Mechatronics Engineer

Mechatronics Engineer: A Comprehensive Career Guide

Mechatronics engineering is a dynamic field that integrates principles from mechanical engineering, electrical engineering, computer science, and control engineering. It focuses on designing and developing intelligent systems and products that involve a blend of mechanics and electronics, controlled by software. Think of sophisticated robots, automated manufacturing lines, or even complex consumer electronics – mechatronics engineers are often behind their creation.

This interdisciplinary approach allows for the creation of systems that are more efficient, reliable, and versatile than those designed within a single engineering discipline. If you're fascinated by how machines work, enjoy solving complex problems, and are interested in bridging the gap between the physical and digital worlds, a career as a mechatronics engineer could be incredibly rewarding. You might find yourself designing the next generation of automated vehicles, developing cutting-edge medical devices, or optimizing smart factory processes.

Introduction to Mechatronics Engineering

What is Mechatronics?

At its core, mechatronics is about synergy. It combines mechanical components (like gears, motors, and structures) with electronic systems (like sensors, microcontrollers, and power circuits) and uses computer control (software algorithms) to make them work together seamlessly. Imagine a modern car's anti-lock braking system (ABS). It uses sensors to detect wheel speed (electrical), a computer to process this data and decide if a wheel is locking (computer science/control), and actuators to modulate brake pressure (mechanical/electrical). This intricate interplay is the essence of mechatronics.

This field isn't just about combining existing technologies; it's about designing integrated systems from the ground up. Mechatronics engineers think holistically, considering how mechanical constraints affect electronic performance, how software can optimize mechanical movement, and how sensors provide the necessary feedback for intelligent control. This requires a broad understanding across multiple engineering domains.

The goal is often to create systems that are "smarter," more automated, and more capable than their purely mechanical or electrical predecessors. This involves incorporating sensors for perception, actuators for action, and control systems for decision-making, often leading to highly sophisticated and autonomous machines.

Here's a topic related to the core idea:

A Brief History

The term "mechatronics" was first coined in Japan in the late 1960s by Tetsuro Mori, an engineer at Yaskawa Electric Corporation. Initially, it described the integration of mechanics and electronics in their industrial robots. The concept gained traction as microprocessors became smaller, cheaper, and more powerful throughout the 1970s and 1980s, enabling more sophisticated control of mechanical systems.

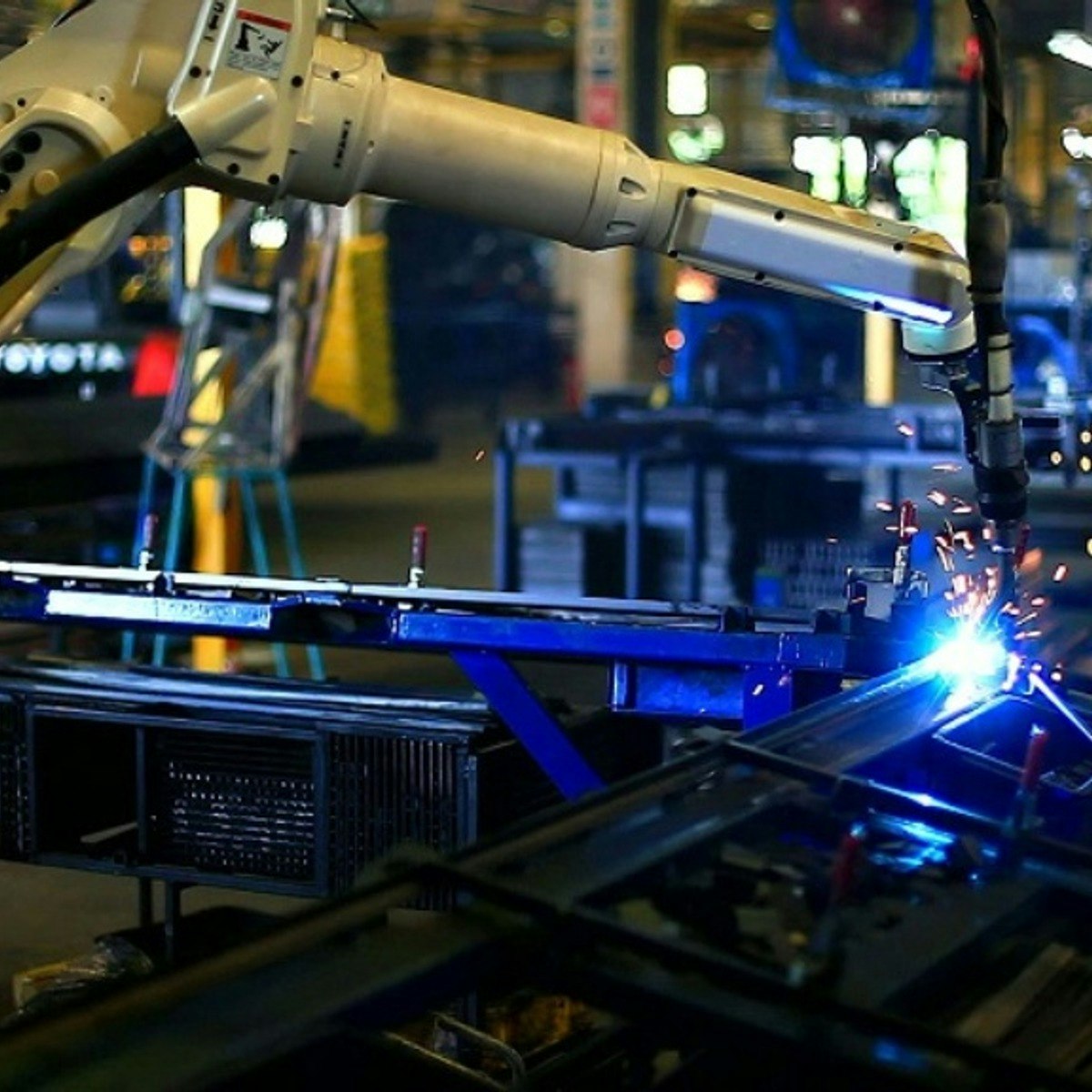

Early applications focused heavily on industrial automation and robotics, improving manufacturing efficiency and precision. Think of automated assembly lines or numerically controlled (CNC) machines. As computer technology advanced, so did mechatronics, incorporating more complex software, sensor fusion, and eventually, elements of artificial intelligence.

Key milestones include the development of programmable logic controllers (PLCs) which standardized industrial control, the rise of embedded systems allowing intelligence to be built directly into products, and the recent explosion of the Internet of Things (IoT), connecting mechatronic devices into vast networks. Today, mechatronics is integral to fields ranging from aerospace and automotive to consumer electronics and biomedical engineering.

Primary Goals: Automation, Robotics, and Intelligent Systems

A central aim of mechatronics is automation – replacing or augmenting human labor with machines, particularly for tasks that are repetitive, dangerous, or require high precision. This spans industrial robots assembling products on a factory floor to automated systems sorting packages in a logistics hub. The integration of sensors and control algorithms allows these systems to operate reliably and efficiently.

Robotics is perhaps the most visible application of mechatronics. From industrial arms to autonomous mobile robots and humanoid assistants, robotics relies heavily on the principles of integrating mechanical structures, electronic sensing and actuation, and intelligent software control. Mechatronics provides the foundation for creating robots that can perceive their environment, make decisions, and interact physically with the world.

Ultimately, mechatronics drives the development of intelligent systems. These are systems capable of adapting to changing conditions, learning from experience, and making complex decisions without direct human intervention. Examples include self-driving cars navigating traffic, smart prosthetics responding to user intent, or adaptive manufacturing systems adjusting to different product requirements. This pursuit of intelligence relies on the sophisticated integration of sensing, processing, and actuation that defines mechatronics.

These foundational courses explore robotics and automation further.

Core Concepts and Technologies in Mechatronics

Essential Components: Sensors, Actuators, and Microcontrollers

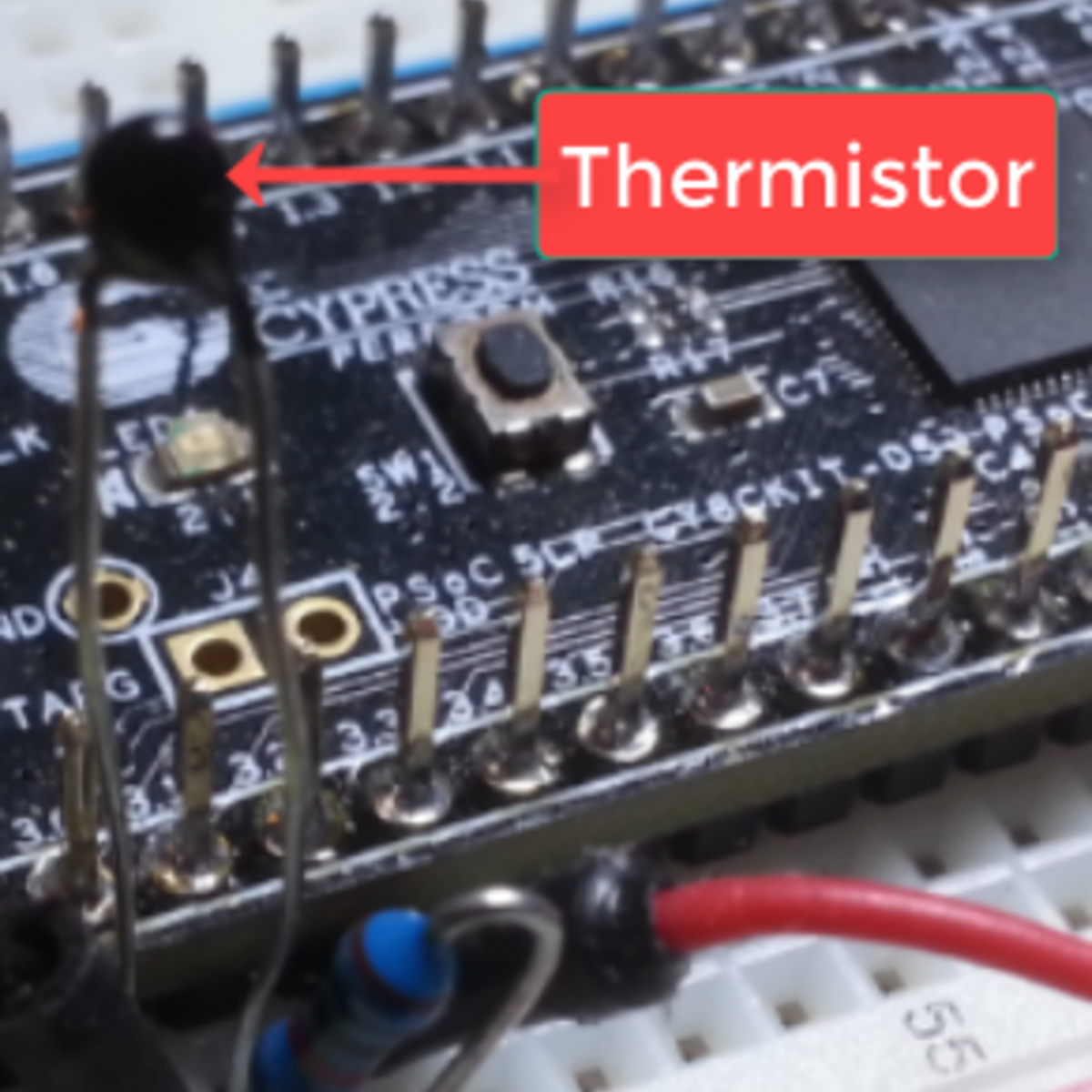

Sensors are the "senses" of a mechatronic system, gathering information about the system itself or its environment. They convert physical phenomena (like temperature, position, light, pressure, or acceleration) into electrical signals that the system's controller can understand. Examples include proximity sensors detecting objects, encoders measuring motor rotation, or cameras capturing visual data.

Actuators are the "muscles" of the system, converting electrical energy back into physical action or motion based on commands from the controller. Common actuators include electric motors (DC, servo, stepper), hydraulic or pneumatic cylinders, solenoids, and even heating elements or light sources. Selecting the right actuator involves considering factors like required force, speed, precision, and power consumption.

Microcontrollers are the "brains." These are small, integrated circuits containing a processor, memory, and input/output peripherals on a single chip. They run the software that reads sensor data, performs calculations and decision-making based on control algorithms, and sends commands to the actuators. They are the central hub connecting the sensing, processing, and actuation aspects of the system.

These courses delve into sensors, actuators, and microcontrollers.

ELI5: Sensors, Actuators, Microcontrollers

Imagine you're playing a game of "Hot and Cold." Your friend hides an object, and you try to find it. Your friend tells you "warmer" when you get closer and "colder" when you move away. In this game:

Sensors are like your ears hearing your friend say "warmer" or "colder." They take information from the outside world (your friend's words) and turn it into something your brain can use.

Actuators are like your legs moving you around the room. Based on what your brain decides, your legs take action and move you.

The Microcontroller is like your brain. It listens to the "sensor" (your ears hearing "warmer/colder"), decides what to do (move left, right, forward), and tells the "actuator" (your legs) to move. It connects the sensing and the acting parts.

The Role of Software and Control

Software is indispensable in mechatronics. Embedded systems programming involves writing code specifically for microcontrollers that directly interact with hardware. This code reads sensor inputs, implements control logic, and drives actuators in real-time. Languages like C and C++ are common due to their efficiency and low-level hardware control capabilities, though higher-level languages like Python (often via MicroPython) are increasingly used for rapid prototyping and less time-critical tasks.

Control algorithms are the mathematical recipes that dictate how the system behaves. Based on sensor readings and desired outcomes (setpoints), these algorithms calculate the appropriate commands for the actuators. Simple examples include On/Off control (like a thermostat), while more complex systems use techniques like Proportional-Integral-Derivative (PID) control, state-space methods, or adaptive control to achieve precise and stable performance, even in changing conditions.

Modeling and simulation are also crucial software-based activities. Engineers create mathematical models of the physical system and use software (like MATLAB/Simulink) to simulate its behavior before building hardware prototypes. This allows for testing different designs, tuning control algorithms, and identifying potential problems early in the development process, saving time and resources.

These resources explore control systems and simulation.

Emerging Tools: AI and Machine Learning Integration

Artificial Intelligence (AI) and Machine Learning (ML) are increasingly finding applications within mechatronics. Instead of relying solely on pre-programmed rules or traditional control algorithms, AI/ML allows systems to learn from data, adapt to unforeseen circumstances, and make more complex, nuanced decisions.

In robotics, for instance, ML can be used for object recognition through computer vision, enabling robots to identify and interact with specific items in unstructured environments. Reinforcement learning can train robots to perform complex manipulation tasks through trial and error. Predictive maintenance is another area where ML analyzes sensor data (like vibration or temperature) to predict potential equipment failures before they happen.

Integrating AI/ML often requires more powerful processing capabilities than traditional microcontrollers offer, sometimes involving specialized hardware like GPUs or TPUs, or leveraging cloud computing. It also necessitates skills in data handling, algorithm training, and validation, adding another layer of complexity and opportunity to the mechatronics field.

This course introduces AI concepts relevant to autonomous systems.

Formal Education Pathways

High School Preparation

Building a strong foundation in high school is crucial for success in any engineering field, including mechatronics. Focus on mastering core STEM subjects: mathematics (especially algebra, trigonometry, and calculus), physics (mechanics, electricity, and magnetism are key), and chemistry. Computer science or programming courses are also highly beneficial.

Beyond coursework, seek hands-on experiences. Participate in robotics clubs (like FIRST Robotics Competition or VEX Robotics), science fairs, or maker spaces. These activities provide practical exposure to building, programming, and troubleshooting systems – skills directly applicable to mechatronics. Developing strong problem-solving abilities and teamwork skills through these activities is equally important.

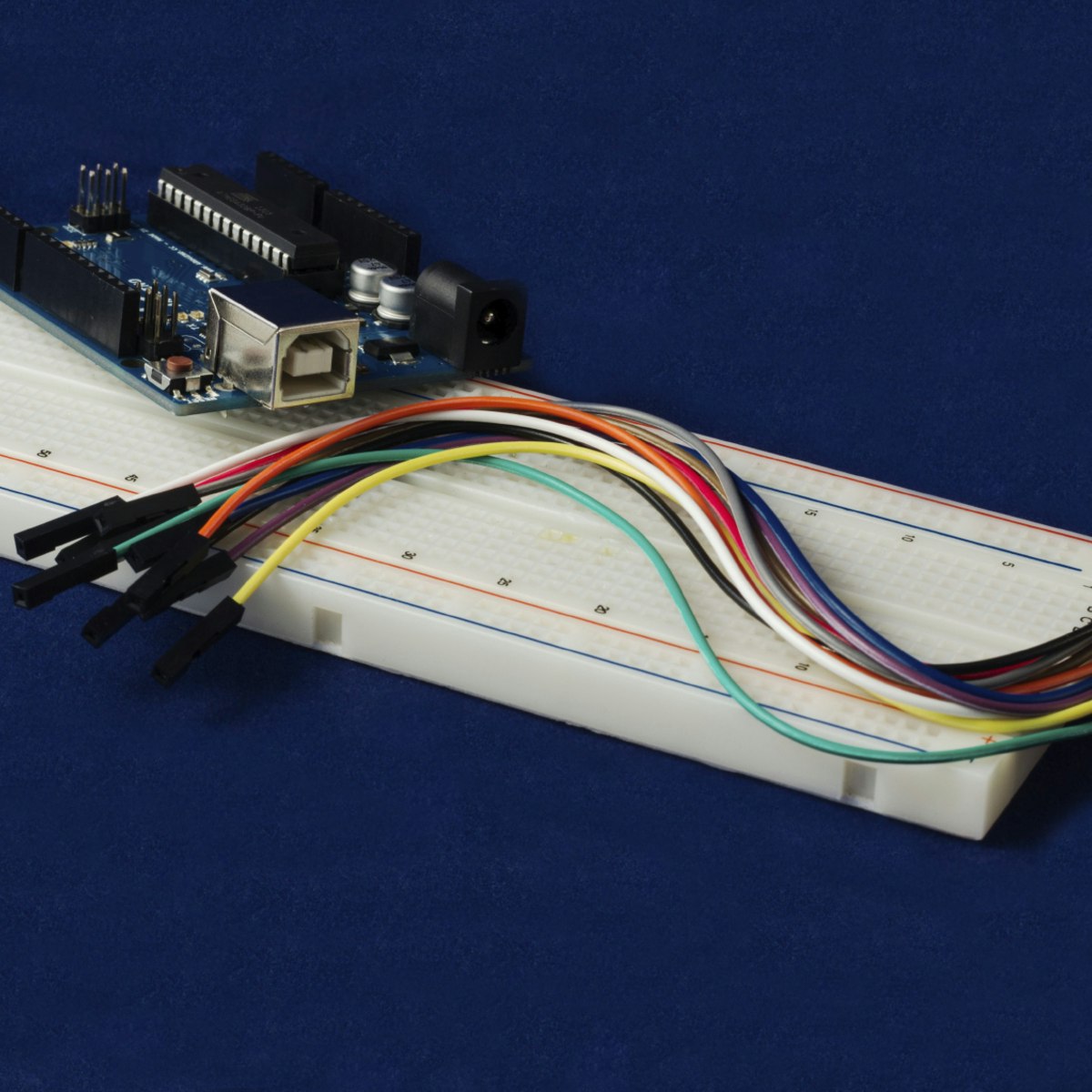

Look for opportunities to learn basic electronics or work with platforms like Arduino or Raspberry Pi. Even simple projects, like building a line-following robot or a sensor-based alarm, can solidify fundamental concepts and ignite passion for the field.

This introductory course is great for those getting started with competitive robotics.

Undergraduate Degrees

A bachelor's degree in Mechatronics Engineering is the most direct route. However, degrees in Mechanical Engineering, Electrical Engineering, or Computer Engineering with a focus or specialization in mechatronics, robotics, or control systems are also common pathways. Ensure the program you choose has a strong interdisciplinary curriculum and hands-on laboratory components.

Typical undergraduate coursework includes foundational engineering topics like statics, dynamics, thermodynamics, and materials science. You'll also dive into electrical circuits, digital logic, electronics, microcontroller programming, embedded systems, signals and systems, and control theory. Specific mechatronics courses will integrate these subjects, often involving project-based learning where you design and build functional mechatronic systems.

Look for programs accredited by organizations like ABET (Accreditation Board for Engineering and Technology) in the US, as this ensures a standard of quality. Co-op programs or internships provide invaluable real-world experience and are highly recommended.

These courses cover typical undergraduate topics.

These books offer foundational knowledge.

Graduate Studies and Research

While a bachelor's degree is sufficient for many entry-level mechatronics positions, a Master's or Ph.D. degree can open doors to specialized roles, research and development (R&D), and academia. Graduate programs allow for deeper dives into specific areas like advanced robotics, autonomous systems, control theory, artificial intelligence, biomedical devices, or micro/nano-electromechanical systems (MEMS).

Master's programs often blend advanced coursework with a significant design project or thesis. Ph.D. programs are heavily research-focused, requiring original contributions to the field culminating in a dissertation. Pursuing graduate studies requires a strong academic record, research aptitude, and often, letters of recommendation and standardized test scores (like the GRE).

Research opportunities might involve working in university labs on projects funded by government agencies or industry partners. Topics could range from developing novel sensors for robotic perception to designing sophisticated control algorithms for autonomous drones or creating miniature robots for medical applications.

These advanced courses touch on topics often explored in graduate studies.

Online and Self-Directed Learning in Mechatronics

Viability of Online Learning Paths

Online learning offers tremendous flexibility and accessibility for aspiring mechatronics engineers, whether supplementing formal education or pursuing a career change. Platforms like OpenCourser aggregate thousands of courses covering foundational topics (mathematics, physics, programming) and specialized mechatronics subjects (robotics, control systems, embedded systems, electronics).

While a purely online path to becoming a fully qualified mechatronics engineer can be challenging due to the hands-on lab requirements of traditional degrees, online courses are exceptionally valuable for building specific skills, exploring interests, and staying current with rapidly evolving technologies. They can effectively supplement a traditional degree or provide foundational knowledge for those pivoting from related fields.

Many universities and reputable organizations offer online courses, certificates, and even micro-credentials in specific mechatronics-related areas. These can demonstrate commitment and acquired knowledge to potential employers, especially when combined with practical project experience.

OpenCourser's Learner's Guide provides valuable tips on structuring self-learning paths and maximizing the benefits of online education.

These courses offer foundational and specialized knowledge accessible online.

The Importance of Project-Based Learning

Theoretical knowledge is essential, but practical application is paramount in mechatronics. Building physical projects is the best way to solidify understanding, develop troubleshooting skills, and create a portfolio showcasing your abilities. Online courses often include project components, but self-directed learners should actively seek out additional project opportunities.

Start with simpler projects using accessible platforms like Arduino or Raspberry Pi. Examples include building a sensor-controlled LED system, a small mobile robot, or an automated plant watering system. As your skills grow, tackle more complex challenges like designing a robotic arm, building a self-balancing robot, or integrating computer vision.

Document your projects thoroughly – take photos/videos, write detailed descriptions of the design process, challenges faced, and solutions implemented. Create a personal website or GitHub repository to host your portfolio. This tangible evidence of your skills is often more compelling to employers than certificates alone, especially for those without a traditional engineering degree.

These project-focused courses provide hands-on experience.

Bridging Theory and Industry Practice

Successfully transitioning from learning (online or traditional) to an industry role requires bridging the gap between theoretical concepts and real-world engineering practices. Industry often uses specific tools, software suites (like CAD software - SolidWorks, Autodesk Fusion 360; simulation tools - MATLAB/Simulink; PLC programming environments), and adheres to particular standards and workflows not always covered in introductory courses.

Seek out online courses or tutorials focused on industry-standard tools. Contribute to open-source robotics or mechatronics projects to gain experience collaborating and working with established codebases. Network with professionals in the field through online forums, conferences (even virtual ones), or local meetups to understand current industry challenges and required skill sets.

Consider creating projects that mimic industrial applications, even on a smaller scale. For example, build a miniature automated sorting system using computer vision or a small PLC-controlled process. Emphasize not just the technical solution but also aspects like system integration, robustness, safety considerations, and documentation – all crucial in professional engineering.

These courses focus on industry-relevant tools and platforms.

These books cover practical design details.

Career Progression for Mechatronics Engineers

Entry-Level Opportunities

Graduates typically start in roles like Junior Mechatronics Engineer, Automation Technician, Robotics Technician, Controls Engineer, or Embedded Systems Engineer. Initial responsibilities often involve assisting senior engineers with design tasks, component selection, building prototypes, testing systems, programming controllers (like PLCs or microcontrollers), and troubleshooting issues on the factory floor or in the lab.

These roles provide foundational experience in applying engineering principles to real-world problems. You'll learn industry-specific tools, software, and processes. Focus areas might include setting up and maintaining automated equipment, programming robotic sequences, designing and testing circuit boards, or developing control software for specific applications.

Strong analytical skills, attention to detail, practical hands-on ability, and good communication are essential. Employers look for candidates with relevant coursework, project experience (personal, academic, or internships), and familiarity with relevant technologies.

Mid-Career Advancement

With several years of experience, mechatronics engineers can advance to roles with greater responsibility and complexity. This might involve leading design projects, managing small teams, specializing in a particular technology (e.g., machine vision, advanced control systems), or focusing on systems integration – ensuring complex mechanical, electrical, and software components work together flawlessly.

Titles could include Mechatronics Engineer, Systems Engineer, Project Engineer, R&D Engineer, or Lead Controls Engineer. Responsibilities often expand to include system architecture design, requirement definition, vendor selection, project management, and mentoring junior engineers. Deeper technical expertise in areas like simulation, advanced control algorithms, or specific industry applications becomes increasingly valuable.

Continuing education, whether through formal courses, workshops, or self-study, is important for staying current. Obtaining professional certifications or a Professional Engineer (PE) license (depending on location and industry) can also aid advancement. Strong problem-solving, project management, and communication skills are critical at this stage.

This course covers advanced robotics topics relevant for mid-career growth.

This book delves into advanced control topics.

Senior Roles and Leadership

Experienced mechatronics engineers can progress into senior technical leadership or management positions. Roles like Principal Engineer, Technical Lead, Engineering Manager, Systems Architect, or Innovation Strategist involve setting technical direction, managing larger teams or departments, overseeing complex multi-disciplinary projects, developing long-term technology roadmaps, and interfacing with business leadership.

At this level, a deep understanding of the technology landscape, strong strategic thinking, excellent leadership and communication skills, and often, business acumen are required. Some senior engineers remain highly technical experts, serving as consultants or architects on the most challenging problems, while others transition more fully into management roles.

Opportunities may also exist in technical sales, product management, or starting one's own engineering consulting firm. A strong track record of successful projects, innovation, and leadership is essential for reaching these senior positions. An advanced degree (Master's or Ph.D.) can sometimes be advantageous, particularly for roles focused on cutting-edge research or technology strategy.

This related career path offers similar progression opportunities.

Industry Applications and Demand

Key Sectors Employing Mechatronics Engineers

Mechatronics engineers are in demand across a wide array of industries due to the prevalence of automated and intelligent systems. Manufacturing is a major employer, with engineers designing, implementing, and maintaining robotic assembly lines, automated quality control systems, and smart factory infrastructure.

The automotive industry heavily relies on mechatronics for features like autonomous driving systems, engine control units, electric vehicle powertrains, and advanced driver-assistance systems (ADAS). Aerospace utilizes mechatronics in flight control systems, unmanned aerial vehicles (UAVs or drones), and satellite mechanisms.

Other significant sectors include biomedical engineering (robotic surgery tools, smart prosthetics, diagnostic equipment), consumer electronics (smart appliances, cameras, gaming peripherals), defense (unmanned systems, advanced weaponry), logistics and warehousing (automated guided vehicles, sorting systems), and energy (smart grids, renewable energy system controls).

Market Trends and Job Outlook

The demand for mechatronics engineers is generally strong and expected to grow, driven by increasing automation across industries and the rise of interconnected smart devices (IoT). According to the U.S. Bureau of Labor Statistics (BLS), employment for related engineering fields like mechanical and electrical engineering shows steady growth, and the specialized, interdisciplinary skillset of mechatronics engineers often positions them favorably within these broader categories.

Global trends like Industry 4.0, the push for sustainable technologies, advancements in AI and robotics, and the expansion of e-commerce (driving logistics automation) all contribute to the positive outlook. Regional demand can vary based on local industry concentrations (e.g., automotive hubs, tech centers, manufacturing regions).

Salaries typically reflect the high demand and required skill level, often competitive with other core engineering disciplines. Factors influencing salary include experience level, education (B.S., M.S., Ph.D.), specific industry, geographic location, and company size.

Impact of Industry 4.0 and Smart Manufacturing

Industry 4.0, often called the fourth industrial revolution, represents the digitalization of manufacturing and industrial processes. It heavily leverages mechatronics principles, integrating cyber-physical systems, IoT, cloud computing, and AI to create "smart factories." Mechatronics engineers are central to designing, implementing, and managing these interconnected systems.

This involves deploying networks of sensors to gather real-time data from machinery, using advanced robotics for flexible automation, implementing machine learning for predictive maintenance and process optimization, and creating digital twins (virtual replicas of physical systems) for simulation and analysis. The goal is increased efficiency, flexibility, productivity, and data-driven decision-making in manufacturing environments.

As more companies adopt Industry 4.0 strategies, the need for engineers who understand the integration of physical processes with digital technologies – the very definition of mechatronics – will continue to escalate. This trend solidifies mechatronics as a critical field for the future of industry.

These courses touch upon industrial automation and smart factory concepts.

Challenges in Mechatronics Engineering

Overcoming Interdisciplinary Barriers

The biggest strength of mechatronics – its interdisciplinary nature – can also be a significant challenge. Effectively integrating mechanical, electrical, and software components requires engineers to communicate across traditional disciplinary boundaries. Mechanical engineers might not fully grasp the limitations of sensor electronics, while software developers may underestimate the complexities of physical dynamics.

Successful mechatronics projects require teams where members have a foundational understanding of each other's domains and can speak a common technical language. Breaking down communication silos, fostering collaboration, and utilizing integrated design tools are crucial. Engineers must be willing to learn concepts outside their primary area of expertise.

Managing the complexity arising from the interaction between different subsystems is also demanding. A change in a mechanical component might necessitate adjustments in control software and sensor calibration, requiring careful system-level analysis and testing.

Ethical Considerations in Automation

As mechatronics drives increasing levels of automation, ethical considerations become prominent. One major concern is potential job displacement as machines take over tasks previously performed by humans. Engineers must consider the societal impact of the technologies they create and participate in discussions about workforce transition and reskilling.

Safety is another critical ethical dimension, especially with autonomous systems like self-driving cars or collaborative robots working alongside humans. Designing systems that are robust, reliable, and fail-safe is an ethical obligation. This involves rigorous testing, validation, and considering edge cases and potential failure modes.

Questions of bias in AI algorithms used within mechatronic systems (e.g., facial recognition in security robots) and data privacy (e.g., data collected by smart devices) also fall under the ethical umbrella. Mechatronics engineers need awareness of these issues and should strive to design systems that are fair, transparent, and respectful of human values.

Keeping Pace with Technological Change

Mechatronics is a rapidly evolving field. New sensors, more powerful microcontrollers, novel actuator technologies, and advancements in software and AI emerge constantly. This rapid technological obsolescence presents a continuous challenge for engineers to keep their skills and knowledge up-to-date.

Lifelong learning is not just beneficial; it's essential for a sustained career in mechatronics. This requires proactively seeking out new information through online courses, attending industry conferences and workshops, reading technical journals and publications, and experimenting with new tools and platforms.

Companies also play a role by investing in employee training and development. However, the onus is largely on individual engineers to remain curious, adaptable, and committed to continuous professional development to stay relevant in this dynamic field.

Using platforms like OpenCourser to find the latest courses on emerging technologies is one way to stay current. Browsing categories like Robotics or Artificial Intelligence can surface relevant learning opportunities.

Future Trends in Mechatronics

Convergence with AI and IoT

The future of mechatronics is deeply intertwined with Artificial Intelligence (AI) and the Internet of Things (IoT). AI algorithms will enable mechatronic systems to become more autonomous, adaptive, and intelligent, capable of learning from data and making complex decisions in real-time. This applies to everything from smarter industrial robots to more capable autonomous vehicles.

IoT connectivity allows mechatronic devices to communicate with each other and with centralized cloud platforms. This enables large-scale data collection for analysis and optimization, remote monitoring and control, and the coordination of distributed systems (like fleets of autonomous robots or smart grids). The combination of localized intelligence (AI) and network connectivity (IoT) will unlock new capabilities and applications.

Engineers will need skills in both traditional mechatronics disciplines and these emerging areas, including data analytics, cloud computing, cybersecurity (for securing connected devices), and AI/ML algorithm implementation.

This course explores IoT sensors and devices.

Sustainable Mechatronic Systems

Sustainability is becoming an increasingly important driver in engineering design, and mechatronics is no exception. Future trends will focus on developing systems that are more energy-efficient, use environmentally friendly materials, and have longer lifespans or are easier to repair and recycle.

This includes designing more efficient electric motors and power electronics, optimizing control algorithms to minimize energy consumption during operation, developing robots for recycling and waste management, and creating smart building systems that reduce energy usage. Mechatronics also plays a role in developing and controlling renewable energy systems like wind turbines and solar trackers.

Engineers will need to consider the entire lifecycle environmental impact of their designs, incorporating principles of eco-design and circular economy into the mechatronics development process.

Advancements in Human-Robot Interaction (HRI)

As robots move beyond structured industrial environments and into homes, workplaces, and public spaces, the interaction between humans and robots (HRI) becomes critical. Future mechatronic systems, especially collaborative robots ("cobots") and service robots, will need to operate safely and intuitively alongside people.

This involves developing advanced sensors for detecting human presence and intent, sophisticated control algorithms for safe motion planning in dynamic human environments, and intuitive interfaces (voice, gesture, graphical) for communication. Research in areas like soft robotics (robots made from compliant materials) also aims to improve safety during physical interaction.

Mechatronics engineers working in HRI will need to blend technical skills with an understanding of human factors, psychology, and user experience design to create robots that are not only functional but also accepted and trusted by humans.

This course introduces HRI concepts.

These books cover robotics fundamentals relevant to HRI.

Frequently Asked Questions (FAQs)

Which industries hire the most mechatronics engineers?

Manufacturing, automotive, aerospace, consumer electronics, and robotics are traditionally the largest employers. However, demand is growing rapidly in logistics/warehousing, biomedical devices, defense, and energy sectors as automation and intelligent systems become more prevalent across the board.

Is a graduate degree necessary for career advancement?

Not always, but it can be beneficial. A bachelor's degree is typically sufficient for entry-level and many mid-career roles. A Master's or Ph.D. is often advantageous or required for specialized R&D positions, roles involving cutting-edge technology development, university research, or senior technical leadership roles where deep expertise is needed.

How does mechatronics differ from robotics engineering?

Robotics engineering is arguably a specialization within the broader field of mechatronics. While mechatronics encompasses any system integrating mechanical, electrical, and computer control (e.g., an ABS system, a smart thermostat), robotics specifically focuses on machines designed to sense, think, and act in the physical world, often involving mobility and manipulation. Most robotics engineers have a strong mechatronics foundation.

What soft skills complement technical expertise?

Excellent problem-solving, critical thinking, and analytical skills are crucial. Because mechatronics is interdisciplinary, strong communication and teamwork abilities are vital for collaborating effectively. Adaptability, creativity, attention to detail, and a commitment to lifelong learning are also highly valued due to the complexity and rapid evolution of the field.

Are mechatronics engineers at risk of automation?

It's highly unlikely in the foreseeable future. While mechatronics engineers design automated systems, the design, integration, troubleshooting, and innovation involved in creating these complex systems require high-level engineering judgment, creativity, and problem-solving skills that are difficult to automate. If anything, the increasing trend towards automation fuels the demand for mechatronics engineers.

How transferable are mechatronics skills internationally?

Mechatronics skills are generally very transferable globally. The fundamental principles of physics, mathematics, electronics, and control theory are universal. While specific industry standards or software preferences might vary slightly by region, the core competencies are in demand worldwide, especially in industrialized nations with strong manufacturing, automotive, or technology sectors. Engineering accreditation agreements (like the Washington Accord) can also facilitate international recognition of degrees.

Embarking on a career as a Mechatronics Engineer involves a commitment to continuous learning and tackling complex, interdisciplinary challenges. It offers the opportunity to be at the forefront of technological innovation, designing the intelligent systems that shape our modern world. Whether you pursue a traditional degree, leverage online learning, or combine both, the path requires dedication, but the potential rewards – both intellectually and professionally – are significant.