostic tools and techniques emerge. This dynamic environment presents the challenge—and opportunity—of continuous learning for Maintenance Technicians.

Keeping skills and knowledge current is essential for career longevity and effectiveness. This may involve participating in manufacturer-provided training for new equipment, attending workshops or seminars on emerging technologies, pursuing additional certifications, or taking online courses to learn new skills.

A proactive approach to professional development is highly valued by employers and helps technicians adapt to changes in their industry. Embracing lifelong learning ensures that Maintenance Technicians can confidently tackle new challenges, work with the latest technologies, and continue to be valuable assets to their organizations. Many find this aspect of the career intellectually stimulating, as there is always something new to learn and master.

This book specifically addresses the importance of reliability and maintainability, which ties into the need for continuous learning as systems evolve.

Essential Tools and Technologies

Maintenance Technicians rely on a diverse array of tools and technologies to perform their duties effectively. From basic hand tools to sophisticated diagnostic equipment and software, these resources are indispensable for troubleshooting, repair, and preventive maintenance tasks.

Diagnostic Instruments

Diagnostic instruments are crucial for Maintenance Technicians to accurately identify the root causes of equipment malfunctions. One of the most commonly used tools is the multimeter, which measures voltage, current, and resistance, essential for troubleshooting electrical circuits and components. Thermal imaging cameras are increasingly used to detect overheating in electrical panels, motors, or mechanical systems, which can indicate potential problems before they escalate.

Vibration analyzers help assess the condition of rotating machinery like motors and pumps by detecting abnormal vibration patterns that could signify issues such as imbalance, misalignment, or bearing wear. For more complex electronic troubleshooting, oscilloscopes may be used to visualize and analyze electrical signals. Other specialized diagnostic tools can include pressure gauges, flow meters, and alignment tools, depending on the type of equipment being maintained.

Proficiency in using these diagnostic instruments, understanding their readings, and interpreting the data are key skills for a Maintenance Technician. Accurate diagnosis is the first step towards effective and efficient repair.

These courses provide training on essential tools and understanding related systems, like electrical equipment and piping diagrams, which are fundamental for a maintenance technician.

Computerized Maintenance Management Systems (CMMS)

A Computerized Maintenance Management System, or CMMS, is software designed to help organizations manage their maintenance operations more efficiently. Maintenance Technicians frequently interact with CMMS as part of their daily workflow. These systems are used to receive work orders, track the status of ongoing tasks, and document completed work.

CMMS software also plays a vital role in preventive maintenance scheduling, inventory management for spare parts, and generating reports on maintenance activities and equipment history. By centralizing maintenance information, CMMS helps to streamline processes, improve communication within the maintenance team, and provide valuable data for decision-making.

Familiarity with using CMMS software is an increasingly important skill for Maintenance Technicians. It allows them to manage their workload effectively, ensure accurate record-keeping, and contribute to the overall efficiency of the maintenance department. Many systems are now mobile-friendly, allowing technicians to access and update information directly from the field.

Specialized and Industry-Specific Tools

Beyond general diagnostic tools, Maintenance Technicians often use a variety of specialized tools tailored to their specific industry or area of expertise. In manufacturing environments, technicians working with automated systems will need to be familiar with tools for programming and troubleshooting Programmable Logic Controllers (PLCs).

Welding equipment is essential for technicians involved in fabrication or repair of metal structures and components. Those working with piping systems will use specialized pipefitting tools such as pipe wrenches, cutters, threaders, and benders. A wide assortment of hand tools (wrenches, screwdrivers, pliers) and power tools (drills, grinders, saws) are fundamental to nearly all maintenance tasks.

The specific toolkit of a Maintenance Technician will vary greatly depending on their role. For example, an HVAC technician will have specialized tools for refrigerant handling and ductwork, while an automotive maintenance technician will use tools specific to vehicle repair. Continuous exposure and training on these specialized tools are part of a technician's skill development.

These courses provide introductions to specialized tools and techniques like welding and CNC machining, which are valuable in many industrial maintenance settings.

Certifications and Licensing

Certifications and licenses can significantly enhance a Maintenance Technician's career prospects, demonstrating a verified level of skill, knowledge, and commitment to safety and professional standards. While not always mandatory for entry-level positions, they can be crucial for advancement and specialized work.

Foundational Safety Certifications

Safety is paramount in the maintenance field, and certifications that validate safety knowledge are highly valued by employers. The OSHA 10-hour or 30-hour General Industry or Construction safety courses are widely recognized and provide foundational knowledge of workplace safety and health standards. Completing such training demonstrates an understanding of hazard identification, avoidance, control, and prevention.

These certifications cover topics like electrical safety, fall protection, machine guarding, and proper use of personal protective equipment (PPE). Holding an OSHA certification not only enhances employability but also contributes to a safer work environment for the technician and their colleagues. Many employers consider this a baseline requirement, particularly in industrial settings.

Beyond general OSHA training, there may be more specific safety certifications relevant to particular tasks, such as confined space entry or lockout/tagout procedures. Investing in safety certifications is an investment in one's career and well-being.

Equipment-Specific and Vendor Certifications

For technicians working with specialized or complex equipment, certifications offered by equipment manufacturers (vendors) can be particularly valuable. These certifications demonstrate proficiency in maintaining, troubleshooting, and repairing specific brands or models of machinery, such as HVAC systems, PLC controllers, or industrial robots.

Vendor certifications often involve intensive training programs that cover the detailed operation and maintenance procedures for their equipment. Earning such a credential can make a technician a go-to expert within their organization for that particular system and can be a strong selling point when seeking employment or advancement.

Examples include certifications from HVAC manufacturers like Trane or Carrier, or automation companies like Rockwell Automation (for Allen-Bradley PLCs) or Siemens. These credentials signal a high level of competence and are often sought after for roles requiring specialized expertise.

This course introduces PLC programming, a skill for which vendor-specific certifications are often available and valuable.

State and Local Licensing Requirements

In certain specialized areas of maintenance work, state or local governments may require technicians to hold specific licenses to perform their duties legally. This is most common for trades that have significant public safety implications, such as electrical work and HVACR services.

For example, many states require electricians to be licensed, which typically involves documenting a certain number of hours of experience, passing an examination on electrical codes and theory, and sometimes completing an apprenticeship. Similarly, technicians who handle refrigerants in HVACR systems often need EPA Section 608 certification, which is a federal requirement in the United States.

It is crucial for Maintenance Technicians planning to work in these specialized areas to research and comply with the licensing requirements in their specific state and locality. Information on licensing can usually be obtained from state departments of labor or professional licensing boards. Holding required licenses not only ensures legal compliance but also enhances credibility and can open doors to more advanced and higher-paying opportunities.

Frequently Asked Questions (Career Focus)

Embarking on or advancing in a career as a Maintenance Technician often brings several questions to mind. Addressing these common queries can help individuals make informed decisions about this dynamic and essential profession.

What is the typical salary range for a Maintenance Technician?

The salary for a Maintenance Technician can vary significantly based on several factors. These include geographic location, the specific industry, the technician's level of experience, possession of specialized skills, and any certifications or licenses held. Entry-level positions will generally offer a lower starting salary, while experienced technicians with specialized expertise in areas like industrial machinery, PLC programming, or HVAC systems can command higher wages.

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for general maintenance and repair workers was $47,960 in May 2023. For industrial machinery mechanics, the median annual wage was $61,420 in May 2023. Some sources suggest that entry-level maintenance technicians might earn around $20-$21 per hour, with potential to earn over $90,000 annually in advanced roles or with specialized industrial maintenance skills. It's advisable to research salary data specific to your region and desired industry for the most accurate picture. The BLS Occupational Outlook Handbook is a valuable resource for wage data across various occupations.

Many companies also offer benefits packages that can include health insurance, retirement plans, and paid time off, which contribute to the overall compensation. Overtime opportunities, which are common in some maintenance roles, can also increase annual earnings.

What is the job outlook for Maintenance Technicians?

The job outlook for Maintenance Technicians is generally positive. As long as there are buildings, machinery, and equipment, there will be a need for skilled individuals to maintain and repair them. The U.S. Bureau of Labor Statistics (BLS) projects that overall employment in installation, maintenance, and repair occupations is expected to grow about as fast as the average for all occupations through 2033.

Demand can vary by specific industry and specialization. For instance, the increasing automation in manufacturing is expected to drive demand for technicians who can maintain and repair complex automated systems. Similarly, the emphasis on energy efficiency and sustainable building practices may create opportunities for technicians skilled in green technologies. The BLS also notes that a significant number of openings will arise from the need to replace workers who retire or transition to other occupations.

Individuals with a broad range of skills, specialized training, and relevant certifications are likely to have the best job prospects. The essential nature of maintenance work provides a degree of job security, as these roles are critical to the functioning of many businesses and organizations across economic cycles.

How can I transition into a Maintenance Technician role from another technical field?

Transitioning into a Maintenance Technician role from another technical field can be a smooth process if you highlight your transferable skills and are willing to acquire any specific knowledge gaps. Many technical fields share common foundational principles with maintenance work, such as problem-solving, understanding schematics, and working with tools. For example, someone with experience in automotive repair, construction, or even IT hardware support may possess valuable transferable skills.

Identify the skills you've gained in your current or previous roles that align with the requirements of a Maintenance Technician. This might include diagnostic abilities, experience with electrical or mechanical systems, or familiarity with safety procedures. Then, determine what specific skills or knowledge areas you need to develop for the type of maintenance role you are targeting. This could involve taking targeted online courses, enrolling in a vocational program, or seeking certifications in areas like HVAC, electrical maintenance, or industrial mechanics. Browsing courses on OpenCourser can help identify relevant training options.

Networking with professionals already in the maintenance field can provide valuable insights and potential job leads. Tailor your resume to emphasize your relevant technical competencies and any new training you've undertaken. Consider starting with an entry-level position or apprenticeship to gain hands-on experience in the new specialization. Remember, many employers value a strong work ethic and a demonstrated ability to learn new technical skills, making career transitions quite feasible with a focused approach.

These books cover foundational aspects of maintenance engineering and management, which can be helpful for anyone, including those transitioning from other technical fields, to understand the breadth of the maintenance role.

Are there part-time or contract opportunities available?

Yes, part-time and contract opportunities for Maintenance Technicians are available, though the prevalence can depend on the industry and specific employer needs. Some smaller businesses or property management companies may hire part-time technicians to handle their maintenance needs without the commitment of a full-time employee.

Contract work is also an option, particularly for specialized tasks or short-term projects. Companies might bring in contract technicians with specific expertise, for example, to assist with a major equipment installation, a facility shutdown for extensive maintenance, or to cover for permanent staff on leave. Staffing agencies that specialize in skilled trades often place technicians in temporary or contract-to-hire positions.

For individuals seeking flexibility or a variety of work experiences, part-time or contract roles can be attractive. However, these positions may not always offer the same level of benefits or job security as full-time permanent employment. It's important to weigh the pros and cons based on personal career goals and financial needs.

What level of physical fitness is required?

A career as a Maintenance Technician generally requires a good level of physical fitness. The role often involves tasks such as standing for long periods, walking extensively within a facility, and lifting or moving heavy objects, tools, or equipment. Technicians may also need to work in awkward positions, such as kneeling, crouching, or reaching overhead, and may need to climb ladders or work in confined spaces.

Good manual dexterity, hand-eye coordination, and the ability to perform repetitive motions are also important. While the specific physical demands can vary by job—for example, maintaining heavy industrial machinery versus light-duty facility upkeep—a general capacity for physical exertion is usually necessary.

Maintaining good physical health and practicing safe lifting techniques are crucial to prevent injuries and sustain a long career in the field. Employers typically provide training on ergonomic best practices and require adherence to safety protocols designed to minimize physical strain.

How is automation affecting the long-term career prospects for Maintenance Technicians?

Automation is indeed changing the landscape for Maintenance Technicians, but it is generally seen as shifting skill requirements rather than eliminating jobs. As industries adopt more automated systems, including robotics and sophisticated computer-controlled machinery, the need for skilled technicians to install, maintain, troubleshoot, and repair this advanced equipment increases.

While some routine manual tasks might be reduced by automation, the complexity of automated systems often requires a higher level of technical expertise from maintenance personnel. Technicians may need to develop skills in areas like PLC programming, sensor technology, data analysis (for predictive maintenance), and networking to effectively manage these systems.

Therefore, the long-term career prospects for Maintenance Technicians who are willing to adapt and continuously update their skills remain strong. The focus is shifting towards a more technologically adept technician who can work alongside and maintain these automated systems. Lifelong learning and embracing new technologies will be key to thriving in this evolving field.

Useful Links and Resources

To further explore the career of a Maintenance Technician and related educational opportunities, the following resources may be helpful:

- OpenCourser: A comprehensive platform to search for online courses and books related to maintenance, specific technical skills, and career development. You can browse categories such as Technical Training and Engineering.

- U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook: Provides detailed information on various occupations, including job duties, education requirements, pay, and job outlook. Specific entries for "Industrial Machinery Mechanics and Machinery Maintenance Workers" and "General Maintenance and Repair Workers" are particularly relevant. You can access it at www.bls.gov/ooh/.

- Society for Maintenance & Reliability Professionals (SMRP): A nonprofit organization for professionals in maintenance, reliability, and physical asset management. Their website, smrp.org, offers resources, certifications (like the CMRP and CMRT), and networking opportunities.

Becoming a Maintenance Technician offers a pathway to a hands-on, problem-solving career with diverse opportunities across many industries. It requires a blend of technical knowledge, practical skills, and a commitment to safety and continuous learning. For those who enjoy understanding how things work and take satisfaction in keeping essential systems operational, it can be a truly rewarding profession.