Power Plant Operator

A Comprehensive Guide to Becoming a Power Plant Operator

Power Plant Operators play a critical role in our modern society, ensuring the reliable generation and distribution of electrical power that fuels homes, businesses, and industries. They are the skilled professionals responsible for controlling, monitoring, and maintaining the complex machinery and systems within power generation facilities. This role demands vigilance, technical aptitude, and a strong commitment to safety and efficiency.

Working as a Power Plant Operator can be engaging for individuals fascinated by large-scale industrial processes and the intricate dance of energy conversion. The responsibility of managing equipment worth millions of dollars, troubleshooting complex issues under pressure, and contributing to the essential service of providing electricity offers a unique sense of purpose. It's a career that blends hands-on work with sophisticated monitoring technology.

Overview of Power Plant Operators

What Does a Power Plant Operator Do?

A Power Plant Operator, sometimes called a Power Plant Dispatcher or Control Room Operator, oversees the machinery that generates electricity. Their primary objective is to ensure the plant operates safely, efficiently, and reliably, meeting energy demands while complying with strict regulations. They monitor instruments, gauges, and control panels to regulate factors like voltage, current, and frequency.

Operators adjust controls to manage the flow of fuel, water, and air, optimizing the generation process based on load requirements and system conditions. They anticipate potential problems, respond to alarms, and coordinate with maintenance crews to address mechanical or electrical issues. Their vigilance is key to preventing system failures and ensuring a steady power supply.

A significant part of the role involves maintaining detailed logs of operations, performance data, and maintenance activities. This documentation is crucial for regulatory compliance, performance analysis, and troubleshooting future issues. Clear communication with other plant personnel and grid operators is also essential for seamless operation.

Types of Power Plants

Power Plant Operators work in various types of facilities, each with unique processes and challenges. Fossil fuel plants, using coal, natural gas, or oil, involve managing combustion processes, steam generation, and emissions control systems. Operators here must be adept at handling high temperatures and pressures safely.

Nuclear power plants require operators with highly specialized training due to the complexities of nuclear reactors and stringent safety protocols governed by agencies like the Nuclear Regulatory Commission (NRC). Handling radioactive materials and managing reactor controls demands exceptional precision and adherence to procedure.

Hydroelectric plants utilize the power of moving water. Operators manage water flow through dams, control turbines connected to generators, and monitor water levels and environmental impacts. Renewable energy facilities, such as solar farms and wind turbine installations, are increasingly common. Operators in these settings monitor energy capture, conversion systems, and grid integration, often remotely.

Core Responsibilities

The core duties revolve around vigilant monitoring of plant systems. This includes observing gauges, meters, control panels, and computer displays to ensure all equipment operates within prescribed parameters. Operators must recognize subtle changes that could indicate a developing problem.

Adjusting controls is another fundamental task. Operators manipulate switches, valves, and other controls to start or stop generators, regulate voltage, control reactor levels (in nuclear plants), or adjust the output based on electricity demand. This requires a deep understanding of how different systems interact.

Maintaining safety protocols is paramount. Operators conduct regular inspections, perform safety checks, and adhere strictly to operational procedures. They are often the first responders to emergencies, initiating shutdown procedures or containment measures when necessary. Ensuring compliance with environmental regulations is also a key part of their daily work.

To gain a foundational understanding of the broader electric industry context, consider exploring resources that cover operations and markets.

How Power Plants Work: A Simple Explanation (ELI5)

Imagine a power plant like a giant kitchen making "electricity food." Most power plants work by boiling water to make steam, like a giant kettle. Instead of coal or gas heating the kettle directly, some plants use controlled nuclear reactions (nuclear) or the flow of water (hydroelectric) to generate heat or motion.

This steam is very powerful and is used to spin something called a turbine, which looks like a giant, complex fan. The spinning turbine is connected to a generator, which is like a bicycle dynamo but much, much bigger. As the generator spins, it creates electricity.

The Power Plant Operator is like the head chef and kitchen manager combined. They watch all the gauges (like oven temperatures), control the "heat" (fuel or reactor), manage the steam "kettle" (boiler), ensure the "fan" (turbine) spins correctly, and check that the "dynamo" (generator) is making the right amount of electricity. They also make sure everything is safe and clean (following rules) and fix things if they break.

Key Responsibilities and Daily Tasks

Operational Monitoring

A typical day involves continuous monitoring of complex systems. Operators watch turbines, generators, boilers, reactors, and auxiliary equipment through control room interfaces. They interpret data from sensors measuring temperature, pressure, flow rates, vibration, and electrical output.

Using sophisticated control systems, often SCADA (Supervisory Control and Data Acquisition), operators track performance trends and look for anomalies. They must understand the normal operating ranges for all equipment and quickly identify deviations that could signal malfunctions or inefficiencies.

Operators also perform routine checks and walk-downs within the plant itself, visually inspecting equipment, listening for unusual noises, and ensuring physical safety barriers are in place. This hands-on observation complements the data gathered in the control room.

Understanding the specific equipment, like boilers and compressors, is crucial. Courses focusing on these components can provide valuable insights.

Emergency Response and Troubleshooting

Power Plant Operators must be prepared to act decisively during emergencies. This could range from minor equipment malfunctions to major system failures or external events like grid disturbances or severe weather. They follow established emergency operating procedures (EOPs) to stabilize the plant and protect personnel and equipment.

Troubleshooting is a critical skill. When alarms sound or parameters drift outside acceptable limits, operators must diagnose the root cause. This involves analyzing system data, consulting technical manuals, and sometimes coordinating with maintenance technicians to isolate and resolve the fault.

Regular drills and simulations help operators maintain proficiency in emergency response. The ability to remain calm under pressure, think logically, and communicate clearly is essential during these high-stakes situations. Safety always takes precedence in any response scenario.

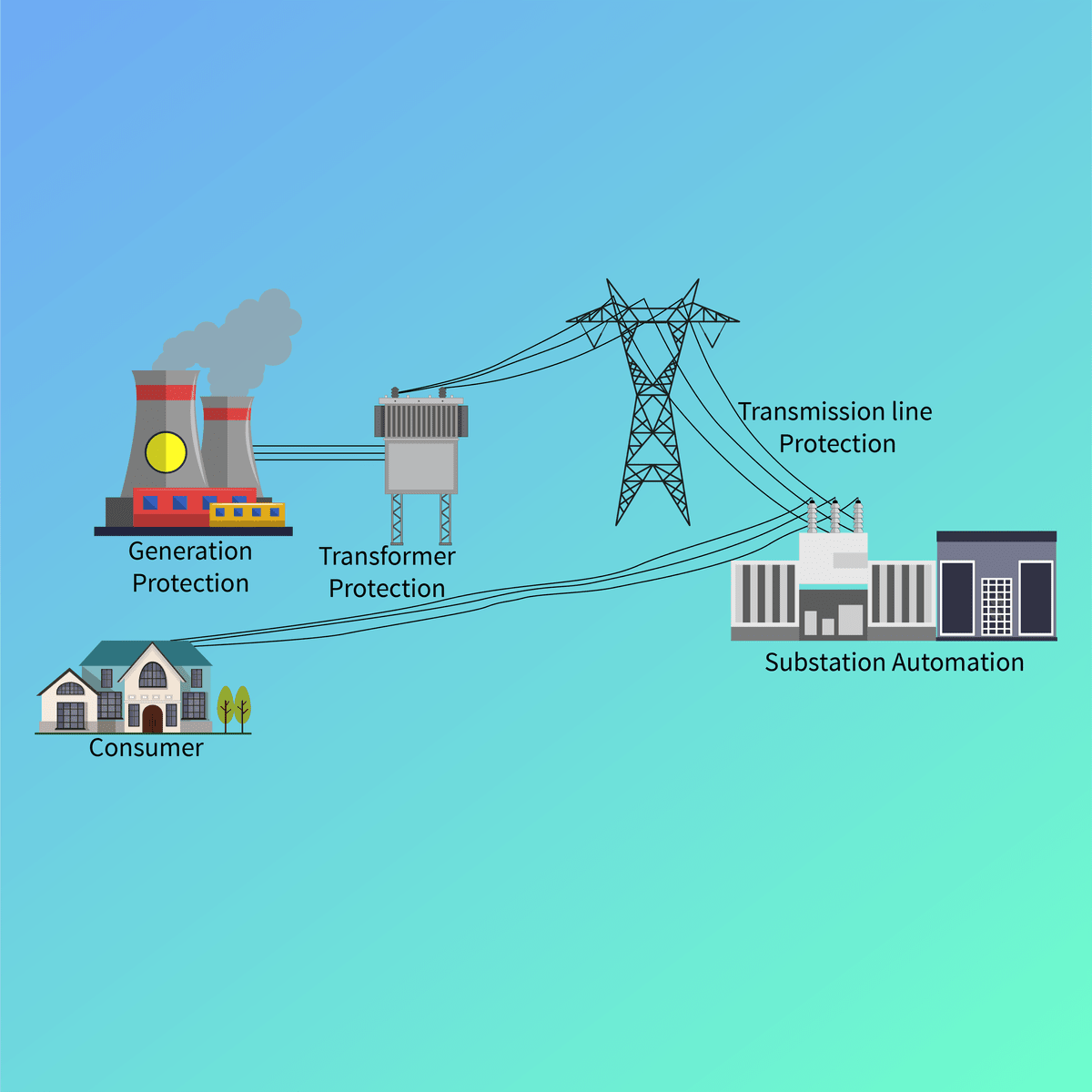

Advanced knowledge of protection schemes helps in understanding how systems react to faults.

Regulatory Compliance and Safety

Adherence to regulations is non-negotiable. Operators must be knowledgeable about and comply with rules set by bodies like the Environmental Protection Agency (EPA) concerning emissions, water usage, and waste disposal, and the Occupational Safety and Health Administration (OSHA) regarding workplace safety.

In the nuclear sector, the Nuclear Regulatory Commission (NRC) imposes extremely stringent operational and safety standards. Operators undergo rigorous training and licensing specific to these requirements. Maintaining compliance involves meticulous record-keeping, regular reporting, and participation in inspections and audits.

Safety culture is deeply ingrained in power plant operations. Operators actively participate in safety programs, identify potential hazards, and follow procedures like lockout/tagout (LOTO) during maintenance. Wearing appropriate personal protective equipment (PPE) is standard practice.

Understanding safety protocols is fundamental for anyone entering the utility industry.

For further information on specific regulations, consulting official sources is recommended, such as the EPA website or the OSHA website.

Formal Education Pathways

High School Foundation

Aspiring Power Plant Operators should build a strong foundation in science, technology, engineering, and mathematics (STEM) during high school. Courses in physics are particularly relevant as they cover principles of energy, mechanics, thermodynamics, and electricity.

Mathematics, including algebra, trigonometry, and potentially calculus, is crucial for understanding technical calculations, interpreting data, and working with formulas related to plant operations. Chemistry provides background for understanding fuel combustion, water treatment, and corrosion control.

Developing strong reading comprehension and technical writing skills is also important for understanding manuals and documenting procedures. Computer literacy is essential, as modern plants rely heavily on digital control systems.

Post-Secondary Education and Training

While a four-year degree isn't always mandatory, many employers prefer candidates with post-secondary education. An associate's degree in Power Plant Technology, Process Technology, Instrumentation Technology, or a related Engineering field is highly advantageous.

These programs typically cover subjects like thermodynamics, electrical circuits, fluid mechanics, control systems, safety procedures, and specific power generation technologies (e.g., boiler operation, turbine mechanics). They often include hands-on lab work that simulates real-world plant environments.

Some community colleges and technical schools offer specialized certificate programs focused directly on power plant operations or specific areas like Renewable Energy technology.

Fundamental courses in thermodynamics and electrical principles are cornerstones of this education.

These foundational books offer in-depth exploration of thermodynamics and energy principles.

Apprenticeships and On-the-Job Training

Apprenticeships offer a direct pathway into the career, combining paid on-the-job training with related classroom instruction. These programs, often sponsored by utility companies or unions, provide practical experience under the guidance of experienced operators.

Even with a degree or certificate, extensive on-the-job training (OJT) is standard for new hires. Trainees learn the specific systems, procedures, and safety protocols of the plant where they work. This period typically lasts several months to a few years, gradually increasing responsibility as competence grows.

OJT includes learning plant layout, equipment operation, control room procedures, safety drills, and regulatory requirements. Passing qualification tests specific to the plant or particular operator positions is usually required to advance from trainee status.

Online and Independent Learning

Using Online Courses for Foundational Knowledge

Online courses offer a flexible way to build foundational knowledge relevant to power plant operations, especially for those exploring the field or supplementing formal education. Platforms like OpenCourser provide access to courses covering thermodynamics, electrical principles, safety standards, and even introductions to specific technologies like nuclear or renewable energy.

While online learning cannot fully replace hands-on experience with actual plant equipment, it can provide theoretical understanding and familiarize learners with key concepts and terminology. Virtual labs and simulations, sometimes included in online courses, can offer interactive ways to grasp system dynamics and control principles, bridging the gap between theory and practice.

For career pivoters or those unable to commit to full-time programs initially, online courses can be an excellent starting point. They allow learners to gauge their interest and aptitude for the technical subjects involved before making larger commitments. OpenCourser's Learner's Guide offers tips on structuring self-study and maximizing learning from online resources.

These courses provide introductions to specific plant types or essential components, accessible online.

Certifications and Skill Enhancement

Online platforms can be valuable for obtaining or preparing for certain industry-relevant certifications, particularly in areas like workplace safety (e.g., OSHA 10 or 30-hour courses) or specific technical skills. While core operator licenses (like NRC licenses for nuclear operators) require extensive in-person training and testing, supplemental online learning can bolster a candidate's profile.

Professionals already working in the field can use online courses for continuing education, staying updated on new technologies, regulations, or safety practices. Courses covering advanced topics like power system protection, energy management, or specific equipment maintenance can aid professional development and career advancement.

Consider creating projects to supplement online learning. For example, after taking a course on electrical diagrams, try interpreting real-world single-line diagrams (publicly available examples might exist). After a thermodynamics course, try modeling a simple energy balance for a hypothetical system using spreadsheet software.

Courses focusing on electrical safety and diagrams are beneficial for practical application.

Integrating Online Learning with Practical Experience

The most effective approach often combines online learning with hands-on experience. Use online courses to build theoretical knowledge before or during an apprenticeship or OJT program. This pre-learning can help trainees grasp practical concepts more quickly.

For example, understanding the principles of thermodynamics online can make learning about boiler operations on-site more intuitive. Similarly, learning about electrical circuits online provides context for understanding generator controls and switchgear operations in the plant.

Remember that becoming a fully qualified Power Plant Operator requires demonstrating practical competence in a real-world setting. Online learning is a powerful supplement and preparation tool, but it must be paired with practical training and experience, especially for safety-critical roles.

Explore foundational topics through OpenCourser's vast library, perhaps starting with Physics or Technical Training categories.

Career Progression and Advancement

Starting Your Career

Most individuals enter the field in entry-level positions such as Assistant Operator, Plant Equipment Operator, or Trainee. These roles typically involve working under the supervision of experienced operators, learning plant systems, performing routine checks, assisting with minor maintenance, and monitoring auxiliary equipment.

Progression usually involves gaining experience across different plant systems, completing required training modules, and passing internal qualification exams. Demonstrating competence, reliability, and a strong understanding of safety procedures are key to advancing.

Initial roles often involve shift work, including nights, weekends, and holidays, as power plants operate 24/7. Physical demands may include climbing stairs and ladders, working in varying temperature conditions, and occasionally lifting heavy objects.

Achieving Senior Roles and Certifications

With experience and further training, operators can advance to roles like Control Room Operator or Senior Operator. These positions carry greater responsibility for overall plant operation, decision-making during normal and emergency conditions, and potentially supervising junior staff.

In the United States, achieving certification from the North American Electric Reliability Corporation (NERC) is often required for operators who have responsibility for the reliability of the bulk power system. There are different levels of NERC certification, such as Reliability Coordinator, Balancing Authority, and Transmission Operator.

Nuclear Power Plant Operators require specific licenses from the NRC, involving rigorous training programs and examinations. Continuous training and requalification are mandatory throughout their careers to maintain these licenses.

Paths to Management and Engineering

Experienced Power Plant Operators have several potential pathways for further advancement. Some move into supervisory roles like Shift Supervisor or Operations Supervisor, overseeing teams of operators and coordinating shift activities.

With additional education (often a bachelor's degree in engineering) and experience, operators may transition into plant management roles, responsible for overall plant performance, budgeting, and strategic planning. Others might move into related technical fields such as Plant Engineering, maintenance planning, safety management, or training.

The deep operational knowledge gained as an operator is highly valuable in these adjacent roles. Some may even specialize further, for instance, becoming experts in specific plant types.

This handbook provides insights into managing energy resources effectively, relevant for those aspiring to leadership roles.

Health and Safety Considerations

Understanding Workplace Hazards

Power plant environments present unique hazards. Operators work with high-pressure steam, rotating machinery, high voltages, and potentially hazardous chemicals used in water treatment or emissions control. Slips, trips, and falls are common industrial risks, compounded by ladders and catwalks.

In fossil fuel plants, risks include exposure to combustion byproducts and potential for fires or explosions. In nuclear plants, the primary concern is exposure to ionizing radiation, although plants operate under extremely strict safety protocols to minimize this risk. Comprehensive training on radiation protection is mandatory for nuclear workers.

Hydroelectric plants have risks associated with large volumes of water and heavy machinery. Renewable energy sites, like wind farms, involve working at heights and dealing with high voltage electrical equipment.

This book details the events and lessons learned from a major nuclear incident, highlighting the importance of safety.

Physical Demands and Ergonomics

The role can be physically demanding. Operators may need to stand or walk for extended periods, climb stairs and ladders, work in confined spaces, and operate valves or equipment that require physical effort. Good physical condition is often necessary.

Control room work, while less physically strenuous, involves long periods of sitting and monitoring screens, which can lead to ergonomic challenges like eye strain or musculoskeletal discomfort if workstations are not properly designed. Maintaining alertness during long shifts, especially overnight, is also a critical aspect.

Shift work itself can impact health and well-being, disrupting sleep patterns and social life. Employers often provide resources and strategies to help workers manage the demands of non-traditional schedules.

Regulatory Oversight and Safety Culture

Regulatory bodies like OSHA, EPA, and NRC play a significant role in ensuring safe operation. Power plants are subject to regular inspections and audits to verify compliance with health, safety, and environmental standards. Operators are directly involved in implementing and upholding these standards.

A strong safety culture is vital. This means safety is prioritized at all levels of the organization, from management to frontline operators. Reporting hazards, following procedures diligently, using protective equipment, and participating in safety training are expectations for everyone working in a power plant.

Continuous improvement in safety practices is common, driven by incident analysis, technological advancements, and evolving regulations. Operators contribute to this by providing feedback and adhering to updated protocols.

Understanding the relationship between energy production and the environment is also increasingly important.

This book explores the critical link between energy systems and environmental concerns.

Industry Trends Impacting Power Plant Operators

Shift Towards Renewable Energy

The global push towards decarbonization is significantly impacting the power generation industry. There's a clear trend away from coal-fired power plants and towards natural gas and renewable sources like wind, solar, and geothermal energy. This shift changes the types of facilities operators work in and the specific technologies they manage.

Operators skilled in managing variable renewable energy sources and grid integration technologies are increasingly in demand. While traditional power plants remain crucial for grid stability, the skillset required is evolving. Adaptability and willingness to learn new systems are becoming more important.

The World Economic Forum's Energy Transition Index tracks global progress and highlights the complexities involved in this shift, impacting workforce needs across the energy sector.

Understanding sustainable energy options is crucial in today's evolving landscape.

Automation and Digitalization

Automation, artificial intelligence (AI), and advanced data analytics are transforming power plant operations. Modern control systems can automate routine tasks, optimize performance based on predictive analytics, and provide operators with more sophisticated tools for monitoring and diagnostics.

While some fear automation will eliminate jobs, it's more likely to change the nature of the operator's role. Operators will likely focus more on overseeing automated systems, interpreting complex data, managing cybersecurity risks, and handling exceptions or complex troubleshooting scenarios that require human judgment.

This trend necessitates enhanced digital literacy and analytical skills. Operators comfortable working with advanced software and data interpretation will be better positioned for the future. Familiarity with concepts like Virtual Power Plants may also become relevant.

Job Market Outlook and Stability

The overall demand for Power Plant Operators is influenced by electricity consumption patterns, the retirement rates of existing workers, and the pace of transition towards new energy sources. According to the U.S. Bureau of Labor Statistics (BLS), employment in this field is projected to show little or no change over the next decade, but openings will arise from the need to replace workers who retire or transition to other occupations.

While jobs at traditional coal plants may decline, opportunities are expected to grow in natural gas plants and renewable energy facilities. The need for skilled operators to maintain grid reliability remains constant, ensuring a degree of job stability, particularly for those with updated skills and certifications.

Regions investing heavily in new power infrastructure, whether fossil fuel-based or renewable, may offer more robust job prospects. Nuclear power also continues to require a highly trained, stable workforce.

These books offer broad perspectives on energy's role in society and its future directions.

Transferable Skills for Power Plant Operators

Technical Troubleshooting and Problem-Solving

The ability to diagnose and resolve complex technical problems is a core competency for Power Plant Operators. This skill is highly transferable to maintenance, technical support, or operations roles in other large-scale industrial settings, such as manufacturing plants, chemical processing facilities, or water treatment plants.

Operators develop a systematic approach to troubleshooting, involving data analysis, logical deduction, and understanding system interdependencies. This analytical mindset is valuable in any field that requires resolving complex issues under pressure.

Regulatory Compliance and Safety Expertise

Power Plant Operators gain deep expertise in navigating and adhering to complex regulatory frameworks (EPA, OSHA, NRC). This knowledge of compliance procedures, documentation requirements, and safety protocols is valuable in quality assurance, environmental health and safety (EHS), or regulatory affairs roles across various industries.

Experience with safety management systems, risk assessment, and emergency preparedness is particularly transferable. Industries that prioritize safety and operate under strict regulations often seek individuals with this background.

Team Coordination and Communication

Operating a power plant requires seamless coordination between control room operators, field operators, maintenance crews, engineers, and external grid operators. Operators develop strong communication skills, both verbal and written (through logs and reports).

The ability to work effectively as part of a team, especially in high-stakes, time-sensitive situations, is a transferable soft skill valued in many collaborative work environments. Experience in shift handovers, where clear and concise information transfer is crucial, further hones these skills.

Consider exploring related technical fields on OpenCourser, such as Industrial Engineering or Manufacturing, where these skills are also highly relevant.

Frequently Asked Questions

Is a college degree mandatory for this role?

A four-year college degree is generally not mandatory to become a Power Plant Operator, especially for entry-level positions in non-nuclear plants. However, requirements vary significantly by employer and plant type. Many employers prefer or require an associate's degree in a relevant technical field (like Power Plant Technology) or equivalent military training.

For nuclear power plant operator roles, educational requirements are often stricter, frequently favoring candidates with degrees or extensive, specific Navy nuclear training. While apprenticeships and on-the-job training can provide pathways without a formal degree, post-secondary education often enhances competitiveness and potential for advancement.

Some operators pursue bachelor's degrees later in their careers to facilitate transitions into management or engineering roles. The necessity of a degree often depends on the specific company's policies and the complexity of the plant.

How does automation affect job security?

Automation is changing the role, but not necessarily eliminating it entirely. While automated systems handle more routine tasks and optimize processes, human oversight, judgment, and troubleshooting skills remain critical, especially during abnormal conditions or emergencies.

The focus of the operator role may shift towards managing and monitoring these complex automated systems, requiring enhanced digital and analytical skills. Job security is likely stronger for operators who adapt to these changes and continuously update their skills.

While the total number of operators might see some pressure due to increased efficiency from automation, the need for qualified personnel to ensure the safe and reliable operation of essential power infrastructure persists. The impact varies by plant type and level of automation adopted.

What are typical salary ranges?

Salaries for Power Plant Operators can vary widely based on factors like location, type of power plant (nuclear operators typically earn more), level of experience, certifications held (e.g., NERC, NRC), and employer (utility company vs. independent power producer).

According to the BLS, the median annual wage for power plant operators, distributors, and dispatchers was $104,090 in May 2023. Entry-level positions will start lower, while experienced senior operators, especially those with specialized licenses in the nuclear sector, can earn significantly more.

Overtime opportunities are common due to the 24/7 nature of operations, which can further increase total compensation. It's advisable to research salary data specific to your region and the type of plant you are interested in using resources like the BLS or reputable salary comparison websites.

Are there specific physical fitness requirements?

Yes, there are typically physical fitness requirements for Power Plant Operator roles. The job often involves walking extensive distances within the plant, climbing stairs and ladders, working in environments with temperature extremes (hot near boilers, cold outdoors), and potentially lifting moderately heavy objects.

Good hearing and vision (correctable to standards) are usually necessary for monitoring equipment and responding to alarms. Some positions, particularly in the nuclear industry, may require passing rigorous physical examinations and drug screenings as part of the hiring and qualification process.

While control room roles are less physically strenuous day-to-day, operators must still be capable of performing plant walk-downs and responding physically during emergencies. Specific requirements are set by the employer based on job demands and safety regulations.

How often do certifications need renewal?

Certification renewal cycles depend on the specific certification. For example, NERC certifications typically require renewal every few years, involving completion of a certain number of continuing education hours (CEHs) covering relevant topics like system operations, emergency preparedness, and regulations.

Nuclear Regulatory Commission (NRC) licenses for nuclear operators require ongoing training and periodic requalification, often including annual exams and simulator evaluations, to ensure continued competence. Company-specific qualifications and safety certifications (like CPR or forklift operation) also have periodic renewal requirements.

Maintaining active certifications and licenses is crucial for continued employment and career progression in the field. Employers usually support or mandate the necessary training for renewals.

Is remote work possible for Power Plant Operators?

Direct operation and control of large power plants (like nuclear, coal, hydro) generally require on-site presence in a central control room due to the need for immediate physical response capabilities, hands-on adjustments, and safety protocols. Therefore, traditional Control Room Operator roles are typically not remote.

However, aspects of monitoring, diagnostics, and dispatch for certain types of facilities, particularly distributed renewable energy assets (like large solar or wind farms), may incorporate remote operations centers (ROCs). Some specialized analysis or support roles related to plant performance might offer remote or hybrid work possibilities.

For the core function of operating major generation facilities, on-site work remains the standard due to the physical nature of the equipment and the critical need for immediate response.

Embarking on a career as a Power Plant Operator is a commitment to a demanding but essential profession. It requires technical skill, continuous learning, and unwavering attention to safety. For those drawn to complex systems and the responsibility of powering communities, it offers a challenging and potentially rewarding path. Explore the resources on OpenCourser to build your foundational knowledge and take the first step towards this vital career.