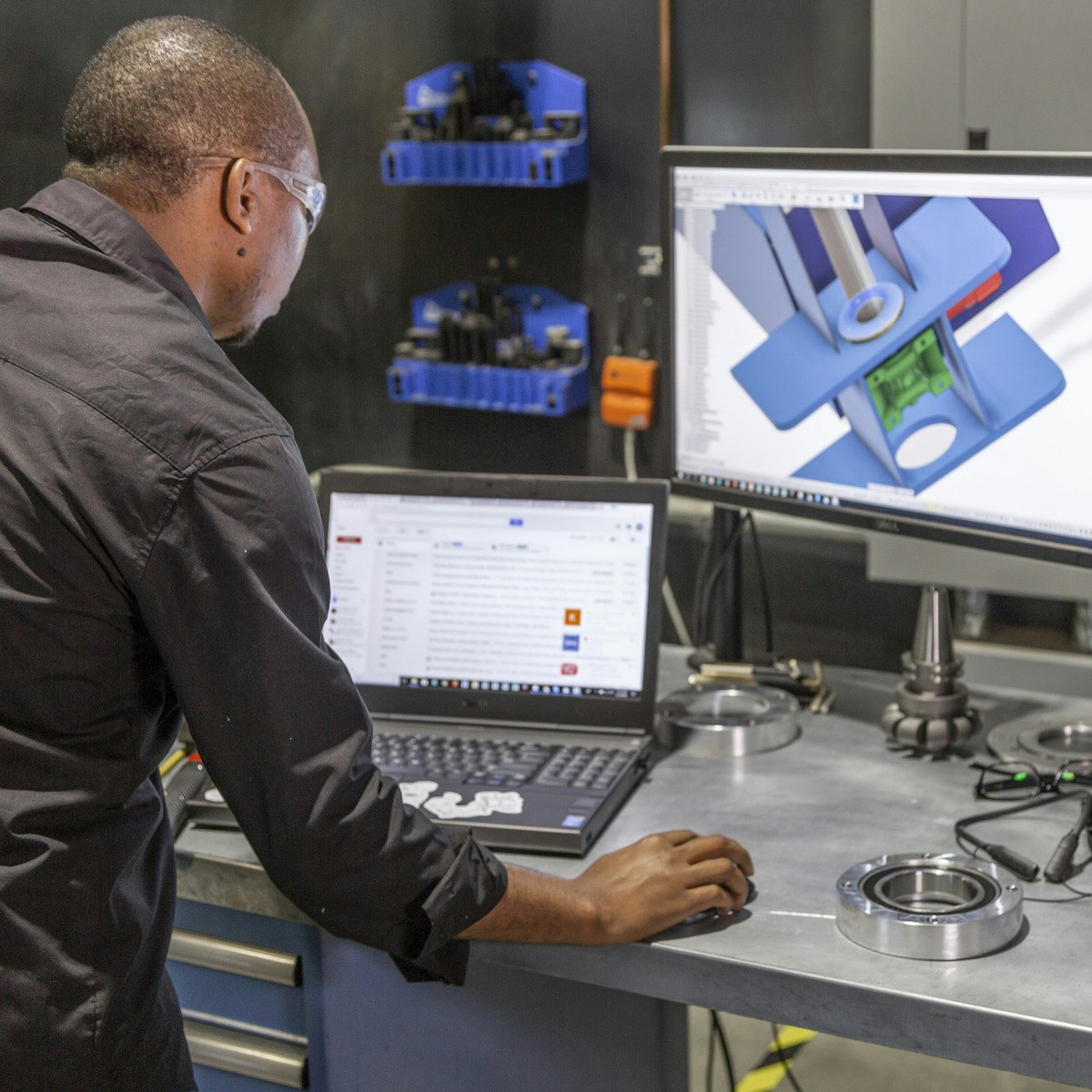

With design for manufacturing, our design process focused on the design over its cost, but always keeping in mind how parts needed to be made. With manufacturing at the core of a design, we're able to fix potential problems in the design phase rather than after production. In many cases, the end product is made up of an assembly of different pieces to simplify manufacturing or to achieve specific design goals. Each piece represents a certain tolerance and put together, things might not work or fit if they weren’t accounted for in the design.

Read more

With design for manufacturing, our design process focused on the design over its cost, but always keeping in mind how parts needed to be made. With manufacturing at the core of a design, we're able to fix potential problems in the design phase rather than after production. In many cases, the end product is made up of an assembly of different pieces to simplify manufacturing or to achieve specific design goals. Each piece represents a certain tolerance and put together, things might not work or fit if they weren’t accounted for in the design.

With design for manufacturing, our design process focused on the design over its cost, but always keeping in mind how parts needed to be made. With manufacturing at the core of a design, we're able to fix potential problems in the design phase rather than after production. In many cases, the end product is made up of an assembly of different pieces to simplify manufacturing or to achieve specific design goals. Each piece represents a certain tolerance and put together, things might not work or fit if they weren’t accounted for in the design.

We'll take a closer look at design and detail for manufacture and create toolpaths to cut parts. Even if the end goal as an engineer isn’t to fabricate your own parts, it’s a valuable skill to understand how things are made and what design decisions can ultimately affect how something is created.

After taking this course, you'll be able to:

- Inspect a multicomponent assembly.

- Identify manufacturing methods based on part inspection.

- Create detailed drawings for manufacturing.

- Practice creating toolpaths for manufacture.

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

What's inside

Syllabus

Drafting for Manufacture

In Week 1, we’ll focus on the creation of detailed drawings for production. Understanding not only how to create or customize a drawing, but also how to identify critical features or aspects of a design on a drawing is key to helping ensure the parts you get are the parts you want.

Read more

Syllabus

Good to know

Save this course

Reviews summary

Fusion 360 cam and design

Activities

Design for Manufacturability and Assembly Review

Show steps

Helps students refine their design considerations by evaluating existing products for manufacturability and assembly.

Show steps

-

Select a manufactured product that requires assembly.

-

Disassemble the product and analyze its components.

-

Identify design features that support manufacturability and assembly.

-

Document observations and findings in a report.

CNC Programming Practice

Show steps

Reinforces the understanding of CNC programming commands and toolpaths, enhancing practical skills.

Browse courses on

CNC Programming

Show steps

-

Complete online or offline CNC programming exercises.

-

Practice creating toolpaths in Fusion 360 or other CAM software.

Peer Review and Discussion

Show steps

Fosters collaboration and peer learning by encouraging students to share and discuss their work.

Show steps

-

Form a study group or connect with classmates.

-

Set up regular meetings to review and discuss assignments.

-

Provide constructive feedback and support to each other.

Five other activities

Expand to see all activities and additional details

Show all eight activities

Design and Build a Simple Part

Show steps

Provides hands-on experience with the design and manufacturing process, reinforcing the concepts learned in the course.

Show steps

-

Design a simple part in Fusion 360.

-

Select the appropriate materials and tooling.

-

Set up the CNC machine and create the toolpaths.

-

Machine the part.

-

Inspect and measure the finished part to ensure accuracy.

Attend a CNC Meet-Up

Show steps

Provides an opportunity to connect with professionals in the field, gain new perspectives, and learn about industry trends.

Browse courses on

CNC Machining

Show steps

-

Find a local CNC meet-up group or event.

-

Register for the event.

-

Attend the meet-up and actively engage in conversations.

Hands-On CNC Workshop

Show steps

Provides immersive and practical experience with CNC machinery, complementing the theoretical concepts covered in the course.

Browse courses on

CNC Machining

Show steps

-

Locate a workshop that offers CNC training.

-

Enroll in the workshop.

-

Attend the workshop and actively participate in hands-on activities.

Advanced CNC Techniques Tutorial

Show steps

Expands students' knowledge and skills in CNC programming by exploring advanced techniques.

Browse courses on

CNC Machining

Show steps

-

Identify online or in-person tutorials on advanced CNC techniques.

-

Follow the tutorials and complete the exercises.

-

Apply the acquired knowledge to practical projects.

Technical Blog Post

Show steps

Encourages critical thinking and knowledge synthesis by requiring students to explain concepts in their own words.

Show steps

-

Choose a topic related to design for manufacture or CNC machining.

-

Research and gather information from reliable sources.

-

Write a well-organized blog post explaining the topic.

-

Include clear examples and illustrations.

-

Publish the blog post on a relevant platform.

Design for Manufacturability and Assembly Review

Show steps

Helps students refine their design considerations by evaluating existing products for manufacturability and assembly.

Show steps

- Select a manufactured product that requires assembly.

- Disassemble the product and analyze its components.

- Identify design features that support manufacturability and assembly.

- Document observations and findings in a report.

CNC Programming Practice

Show steps

Reinforces the understanding of CNC programming commands and toolpaths, enhancing practical skills.

Browse courses on

CNC Programming

Show steps

- Complete online or offline CNC programming exercises.

- Practice creating toolpaths in Fusion 360 or other CAM software.

Peer Review and Discussion

Show steps

Fosters collaboration and peer learning by encouraging students to share and discuss their work.

Show steps

- Form a study group or connect with classmates.

- Set up regular meetings to review and discuss assignments.

- Provide constructive feedback and support to each other.

Design and Build a Simple Part

Show steps

Provides hands-on experience with the design and manufacturing process, reinforcing the concepts learned in the course.

Show steps

- Design a simple part in Fusion 360.

- Select the appropriate materials and tooling.

- Set up the CNC machine and create the toolpaths.

- Machine the part.

- Inspect and measure the finished part to ensure accuracy.

Attend a CNC Meet-Up

Show steps

Provides an opportunity to connect with professionals in the field, gain new perspectives, and learn about industry trends.

Browse courses on

CNC Machining

Show steps

- Find a local CNC meet-up group or event.

- Register for the event.

- Attend the meet-up and actively engage in conversations.

Hands-On CNC Workshop

Show steps

Provides immersive and practical experience with CNC machinery, complementing the theoretical concepts covered in the course.

Browse courses on

CNC Machining

Show steps

- Locate a workshop that offers CNC training.

- Enroll in the workshop.

- Attend the workshop and actively participate in hands-on activities.

Advanced CNC Techniques Tutorial

Show steps

Expands students' knowledge and skills in CNC programming by exploring advanced techniques.

Browse courses on

CNC Machining

Show steps

- Identify online or in-person tutorials on advanced CNC techniques.

- Follow the tutorials and complete the exercises.

- Apply the acquired knowledge to practical projects.

Technical Blog Post

Show steps

Encourages critical thinking and knowledge synthesis by requiring students to explain concepts in their own words.

Show steps

- Choose a topic related to design for manufacture or CNC machining.

- Research and gather information from reliable sources.

- Write a well-organized blog post explaining the topic.

- Include clear examples and illustrations.

- Publish the blog post on a relevant platform.

Career center

Mechanical Engineer

Manufacturing Engineer

Production Engineer

Design Engineer

Tool and Die Maker

CNC Machinist

Quality Control Inspector

Product Designer

Technical Writer

Sales Engineer

Project Manager

Marketing Manager

Business Analyst

Educator

Consultant

Reading list

Share

Similar courses

OpenCourser helps millions of learners each year. People visit us to learn workspace skills, ace their exams, and nurture their curiosity.

Our extensive catalog contains over 50,000 courses and twice as many books. Browse by search, by topic, or even by career interests. We'll match you to the right resources quickly.

Find this site helpful? Tell a friend about us.

We're supported by our community of learners. When you purchase or subscribe to courses and programs or purchase books, we may earn a commission from our partners.

Your purchases help us maintain our catalog and keep our servers humming without ads.

Thank you for supporting OpenCourser.