Packaging Engineer

A Comprehensive Guide to a Career as a Packaging Engineer

Packaging engineering is a specialized field focused on the design, development, testing, and production of packaging. These engineers work to ensure that products can be transported, stored, and presented effectively, safely, and economically. They play a crucial role in getting goods from the manufacturer to the consumer in optimal condition.

Working as a packaging engineer involves a fascinating blend of creativity and technical skill. You might find yourself developing innovative packaging for a new food product, ensuring medical devices remain sterile, or designing sustainable solutions that minimize environmental impact. It's a field where you can see the tangible results of your work on store shelves and in people's homes every day.

This career path often involves collaborating with diverse teams, including marketing, manufacturing, and logistics, to balance aesthetics, functionality, cost, and sustainability. If you enjoy problem-solving, working with materials, and contributing to both product success and environmental well-being, packaging engineering could be an exciting direction for you.

Introduction to Packaging Engineering

What is Packaging Engineering?

Packaging engineering is a dynamic discipline that merges principles from engineering, design, and materials science. At its core, it involves creating solutions that protect products during transit, storage, and use. This goes beyond simply putting items in a box; it requires understanding how different materials interact with products and the environment.

The scope is vast, covering everything from the microscopic protection needed for sensitive electronics or pharmaceuticals to the robust containment required for industrial chemicals or heavy machinery. Engineers consider factors like durability, cost-effectiveness, consumer appeal, and regulatory compliance.

Essentially, packaging engineers ensure that products arrive safely, maintain their quality, communicate brand identity, and meet the practical needs of consumers and the supply chain. They are the architects behind the containers that hold almost everything we buy and use.

Key Industries and Applications

Packaging engineers are vital across numerous sectors. The food and beverage industry heavily relies on them to design packaging that preserves freshness, ensures safety, and attracts consumers on crowded shelves. Think about the complex layers in a bag of chips or the specific bottle shape designed for easy pouring.

The pharmaceutical and medical device industries demand packaging that guarantees sterility, protects sensitive contents, and complies with strict health regulations. Packaging here often includes features for tamper evidence and ease of use for patients or healthcare professionals.

Consumer goods, from electronics to cosmetics to toys, require packaging that not only protects the item but also serves as a key marketing tool. Engineers work to create packaging that is visually appealing, informative, and often, reusable or easily recyclable. Other significant areas include industrial goods, automotive parts, and e-commerce, where packaging must withstand the rigors of complex global supply chains.

The Interdisciplinary Nature of the Role

Packaging engineering is inherently interdisciplinary, drawing knowledge from various fields. A strong foundation in materials science is essential to select the right plastics, papers, metals, glass, or composites for a specific application, considering properties like strength, barrier protection, and recyclability.

Understanding logistics and supply chain management is also crucial. Engineers must design packaging that is efficient to transport, store, and handle, often optimizing designs to fit pallets or shipping containers perfectly, minimizing wasted space and fuel consumption.

Furthermore, sustainability has become a central pillar. Packaging engineers are increasingly focused on using eco-friendly materials, designing for recyclability or compostability, reducing material usage (lightweighting), and considering the entire lifecycle environmental impact of their designs. This requires collaboration across design, manufacturing, and environmental science domains.

Roles and Responsibilities of a Packaging Engineer

Designing Functional and Sustainable Packaging

A core responsibility of a packaging engineer is to design packaging that works effectively and aligns with environmental goals. Functionality means protecting the product from damage, spoilage, or contamination under various conditions – from the factory floor to the consumer's hands.

This involves selecting appropriate materials, determining structural requirements, and ensuring ease of opening and use for the end-consumer. Engineers use tools like Computer-Aided Design (CAD) software to create detailed specifications and models.

Sustainability is equally important. Engineers actively seek ways to reduce material use, incorporate recycled content, choose renewable resources, and design packaging that can be easily recycled or composted after use, contributing to a circular economy.

These courses offer insights into packaging design principles, including considerations for sustainability and material selection.

Collaboration Across Teams

Packaging engineers rarely work in isolation. They collaborate closely with manufacturing teams to ensure designs are feasible to produce efficiently and cost-effectively on existing or new production lines. This might involve troubleshooting issues during production runs or adapting designs based on machinery capabilities.

Interaction with supply chain and logistics teams is vital for optimizing packaging for transportation and storage. This could mean designing packaging that stacks efficiently, withstands specific shipping stresses, or meets warehousing requirements.

Marketing and product development teams also rely on packaging engineers to translate brand requirements and consumer needs into tangible designs. The engineer ensures the final package aligns with the product's image while meeting all technical specifications.

Ensuring Compliance and Safety

Adherence to standards and regulations is a critical aspect of the role. Packaging engineers must ensure their designs meet safety requirements, protecting both the product and the consumer from harm. This is especially stringent in industries like food, pharmaceuticals, and hazardous materials.

They need a thorough understanding of relevant regulations, which can vary by region and product type. This includes rules regarding materials safety (e.g., food contact materials), labeling requirements (ingredients, warnings, nutritional information), and transportation standards.

Environmental regulations also play a significant role, dictating rules around recycled content, recyclability labeling, and restrictions on certain materials. Engineers are responsible for ensuring packaging meets these evolving environmental mandates, often requiring rigorous testing and documentation.

For those interested in the technical aspects of materials and processes involved in packaging, these resources provide foundational knowledge.

Formal Education Pathways

Relevant Undergraduate Degrees

A bachelor's degree is typically the entry point for a career as a packaging engineer. While some universities offer dedicated packaging engineering or packaging science programs, many professionals enter the field with degrees in related engineering disciplines.

Degrees in Mechanical Engineering provide a strong foundation in design, mechanics, and materials. Materials Science and Engineering focuses deeply on the properties and processing of materials like plastics, metals, and composites, which is highly relevant.

Other relevant degrees include Chemical Engineering, Industrial Engineering, or even Food Science, depending on the specific industry one aims to enter. Regardless of the specific major, coursework in mathematics, physics, chemistry, and computer-aided design (CAD) is essential.

This course provides a background in chemistry, a fundamental science for understanding materials used in packaging.

Graduate Programs and Specializations

While not always required for entry-level positions, a master's degree can provide deeper specialization and open doors to research or advanced technical roles. Graduate programs might focus on areas like advanced materials, polymer science, packaging sustainability, or supply chain optimization.

Specialized certifications can also enhance a packaging engineer's credentials. These often focus on specific areas like hazardous materials transport, medical device packaging, or specific testing protocols. They demonstrate a commitment to ongoing learning and expertise in a niche area.

Some professionals pursue PhDs, particularly if they are interested in academic research, leading R&D efforts in large corporations, or developing fundamentally new packaging technologies or materials.

Importance of Internships and Co-ops

Practical experience gained through internships or cooperative education (co-op) programs is highly valued by employers. These opportunities allow students to apply classroom knowledge in real-world settings, working on actual packaging projects under the guidance of experienced engineers.

Internships provide exposure to industry practices, specific software tools, testing procedures, and the collaborative nature of the work. They help students build a professional network and gain insights into different sectors where packaging engineers work.

Many employers use internship and co-op programs as a primary pipeline for hiring full-time entry-level engineers. Successfully completing such a program significantly improves a graduate's competitiveness in the job market.

Online Learning and Skill Development

Transitioning via Online Education

For those looking to pivot into packaging engineering or enhance existing skills, online learning offers flexible and accessible pathways. While a full engineering degree typically requires in-person labs, online courses can effectively build foundational knowledge and specific technical skills.

Individuals with existing engineering or science backgrounds may find online courses particularly useful for acquiring specialized knowledge in packaging materials, design principles, sustainability practices, or relevant software. It's a viable way to supplement traditional education or facilitate a career change.

Successfully transitioning often involves combining online coursework with practical projects, networking, and potentially seeking entry-level roles like technician positions to gain hands-on experience. It requires dedication and a proactive approach to bridge any gaps between online learning and industry expectations.

OpenCourser offers a vast library of courses. You can explore engineering topics or search for specific skills to support your learning journey.

Key Topics for Online Study

Prioritizing specific subjects is key when using online resources. Courses focusing on packaging materials – their properties, applications, and limitations – are fundamental. Understanding plastics, paperboard, glass, and metals is essential.

Proficiency in Computer-Aided Design (CAD) software is crucial for creating technical drawings and 3D models. Online tutorials and courses can provide training in industry-standard software packages.

Sustainability principles are increasingly important. Look for courses covering life cycle assessment, circular economy concepts, biodegradable and compostable materials, and designing for recyclability. Knowledge of packaging testing methods and regulations is also highly valuable.

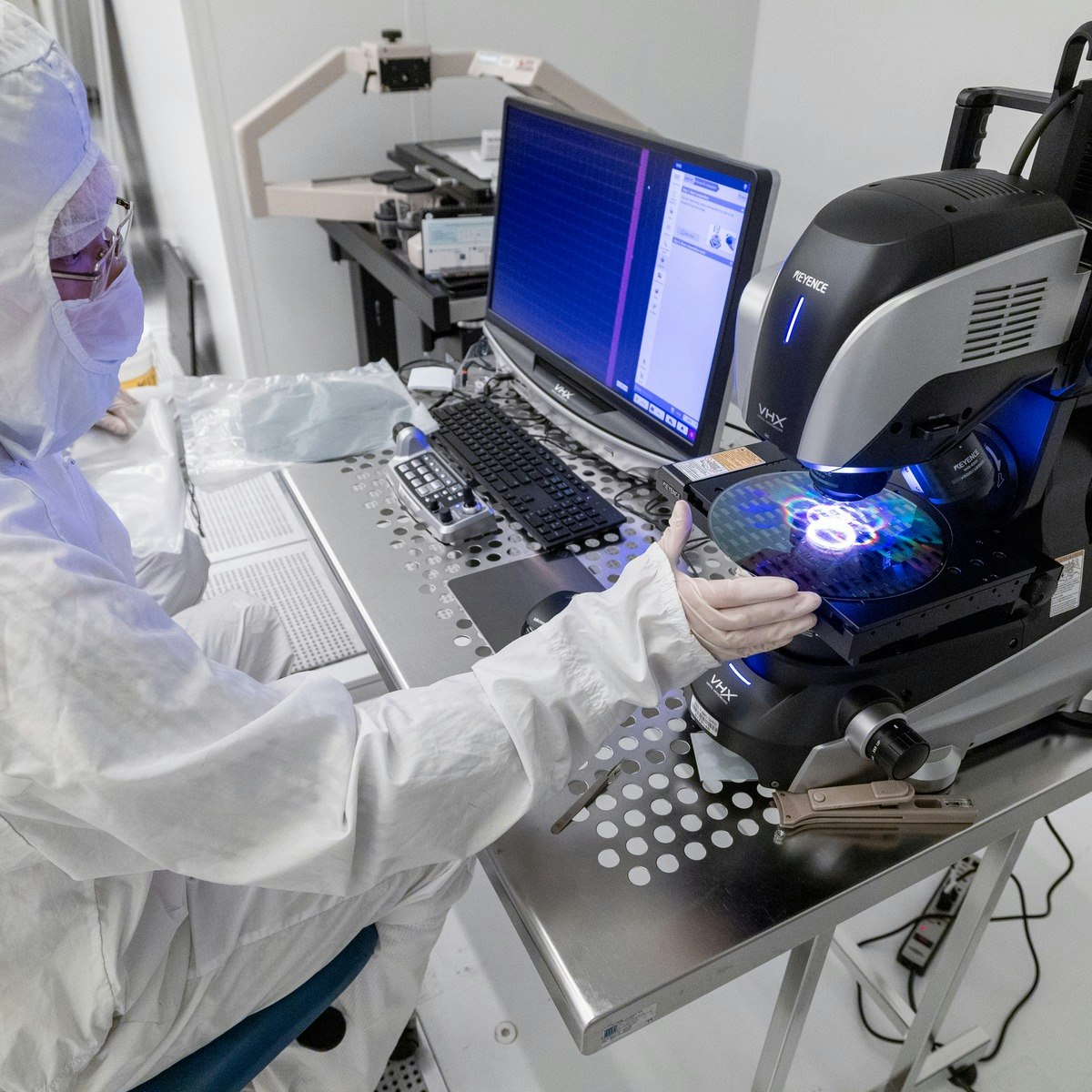

These online courses cover crucial areas like sustainability, specialized packaging applications (like semiconductors), and design software.

Building a Portfolio with Projects

Demonstrating practical skills is vital, especially when relying heavily on online learning. Independent projects allow you to apply theoretical knowledge and showcase your abilities to potential employers. Consider redesigning existing packaging for improved sustainability or functionality.

You could analyze the packaging of common products, identifying strengths and weaknesses, and proposing data-backed improvements. Document your process, including material selection rationale, design sketches or CAD models, and considerations for manufacturing and disposal.

Contributing to open-source design projects or participating in student design competitions can also provide valuable experience and portfolio pieces. Clearly document your contributions and the skills you utilized. A well-presented portfolio can significantly strengthen your job applications.

The OpenCourser Learner's Guide offers tips on how to structure your learning and leverage online courses effectively for career goals.

Career Progression and Entry-Level Opportunities

Typical Entry-Level Roles

Graduates often start in roles like Junior Packaging Engineer, Packaging Technician, or Design Assistant. These positions provide foundational experience under the supervision of senior engineers. Responsibilities might include assisting with design modifications, conducting basic material tests, creating prototypes, or managing documentation.

Packaging Technicians often focus more on the hands-on aspects, such as operating testing equipment, setting up trial runs on production lines, or inspecting incoming materials and finished packaging.

These initial roles are crucial for learning industry standards, company processes, and practical problem-solving skills. They build the groundwork for future advancement within the field.

Mid-Career Advancement

With several years of experience, engineers can advance to roles like Packaging Engineer or Senior Packaging Engineer. Responsibilities typically expand to include leading smaller projects, managing specific product lines, developing new packaging concepts, and mentoring junior staff.

Further progression might lead to roles such as Project Manager, overseeing complex packaging development initiatives from concept to launch, coordinating cross-functional teams, and managing budgets and timelines. Specialization in areas like sustainability, materials R&D, or specific industries (e.g., pharmaceutical packaging) is also common.

Strong technical skills combined with project management capabilities and cross-functional experience are key drivers for advancement during this stage.

Leadership Roles and Certifications

Senior-level positions include Packaging Engineering Manager, Director of Packaging, or R&D Lead. These roles involve strategic oversight of packaging functions, managing teams of engineers, setting departmental goals, and influencing company-wide packaging strategy, often with a significant focus on innovation and cost optimization.

Industry certifications can bolster career progression. The Certified Packaging Professional (CPP) designation, offered by the Institute of Packaging Professionals (IoPP), is a widely recognized credential demonstrating significant expertise and experience. Earning the CPP often requires several years of experience and passing a comprehensive exam, and research suggests CPPs may earn higher salaries.

Another related credential for those starting out is the Certified Packaging Professional In Training (CPIT), also from IoPP, designed for individuals newer to the industry. Continuous learning and staying abreast of industry trends are vital for sustained career growth.

Key Skills and Qualifications

Technical Expertise

A strong technical skillset is the foundation of packaging engineering. This includes a deep understanding of various packaging materials (plastics, paper, glass, metals) and their properties. Knowledge of manufacturing processes, such as extrusion, molding, printing, and filling, is also essential.

Proficiency in CAD software is standard for design and documentation. Engineers must also be adept at performing material and package testing – understanding procedures for assessing strength, barrier properties, durability during transit (shock, vibration), and compatibility with the product.

Familiarity with prototyping techniques, whether through manual methods or rapid prototyping technologies like 3D printing, allows engineers to quickly iterate and validate designs before committing to large-scale production.

This book provides a comprehensive overview of packaging technology and engineering principles.

Essential Soft Skills

Technical skills alone are insufficient; strong soft skills are crucial for success. Effective communication is vital for collaborating with diverse teams (marketing, manufacturing, logistics, suppliers) and presenting technical information clearly to non-technical stakeholders.

Problem-solving and analytical thinking are needed daily to address challenges related to cost, performance, sustainability, or production issues. Creativity is important for developing innovative and effective packaging solutions.

Project management skills help engineers manage timelines, budgets, and resources effectively. Attention to detail is critical for ensuring accuracy in specifications, testing, and compliance documentation. Regulatory literacy, understanding and applying relevant standards and laws, is also a key competency.

Industry Certifications

Beyond formal education, certifications validate specific expertise. As mentioned, the Certified Packaging Professional (CPP) from IoPP is a highly respected credential signifying broad industry knowledge and experience.

The International Safe Transit Association (ISTA) offers certifications related to transport packaging testing. ISTA certification for labs or individuals demonstrates proficiency in simulating the hazards of distribution environments to ensure package integrity. This is often required by major retailers and distributors.

Depending on the industry, other certifications might be relevant, such as those related to hazardous materials packaging (e.g., DOT regulations) or specific quality management systems (e.g., ISO standards). These credentials enhance credibility and marketability.

Industry Applications and Economic Impact

Reducing Waste and Supply Chain Costs

Packaging engineers play a significant role in optimizing supply chains and reducing costs. By designing packaging that uses less material (lightweighting) or enables denser packing, they can lower material expenses and transportation fuel consumption.

Effective packaging design minimizes product damage during transit, reducing losses from unsaleable goods and the costs associated with returns and replacements. This directly impacts a company's bottom line.

Furthermore, designing for efficient manufacturing processes – minimizing assembly time, reducing material waste during production – contributes to overall operational efficiency and cost savings. Sustainable designs that facilitate recycling or reuse can also reduce end-of-life disposal costs.

Impact on Product Lifecycle and Consumer Behavior

Packaging is often the first physical interaction a consumer has with a product, influencing purchasing decisions and brand perception. Engineers work with marketing to create designs that are attractive, informative, and align with the brand's image.

Packaging choices impact the entire product lifecycle. Material selection affects environmental footprint from raw material extraction to disposal. Design features influence usability, convenience, and safety for the consumer.

Sustainable packaging choices, increasingly demanded by consumers, can enhance brand reputation and loyalty. Engineers are key in navigating the trade-offs between cost, performance, aesthetics, and environmental responsibility to meet evolving consumer expectations.

Emerging Markets and Global Trends

Globalization and the rise of e-commerce have increased the complexity of supply chains and the demands placed on packaging. Engineers must design solutions that protect products across longer, more varied transit routes and handling conditions.

Emerging economies present significant growth opportunities for packaged goods, driving demand for skilled packaging engineers. However, this also requires navigating different regulatory landscapes, consumer preferences, and waste management infrastructures.

According to market reports like one highlighted by ResearchAndMarkets.com, the global sustainable packaging market is projected to see significant growth, driven by regulations and consumer demand, with materials like paper, board, and bio-based plastics leading the way.

Sustainability and Ethical Considerations

Materials and Circular Economy Principles

Sustainability is a major focus in modern packaging engineering. Engineers are constantly exploring and implementing materials with lower environmental impact, such as recycled plastics, sustainably sourced paper fibers, biodegradable polymers, and innovative options like seaweed-based materials.

The principles of a circular economy – designing out waste, keeping materials in use, and regenerating natural systems – guide much of this work. This involves designing packaging for easy disassembly and recycling, promoting reusable packaging systems, or utilizing compostable materials where appropriate collection infrastructure exists.

Engineers evaluate the entire lifecycle, from raw material extraction and manufacturing energy to end-of-life options, aiming to minimize the overall environmental footprint.

This course delves deeper into the concepts of sustainable design within a circular economy framework.

This book explores product-service systems with a focus on sustainability, relevant to packaging innovation.

Regulatory and Consumer Pressures

Governments worldwide are implementing stricter regulations regarding packaging waste, recycled content mandates, and restrictions on single-use plastics. Packaging engineers must stay informed about these evolving legal requirements and ensure their designs comply.

Consumer awareness and demand for sustainable options are also powerful drivers. Brands are responding by setting ambitious sustainability goals, often requiring engineers to find innovative solutions that meet both environmental targets and performance needs.

Transparency is increasingly expected, with consumers wanting clear information about the materials used and the recyclability or compostability of packaging. Engineers play a role in ensuring accurate labeling and communication.

Balancing Cost, Functionality, and Environment

A key challenge for packaging engineers is navigating the inherent trade-offs between cost, functionality, and environmental impact. Sustainable materials may sometimes be more expensive or offer different performance characteristics than conventional options.

Optimizing a design for minimal material use might compromise product protection if not carefully engineered. Ensuring recyclability might limit material choices or design complexity.

Engineers must use their technical expertise, creativity, and analytical skills to find the optimal balance that meets business objectives, protects the product effectively, satisfies consumer needs, and minimizes harm to the environment. This often requires innovative thinking and exploring new technologies and materials.

Challenges and Future Trends

Automation and Digitalization

Automation is increasingly impacting packaging design and production. AI-driven software can help optimize designs for material efficiency and performance prediction. Robotic systems are being used more frequently on packaging lines for tasks like filling, sealing, and palletizing.

Digital tools like advanced simulation software allow engineers to test package performance under various conditions virtually, reducing the need for extensive physical prototyping and testing. This speeds up the development process and allows for more complex analyses.

Engineers need to adapt by becoming proficient in these digital tools and understanding how automation integrates into the manufacturing environment. This shift requires a blend of traditional engineering principles and digital literacy.

Smart Packaging and IoT

Smart packaging, incorporating technologies like sensors, QR codes, NFC tags, or RFID, is an emerging trend. These technologies can provide enhanced functionality, such as tracking product location and temperature in the supply chain, verifying authenticity, or providing interactive experiences for consumers.

Integrating Internet of Things (IoT) capabilities allows packaging to communicate data, offering insights into product usage, supply chain conditions, or facilitating reordering. For example, packaging might monitor freshness or indicate proper storage conditions.

Packaging engineers will increasingly need to understand how to integrate these electronic components into packaging designs without compromising core functions like protection or recyclability. This bridges packaging engineering with electronics and data science.

This Spanish-language course explores the application of 2D codes, a component often used in smart packaging strategies.

Supply Chain Disruptions and Resilience

Recent global events have highlighted the vulnerability of complex supply chains. Packaging engineers play a role in building resilience by designing packaging that can withstand longer transit times or variable handling conditions.

Material shortages or price volatility also pose challenges. Engineers may need to quickly qualify alternative materials or redesign packaging to accommodate available resources without sacrificing quality or compliance.

Designing for supply chain flexibility and robustness, considering factors like regional sourcing options and standardized components, is becoming increasingly important in mitigating the impact of future disruptions.

Frequently Asked Questions

What is the typical salary range and demand for Packaging Engineers?

Salaries for packaging engineers vary based on experience, location, industry, and education level. According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for architecture and engineering occupations overall was $91,420 in May 2023, significantly higher than the median for all occupations. While BLS doesn't provide specific data *only* for packaging engineers, salaries often align with related fields like industrial or mechanical engineering.

Entry-level positions might start lower, while senior engineers or managers with significant experience and certifications like the CPP can command much higher salaries. The BLS Occupational Outlook Handbook indicates projected growth for engineering occupations generally.

Demand is often tied to the health of manufacturing sectors, particularly consumer goods, food, and pharmaceuticals. Regions with strong manufacturing bases typically have higher demand. Sustainability initiatives are also driving demand for engineers skilled in eco-friendly packaging design.

How does Packaging Engineering compare to Industrial Design or Materials Engineering?

While related, these fields have distinct focuses. Industrial Designers often concentrate more on the aesthetics, ergonomics, and user experience of a product itself, though they may consider packaging as part of the overall product presentation.

Materials Engineers specialize deeply in the properties, processing, and application of materials (metals, ceramics, polymers, composites). They might develop new materials that packaging engineers then utilize, or consult on material selection, but typically don't focus on the overall package design and system.

Packaging Engineering synthesizes aspects of both, focusing specifically on designing the container or system that holds, protects, and presents the product. It requires knowledge of materials, manufacturing processes, logistics, regulations, sustainability, *and* design principles, all applied specifically to the packaging context.

Is it possible to transition from other engineering fields?

Yes, transitioning from other engineering disciplines is quite common. Mechanical, chemical, industrial, or materials engineers often possess strong foundational knowledge applicable to packaging. The key is supplementing this background with packaging-specific knowledge.

This might involve taking specialized courses (online or in-person) in packaging materials, processes, testing, and regulations. Gaining practical experience through projects or entry-level roles is also beneficial.

Highlighting transferable skills like problem-solving, project management, CAD proficiency, and materials understanding during job applications is important. Networking within the packaging industry can also facilitate the transition.

How is Artificial Intelligence (AI) impacting job prospects?

AI is beginning to influence packaging engineering, but it's more likely to augment rather than replace engineers in the near future. AI tools can accelerate design optimization, predict material performance, improve quality control through automated inspection, and enhance supply chain logistics, as noted in articles by Global Trade Magazine and others.

Engineers who embrace AI tools for simulation, data analysis, and design assistance may find their efficiency and capabilities enhanced. However, the role still requires critical thinking, creativity, regulatory understanding, and cross-functional collaboration – skills where human oversight remains essential.

The need for engineers to integrate AI into workflows, manage AI-driven automation, and interpret complex data may evolve the skillset required, but fundamental engineering knowledge remains crucial. Job prospects remain positive, especially for those adaptable to new technologies.

Are there freelance or consulting opportunities?

Yes, experienced packaging engineers can find opportunities for freelance or consulting work. Smaller companies without dedicated in-house packaging teams often hire consultants for specific projects, such as developing packaging for a new product launch, optimizing existing packaging for cost or sustainability, or navigating complex regulatory requirements.

Consultants might specialize in particular industries (e.g., medical devices, food), materials, or areas like sustainability or transit testing. Building a strong network, a portfolio of successful projects, and potentially certifications like the CPP can enhance credibility for consulting roles.

Freelancing requires strong self-management, business development skills, and the ability to quickly understand diverse client needs. It offers flexibility but also less stability than traditional employment.

What are the essential tools and software?

Proficiency in Computer-Aided Design (CAD) software is almost universally required. Common packages include SolidWorks, AutoCAD, and sometimes specialized packaging design software like ArtiosCAD. Engineers use these to create 2D drawings and 3D models of packages.

Familiarity with simulation software (e.g., Finite Element Analysis - FEA) can be valuable for predicting package performance under stress. Project management software helps track timelines and tasks.

Knowledge of basic productivity software (spreadsheets for data analysis, presentation software) is standard. Depending on the role, familiarity with enterprise resource planning (ERP) systems or specific testing equipment software might also be necessary.

Packaging engineering is a challenging yet rewarding field that blends technical knowledge with creative problem-solving. It offers the opportunity to work across diverse industries, make tangible contributions to product success, and play a key role in advancing sustainability. Whether you are a student exploring options, a professional considering a pivot, or an engineer looking to specialize, the world of packaging offers dynamic and impactful career paths.