Industrial Automation Technician

Exploring a Career as an Industrial Automation Technician

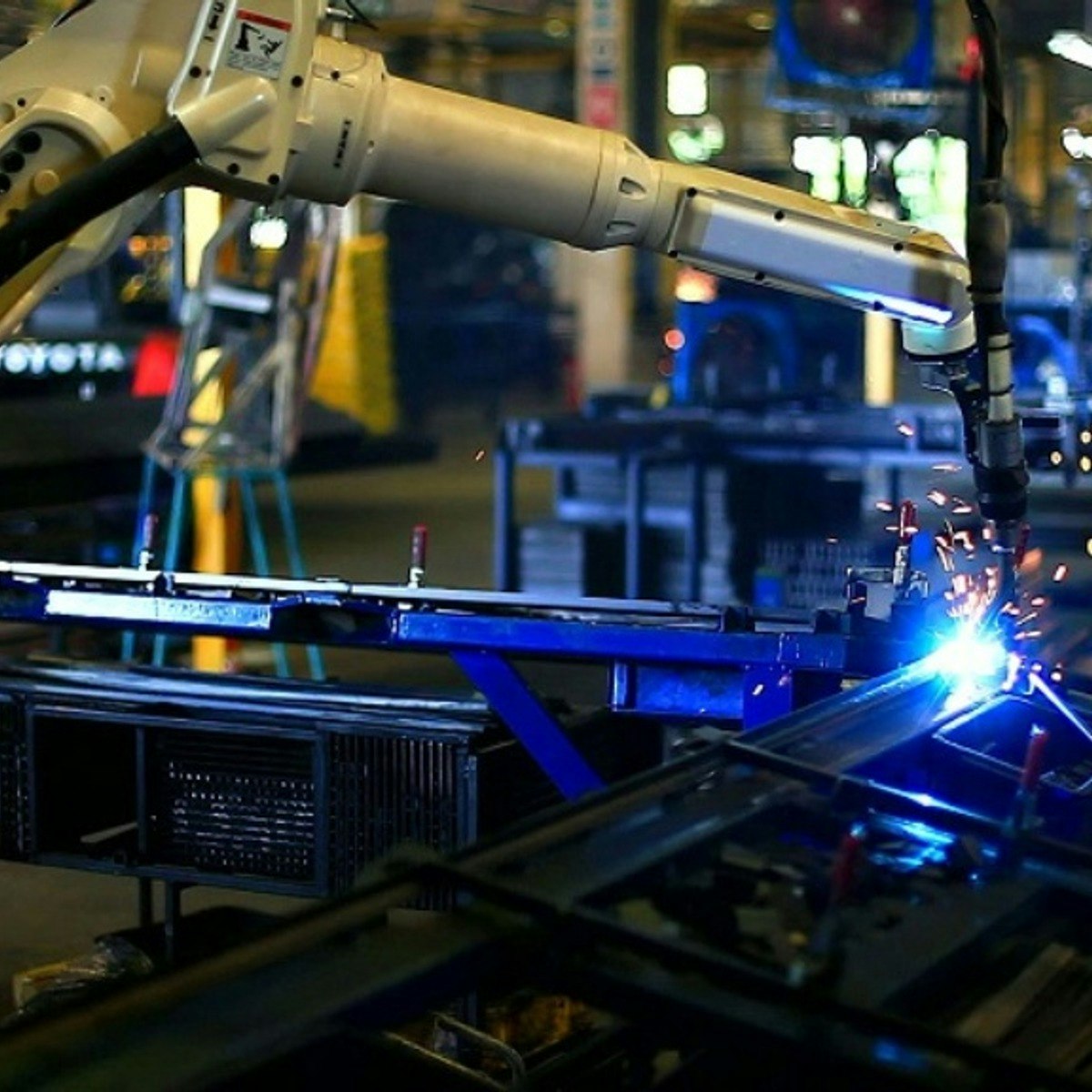

Industrial Automation Technicians are the skilled professionals who bridge the gap between machinery and intelligence in modern industrial settings. They install, maintain, troubleshoot, and repair the automated systems—like robots, programmable logic controllers (PLCs), and sophisticated sensor networks—that keep factories, power plants, and other industrial facilities running efficiently and safely. Think of them as the essential troubleshooters and implementers ensuring the complex dance of automated production happens without a hitch.

Working in this field can be incredibly engaging. You'll constantly interact with cutting-edge technology, from intricate robotic arms to complex control systems governing entire production lines. The role often involves hands-on problem-solving, requiring both analytical thinking and practical skills to diagnose and fix issues under pressure. Furthermore, contributing to the efficiency and innovation within vital industries like manufacturing, energy, or logistics provides a tangible sense of impact.

What Does an Industrial Automation Technician Do?

This section delves into the typical responsibilities and environments associated with the role, giving you a clearer picture of the day-to-day work involved.

Installing, Maintaining, and Programming Automated Systems

A core function involves the installation and setup of new automation equipment. This includes wiring components, configuring software, and integrating systems like PLCs and Supervisory Control and Data Acquisition (SCADA) systems. These systems act as the brains and nervous system of automated processes, monitoring inputs and controlling outputs.

Preventive maintenance is crucial to minimize downtime. Technicians perform regular checks, calibrations, and updates on equipment. They also handle programming tasks, often using languages like ladder logic to tell machines how to operate, adjust parameters, and optimize performance based on production needs.

Understanding how these components interact is key. Technicians need a solid grasp of electrical circuits, mechanical systems, and software logic to ensure seamless operation. This often involves reading blueprints, electrical schematics, and technical manuals.

These courses provide foundational knowledge in PLC programming and industrial control systems, essential for handling installation and maintenance tasks.

For deeper dives into specific PLC programming languages and control concepts, these books offer valuable insights.

Troubleshooting Production Lines

When automated systems malfunction, technicians are the first responders. They employ systematic troubleshooting techniques to diagnose the root cause of problems, which could range from faulty sensors or wiring issues to software glitches or mechanical failures. This requires keen observation skills and logical deduction.

Effective troubleshooting often involves using diagnostic tools, such as multimeters, oscilloscopes, and specialized software, to test components and analyze system behavior. Isolating the problem quickly and accurately is vital to minimize production losses.

Once the issue is identified, technicians perform the necessary repairs or adjustments. This might involve replacing components, rewriting code segments, or recalibrating machinery. Documenting the problem and the solution is also an important part of the process for future reference and continuous improvement.

Collaborating Across Teams

Industrial Automation Technicians rarely work in isolation. They frequently collaborate with engineers who design the automation systems, machine operators who run the equipment daily, and maintenance staff responsible for mechanical upkeep. Clear communication is essential for effective teamwork.

Technicians provide valuable feedback to engineers on system performance and potential improvements based on their hands-on experience. They also train operators on how to interact with new or modified automated systems safely and efficiently.

This collaborative environment means technicians need good interpersonal skills alongside their technical expertise. Being able to explain complex technical issues in understandable terms to non-technical colleagues is a valuable asset.

Ensuring Workplace Safety

Safety is paramount in industrial environments. Technicians play a critical role in implementing and enforcing safety protocols related to automated machinery. This includes ensuring proper machine guarding, lockout/tagout procedures, and emergency stop functionality.

They are often involved in risk assessments for new or modified automation systems, identifying potential hazards and recommending mitigation measures. Staying updated on Occupational Safety and Health Administration (OSHA) standards and other relevant safety regulations is part of the job.

Promoting a safety-conscious culture among colleagues is also important. Technicians lead by example, adhering strictly to safety rules and encouraging others to do the same, contributing to a safer working environment for everyone.

Essential Skills and Important Certifications

Success in this field relies on a blend of technical knowledge, practical skills, and often, formal certifications that validate competency.

Mastering PLC Programming and Logic

Programmable Logic Controllers (PLCs) are the workhorses of industrial automation. Proficiency in programming PLCs using standard languages, particularly ladder logic, is fundamental. Understanding function block diagrams (FBD) and structured text (ST) is also increasingly valuable.

This involves not just writing code, but also debugging it, modifying existing programs, and understanding how PLC logic interacts with physical inputs (sensors, switches) and outputs (motors, valves, actuators). Technicians must be comfortable navigating PLC software environments from various vendors.

Developing strong logical reasoning skills is crucial for designing efficient and reliable control sequences. The ability to visualize process flow and translate it into programmable steps is a core competency.

These courses offer focused training on PLC programming, covering essential concepts and practical application.

These books provide comprehensive guides to PLC programming, including specific vendor platforms and standard languages.

Understanding Robotics and Integration

Industrial robots are increasingly common on production floors. Technicians need foundational knowledge of robot operation, programming (teach pendants, offline programming), and maintenance. Understanding different robot types (articulated, SCARA, delta) and their applications is important.

Integrating robots into larger automated systems is a key task. This involves configuring communication between the robot controller and PLCs or other control systems, ensuring coordinated movement and interaction with other machinery.

Safety considerations specific to robotics, such as establishing safe work zones and programming collaborative robot interactions, are critical. As robotics technology evolves, continuous learning is necessary.

Explore the fundamentals of robotics and their application in modern industry with these introductory courses.

This book offers a deeper look into the integration of robotics within automated systems.

Navigating Industrial Networks

Modern automation systems rely heavily on industrial communication networks (e.g., EtherNet/IP, PROFINET, Modbus TCP/IP) to exchange data between controllers, devices, and monitoring systems. Technicians must understand network topologies, protocols, and addressing schemes.

Troubleshooting network connectivity issues is a common task. This requires familiarity with network diagnostic tools and techniques to identify problems like configuration errors, faulty cables, or device failures.

As Industrial Internet of Things (IIoT) concepts gain traction, understanding how Operational Technology (OT) networks interface with Information Technology (IT) networks, and the associated cybersecurity implications, is becoming increasingly important.

This book provides insights into the communication buses used in industrial processes.

Acquiring Safety and Vendor Certifications

Formal certifications can significantly enhance credibility and job prospects. OSHA safety certifications (e.g., OSHA 10-hour or 30-hour General Industry) demonstrate a commitment to and understanding of workplace safety standards, which are non-negotiable in industrial settings.

Many employers value vendor-specific certifications related to the PLC, HMI, robot, or drive manufacturers they use (e.g., Rockwell Automation, Siemens, FANUC). These certifications prove proficiency with specific hardware and software platforms.

Other relevant certifications might include those related to industrial networking (like CompTIA Network+ with an industrial focus) or specialized areas like machine vision or motion control. Pursuing certifications demonstrates initiative and a dedication to professional development.

Educational Pathways to Become a Technician

Several educational routes can lead to a career as an Industrial Automation Technician, catering to different learning styles and career goals.

Associate Degrees and Technical Diplomas

A common entry point is an Associate of Applied Science (A.A.S.) degree or a technical diploma in fields like Industrial Maintenance, Mechatronics, Electronics Technology, or Industrial Automation. These programs, typically offered by community colleges and technical schools, provide a strong mix of theoretical knowledge and hands-on lab experience.

Coursework often includes electronics fundamentals, PLC programming, motor controls, hydraulics and pneumatics, robotics basics, and troubleshooting techniques. These programs are designed to equip graduates with the practical skills needed for entry-level technician roles.

These programs often incorporate internships or co-op experiences, providing valuable real-world exposure and networking opportunities within local industries. They offer a direct and efficient path into the workforce.

Apprenticeship Programs

Apprenticeships offer a structured, employer-sponsored pathway combining on-the-job training with related technical instruction. Apprentices work alongside experienced technicians, learning skills directly in the industrial environment while earning a wage.

These programs typically last several years and cover a broad range of competencies required for the role. The classroom component reinforces the practical training with theoretical knowledge in areas like electrical theory, schematics, and automation principles.

Completing a registered apprenticeship often leads to journeyman status and recognized credentials. This "earn while you learn" model is an excellent option for those who prefer hands-on learning and want to avoid significant educational debt. Information on apprenticeships can often be found through state labor departments or industry associations.

Bachelor's Degrees for Advanced Roles

While not always required for entry-level technician roles, a Bachelor's degree in fields like Electrical Engineering Technology, Mechanical Engineering Technology, or Mechatronics Engineering can open doors to more advanced positions and leadership opportunities.

These four-year programs provide a deeper theoretical understanding of engineering principles, system design, and project management. Graduates may start in technician roles but often have a faster track towards becoming Automation Engineers, system designers, or project managers.

A bachelor's degree can be particularly beneficial for those interested in the design, development, and implementation of complex automation systems, rather than primarily focusing on maintenance and troubleshooting.

The Importance of Continuous Learning

The field of industrial automation is constantly evolving. New technologies, software updates, and communication protocols emerge regularly. Regardless of the initial educational path, a commitment to lifelong learning is essential for career longevity and advancement.

This may involve taking manufacturer training courses for specific equipment, pursuing additional certifications, attending industry conferences, or utilizing online learning platforms to stay abreast of new developments in areas like IIoT, cybersecurity, or advanced robotics.

Employers often support or require continuing education to ensure their technicians can work effectively with the latest automation technologies. Being proactive about skill development is key to remaining a valuable asset in this dynamic field.

Explore platforms like OpenCourser to find courses relevant to new technologies and skill updates in industrial automation.

Leveraging Online Learning for Skill Development

Online courses and resources offer flexible and accessible ways to build foundational knowledge, acquire specific skills, and supplement traditional education or on-the-job training in industrial automation.

Using Virtual Simulators and Tools

One challenge in learning automation is accessing expensive hardware like PLCs and robots. Online platforms increasingly offer access to virtual simulation software that mimics real-world equipment. This allows learners to practice PLC programming, test logic, and understand system behavior without needing physical hardware.

Simulators provide a safe environment to experiment and make mistakes without risking damage to actual equipment or disrupting production. They are excellent tools for reinforcing concepts learned through theoretical study and preparing for hands-on lab work or job tasks.

Exploring open-source automation tools and software can also provide practical experience. While perhaps not identical to industry-standard proprietary systems, they often share underlying principles and offer valuable learning opportunities at low or no cost.

This course introduces Node-RED and Raspberry Pi, tools often used in educational and prototyping contexts for automation projects.

Embracing Project-Based Learning Online

Many online courses focus on practical, project-based learning. Following structured projects, such as building a simulated control system for a specific process or programming a sequence for a virtual robot, helps solidify understanding and build a portfolio of work.

These projects bridge the gap between theory and practice. Completing them demonstrates initiative and practical capability to potential employers, especially for those transitioning into the field or supplementing formal education.

Look for courses that include hands-on exercises, coding challenges, and capstone projects relevant to industrial scenarios. OpenCourser's extensive catalog, which you can browse by categories like Industrial Engineering, can help you find project-focused learning opportunities.

These courses provide hands-on learning experiences in automation and related technologies.

Supplementing Hands-On Experience

While online learning is powerful, it typically cannot fully replace the hands-on experience gained through labs, apprenticeships, or working directly with equipment. However, online resources are invaluable for supplementing that experience.

Technicians can use online courses to learn about specific new equipment before encountering it on the job, refresh their knowledge on particular protocols or programming languages, or explore advanced topics beyond their daily tasks. This blended approach – combining practical work with targeted online study – is highly effective.

For career pivoters or those lacking direct experience, online learning builds essential foundational knowledge, making them more competitive candidates for entry-level positions or apprenticeships where they can gain the necessary hands-on skills. Utilizing resources like the OpenCourser Learner's Guide can help structure self-study effectively.

These courses cover foundational concepts and specific skills relevant to industrial automation, useful for supplementing practical knowledge.

Career Growth and Advancement Opportunities

A career as an Industrial Automation Technician offers various paths for growth, specialization, and transition into related roles.

From Entry-Level to Senior Technician

Entry-level technicians typically start under supervision, focusing on routine maintenance, basic troubleshooting, and assisting senior technicians with installations and programming tasks. As they gain experience and demonstrate proficiency, their responsibilities expand.

Senior technicians handle more complex troubleshooting challenges, lead installation projects, develop and modify PLC programs, and may mentor junior staff. They often possess deep knowledge of specific systems or processes within their facility.

Advancement typically depends on performance, demonstrated skill development (including acquiring new certifications), and sometimes, further education. Specializing in high-demand areas like robotics or specific PLC platforms can also accelerate career progression.

Transitioning to Engineering Roles

Experienced technicians with strong analytical skills and a deep understanding of automation systems are well-positioned to transition into Automation Engineering roles. This often involves pursuing further education, such as a Bachelor's degree in engineering or engineering technology.

Automation Engineers focus more on the design, development, specification, and implementation of new automation solutions. They work on system architecture, select components, manage projects, and oversee the work of technicians during installation and commissioning.

The practical experience gained as a technician provides invaluable context for an engineering role, leading to more robust and maintainable system designs. This is a common and rewarding advancement path.

Exploring Management and Leadership

With significant experience and demonstrated leadership qualities, technicians can move into supervisory or management positions. This might involve leading a team of automation technicians, overseeing the maintenance department, or managing automation projects.

Management roles require strong organizational, communication, and people skills in addition to technical expertise. Responsibilities shift towards planning, budgeting, scheduling work, performance management, and interfacing with other departments and upper management.

Further education in business administration or management can be beneficial for those aspiring to leadership positions within an industrial organization.

Developing Specializations

The field of industrial automation is broad, allowing for specialization in niche areas. Technicians might choose to focus on robotics, becoming experts in programming, maintenance, and integration of specific robot brands or applications.

Other specializations include areas like machine vision systems, motion control, industrial networking and cybersecurity, process control in specific industries (e.g., pharmaceuticals, food and beverage), or expertise in particular SCADA/HMI platforms.

Developing deep expertise in a specialized, high-demand area can lead to higher earning potential and make technicians highly sought after in the job market. This often involves targeted training and certifications.

Key Industry Trends Shaping the Future

The landscape of industrial automation is rapidly evolving, driven by technological advancements and shifting economic pressures. Understanding these trends is crucial for technicians aiming for long-term career success.

Rise of IIoT and Predictive Maintenance

The Industrial Internet of Things (IIoT) involves connecting industrial equipment, sensors, and systems to networks, enabling vast amounts of data collection and analysis. This trend allows for real-time monitoring, remote diagnostics, and, crucially, predictive maintenance.

Instead of waiting for equipment to fail (reactive maintenance) or performing maintenance on a fixed schedule (preventive), predictive maintenance uses data analysis to anticipate failures before they happen. Technicians will increasingly work with IIoT platforms and sensors, interpreting data to schedule maintenance proactively, minimizing downtime and optimizing asset lifespan. According to insights from consulting firms like McKinsey, leveraging data analytics is key to future manufacturing competitiveness.

This requires technicians to develop skills in data interpretation, understanding sensor technology, and familiarity with cloud platforms and analytics software used in IIoT applications.

Integration of Collaborative Robots (Cobots)

Collaborative robots, or "cobots," are designed to work safely alongside humans without traditional safety cages. They are typically easier to program and deploy than traditional industrial robots, opening up automation possibilities for smaller companies and more varied tasks.

Technicians will increasingly be involved in installing, programming, and maintaining cobots. This requires understanding the specific safety standards and programming interfaces associated with collaborative robotics, which differ from those of conventional industrial robots.

The rise of cobots means technicians may work more closely with robotic systems and need skills in human-robot interaction and workflow design to optimize collaborative processes safely and efficiently.

Cybersecurity in Operational Technology (OT)

As industrial control systems become more connected (due to IIoT and remote access needs), they become more vulnerable to cyber threats. Protecting Operational Technology (OT) environments – the systems controlling physical processes – is a growing concern.

Technicians are on the front lines of OT cybersecurity. They need awareness of common threats, security best practices (like network segmentation, access control, patching), and how to respond to potential security incidents. While dedicated cybersecurity specialists exist, technicians play a vital role in implementing and maintaining secure configurations.

Understanding the intersection of IT and OT security, and adhering to relevant standards (like ISA/IEC 62443), will become increasingly important parts of the technician's skillset.

Automation Demands in Global Supply Chains

Global events and economic pressures have highlighted the need for more resilient and efficient supply chains. Automation plays a key role in achieving this, from automated warehouses and logistics operations to more flexible and responsive manufacturing processes.

This drives demand for skilled technicians who can implement and maintain automation systems in logistics centers, ports, and manufacturing facilities involved in global trade. The ability to work with systems that enhance speed, accuracy, and visibility across the supply chain is highly valuable.

Technicians working in these areas may encounter a wider range of technologies, including autonomous mobile robots (AMRs), automated storage and retrieval systems (AS/RS), and sophisticated tracking and sorting systems, requiring a broad skillset.

Navigating the Challenges of the Role

While rewarding, the career of an Industrial Automation Technician comes with its own set of challenges that require resilience, adaptability, and continuous learning.

Keeping Pace with Technological Change

Automation technology advances rapidly. Skills learned today might become outdated relatively quickly. Technicians must constantly update their knowledge of new hardware, software, programming languages, and communication protocols.

This requires a proactive approach to learning, seeking out training opportunities, reading industry publications, and experimenting with new technologies. Failing to keep pace can limit career advancement and effectiveness in the role.

Embracing lifelong learning isn't just beneficial; it's often a necessity for long-term success in this dynamic field. This commitment can feel demanding alongside regular job duties.

Bridging Disciplinary Divides

Automation systems involve electrical, mechanical, and software components. Technicians need a cross-disciplinary understanding to effectively troubleshoot issues that might span multiple domains. Communicating technical details effectively with engineers, IT staff, and operators from different backgrounds can also be challenging.

A technician might need to explain an electrical fault to a mechanical engineer or a software limitation to an operator. This requires not only broad technical knowledge but also strong communication and translation skills.

Misunderstandings or poor communication between different technical disciplines can lead to delays, errors, and frustration. Building rapport and finding common language across teams is crucial.

Managing Work Environment Stressors

Industrial environments can be demanding. Technicians often work in noisy factories, may be exposed to varying temperatures, and sometimes need to work in confined spaces or at heights. The work can be physically demanding at times.

Shift work, including nights, weekends, and holidays, is common, especially in facilities with 24/7 operations. Being on-call for emergency breakdowns can also disrupt personal time and add pressure.

Troubleshooting critical equipment under pressure, when production downtime costs are high, can be stressful. Developing coping mechanisms and maintaining a focus on safety under pressure are important aspects of the job.

Adapting to Global Manufacturing Dynamics

The manufacturing sector is subject to global economic trends and competition. Company decisions regarding investment in automation, offshoring, or reshoring can impact job security and the types of projects technicians work on.

Technicians may need to adapt to working with equipment and standards from different global manufacturers. In some regions, competition for technician roles can be influenced by the overall health of the local manufacturing industry.

Staying adaptable, continuously developing skills, and being potentially open to relocating or working across different industrial sectors can help mitigate risks associated with these broader economic forces.

Upholding Safety and Ethical Standards

Working with powerful automated machinery and influencing production processes carries significant responsibilities regarding safety and ethical conduct.

Prioritizing Machine Safeguarding

Ensuring that automated machinery is safe for operators and maintenance personnel is a primary ethical and legal responsibility. This involves correctly implementing physical guards, light curtains, emergency stops, lockout/tagout procedures, and other safety mechanisms.

Technicians must understand and apply relevant safety standards (like those from OSHA, ISO, or ANSI) during installation, maintenance, and modification of equipment. Compromising on safety features to save time or cost is unacceptable and can have severe consequences.

Regularly inspecting and testing safety systems, and training others on their proper use, are critical components of maintaining a safe automated environment.

Considering Environmental Responsibility

Automation can impact the environment, both positively and negatively. Efficient automated processes can reduce energy consumption and material waste. However, the manufacturing and disposal of automation equipment also have environmental footprints.

Technicians can contribute positively by optimizing systems for energy efficiency, ensuring proper disposal of electronic waste, and supporting initiatives to use automation for environmental monitoring or pollution control within their facilities.

Being mindful of the environmental consequences of automation choices and advocating for sustainable practices within their scope of influence is an emerging aspect of ethical responsibility in the field.

Addressing Workforce Impact Concerns

The implementation of automation often raises concerns about job displacement for human workers. While automation creates new roles (like technicians), it can also change or eliminate existing ones.

Technicians should be sensitive to these concerns and focus on how automation can augment human capabilities, improve safety, and handle tasks that are dangerous or ergonomically challenging. Engaging in discussions about workforce transitions and retraining opportunities can be part of a responsible approach.

While technicians implement the technology, broader societal and company policies determine how the workforce impact is managed. However, understanding this context is important for ethical practice.

Navigating Responsible AI Implementation

As artificial intelligence (AI) and machine learning become more integrated into industrial automation (e.g., for advanced process control, quality inspection, or predictive maintenance), new ethical considerations arise.

Technicians may be involved in implementing or maintaining systems that use AI. This requires awareness of potential biases in data or algorithms, transparency in how AI-driven decisions are made, and ensuring that AI systems operate reliably and safely.

While deep AI expertise might not be required for all technicians, a basic understanding of AI principles and the ethical questions surrounding its use in industrial settings will become increasingly relevant.

Frequently Asked Questions about the Role

Here are answers to some common questions potential Industrial Automation Technicians have about the career path.

What is the typical salary range?

Salaries for Industrial Automation Technicians vary based on experience, location, industry, education, and certifications. Entry-level positions might start lower, while experienced senior technicians, especially those with specialized skills or working in high-demand regions, can earn significantly more.

According to the U.S. Bureau of Labor Statistics (BLS), electro-mechanical and mechatronics technologists and technicians, a closely related field, had a median annual wage of $67,940 in May 2023. However, actual salaries can range widely.

It's advisable to research salary data specific to your geographic region and target industry using resources like BLS, salary comparison websites, and job postings.

What experience is needed for entry-level jobs?

Many entry-level positions require an associate's degree or technical diploma in a relevant field (mechatronics, industrial maintenance, electronics). Some employers may hire candidates with a strong mechanical or electrical aptitude and provide on-the-job training or sponsor an apprenticeship.

Prior hands-on experience, even from school labs, internships, co-ops, or personal projects (like working with Arduino or Raspberry Pi), is highly advantageous. Demonstrating familiarity with basic tools, electrical safety, and troubleshooting concepts strengthens an application.

Strong foundational knowledge of PLCs, electrical circuits, and mechanical principles is often expected, even if extensive programming experience isn't required initially. Soft skills like problem-solving, communication, and attention to detail are also important.

Is this a stable career path with increasing automation?

While automation might displace some manual labor roles, it simultaneously creates demand for skilled technicians who can install, maintain, and troubleshoot these complex systems. As industries adopt more automation, the need for qualified technicians generally increases.

The role itself evolves with technology. Technicians must commit to continuous learning to remain relevant. Those who adapt and acquire skills in areas like IIoT, robotics, and OT cybersecurity are likely to find strong career stability and opportunities.

The BLS projects employment growth for electro-mechanical and mechatronics technologists and technicians to be about average compared to all occupations through 2032, indicating continued need for these skills.

How can I transition from another technical field?

Individuals with backgrounds in electrical work, electronics repair, IT support, or mechanical maintenance often have transferable skills. Identify the gaps between your current skillset and the requirements of an Industrial Automation Technician role.

Focus on acquiring specific knowledge in areas like PLC programming, industrial controls, robotics, and industrial networking. Online courses, community college programs, or targeted certifications can help bridge these gaps efficiently.

Highlight your existing technical troubleshooting, problem-solving, and hands-on skills in your resume and interviews. Emphasize your ability and willingness to learn the specific automation technologies required for the role. Networking with people in the industry can also uncover transition opportunities.

Will Artificial Intelligence (AI) replace technicians?

AI is more likely to change the nature of the technician's job rather than eliminate it entirely in the foreseeable future. AI tools might assist with diagnostics, predictive maintenance analysis, and optimizing system performance, becoming another tool in the technician's toolkit.

However, the hands-on installation, repair, physical troubleshooting, and adaptation of systems to specific plant environments still require human skills and intervention. AI currently lacks the physical dexterity, complex problem-solving adaptability in novel situations, and contextual understanding needed for the full scope of a technician's work.

Technicians who learn to work alongside AI-powered tools and understand their capabilities and limitations will likely be more effective and valuable in the future.

Are there opportunities to work internationally?

Yes, industrial automation is a global field. Many large manufacturing, energy, and technology companies operate internationally, creating opportunities for technicians to work abroad, either on temporary assignments or permanent relocations.

Skills in industrial automation are often transferable across borders, although specific standards, regulations, and dominant equipment vendors might vary by region. Proficiency in the local language and understanding cultural nuances are typically important for international roles.

Technicians working for multinational corporations or specialized automation integrators with global projects may have more opportunities for international assignments.

Embarking on a career as an Industrial Automation Technician offers a pathway into the heart of modern industry, blending hands-on work with sophisticated technology. It demands continuous learning and adaptability but provides the satisfaction of solving complex problems and keeping essential systems running. If you enjoy troubleshooting, working with technology, and contributing to efficient industrial operations, this dynamic field holds significant promise.