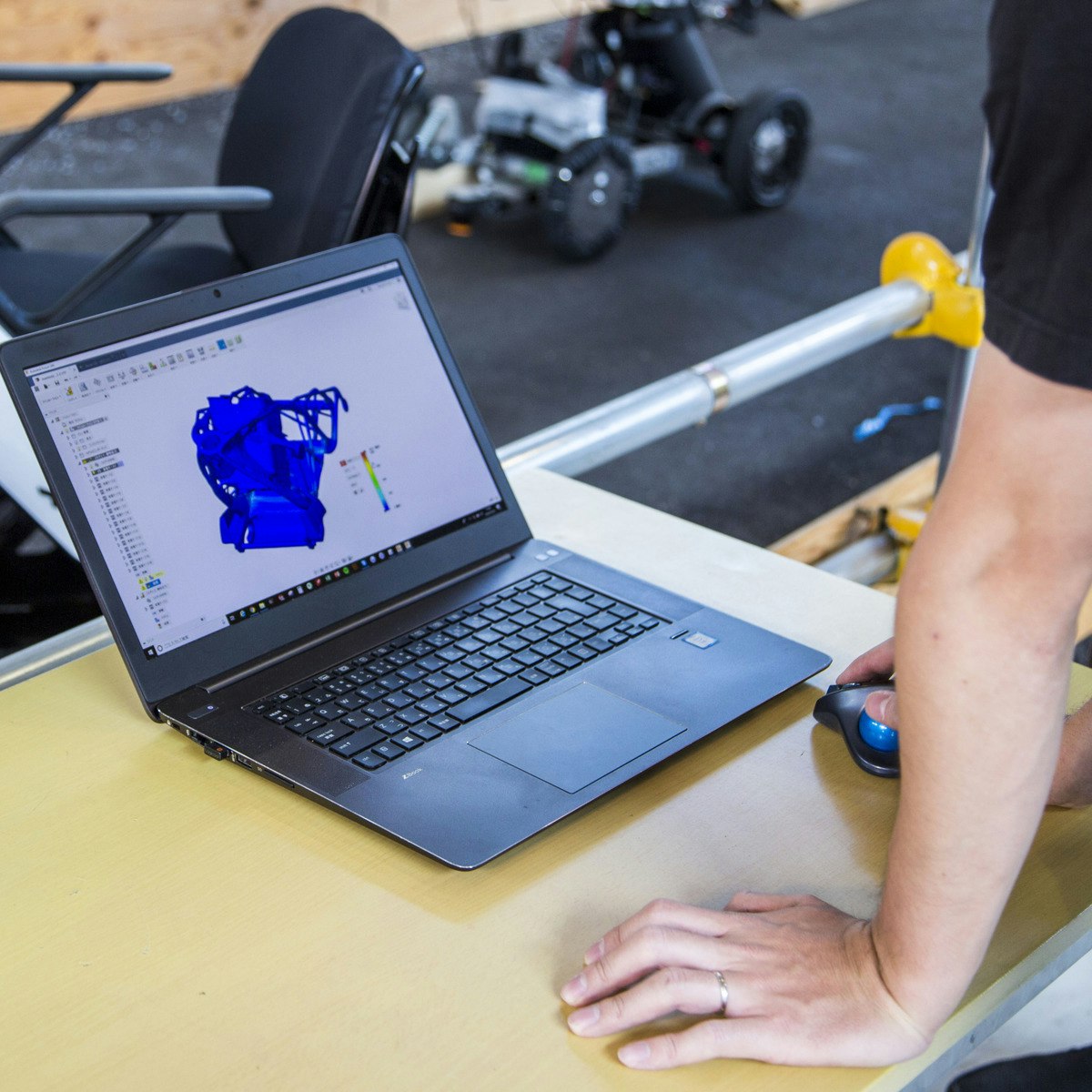

The foundation of engineering design is often coupled with validation. Simulation is a great tool that allows engineers to test, validate, and modify designs before they become a physical prototype. When used early in the process for simulation driven design and throughout the development process, simulation can help drive the design, make informed design decisions, speed up time to production, and most importantly, identify and eliminate costly design mistakes.

Read more

The foundation of engineering design is often coupled with validation. Simulation is a great tool that allows engineers to test, validate, and modify designs before they become a physical prototype. When used early in the process for simulation driven design and throughout the development process, simulation can help drive the design, make informed design decisions, speed up time to production, and most importantly, identify and eliminate costly design mistakes.

The foundation of engineering design is often coupled with validation. Simulation is a great tool that allows engineers to test, validate, and modify designs before they become a physical prototype. When used early in the process for simulation driven design and throughout the development process, simulation can help drive the design, make informed design decisions, speed up time to production, and most importantly, identify and eliminate costly design mistakes.

Like any other tool though, it must be used properly to yield the best results. In this course, we’ll explore the usage static stress simulation, shape optimization, thermal and other mechanical simulation types to better understand how we can apply these tools to everyday design problems.

After taking this course, you'll be able to:

- Describe the simulation workflow in Fusion 360.

- Summarize the use cases for various types of simulation studies.

- Demonstrate knowledge and skills in more advanced Fusion 360 CAD and CAE skills.

- Explain and identify simulation results

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

What's inside

Syllabus

Static Stress Simulation

In Week 1, we’ll explore the setup, solve, and understanding surrounding static stress simulations. Starting with the basics and moving to more advanced tools such as bolted connections we’ll walk through how to prepare and process a static simulation.

Read more

Syllabus

Good to know

Save this course

Reviews summary

Simulation analysis for mechanical engineers

Activities

Review Static Stress Simulation and Shape Optimization

Show steps

Refresh your prior knowledge in these concepts to better succeed in this course

Show steps

-

Recall the setup and execution of Static Stress Simulations

-

Go over Shape Optimization to prepare for its application

Reach out to industry professionals for mentorship

Show steps

Gain insights and guidance from experienced professionals

Browse courses on

Mentorship

Show steps

-

Identify potential mentors in the field

-

Reach out to them and request their guidance

Build a Mechanical Assembly using Fusion 360

Show steps

Complete a hands-on project that applies the principles you learn in this course

Browse courses on

Fusion 360

Show steps

-

Identify a suitable mechanical assembly to build

-

Collect the necessary materials and components

-

Use Fusion 360 to design the assembly

-

Assemble and test the mechanical assembly

Three other activities

Expand to see all activities and additional details

Show all six activities

Conduct Thermal and Nonlinear Response Simulations

Show steps

Solidify your understanding through repetitive exercises

Show steps

-

Define the necessary boundary conditions and loading

-

Run the simulations and analyze the results

Mentor other students in the course

Show steps

Strengthen your understanding by teaching others

Browse courses on

Mentoring

Show steps

-

Identify students who may need assistance

-

Provide guidance, support, and encouragement

Participate in design challenges or hackathons

Show steps

Test your skills and knowledge in a competitive environment

Show steps

-

Identify relevant design challenges or hackathons

-

Form a team and develop a solution to the challenge

-

Submit your solution and compete for prizes or recognition

Review Static Stress Simulation and Shape Optimization

Show steps

Refresh your prior knowledge in these concepts to better succeed in this course

Show steps

- Recall the setup and execution of Static Stress Simulations

- Go over Shape Optimization to prepare for its application

Reach out to industry professionals for mentorship

Show steps

Gain insights and guidance from experienced professionals

Browse courses on

Mentorship

Show steps

- Identify potential mentors in the field

- Reach out to them and request their guidance

Build a Mechanical Assembly using Fusion 360

Show steps

Complete a hands-on project that applies the principles you learn in this course

Browse courses on

Fusion 360

Show steps

- Identify a suitable mechanical assembly to build

- Collect the necessary materials and components

- Use Fusion 360 to design the assembly

- Assemble and test the mechanical assembly

Conduct Thermal and Nonlinear Response Simulations

Show steps

Solidify your understanding through repetitive exercises

Show steps

- Define the necessary boundary conditions and loading

- Run the simulations and analyze the results

Mentor other students in the course

Show steps

Strengthen your understanding by teaching others

Browse courses on

Mentoring

Show steps

- Identify students who may need assistance

- Provide guidance, support, and encouragement

Participate in design challenges or hackathons

Show steps

Test your skills and knowledge in a competitive environment

Show steps

- Identify relevant design challenges or hackathons

- Form a team and develop a solution to the challenge

- Submit your solution and compete for prizes or recognition

Career center

Simulation Engineer

CAE Engineer

Mechanical Engineer

R&D Engineer

Product Engineer

Design Engineer

Systems Engineer

Quality Engineer

Design Verification Engineer

Manufacturing Engineer

Materials Engineer

Test Engineer

Validation Engineer

Technical Sales Engineer

Project Manager

Reading list

Share

Similar courses

OpenCourser helps millions of learners each year. People visit us to learn workspace skills, ace their exams, and nurture their curiosity.

Our extensive catalog contains over 50,000 courses and twice as many books. Browse by search, by topic, or even by career interests. We'll match you to the right resources quickly.

Find this site helpful? Tell a friend about us.

We're supported by our community of learners. When you purchase or subscribe to courses and programs or purchase books, we may earn a commission from our partners.

Your purchases help us maintain our catalog and keep our servers humming without ads.

Thank you for supporting OpenCourser.