Materials Engineer

Materials Engineer

Materials engineering sits at the fascinating intersection of science, engineering, and design. It's the field dedicated to understanding, developing, and applying materials – the very stuff from which everything around us is made. From the plastics in your phone to the alloys in an airplane engine, materials engineers work at the atomic and molecular levels to create substances with specific, desirable properties.

This field is inherently interdisciplinary, drawing heavily from physics, chemistry, and mechanics. Materials engineers might find themselves improving the strength of steel, developing lighter composites for vehicles, creating biocompatible materials for medical implants, or designing novel semiconductors for electronics. The work often involves manipulating the structure of materials to enhance performance, durability, cost-effectiveness, or sustainability, making it a critical driver of technological advancement.

Core Responsibilities of a Materials Engineer

Understanding the day-to-day activities of a materials engineer provides insight into the practical application of this scientific discipline. The role is varied, often involving a blend of laboratory work, computer modeling, analysis, and collaboration.

Material Selection, Testing, and Analysis

A primary task for materials engineers is selecting the optimal material for a specific application. This involves considering factors like strength, weight, cost, corrosion resistance, electrical conductivity, and environmental impact. Engineers weigh these requirements against the properties of available materials to make informed decisions.

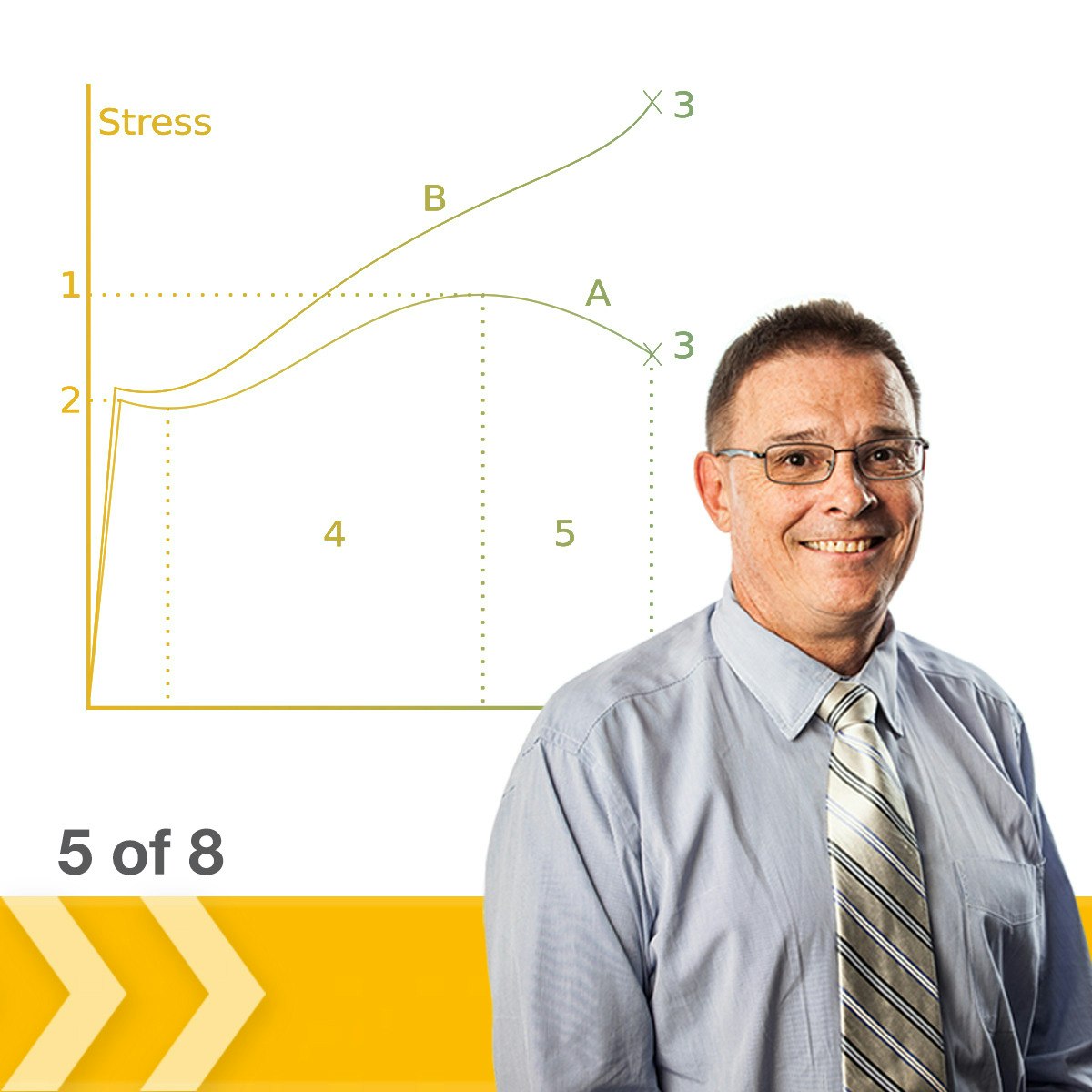

Once a material is chosen or developed, rigorous testing is essential. Materials engineers design and conduct experiments to measure properties under various conditions (e.g., high temperature, stress, corrosive environments). Techniques like tensile testing, hardness testing, and microscopy are common tools.

Failure analysis is another crucial responsibility. When a component or product fails, materials engineers investigate the cause by examining the material's structure and properties. This helps prevent future failures and improve designs. Understanding how and why materials break down is key to building safer and more reliable products.

For those looking to delve into the fundamental behavior of materials under stress and strain, certain foundational courses can be very helpful.

Understanding testing methodologies is also critical in practice.

These books offer a comprehensive look into the mechanics and failure of materials.

Developing New Materials

Innovation is central to materials engineering. Engineers constantly work to develop new materials with enhanced properties or entirely novel functionalities. This might involve creating advanced composites, which combine different materials to achieve superior performance, like carbon fiber reinforced polymers used in aircraft.

Nanomaterials, engineered at the nanometer scale, offer unique properties and are a major focus of research. Materials engineers explore applications ranging from stronger, lighter materials to more efficient catalysts and advanced sensors.

Other areas include developing new alloys, advanced ceramics, smart materials that respond to stimuli, and biomaterials designed to interact safely with biological systems. This research pushes the boundaries of what's possible in various industries.

Collaboration Across Teams

Materials engineers rarely work in isolation. They collaborate closely with research and development (R&D) teams to explore new material possibilities and with design engineers to integrate materials into products. They also work with manufacturing teams to ensure materials can be processed effectively and consistently.

This cross-functional collaboration ensures that material considerations are integrated throughout the product lifecycle, from initial concept to final production. Effective communication and teamwork skills are therefore essential for success in this role.

Understanding manufacturing processes is vital for effective collaboration.

Formal Education Pathways

Embarking on a career as a materials engineer typically begins with a strong foundation in science and mathematics, followed by specialized engineering education. Understanding the educational landscape helps aspiring engineers plan their journey.

Undergraduate Foundations

A bachelor's degree in materials science and engineering (MSE) is the most direct route. These programs build upon core science courses taken in the first year or two of university, typically including calculus, differential equations, physics (mechanics, electricity, magnetism, thermodynamics), and general and organic chemistry.

MSE programs then delve into specialized topics such as crystallography (the study of atomic arrangements), thermodynamics of materials, kinetics (rates of processes), mechanical behavior, and the properties of different material classes (metals, ceramics, polymers, composites).

Laboratory courses are integral, providing hands-on experience with characterization techniques like microscopy (scanning electron microscopy, transmission electron microscopy) and mechanical testing. Some programs may require or offer courses in computational materials science, using software for simulations and modeling.

These introductory courses provide a solid overview of the field.

These foundational textbooks are widely used in undergraduate programs.

Graduate Studies and Specialization

While a bachelor's degree is sufficient for many entry-level positions, a master's or Ph.D. degree is often required for research-intensive roles or specialized fields. Graduate programs allow students to deepen their knowledge in specific areas.

Common specializations include metallurgy (metals and alloys), polymer science (plastics and rubbers), ceramics (inorganic, non-metallic solids), composite materials, biomaterials (for medical applications), electronic materials (semiconductors), and computational materials science.

Graduate studies heavily emphasize research, culminating in a thesis (Master's) or dissertation (Ph.D.) based on original work. This advanced training prepares engineers for roles in cutting-edge R&D, academia, or highly technical consulting.

Courses focusing on specific material classes or properties are common at the graduate level.

Research Opportunities and Career Pivots

Research is a cornerstone of materials engineering, both in university settings and industrial labs. Students gain research experience through coursework, projects, internships, or co-op programs. Academia focuses on fundamental discovery, while industry research often targets specific product development or process improvement goals.

For individuals considering a career change into materials engineering from related fields like chemistry, physics, or other engineering disciplines, the path often involves graduate study. A Master's degree can provide the specialized knowledge needed. Foundational understanding from these related fields provides strong transferable skills. The analytical mindset, problem-solving abilities, and scientific rigor developed in these areas are highly valuable in materials engineering.

Transitioning requires dedication, but the interdisciplinary nature of materials science often makes it a feasible and rewarding pivot. Supplementing existing knowledge with targeted coursework, perhaps even starting with online courses, can bridge gaps and prepare for a formal program or entry-level role.

Exploring advanced characterization or computational methods can be valuable.

Online Learning and Skill Development

The rise of online education offers new avenues for learning and skill development in materials engineering. While a formal degree remains the standard entry point, online resources provide valuable opportunities for exploration, supplementation, and upskilling.

Exploring the Field Through Self-Study

Can someone become a materials engineer solely through online courses? Realistically, achieving the full qualifications and hands-on lab experience required for most engineering roles typically necessitates a formal degree program. However, online learning is an excellent way to build foundational knowledge and gauge interest in the field.

For those curious about materials engineering, or perhaps considering a career change, online courses can offer accessible introductions to core concepts like material properties, structures, and processing. This can help individuals decide if the field is a good fit before committing to a full degree program.

Platforms like OpenCourser aggregate thousands of courses, making it easy to find introductory materials science content. Learners can browse specific topics and compare offerings from various institutions.

Key Skills for Independent Learners

Online platforms excel at teaching specific skills relevant to materials engineering. Individuals can learn about materials characterization techniques, processing methods, or phase diagrams through dedicated online modules. Software skills, crucial in modern engineering, are also well-suited for online learning.

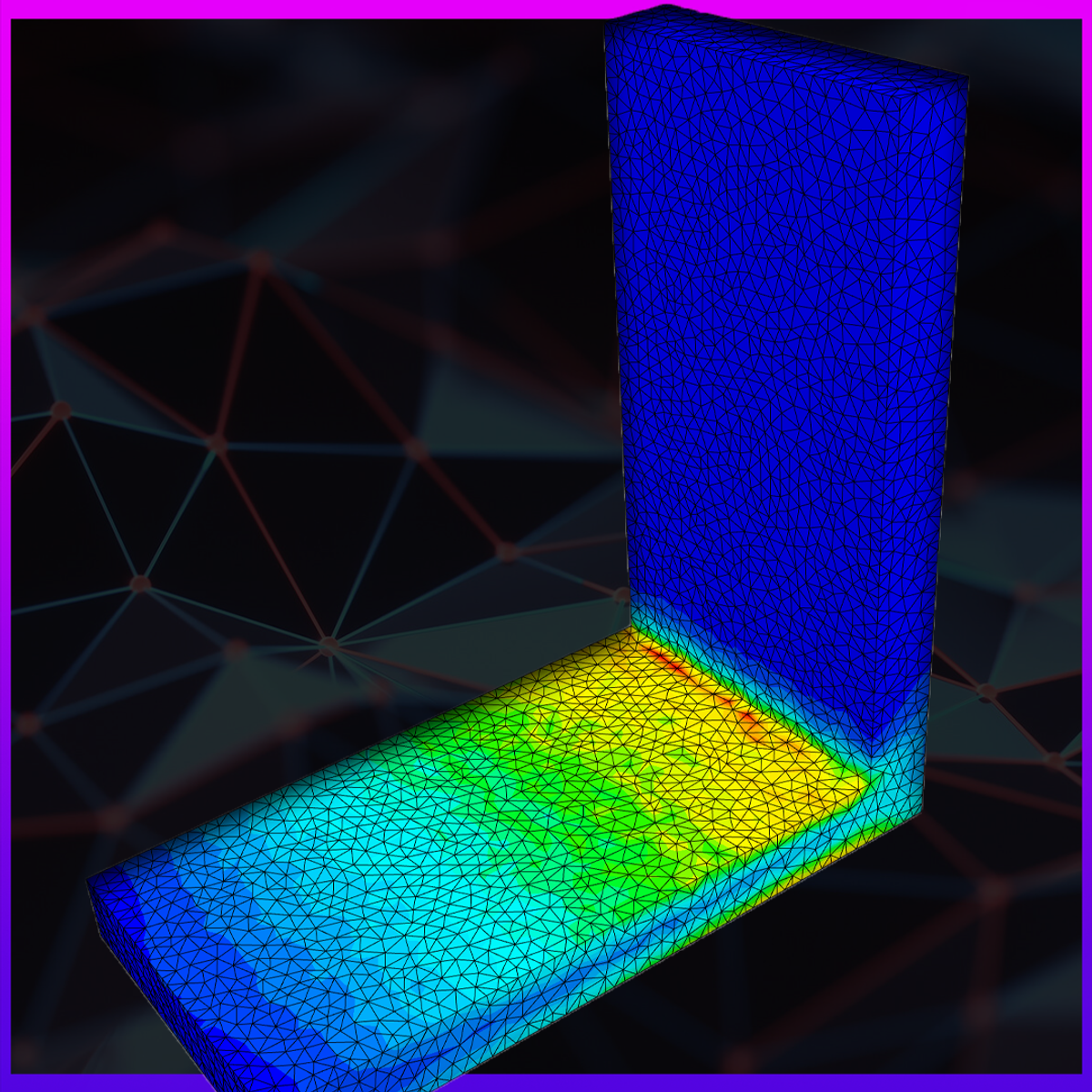

Courses covering Computer-Aided Design (CAD) software are widely available, teaching users how to create 2D and 3D models. Simulation software, such as Finite Element Analysis (FEA) tools used for stress analysis, can also be learned online. Data analysis skills, increasingly important for interpreting experimental results and computational data, are another area where online courses shine.

These skills can supplement formal education or help professionals stay current with industry tools. For career changers, mastering relevant software can significantly enhance their profile.

Building a Portfolio with Projects

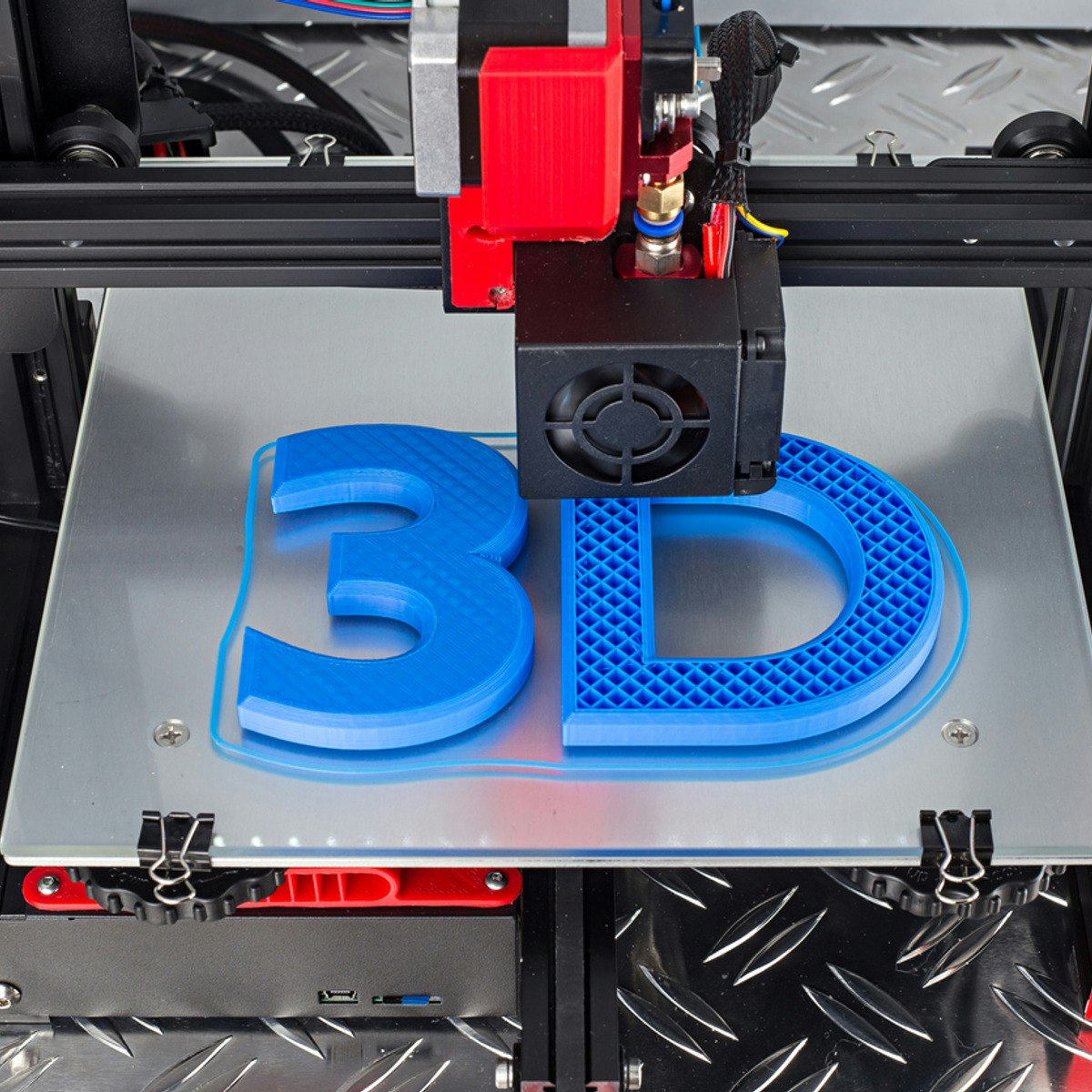

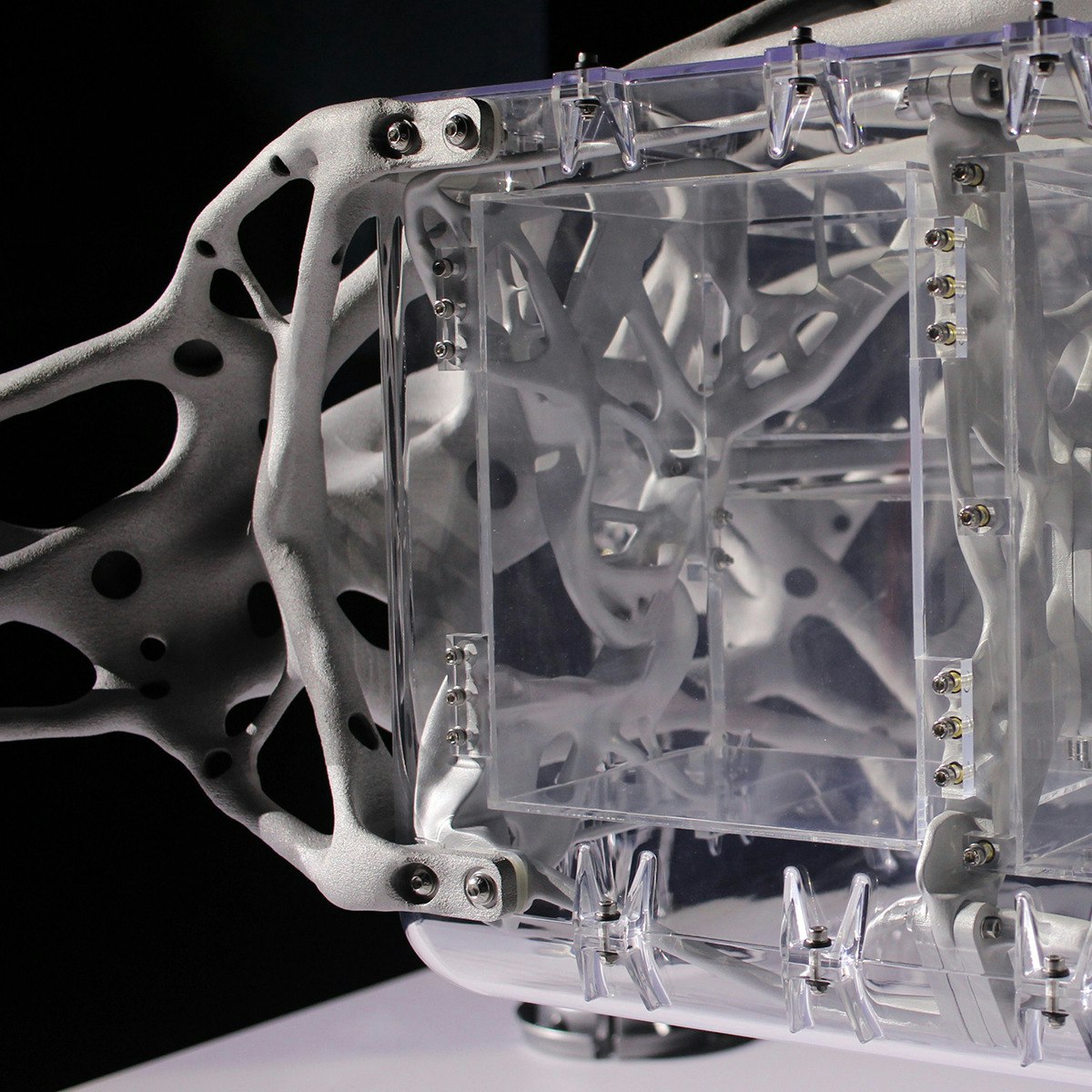

While online courses provide theoretical knowledge, demonstrating practical application is key. Independent learners can build a portfolio through hands-on projects. The accessibility of technologies like 3D printing opens up opportunities.

For example, learners could design and 3D print components using different materials or settings to test their properties. Experimenting with creating simple composites or testing the properties of common household materials (with appropriate safety precautions) can also demonstrate initiative and understanding.

Documenting these projects, including the design process, materials used, testing methods, results, and analysis, creates tangible evidence of skills and passion for the field. This portfolio can be invaluable when applying for internships, academic programs, or even entry-level positions that value practical aptitude.

Career Progression and Opportunities

A career in materials engineering offers diverse pathways and opportunities for growth. Understanding the typical trajectory can help individuals plan their professional development and navigate transitions.

Starting Your Career

Graduates typically enter the field in roles such as Junior Materials Engineer, Process Engineer, Quality Engineer, or Research Assistant. Initial responsibilities often involve supporting senior engineers, conducting routine tests, analyzing data, and learning specific company processes and materials.

These entry-level positions provide essential practical experience, building upon the theoretical knowledge gained during education. Industries hiring materials engineers are broad, including aerospace, automotive, biomedical, electronics, energy, construction, and manufacturing.

Mid-Career Advancement and Transitions

With experience, materials engineers take on more complex projects and responsibilities. They may become Senior Materials Engineers, leading projects, mentoring junior staff, and specializing in particular material types or processes. Technical expertise is highly valued.

Opportunities often arise for transitioning into related roles. Some engineers move into Project Management, overseeing timelines, budgets, and cross-functional teams for materials-related projects. Others might leverage their technical expertise in consulting roles, advising clients on material selection, failure analysis, or process optimization.

Further specialization through certifications or advanced degrees can open doors to roles like Materials Specialist or Research Scientist, focusing on deep technical challenges within a specific domain like corrosion, polymers, or welding technology.

Leadership and Related Paths

Experienced materials engineers with strong technical and leadership skills can advance to management positions. Roles like R&D Manager, Engineering Manager, or Director involve overseeing teams, setting strategic direction for materials innovation, and managing departmental budgets.

At the highest levels, individuals might reach executive positions such as Chief Technology Officer (CTO) or Vice President of Engineering, particularly in technology-driven companies where materials are critical. Some engineers also pursue entrepreneurial paths, starting their own consulting firms or materials-focused companies.

The skills developed as a materials engineer – analytical thinking, problem-solving, understanding structure-property relationships – are transferable. Some may pivot into fields like technical sales, intellectual property law (with further legal education), or even data science, applying their analytical skills to different domains. Related careers include Materials Scientist, Metallurgical Engineer, Polymer Engineer, or Ceramics Engineer, often requiring similar foundational knowledge but with different focuses.

Materials Engineer in the Modern Economy

The role of materials engineers is deeply intertwined with global economic trends, technological shifts, and societal demands. Understanding this broader context highlights the field's significance and future direction.

Supply Chains and Global Dynamics

Materials are sourced, processed, and utilized globally. Fluctuations in supply chains, geopolitical events, and trade policies directly impact the availability and cost of raw materials, affecting industries from electronics to construction. Materials engineers play a role in mitigating these risks by developing alternative materials or more efficient processing methods.

The drive for resource security encourages research into domestically sourced materials or materials based on abundant elements. Engineers work to design products that use less critical material or are easier to recycle, contributing to supply chain resilience.

Understanding the sourcing and processing of materials used in specific industries, like oil and gas, is important.

Demand for Sustainable Solutions

Sustainability is a major driver in materials engineering. There's increasing pressure to develop materials that are environmentally friendly throughout their lifecycle – from extraction and processing to use and disposal. This includes creating biodegradable plastics, using renewable resources, and improving energy efficiency in materials production.

Materials engineers are key players in the transition to a circular economy, designing materials for durability, reuse, and recyclability. Lightweight materials for transportation reduce fuel consumption, while advanced materials for renewable energy technologies (like solar cells and batteries) are crucial for combating climate change. According to market analyses, the demand for green materials is steadily rising across multiple sectors.

Geographic Centers of Innovation

While materials engineering opportunities exist globally, certain regions emerge as hubs for innovation due to concentrations of universities, research institutions, and specific industries. Areas with strong aerospace, automotive, semiconductor, or biomedical industries often foster vibrant materials science communities.

Research parks and technology clusters, often located near major research universities, serve as epicenters for materials development. Government investment and industry collaboration further fuel innovation in these geographic hotspots. However, the distributed nature of manufacturing means skilled materials engineers are needed worldwide.

Emerging Technologies and Trends

Materials engineering is a dynamic field constantly evolving with new scientific discoveries and technological capabilities. Staying abreast of emerging trends is crucial for long-term career success.

AI and Computational Materials Science

Artificial intelligence (AI) and machine learning (ML) are revolutionizing materials discovery and design. These tools can analyze vast datasets from experiments and simulations to predict the properties of new materials or optimize compositions much faster than traditional methods.

Computational materials science uses modeling and simulation to understand material behavior at various scales, from atoms to macroscopic structures. This reduces the need for costly and time-consuming physical experiments, accelerating the development cycle for new materials.

Integrating AI with computational tools, often referred to as Materials Informatics, is creating powerful platforms for designing materials with precisely tailored properties for specific applications, from catalysts to structural components.

Advanced and Bio-Inspired Materials

Research continues to push the boundaries of material capabilities. Nanomaterials, with features engineered at the billionth-of-a-meter scale, offer exceptional strength-to-weight ratios, unique electronic properties, and enhanced reactivity.

Bio-inspired materials look to nature for design cues, mimicking structures found in organisms (like the toughness of nacre or the adhesive properties of gecko feet) to create high-performance synthetic materials. Smart materials, which can change their properties in response to external stimuli like temperature, light, or stress, are enabling new applications in sensors, actuators, and adaptive structures.

The development of advanced composites, ceramics, and polymers also continues, driven by demands for higher performance, lighter weight, and improved durability in extreme environments.

Circular Economy and Sustainable Manufacturing

The principles of the circular economy – designing out waste, keeping products and materials in use, and regenerating natural systems – are increasingly influencing materials engineering. This involves designing for durability, repairability, and recyclability from the outset.

Engineers are developing novel recycling processes and materials derived from waste streams or bio-based feedstocks. Additive manufacturing (3D printing) also plays a role, enabling on-demand production, reducing material waste, and allowing for complex geometries optimized for performance and minimal material usage.

The focus is shifting towards a holistic view of a material's lifecycle, considering not just its performance during use but also its environmental impact from creation to end-of-life management.

Ethical and Environmental Considerations

The power to create and manipulate materials comes with significant responsibilities. Materials engineers must increasingly consider the broader ethical and environmental implications of their work.

Lifecycle Assessment and Impact

Lifecycle assessment (LCA) is a methodology used to evaluate the environmental impacts associated with all stages of a product's life, from raw material extraction through processing, manufacture, distribution, use, repair, and disposal or recycling. Materials engineers use LCA to compare the footprint of different material choices.

This involves quantifying energy consumption, greenhouse gas emissions, water usage, toxicity, and resource depletion associated with a material. Understanding these impacts helps guide the development of more sustainable alternatives and informs design decisions.

The social impacts, such as labor conditions in mining or manufacturing, are also increasingly part of a broader ethical assessment of material sourcing and production.

Balancing Performance and Sustainability

Often, there are trade-offs between a material's performance characteristics (like strength or conductivity) and its environmental footprint or cost. High-performance materials might require energy-intensive processing or rely on scarce or toxic elements.

Materials engineers grapple with these complex decisions, seeking innovative solutions that minimize negative impacts without compromising necessary functionality and safety. This might involve developing new, greener synthesis routes, designing products to use less material, or finding ways to substitute problematic substances.

The goal is to move towards solutions that offer both high performance and long-term sustainability, a challenge that requires creativity and a deep understanding of material science principles.

Regulatory Landscape and Material Safety

The use of certain materials, particularly those deemed hazardous to human health or the environment, is subject to government regulations. Examples include restrictions on lead, cadmium, mercury, and certain flame retardants (e.g., RoHS directive in the EU) or regulations concerning chemicals (e.g., REACH in the EU).

Materials engineers must be aware of these regulations and ensure their designs and material choices comply. This involves understanding material composition, potential hazards, and safe handling procedures. As new materials are developed, particularly at the nanoscale, careful assessment of their potential long-term health and environmental effects is an ongoing ethical responsibility.

Frequently Asked Questions

Q: What is the typical salary range for a Materials Engineer?

A: Salaries vary based on experience, education level (B.S., M.S., Ph.D.), industry, specific role, and geographic location. According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for materials engineers was $104,620 in May 2023. Entry-level positions typically start lower, while experienced engineers, specialists, and managers can earn significantly more.

Q: How competitive is the job market for new graduates?

A: The job market competitiveness can fluctuate with economic conditions and industry demand. The BLS projects employment of materials engineers to grow about 2 percent from 2022 to 2032, slower than the average for all occupations. However, demand remains steady in key sectors like aerospace, electronics, energy, and biomedical engineering. Graduates with strong academic records, internship experience, and specialized skills (e.g., computational modeling, specific material classes) often have better prospects.

Q: What's the difference between Materials Engineering and Chemical Engineering?

A: While there is overlap, Materials Engineering focuses primarily on the relationship between a material's structure (at atomic, micro, and macro levels), its processing, and its resulting properties and performance. Chemical Engineering typically focuses more on large-scale chemical processes, designing, operating, and optimizing industrial chemical plants for transforming raw materials into products, often involving fluid dynamics, heat transfer, and reaction kinetics. Materials Engineers design the *stuff*, Chemical Engineers often design the *process* to make the stuff or use it.

Q: How is automation impacting the Materials Engineering profession?

A: Automation is changing aspects of the job. Automated testing equipment can perform routine analyses more efficiently. AI and machine learning are accelerating material discovery and data analysis. However, this doesn't necessarily reduce the need for materials engineers. Instead, it shifts the focus towards higher-level tasks like interpreting complex data, designing novel experiments, developing new materials based on AI predictions, and solving complex integration problems. Skills in data analysis and computational tools are becoming increasingly important.

Q: What are some essential software tools for Materials Engineers?

A: Proficiency in certain software is often expected. CAD software (like SolidWorks, AutoCAD, CATIA) is used for design. FEA software (like ANSYS, Abaqus, COMSOL) is used for stress, thermal, and other simulations. Materials databases (like Granta Design) help in material selection. Data analysis software (like MATLAB, Python libraries, Excel) is crucial for interpreting experimental and simulation results. Specialized software for thermodynamic modeling (like Thermo-Calc) or crystallographic analysis may also be used.

Q: Are there global opportunities for Materials Engineers?

A: Yes, materials engineering is a global field. Multinational corporations in sectors like electronics, automotive, aerospace, and chemicals have R&D and manufacturing facilities worldwide, creating opportunities for engineers to work abroad. Research institutions and universities globally also employ materials engineers. Opportunities may depend on specialization, language skills, and visa requirements.

Exploring foundational principles is always beneficial.

Conclusion

Materials Engineering is a challenging yet deeply rewarding field, fundamental to virtually every technology we rely on. It demands a strong foundation in science, analytical rigor, creativity, and a collaborative spirit. From developing life-saving medical implants to enabling sustainable energy solutions and pushing the frontiers of electronics and aerospace, materials engineers are at the forefront of innovation.

Whether you are a student mapping out your education, a professional considering a pivot, or simply curious about the materials that shape our world, this field offers diverse pathways and the potential to make a tangible impact. The journey requires dedication, but the opportunity to contribute to technological progress and address societal challenges makes it a compelling career choice. If you're ready to explore further, start by browsing materials engineering courses on OpenCourser to build your foundation.