Process Design

A Comprehensive Guide to Process Design

Process design is the thoughtful creation, analysis, and optimization of the sequences of operations that transform inputs into desired outputs. At a high level, it's about figuring out the best way to do something, whether that "something" is manufacturing a product, delivering a service, or even managing information. It's a discipline that blends scientific principles with practical problem-solving to achieve specific goals, such as improved efficiency, enhanced quality, greater sustainability, or increased scalability. Essentially, process design provides the blueprint for how work gets done.

Working in process design can be deeply engaging. It offers the intellectual challenge of dissecting complex systems and the creative satisfaction of building something better. Professionals in this field often find excitement in identifying bottlenecks and inefficiencies that others might overlook, and then architecting elegant solutions that can have a tangible impact on an organization's performance and bottom line. Furthermore, as industries increasingly focus on sustainability and resilience, process designers play a crucial role in shaping operations that are not only effective but also responsible.

Introduction to Process Design

This section aims to lay a solid foundation for understanding what process design entails, its historical roots, and its vital role in today's world. Whether you are a student exploring future career paths, a professional considering a change, or simply curious about how things work, understanding process design is increasingly valuable.

Defining Process Design and Its Core Objectives

Process design, at its core, is the act of planning and specifying how a series of actions or operations will achieve a particular goal. It involves determining the necessary steps, the sequence of these steps, the resources required (like materials, equipment, and people), and the controls needed to ensure the desired outcome. Think of it as creating a detailed recipe for a complex dish, but instead of a culinary creation, the output could be anything from a smartphone to a patient's successful recovery in a hospital, or the efficient delivery of online orders.

The primary objectives of process design are multifaceted. A key goal is to enhance efficiency, meaning achieving the desired output with minimal waste of resources such as time, money, materials, and energy. Another crucial objective is to ensure and improve quality, so that the product or service consistently meets or exceeds customer expectations and predefined standards. Scalability is also a common aim, allowing the process to handle increasing volumes of work without a proportional increase in complexity or cost. Furthermore, modern process design increasingly emphasizes sustainability, aiming to minimize environmental impact and promote long-term viability.

Ultimately, effective process design seeks to create systems that are robust, reliable, and adaptable. It's not just about designing a process that works under ideal conditions, but one that can also handle variations, disruptions, and evolving requirements. This involves a deep understanding of the inputs, the transformations that occur, and the desired outputs, as well as the broader context in which the process operates.

Historical Evolution and Key Milestones

The concepts underpinning process design have ancient roots, with early examples found in agriculture, construction, and manufacturing throughout history. However, process engineering as a distinct discipline began to formalize with the scientific and industrial revolutions. The development of thermodynamics and the law of conservation of mass in the late 18th century provided a scientific basis for analyzing and optimizing processes. The Industrial Revolution itself was a hotbed of process innovation, driven by the need to mass-produce goods like textiles and machinery.

The early 20th century saw the emergence of "scientific management," spearheaded by figures like Frederick Winslow Taylor, which focused on optimizing manual labor tasks for efficiency. Henry Ford's development of the assembly line for automobile manufacturing was a landmark in process design, dramatically increasing output and reducing costs. Later, in the mid-20th century, concepts like Statistical Process Control, championed by Walter Shewhart and W. Edwards Deming, introduced rigorous statistical methods for quality improvement.

The latter half of the 20th century brought further evolution with the rise of Japanese manufacturing philosophies, notably the Toyota Production System, which introduced principles like Just-In-Time (JIT) manufacturing and Lean thinking. The advent of computers and information technology opened new frontiers for process modeling, simulation, and automation. By the 1980s, process engineering was recognized as a discipline applicable across numerous industries, not just chemical engineering where many of its early formal techniques were developed. More recently, methodologies like Six Sigma gained prominence for their structured approach to minimizing defects and variability. The ongoing digital transformation, including advancements in data analytics, artificial intelligence, and automation, continues to shape the evolution of process design, pushing towards more agile, intelligent, and interconnected systems.

Role in Optimizing Efficiency, Sustainability, and Scalability Across Industries

Process design is a cornerstone of operational excellence in virtually every industry. Its role in optimizing efficiency is perhaps its most well-known contribution. By meticulously analyzing workflows, eliminating redundant steps, streamlining operations, and strategically allocating resources, process design helps organizations produce more with less. This directly translates to reduced operational costs, faster delivery times, and improved productivity, all of which are critical for maintaining a competitive edge.

In an era of increasing environmental awareness and regulatory pressure, the role of process design in promoting sustainability has become paramount. Designers are tasked with creating processes that minimize waste, reduce energy consumption, lower greenhouse gas emissions, and incorporate principles of the circular economy, such as designing products for durability, repairability, and recyclability. This involves careful selection of materials, optimization of energy usage in production, and designing efficient reverse logistics for product end-of-life management. Sustainable process design not only helps protect the environment but can also lead to cost savings and enhance brand reputation.

Scalability, the ability of a process to handle growth effectively, is another critical area where process design plays a vital role. As businesses expand their operations, enter new markets, or experience increased demand, their underlying processes must be able to adapt without breaking down or becoming prohibitively expensive. Process designers achieve scalability by creating modular systems, automating tasks where feasible, and implementing flexible workflows that can be easily adjusted to accommodate higher volumes or new requirements. This foresight in design ensures that an organization can grow smoothly and sustainably, capitalizing on opportunities without being crippled by operational limitations.

Key Principles and Methodologies

Understanding the foundational principles and methodologies of process design is crucial for anyone looking to work in or understand this field. These frameworks provide the tools and approaches for systematically analyzing, creating, and improving processes.

Guiding Philosophies: Lean, Six Sigma, and Systems Thinking

Several guiding philosophies underpin modern process design, with Lean, Six Sigma, and Systems Thinking being among the most influential. Lean, originating from the Toyota Production System, focuses on maximizing customer value while minimizing waste. Waste, in Lean terms, encompasses anything that does not add value from the customer's perspective, such as overproduction, waiting time, unnecessary transport, excess inventory, over-processing, defects, and underutilized talent. The core idea is to create a smooth, continuous flow of value-adding activities.

Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects in any process – from manufacturing to transactional and from product to service. The fundamental objective of the Six Sigma methodology is the implementation of a measurement-based strategy that focuses on process improvement and variation reduction through the application of Six Sigma improvement projects. This is accomplished through the use of two Six Sigma sub-methodologies: DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify). The term "Six Sigma" refers to the goal of achieving a process that is 99.99966% defect-free.

Systems Thinking provides a broader perspective, encouraging designers to view processes not as isolated activities but as interconnected parts of a larger system. It emphasizes understanding the relationships, interactions, and feedback loops within a system and how changes in one part can affect others. By adopting a holistic view, systems thinking helps to identify root causes of problems rather than just treating symptoms, and to design solutions that optimize the performance of the overall system, not just individual components. This approach is vital for tackling complex problems and avoiding unintended negative consequences.

These courses can help build a foundation in these important guiding philosophies.

The Journey of Process Design: From Analysis to Monitoring

The process of designing or redesigning a process typically follows a structured journey, often conceptualized in several key stages. The first stage is **Analysis**. This involves thoroughly understanding the current state if an existing process is being improved, or clearly defining the requirements and goals if a new process is being created. Activities in this stage include gathering data, mapping the existing process (e.g., using flowcharts), identifying problems, bottlenecks, inefficiencies, and understanding stakeholder needs.

The next stage is **Modeling or Design**. Based on the insights from the analysis phase, potential solutions or new process designs are developed. This is a creative phase where different approaches might be brainstormed and evaluated. Process models, often visual, are created to represent the proposed new workflow. Simulation tools may be used to test different design options and predict their performance before actual implementation. The aim is to develop a robust and efficient process that meets the defined objectives.

Following the design phase is **Implementation**. This is where the newly designed process is put into action. It can involve developing new procedures, training staff, acquiring new equipment or technology, and managing the change within the organization. Careful planning and communication are crucial for a successful implementation to minimize disruption and ensure buy-in from those involved in the process.

Once implemented, the process moves into the **Monitoring and Control** stage. Key performance indicators (KPIs) are tracked to measure how well the process is performing against its objectives. Regular monitoring helps to identify any deviations from the desired performance, allowing for timely corrective actions. This stage often feeds back into the analysis phase, creating a cycle of continuous improvement, where the process is regularly reviewed and refined over time.

The following book offers insights into the dynamics and control aspects relevant to process design.

Strategic Choices: Top-Down versus Iterative Approaches

When approaching process design, organizations often choose between, or combine elements of, top-down and iterative (or bottom-up) strategies. A **top-down approach** typically starts with the organization's overall strategic objectives. Senior management defines the goals and performance targets, and these are then cascaded down to various departments and teams, who design or redesign their processes to align with these overarching aims. This ensures that process improvements are directly linked to business strategy and that there is a unified direction across the organization. However, a purely top-down approach can sometimes overlook the practical realities and insights of those directly involved in the day-to-day execution of processes.

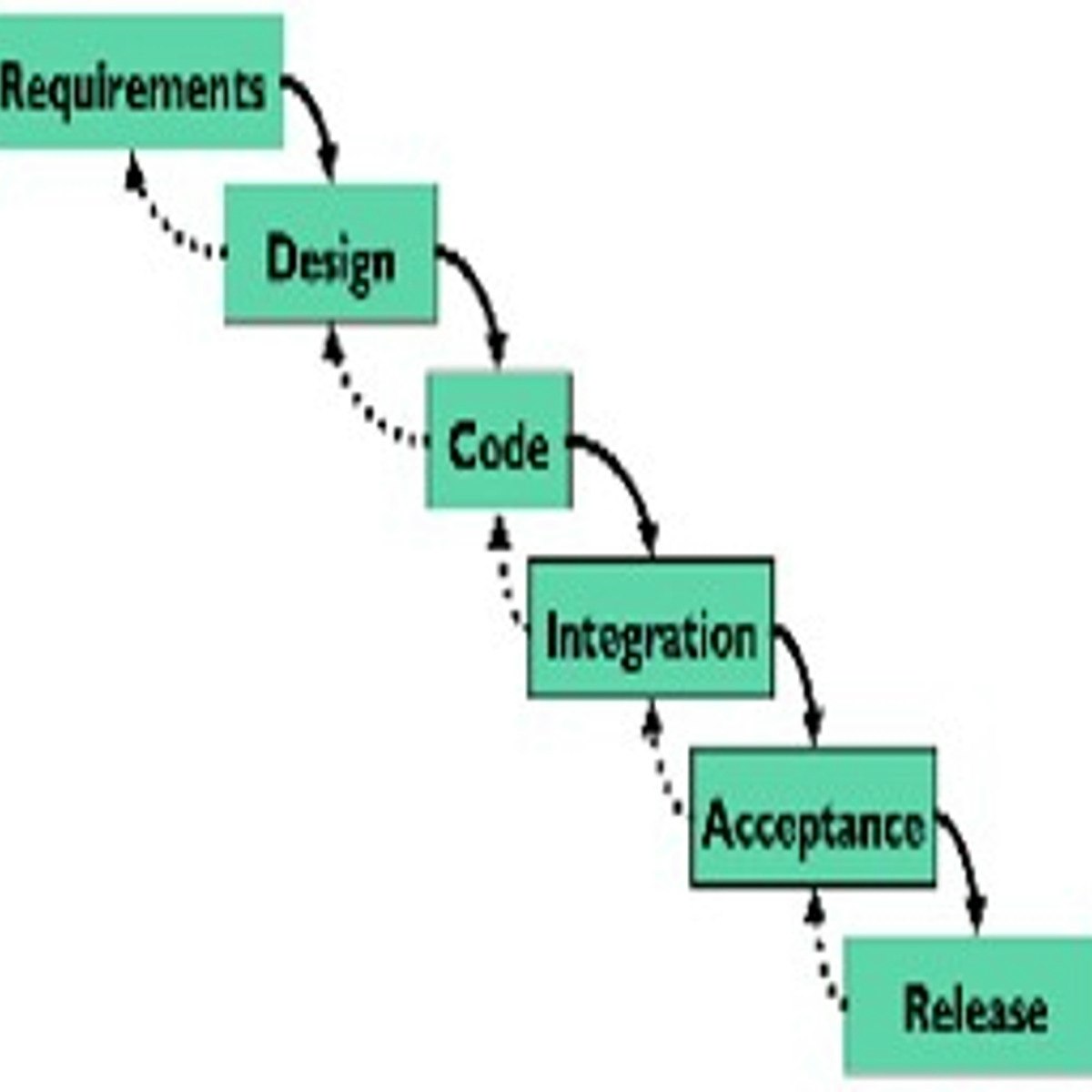

Conversely, an **iterative or bottom-up approach** often begins with identifying specific problems or opportunities for improvement at the operational level. Teams working directly with processes might initiate changes based on their hands-on experience and observations. This approach is often more agile and can lead to quick wins and practical solutions. Methodologies like Agile and Lean Startup often favor iterative development, where processes are built and refined in short cycles based on feedback and learning. The challenge with a purely bottom-up approach is ensuring that these localized improvements align with broader organizational goals and don't lead to fragmented or conflicting efforts.

In practice, many successful process design initiatives blend these two approaches. Strategic direction from the top provides the "why" and the overall goals, while iterative, participatory methods involving front-line employees provide the "how" and ensure practical, sustainable solutions. This combination allows for both strategic alignment and operational effectiveness, fostering a culture of continuous improvement that is both goal-oriented and responsive to on-the-ground realities.

Process Design Tools and Technologies

The practice of process design is significantly enhanced by a variety of tools and technologies. These range from software that helps visualize and analyze processes to advanced systems that automate and optimize workflows. Familiarity with these tools is increasingly important for professionals in the field.

Visualizing and Simulating: Software in Process Design

Software tools are indispensable in modern process design for visualizing, analyzing, and simulating processes. Flowcharting software, such as Microsoft Visio, Lucidchart, or Miro, allows designers to create visual maps of processes. These diagrams help in understanding the sequence of steps, decision points, inputs, and outputs, making it easier to identify inefficiencies or areas for improvement. Business Process Model and Notation (BPMN) is a standardized graphical representation for specifying business processes in a business process model, and many tools support this standard.

Beyond simple visualization, process simulation software (e.g., Arena, AnyLogic, Simul8) enables designers to create dynamic models of processes and test how they behave under different conditions. Users can input variables such as arrival rates, processing times, resource availability, and costs. The software then simulates the process over time, providing data on performance metrics like throughput, cycle time, resource utilization, and bottlenecks. This allows for "what-if" analysis, where different design alternatives can be compared without the risk and expense of real-world experimentation. Simulation is particularly valuable for complex systems where the interactions between different parts are not immediately obvious.

Other relevant software includes Business Process Management (BPM) suites, which offer a comprehensive set of tools for designing, implementing, monitoring, and optimizing business processes. These suites often include features for workflow automation, rules management, and performance analytics, providing an integrated platform for managing the entire process lifecycle.

For those interested in the intersection of design and practical tools, the following course might be of interest, particularly its application of canvas-based thinking which can be analogous to certain process mapping techniques.

The Rise of Intelligent Operations: Automation and AI

Automation and Artificial Intelligence (AI) are profoundly transforming process design and execution. Robotic Process Automation (RPA) involves using software "bots" to perform repetitive, rule-based tasks previously handled by humans, such as data entry, form processing, and report generation. RPA can significantly improve efficiency, reduce errors, and free up human workers to focus on more complex, value-added activities. The design of processes needs to account for which tasks are suitable for RPA and how human and bot workflows will interact.

Artificial Intelligence takes automation a step further by enabling systems to perform tasks that traditionally require human intelligence, such as decision-making, pattern recognition, and natural language understanding. In process design, AI can be used for predictive analytics (e.g., forecasting demand or predicting equipment failure), process optimization (e.g., dynamically adjusting parameters for optimal performance), and intelligent decision support. Machine learning algorithms can analyze vast amounts of process data to uncover hidden inefficiencies, suggest improvements, or even autonomously adapt processes in real time.

The integration of AI also enables more sophisticated forms of process monitoring and control, allowing for proactive interventions rather than reactive fixes. For instance, AI-powered computer vision can be used for quality control in manufacturing, identifying defects far more quickly and accurately than human inspectors. As AI capabilities continue to advance, their role in designing, managing, and continuously improving processes will only grow, leading to what many call "intelligent operations."

These courses delve into aspects of operational excellence and digital transformation, which heavily involve automation and intelligent systems.

The following book explores optimization, a key area where AI and advanced algorithms play a significant role in process design.

Learning from Practice: Technology-Driven Optimization Case Studies

Examining real-world case studies illustrates how technology drives process optimization across various sectors. In manufacturing, for instance, companies like BMW and General Electric have implemented "digital twin" technology. A digital twin is a virtual replica of a physical asset, process, or system. By continuously feeding real-time data from sensors on the factory floor to the digital twin, engineers can simulate different production scenarios, predict potential equipment failures, and optimize energy consumption without disrupting actual operations. This has led to significant reductions in downtime and improvements in overall equipment effectiveness (OEE).

In the logistics and supply chain industry, companies like Amazon and DHL leverage sophisticated warehouse automation systems, including robotic arms for picking and packing, autonomous guided vehicles (AGVs) for moving goods, and AI-powered route optimization software for delivery fleets. These technologies have drastically increased the speed and efficiency of order fulfillment and reduced operational costs. Process design in these environments focuses on orchestrating the seamless interaction between human workers and these advanced automated systems.

Healthcare is another sector benefiting from technology-driven process optimization. Hospitals are using AI for tasks such as analyzing medical images to detect diseases earlier, optimizing patient scheduling to reduce wait times, and managing electronic health records more efficiently. RPA is used to automate administrative tasks like patient registration and billing. These applications of technology in healthcare process design aim to improve patient outcomes, enhance operational efficiency, and reduce the burden on medical staff. These examples showcase the transformative power of integrating technology thoughtfully into process design.

Formal Education Pathways

For those aspiring to a career in process design, a strong educational foundation is often a key starting point. Several academic disciplines provide the knowledge and skills necessary to excel in this field, complemented by specialized certifications that can further enhance one's credentials.

Degrees that Pave the Way: Engineering, Operations, and More

A common route into process design is through an undergraduate or graduate degree in Industrial Engineering. This field directly focuses on the design, improvement, and installation of integrated systems of people, materials, information, equipment, and energy. Coursework typically includes operations research, production planning, quality control, ergonomics, and supply chain management, all of which are highly relevant to process design.

Another strong pathway is a degree in Operations Management or Business Administration with a concentration in operations. These programs emphasize the management of resources and processes necessary to produce goods and services efficiently and effectively. Students learn about process analysis, project management, supply chain logistics, and strategic decision-making in an operational context.

Chemical Engineering is a traditional path for process design roles, particularly in industries like oil and gas, pharmaceuticals, and materials manufacturing. These programs focus on the design and operation of chemical plants and equipment, involving complex physical and chemical transformations. Mechanical Engineering and Manufacturing Engineering also provide solid foundations, especially for roles involving the design of physical products and production systems. Increasingly, degrees in fields like Computer Science or Data Science are becoming relevant, especially with the rise of automation, AI, and data-driven process optimization.

These courses touch upon specialized areas of process design within engineering contexts, such as chemical and water treatment processes.

The following book is a cornerstone text for those studying chemical process design.

Advanced Studies: Research and Thesis Opportunities

For those wishing to delve deeper into process design, pursuing graduate studies (Master's or PhD) offers opportunities for advanced research and specialization. Research in process design can span a wide array of topics, often at the intersection of engineering, computer science, and management. Potential thesis topics could involve developing novel algorithms for process optimization, exploring the application of AI and machine learning to automate complex decision-making in processes, or designing sustainable processes for emerging industries like biorefining or circular economy initiatives.

Other research areas might include human factors in process design, focusing on how to design work systems that are not only efficient but also safe and engaging for human operators. Investigating the resilience of supply chains through advanced process modeling and simulation is another critical area, especially in light of global disruptions. Students might also explore the ethical implications of process automation and data-driven decision-making, or develop new methodologies for integrating sustainability criteria into the earliest stages of process design.

Universities with strong engineering and business schools often have dedicated research labs or centers focusing on operations research, manufacturing systems, supply chain management, or sustainable engineering, providing fertile ground for such advanced studies. Engaging in research allows students to contribute new knowledge to the field and tackle some of the most pressing challenges facing industries today.

Credentials for Advancement: Professional Certifications

Beyond formal degrees, professional certifications can significantly enhance a process designer's qualifications and career prospects. One of the most widely recognized sets of certifications is in Lean Six Sigma. These certifications are typically offered in a tiered "belt" system, such as Yellow Belt (foundational awareness), Green Belt (leading small improvement projects), Black Belt (leading complex improvement projects and mentoring Green Belts), and Master Black Belt (strategic deployment and training). Organizations like the American Society for Quality (ASQ) and various private training providers offer Lean Six Sigma certification programs.

Project Management Professional (PMP) certification from the Project Management Institute (PMI) is also highly valuable, as many process design initiatives are managed as projects. A PMP certification demonstrates proficiency in leading and directing projects, a crucial skill for implementing new or redesigned processes. For those specializing in supply chain management, certifications like APICS Certified Supply Chain Professional (CSCP) or Certified in Logistics, Transportation and Distribution (CLTD) can be beneficial.

In specific industries, there might be other relevant certifications. For example, in IT, certifications related to IT Service Management (ITSM) frameworks like ITIL (Information Technology Infrastructure Library) can be useful for designing and managing IT processes. These credentials signal a commitment to professional development and a recognized level of expertise in specific methodologies and domains within process design.

Online Learning and Skill Development

The digital age has democratized access to education, and process design is no exception. Online learning platforms offer a wealth of resources for individuals looking to enter the field, upskill, or complement their existing formal education. For career pivoters and self-taught learners, online courses can be an invaluable gateway.

OpenCourser is a leading platform for discovering such educational opportunities, allowing learners to easily browse through thousands of courses from various providers. Features like saving courses to a list, comparing syllabi, and reading summarized reviews can help you find the perfect online course to build your process design skills. Moreover, for those seeking guidance on how to best utilize these resources, the OpenCourser Learner's Guide offers articles on topics like earning certificates and structuring a self-learning curriculum.

Learning the Ropes: Self-Directed Study for Foundational Roles

It is indeed feasible to build a strong foundation for entry-level roles in process design through self-directed online learning. Many platforms offer introductory courses in operations management, Lean principles, Six Sigma fundamentals, and business process modeling. These courses can equip learners with the core concepts, terminology, and basic analytical tools used in the field. For example, understanding how to create a value stream map, identify the "seven wastes" in Lean, or apply basic statistical process control charts can be learned effectively online.

The key to successful self-directed learning is discipline, a structured approach, and a focus on practical application. Learners should aim to not just passively consume video lectures but actively engage with the material, complete assignments, and participate in any available online forums or communities. Building a portfolio of small projects or case study analyses based on online course learnings can demonstrate practical skills to potential employers.

While a formal degree might be preferred or required by some employers, particularly for engineering-heavy roles, a demonstrated understanding of process design principles acquired through rigorous online study, coupled with relevant project work, can certainly open doors to roles like process analyst, junior operations analyst, or quality assurance support, especially in small to medium-sized enterprises or in industries where practical skills are highly valued.

These courses provide excellent starting points for understanding operational excellence and specific process design applications, suitable for self-directed study.

Theory Meets Practice: Online Courses and Hands-On Projects

The most effective way to learn process design, especially through online channels, is to balance theoretical coursework with hands-on projects. While online courses provide the necessary knowledge and frameworks, applying these concepts to real-world or simulated scenarios solidifies understanding and builds practical skills. Many online courses now incorporate project-based learning, guiding students through the analysis and redesign of a sample process or challenging them to solve a specific operational problem.

Learners can also seek out opportunities for hands-on experience independently. This could involve volunteering to help a local non-profit organization improve one of its processes, or undertaking a personal project, such as optimizing a household workflow or a small side business operation. Documenting these projects, including the problem statement, the analysis performed, the proposed solution, and the (even hypothetical) results, can create valuable portfolio pieces.

Furthermore, many software tools used in process design, such as flowcharting or basic simulation software, offer free trials or student versions. Learners can use these tools to practice process mapping, modeling, and analysis techniques learned in their online courses. Participating in online challenges or competitions related to process improvement or data analysis can also provide excellent hands-on experience and a chance to showcase skills.

This course specifically focuses on using a digital tool for a Lean UX canvas, which is a hands-on approach to design thinking and experimentation.

Enhancing Your Degree: Specialized Online Modules

For individuals already pursuing or holding a formal degree, online courses and specialized modules offer an excellent way to complement their education and gain expertise in niche areas of process design. University curricula, while comprehensive, may not always cover the latest tools, specific industry applications, or emerging methodologies in great depth. Online learning can bridge these gaps.

For example, an industrial engineering student might take an advanced online module on AI applications in manufacturing process optimization, or a business student could supplement their operations management degree with a deep dive into sustainable supply chain design. Someone with a chemical engineering background might explore online courses on biorefinery process design or advanced process control systems. These specialized modules can provide cutting-edge knowledge and skills that make a graduate more attractive to employers in specific sectors.

Moreover, online courses can offer practical training in specific software tools or certifications (like Lean Six Sigma Green Belt) that might not be part of a standard degree program. This allows students and recent graduates to tailor their skillset to particular career interests and demonstrate a proactive approach to learning and professional development. Adding these specialized online credentials to a resume can significantly enhance one's profile.

These specialized courses focus on particular industrial applications of process design, which can be excellent complements to a broader engineering or management degree.

[course] Industrial FermentationBooks like the following delve into specific, advanced areas of process design and optimization, valuable for deeper specialization.

Career Progression and Opportunities

A career in process design offers diverse pathways and significant opportunities for growth. As organizations across all sectors continuously seek to improve efficiency, quality, and sustainability, the demand for skilled process design professionals remains robust. Understanding the typical career trajectory and market demand can help aspiring individuals navigate this rewarding field.

Starting Your Journey: Entry-Level Roles

Entry-level positions in process design often serve as a launchpad for a fulfilling career. Common titles include **Process Analyst**, **Junior Industrial Engineer**, **Operations Analyst**, or **Quality Assurance Technician**. In these roles, individuals typically support senior designers and managers by gathering and analyzing data, mapping existing processes, identifying inefficiencies, and assisting in the development and implementation of improvement initiatives. They might use tools like Excel, flowcharting software, and basic statistical methods to support their work.

A Process Analyst, for example, might be tasked with documenting current workflows in a service organization, interviewing staff to understand pain points, and then proposing streamlined procedures. A Junior Industrial Engineer in a manufacturing plant could be involved in time studies, plant layout analysis, or small-scale projects to reduce waste on a production line. These roles provide invaluable hands-on experience and exposure to real-world operational challenges.

The educational background for these roles often includes a bachelor's degree in industrial engineering, operations management, business administration, or a related field. Strong analytical skills, attention to detail, problem-solving abilities, and good communication skills are highly valued. For those looking for salary information, resources like the U.S. Bureau of Labor Statistics (BLS Occupational Employment Statistics) can provide data on related occupations, though specific "Process Designer" categories may vary. Zippia and other career sites also compile salary data; for instance, as of early 2025, the average hourly pay for a Process Analyst in the United States was around $38.84, though this can vary significantly by location, experience, and industry. Another source suggests an average salary for a process analyst in the U.S. is around $73,233 annually.

Climbing the Ladder: Mid-Career Specialization

As process design professionals gain experience, they often move into more specialized and responsible roles. Mid-career paths can include **Senior Process Engineer**, **Process Improvement Manager**, **Lean Six Sigma Black Belt**, **Supply Chain Analyst/Manager**, or **Operations Manager**. At this stage, individuals are typically expected to lead larger and more complex projects, mentor junior staff, and contribute to strategic decision-making related to process optimization.

Specialization can occur along several dimensions. Some may focus on specific methodologies, becoming experts in Lean or Six Sigma and driving continuous improvement programs across an organization. Others might specialize in particular industries (e.g., healthcare process improvement, manufacturing operations, financial services process re-engineering) or specific technologies (e.g., automation specialist, ERP systems analyst). A Supply Chain Manager, for example, would focus on optimizing the end-to-end flow of goods and information, from raw material sourcing to final delivery.

Strong project management skills, advanced analytical capabilities, and the ability to lead change become increasingly important. Many professionals pursue advanced certifications (like a Six Sigma Black Belt or PMP) or a master's degree (e.g., MBA with an operations focus, Master's in Engineering Management) to further their careers. According to the U.S. Bureau of Labor Statistics, employment for industrial engineers, a closely related field, is projected to grow 12 percent from 2023 to 2033, much faster than the average for all occupations. The median annual wage for industrial engineers was $101,140 in May 2024. For operations managers more broadly, the job outlook is also positive.

Reaching the Top: Leadership in Operations

With significant experience and a proven track record, process design professionals can ascend to senior leadership roles within operations and beyond. These positions might include **Director of Operations**, **Vice President of Operations**, **Chief Operating Officer (COO)**, or **Head of Process Excellence/Transformation**. In such roles, individuals are responsible for setting the strategic direction for an organization's operational capabilities, overseeing large teams, managing substantial budgets, and driving innovation across multiple processes and departments.

Leadership in operations involves not just technical expertise in process design but also strong strategic thinking, financial acumen, exceptional communication and interpersonal skills, and the ability to inspire and motivate teams. These leaders play a critical role in ensuring that an organization's operations are aligned with its overall business strategy and can adapt to changing market conditions and technological advancements. They are often key players in major organizational changes, such as mergers and acquisitions, new product launches, or entries into new markets.

The path to these top roles typically requires extensive experience, continuous learning, and often an advanced degree like an MBA. Networking and developing a strong professional reputation are also crucial. The U.S. Bureau of Labor Statistics (BLS) projects that employment in management occupations overall is expected to grow faster than average, with about 1.2 million openings projected each year on average from 2023 to 2033. The median annual wage for this broad group was $122,090 in May 2024, with top executives earning significantly more.

Process Design in Industry Applications

Process design is not a one-size-fits-all discipline; its application varies significantly across different industries and organizational contexts. From the factory floor to the hospital ward, the core principles of optimizing workflows, enhancing quality, and improving efficiency are adapted to meet unique challenges and objectives.

Manufacturing versus Service-Sector Adaptations

While the fundamental goals of process design—efficiency, quality, cost-effectiveness—are shared, their application differs notably between manufacturing and service sectors. In **manufacturing**, process design often focuses on the physical transformation of raw materials into tangible products. Key concerns include production line balancing, inventory management (e.g., Just-In-Time systems), quality control at various stages of production, equipment maintenance (e.g., Total Productive Maintenance), and plant layout optimization. Methodologies like Lean manufacturing and Six Sigma are heavily utilized to minimize defects, reduce waste (muda), and streamline production flows. The output is a physical good, and metrics often revolve around production volume, defect rates, and machine uptime.

In the **service sector**, process design centers on the delivery of intangible value to customers. Examples include healthcare delivery, financial transactions, customer support, education, and hospitality. Here, processes often involve information flows, customer interactions, and decision-making by service providers. Key concerns include managing customer wait times, ensuring service consistency and quality, personalizing service experiences, and optimizing the productivity of service personnel. The "customer journey" is a critical concept, and process design aims to make this journey as smooth and positive as possible. While some service processes can be highly standardized and automated (like online banking transactions), many involve a higher degree of human interaction and customization, making process design more complex in different ways than in manufacturing.

Despite these differences, there's also convergence. Many manufacturing companies are increasingly incorporating service components (e.g., after-sales support, maintenance services), and service industries are adopting manufacturing principles (e.g., "service factories" that standardize routine service tasks) to improve efficiency and consistency. For those looking to explore courses relevant to both sectors, OpenCourser offers a wide selection under categories like Industrial Engineering and Management.

These courses offer perspectives relevant to operational excellence which is applicable in both manufacturing and service contexts.

This book is foundational for chemical manufacturing processes but its principles of design and integration are broadly informative.

Spotlight on Sectors: Healthcare and Supply Chain Case Studies

The impact of process design is particularly evident in critical sectors like healthcare and supply chain management. In **healthcare**, effective process design can literally be a matter of life and death. Hospitals and clinics constantly strive to improve patient flow, reduce wait times for appointments and procedures, minimize medical errors, and enhance the overall patient experience. For example, redesigning the emergency room triage process can ensure that critically ill patients are seen more quickly. Implementing standardized checklists for surgical procedures (a process design intervention) has been shown to dramatically reduce infections and complications. The adoption of Electronic Health Records (EHR) systems, while challenging, is a major process redesign aimed at improving information flow and coordination of care.

In **supply chain management**, process design is crucial for ensuring the efficient and timely flow of goods, information, and finances from suppliers to end customers. This involves designing processes for procurement, inventory management, warehousing, transportation, and last-mile delivery. For instance, companies like Amazon have revolutionized e-commerce through meticulous design of their fulfillment center processes and logistics networks, utilizing automation and sophisticated data analytics. In the wake of global disruptions, there's an increased focus on designing resilient supply chain processes that can better withstand shocks, often involving diversification of suppliers, strategic inventory positioning, and enhanced visibility through digital tools.

Both sectors are increasingly leveraging technology, from RPA for administrative tasks in healthcare to IoT sensors for tracking goods in supply chains. The core challenge remains aligning complex series of actions to achieve specific outcomes, whether it's a healthier patient or a product delivered on time.

The following course touches upon biorefineries, which involve complex supply chains for biomass and processing.

The Bottom Line: Impact on Cost Reduction and Risk Mitigation

Ultimately, a significant driver for investing in process design is its direct impact on an organization's bottom line, primarily through cost reduction and risk mitigation. Well-designed processes eliminate waste, whether it's wasted materials in manufacturing, wasted time due to inefficient workflows, or wasted resources from errors and rework. By streamlining operations and improving resource utilization, companies can significantly lower their operating costs. For example, optimizing a production line to reduce energy consumption or redesigning a service process to handle more customers with the same staff directly contributes to profitability.

Process design also plays a critical role in risk mitigation. Standardized processes with clear controls and checkpoints help reduce the likelihood of errors, accidents, and compliance failures. In manufacturing, robust quality control processes minimize the risk of defective products reaching the market, which could lead to recalls, reputational damage, and legal liabilities. In financial services, well-designed processes for handling transactions and customer data are essential for preventing fraud and ensuring regulatory compliance. By identifying potential failure points in a process (e.g., through Failure Mode and Effects Analysis - FMEA) and designing safeguards, organizations can reduce their exposure to various operational, financial, and legal risks.

Furthermore, processes designed for resilience and adaptability can help organizations better navigate unforeseen disruptions, such as supply chain interruptions, natural disasters, or sudden shifts in market demand. This ability to maintain operations or recover quickly in the face of adversity is a crucial aspect of risk management and business continuity, directly supported by thoughtful process design.

This book on optimization is highly relevant to cost reduction efforts within process design.

Emerging Trends and Innovations

The field of process design is dynamic, continuously evolving with technological advancements and shifting business priorities. Staying abreast of emerging trends and innovations is crucial for professionals who wish to remain at the forefront and for organizations aiming to build future-ready operations.

The AI Revolution: Intelligent Process Automation and Augmentation

Artificial Intelligence (AI) is arguably the most transformative trend currently impacting process design. Beyond basic Robotic Process Automation (RPA), AI is enabling more sophisticated forms of **intelligent process automation (IPA)**, where systems can handle more complex, less structured tasks and make data-driven decisions. Machine learning algorithms can analyze historical process data to identify patterns, predict outcomes (like equipment failure or demand fluctuations), and optimize process parameters in real time. For example, in manufacturing, AI can adjust machine settings dynamically to maintain quality or optimize energy use.

AI is also augmenting human capabilities in process design and execution. AI-powered tools can assist designers by generating multiple design alternatives based on specified constraints or by simulating the impact of different process changes much faster than traditional methods. In ongoing operations, AI can provide decision support to human workers, offering recommendations or highlighting potential issues that require attention. This "human-in-the-loop" approach combines the analytical power of AI with human judgment and expertise. The trend is towards creating "agentic AI" systems where AI agents can autonomously perform tasks and even collaborate to achieve broader process goals, though this is still an innovator trend requiring careful design for trust and observability.

As AI becomes more integrated, process design will increasingly focus on how to effectively orchestrate human-AI collaboration, ensure the ethical use of AI (e.g., avoiding bias in AI-driven decisions), and manage the new types of data and skills required.

These courses provide insights into digital transformation and operational excellence, which are heavily influenced by AI.

Green Imperatives: Sustainability and the Circular Economy

Sustainability is no longer a niche concern but a central driver of process design innovation. There is a growing imperative to design processes that minimize environmental impact, conserve resources, and support a circular economy. This involves a lifecycle perspective, considering the environmental footprint of a product or service from raw material extraction through manufacturing, use, and end-of-life. Process designers are tasked with reducing energy consumption, minimizing waste generation, eliminating hazardous substances, and increasing the use of renewable and recycled materials.

The principles of the circular economy are particularly influential, encouraging the design of products and processes that keep materials in use for as long as possible. This includes designing for durability, repairability, reusability, and recyclability. For example, a company might redesign its product to be easily disassembled so that components can be recovered and reused, or it might develop closed-loop processes where waste from one part of the operation becomes an input for another. This shift requires innovative thinking about material flows, reverse logistics, and business models.

Tools like Life Cycle Assessment (LCA) are used to quantify the environmental impact of different process designs, helping organizations make more informed, sustainable choices. The push for sustainability is driven by consumer demand, regulatory pressures, and a growing recognition that sustainable practices can also lead to long-term cost savings and enhanced brand reputation.

These courses focus on biobased products and industrial fermentation, areas where sustainable process design is critical.

[course] Industrial FermentationThe Future of Work: Decentralized and Agile Workflows

The nature of work itself is changing, driven by trends like remote work, globalization, and the gig economy. This is leading to more decentralized and agile workflows, and process design must adapt accordingly. Traditional, highly centralized processes designed for co-located teams are often not suitable for distributed work environments. Instead, there's a move towards designing processes that are more modular, flexible, and supported by collaborative digital tools.

Agile methodologies, originally developed for software development, are increasingly being applied to other types of process design and improvement. This involves working in shorter cycles, focusing on iterative improvements, and maintaining flexibility to respond to changing requirements or feedback. Cloud-based collaboration platforms, project management software, and communication tools become critical infrastructure for supporting these agile and decentralized workflows.

Process design in this context also needs to consider how to maintain visibility, coordination, and a sense of team cohesion when workers are not physically together. This might involve designing explicit communication protocols, using shared digital dashboards to track progress, and fostering a culture of trust and accountability. The rise of "low-code" and "no-code" platforms is also empowering non-technical users to design and automate their own simple workflows, further decentralizing process creation and modification, though architects need to be aware of quality and governance with such tools.

Challenges and Ethical Considerations

While process design offers immense potential for improving efficiency and effectiveness, it also presents certain challenges and raises important ethical considerations. Navigating these requires careful thought and a commitment to responsible practice.

The Human Element: Balancing Efficiency with Workforce Impact

One of the most significant challenges in process design, particularly with the rise of automation and AI, is balancing the drive for efficiency with the impact on the human workforce. Automation can lead to increased productivity and reduced costs, but it can also result in job displacement or significant changes in job roles for employees. Process designers and organizational leaders have an ethical responsibility to consider these human consequences.

This involves not only assessing which tasks can be automated but also thinking about how to reskill or upskill employees whose roles are affected. It may mean designing new roles that complement automated systems, focusing on tasks that require uniquely human skills like complex problem-solving, creativity, and empathy. Open communication with employees about planned changes, involving them in the design of new processes, and providing support during transitions are crucial for managing this challenge ethically and effectively.

Furthermore, poorly designed automated processes can sometimes lead to increased stress or a diminished sense of autonomy for human workers who interact with them. The "automation bias," where humans overly rely on or trust automated decisions even when they might be flawed, is another concern that needs careful management through design and training. The goal should be to create human-centered processes where technology augments and supports human capabilities, rather than simply replacing them or creating a more difficult work environment.

Data Governance: Privacy and Security in Monitored Systems

Modern process design often involves collecting and analyzing vast amounts of data, including data about employee performance, customer behavior, and operational details. While this data is invaluable for monitoring, controlling, and optimizing processes, it also raises significant ethical concerns related to privacy and security. Organizations must ensure that data collection is transparent, that individuals are aware of what data is being collected and how it's being used, and that appropriate consents are obtained.

Robust data governance frameworks are essential. This includes implementing strong security measures to protect sensitive data from breaches or unauthorized access. Data anonymization or pseudonymization techniques should be used where possible to protect individual privacy. Clear policies are needed regarding data retention, access controls, and the permissible uses of collected data. Process designers need to build these privacy and security considerations into the process from the outset ("privacy by design"), rather than treating them as afterthoughts.

The ethical use of employee monitoring data is a particularly sensitive area. While monitoring can help identify inefficiencies or ensure compliance, it can also feel intrusive if not handled properly. Transparency about monitoring practices, a clear rationale for why monitoring is necessary, and safeguards against misuse of the data are critical for maintaining employee trust.

Weighing the Scales: Environmental Trade-offs in Optimization

While sustainability is an increasingly important goal in process design, there can sometimes be trade-offs between optimizing for one environmental factor and inadvertently creating negative impacts elsewhere, or between environmental goals and other business objectives like cost or speed. For example, a process designed to minimize energy consumption might require the use of a raw material that is more difficult to recycle or has a more harmful extraction process. Or, a shift to a more environmentally friendly but more expensive material could impact product affordability.

Process designers must carefully evaluate these potential trade-offs using tools like Life Cycle Assessment (LCA) and multi-criteria decision analysis. This involves considering the entire lifecycle of a product or service and assessing its impact across various environmental dimensions (e.g., carbon footprint, water use, toxicity, resource depletion) as well as social and economic factors.

Achieving true sustainability often requires a holistic approach that seeks to find synergies rather than just managing trade-offs. For example, designing products for durability and repairability not only reduces waste (an environmental benefit) but can also enhance customer loyalty and create new service revenue streams (economic benefits). Transparently communicating these trade-offs and the rationale behind design decisions to stakeholders is also an important ethical consideration.

Frequently Asked Questions (FAQs)

Navigating the world of process design can bring up many questions, especially for those new to the field or considering it as a career. Here are answers to some common inquiries.

Is an engineering degree mandatory for entry into process design?

While an engineering degree, particularly in industrial, chemical, or mechanical engineering, is a very common and often preferred qualification for many process design roles (especially in manufacturing or technical environments), it is not always strictly mandatory for all entry points. Fields like operations management, business analysis, or even specialized roles in quality assurance may have process design components where a business degree with a strong analytical focus, or significant relevant experience coupled with certifications (like Lean Six Sigma), can be sufficient. Roles that are more focused on business process analysis in service industries, for example, might prioritize analytical and problem-solving skills over a specific engineering background. However, for roles titled "Process Engineer" or those involving complex technical systems, an engineering degree is typically expected.

How does process design intersect with project management?

Process design and project management are closely related and often intersecting disciplines. The design or redesign of a significant process is almost always undertaken as a project. Project management provides the framework, tools, and techniques to plan, execute, and control the work required to achieve the specific goals of the process design initiative within defined constraints of scope, time, and budget. For instance, implementing a new CRM system (a process redesign for customer relationship management) would be managed as a project, with distinct phases, deliverables, and resource allocation.

Process designers often work as part of project teams or may even lead process improvement projects. Understanding project management principles (e.g., defining scope, creating work breakdown structures, managing risk, stakeholder communication) is therefore highly beneficial for process design professionals. Conversely, project managers involved in operational improvement projects need a good understanding of process design principles to effectively guide their teams and ensure the project delivers the desired process outcomes.

What industries hire the most process designers?

Process designers are in demand across a vast range of industries because virtually every organization has processes that can be improved. However, some sectors traditionally have a very high concentration of process design roles. Manufacturing is a major employer, including automotive, aerospace, electronics, pharmaceuticals, chemicals, and consumer goods. These industries rely heavily on efficient and well-controlled production processes.

The logistics and supply chain sector is another large employer, driven by the need to optimize the movement of goods and information. Healthcare organizations (hospitals, clinics) are increasingly hiring process improvement specialists to enhance patient care, reduce costs, and improve operational efficiency. Financial services (banking, insurance) employ process designers to streamline transactions, manage risk, and ensure regulatory compliance. Technology companies, particularly in software development and IT services, also have a strong need for process design to manage development lifecycles, service delivery, and infrastructure operations. Government agencies and consulting firms also hire a significant number of professionals with process design skills.

Can freelance or consulting opportunities thrive in process design?

Yes, freelance and consulting opportunities can certainly thrive in process design. Many organizations, especially small to medium-sized enterprises (SMEs), may not have the resources or ongoing need to employ full-time process design experts. They often turn to external consultants or freelance process designers for specific projects, such as implementing a Lean initiative, redesigning a key business process, or preparing for a quality certification.

Experienced process designers with a strong track record and expertise in particular methodologies (like Six Sigma Black Belts) or industries can build successful consulting practices. Freelancing offers flexibility and the opportunity to work on diverse challenges across different organizations. Success in this area typically requires strong self-marketing skills, a good professional network, and the ability to quickly understand a client's business and deliver tangible results. Platforms that connect freelancers with projects also feature opportunities for process design work.

How resilient is the field of process design to economic downturns?

The field of process design tends to be relatively resilient during economic downturns, though no field is entirely immune. During recessions or periods of economic uncertainty, organizations often intensify their focus on cost reduction, efficiency improvements, and operational excellence to maintain profitability and competitiveness. These are precisely the areas where process design expertise is most valuable. Companies may look to streamline their operations, eliminate waste, and optimize resource utilization, all of which fall under the purview of process design.

While hiring for new, large-scale expansion projects might slow down, the demand for professionals who can help organizations do more with less often remains steady or can even increase. Skills in Lean, Six Sigma, and other efficiency-focused methodologies are particularly sought after during such times. However, the nature of projects might shift from large-scale innovation to more focused cost-cutting and optimization initiatives.

What soft skills complement technical expertise in process design?

While technical expertise is crucial, soft skills are equally important for success in process design. **Communication skills** are paramount, as process designers need to clearly explain complex ideas to diverse audiences, from front-line staff to senior executives. This includes written communication (for reports and documentation) and verbal communication (for presentations and interviews). **Problem-solving and analytical thinking** are at the heart of process design, requiring the ability to dissect complex situations, identify root causes, and develop creative solutions.

**Collaboration and teamwork** are essential, as process design initiatives almost always involve working with cross-functional teams. The ability to build relationships, facilitate discussions, and manage conflict is key. **Change management skills** are also vital, as implementing new processes often means changing how people work, which can meet with resistance. Process designers need to be adept at guiding organizations through change. Finally, **curiosity and a continuous learning mindset** are important for staying up-to-date with new methodologies, technologies, and industry best practices in this evolving field.

Further Resources and Learning

To continue your exploration of process design, consider browsing the extensive catalog of courses and books available through OpenCourser. You can find resources tailored to specific industries, methodologies, and skill levels. The OpenCourser Notes blog also features articles and insights related to online learning and career development in various fields, including those related to operations and engineering.

For those looking for academic programs or specific certifications, searching within relevant categories on OpenCourser, such as Engineering or Business, can provide a good starting point. Remember that continuous learning is key in this dynamic field.

We hope this overview has provided you with a comprehensive understanding of process design and the exciting opportunities it offers. Whether you are just starting to explore this path or looking to advance your existing career, the principles of process design offer valuable tools for making a meaningful impact.