Semiconductor Engineer

A Comprehensive Guide to a Career as a Semiconductor Engineer

Semiconductor engineering is a specialized field of electrical engineering that focuses on the design, development, manufacturing, and testing of semiconductor devices. These devices, commonly known as chips or integrated circuits (ICs), are the foundational components of most modern electronic systems. From the smartphones in our pockets to the complex servers powering the internet and the advanced systems in automobiles and medical equipment, semiconductor engineers are at the forefront of technological advancement. This career involves a deep understanding of physics, materials science, and electronics to manipulate semiconducting materials like silicon to create these intricate and powerful components.

Working as a semiconductor engineer can be incredibly engaging. Engineers in this field often find themselves solving complex puzzles at the atomic level, pushing the boundaries of what's technologically possible. They might be involved in creating the next generation of processors that are faster and more energy-efficient, or developing new types of sensors with unprecedented capabilities. The impact of this work is vast, influencing global economies and shaping the future of technology by enabling innovations in areas like artificial intelligence, quantum computing, and renewable energy.

Key Responsibilities of a Semiconductor Engineer

The role of a semiconductor engineer is multifaceted, involving a range of technical and collaborative tasks. These professionals are integral to the entire lifecycle of a semiconductor device, from initial concept to mass production and beyond. Their responsibilities often require a blend of deep theoretical knowledge and practical, hands-on expertise.

Designing and Fabricating Semiconductor Devices

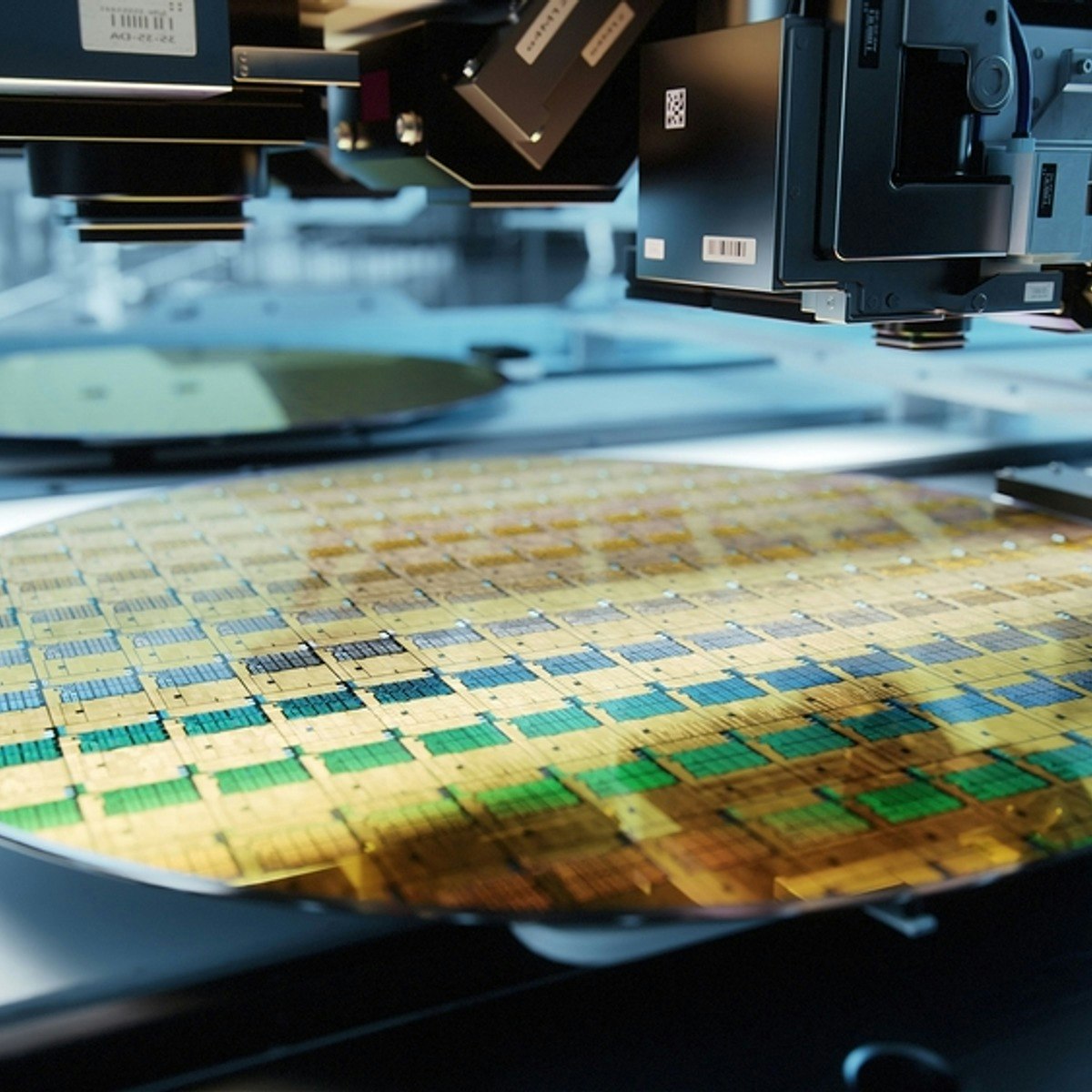

A primary responsibility for many semiconductor engineers is the design of semiconductor devices and integrated circuits. This involves using sophisticated computer-aided design (CAD) tools to create the intricate layouts of transistors, resistors, capacitors, and their interconnections on a chip. Engineers must consider factors like performance, power consumption, and manufacturing feasibility. Once a design is finalized, fabrication begins. This highly complex process involves numerous steps, often performed in specialized cleanroom environments. Engineers oversee and refine these fabrication processes to ensure the designs are accurately translated into physical devices.

For those new to the concept, imagine designing a miniature city, where buildings are transistors and roads are the wires connecting them. The design engineer is like the city planner, deciding where everything goes to make the city function efficiently. Fabrication is like constructing this microscopic city, layer by layer, using incredibly precise techniques.

To gain a foundational understanding of semiconductor device principles and processing, aspiring engineers can explore online courses. These resources can provide a solid introduction to the complex world of chip design and manufacturing.

Optimizing Manufacturing Processes

Semiconductor manufacturing is a delicate and highly optimized operation. Engineers in this area focus on improving the efficiency, yield (the percentage of good chips produced), and quality of manufacturing processes like photolithography, etching, deposition, and ion implantation. Photolithography, for instance, is a critical step akin to photographic printing, where patterns are transferred onto the silicon wafer. Etching then selectively removes material to create the desired features. Process engineers continuously monitor these steps, analyze data, and implement changes to reduce defects and costs. They work to make these intricate processes more reliable and repeatable.

Consider a bakery trying to produce perfectly identical cookies every time. A process engineer in a semiconductor fab (fabrication plant) has a similar goal, but on a microscopic scale with far more complex "recipes" and "baking" conditions. Any tiny deviation can ruin a batch of chips worth a significant amount of money.

Understanding the intricacies of these manufacturing steps is crucial. Online courses can offer insights into various semiconductor processes and the challenges involved in optimizing them.

Ensuring Quality Control and Performing Failure Analysis

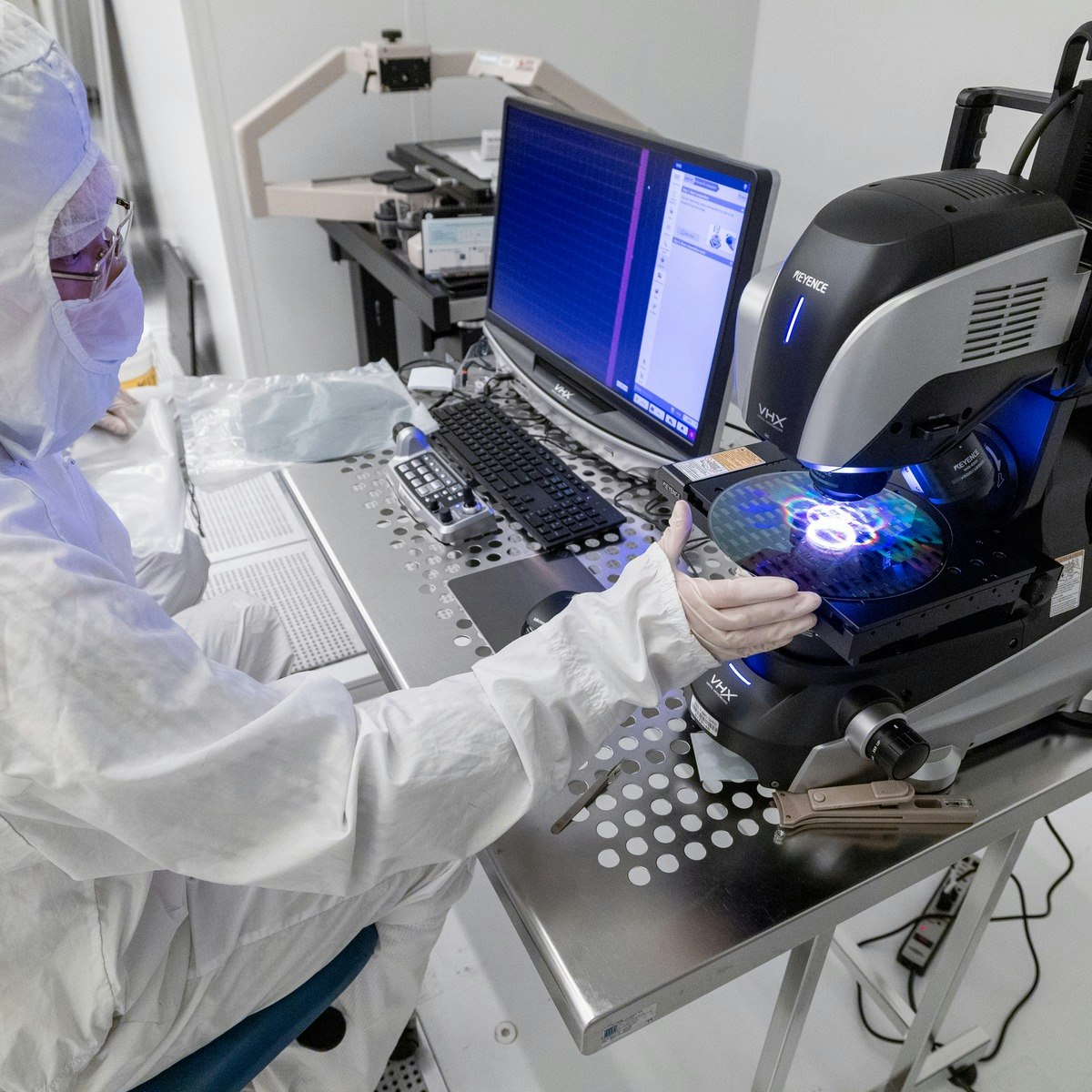

Quality control is paramount in semiconductor manufacturing. Engineers design and implement testing procedures at various stages to ensure that devices meet stringent specifications for performance, reliability, and longevity. This involves using specialized equipment to measure electrical characteristics and identify any defects. When devices fail, failure analysis engineers step in. They act like detectives, meticulously examining faulty chips to determine the root cause of the failure. This information is then fed back to design and process teams to prevent future occurrences, contributing to a cycle of continuous improvement.

Think of it like a high-stakes quality check on a luxury car assembly line. Every component must be perfect. If a car fails inspection, a team of experts will dissect it to understand exactly what went wrong and how to fix it for all future cars. Semiconductor quality and failure analysis operate on a similar principle but at a much smaller and more complex scale.

To delve into the specifics of ensuring chip quality and analyzing failures, consider exploring resources that cover semiconductor testing and reliability.

Collaborating with Cross-Functional Teams

Semiconductor engineering is rarely a solo endeavor. Engineers work closely with a diverse range of professionals, including materials scientists who develop new semiconducting materials, electrical engineers who design the broader systems into which chips are integrated, software engineers who develop testing programs, and manufacturing technicians who operate the fabrication equipment. Effective communication and teamwork are essential to navigate the complexities of chip development and production, ensuring that all aspects of the project are aligned and progressing smoothly. This collaborative environment fosters innovation and problem-solving across different disciplines.

Imagine a team building a complex spacecraft. You have experts in propulsion, navigation, life support, and materials, all needing to work together seamlessly. A semiconductor engineer is often a key player in a similar interdisciplinary team, ensuring their specialized component integrates perfectly with the larger technological system.

Formal Education Pathways

Embarking on a career as a semiconductor engineer typically begins with a strong educational foundation in science and engineering. The specific path can vary, but certain disciplines and advanced studies are particularly relevant for aspiring professionals in this cutting-edge field.

Undergraduate Degrees: Laying the Groundwork

A bachelor's degree is generally the minimum educational requirement for entry-level positions in semiconductor engineering. The most common and relevant undergraduate degrees include Electrical Engineering, Materials Science and Engineering, and Physics. An Electrical Engineering curriculum often provides a broad understanding of circuits, electronics, and electromagnetism, all crucial for chip design and function. Materials Science and Engineering focuses on the properties and processing of materials, including the semiconductors themselves. A Physics degree, particularly with a concentration in solid-state physics or condensed matter physics, offers deep insights into the fundamental principles governing semiconductor behavior.

Regardless of the specific major, coursework in mathematics (especially calculus and differential equations) and physics (covering mechanics, electricity, magnetism, and modern physics) is foundational. Strong analytical and problem-solving skills, honed through these rigorous programs, are essential for success. Many universities also offer specialized elective courses in semiconductor devices, microelectronics, or VLSI (Very Large Scale Integration) design, which can provide a valuable head start.

For students looking to supplement their formal education or explore the basics before committing to a degree program, online platforms like OpenCourser's engineering section offer a wealth of introductory and specialized courses.

Graduate Studies: Specializing in the Field

While a bachelor's degree can open doors to some roles, many semiconductor engineers, particularly those in research and development or highly specialized design roles, pursue graduate studies. A Master of Science (M.S.) or Doctor of Philosophy (Ph.D.) degree allows for deeper specialization in areas like semiconductor physics, nanoelectronics, device fabrication, or integrated circuit design. Graduate programs often involve intensive research projects, providing hands-on experience with advanced tools and techniques. An M.S. can provide a competitive edge and lead to roles with greater responsibility and higher earning potential. A Ph.D. is often required for positions in cutting-edge research, academia, or leading advanced development teams.

Specializations at the graduate level might include areas like compound semiconductors (such as Gallium Nitride - GaN, or Gallium Arsenide - GaAs), which offer advantages over silicon for certain applications like high-frequency communications or power electronics. Another area is nanoelectronics, which deals with the design and fabrication of devices at the nanometer scale.

Consider these books to gain a deeper understanding of computer architecture and processor design, which are closely related to semiconductor engineering.

PhD Research Areas: Pushing the Frontiers

For those aiming to be at the vanguard of semiconductor innovation, a Ph.D. offers the opportunity to contribute to groundbreaking research. Current PhD research often focuses on overcoming the limitations of existing technologies and exploring entirely new paradigms. Key research areas include the development and characterization of emerging materials beyond silicon, such as Gallium Nitride (GaN) for power electronics, two-dimensional (2D) materials like graphene or transition metal dichalcogenides (TMDCs) for ultra-thin and flexible electronics, or materials for quantum computing components. Researchers might also investigate novel device architectures, advanced lithography techniques for patterning ever-smaller features, or new approaches to chip packaging and integration.

The pursuit of a PhD in this field is an intensive commitment, demanding intellectual curiosity, perseverance, and a passion for discovery. It positions individuals to lead research teams in industry, national laboratories, or academic institutions, shaping the future trajectory of semiconductor technology.

Exploring topics related to the fundamental building blocks of semiconductors, such as MOSFETs, can provide context for advanced research.

Laboratory and Cleanroom Training: Essential Hands-On Experience

Theoretical knowledge alone is insufficient for a semiconductor engineer. Practical experience, particularly in laboratory and cleanroom environments, is critical. Cleanrooms are specially designed facilities with highly controlled levels of dust and other contaminants, essential for the fabrication of sensitive semiconductor devices. University programs in relevant fields often include laboratory courses where students gain hands-on experience with semiconductor processing equipment (like deposition systems, etchers, and lithography tools) and characterization instruments (such as microscopes and electrical probers). This practical training allows students to understand the real-world challenges and intricacies of making and testing chips. Internships in semiconductor companies provide invaluable on-the-job training in industrial cleanroom settings and exposure to state-of-the-art processes.

Imagine trying to perform surgery in a dusty room – the risk of contamination and failure would be enormous. Semiconductor fabrication is even more sensitive to impurities, which is why cleanrooms are orders of magnitude cleaner than a surgical operating room. Working in this environment requires specialized protocols and attire.

Online Learning and Skill Development

The rapidly evolving nature of the semiconductor industry means that continuous learning and skill development are essential, not just for aspiring engineers but also for seasoned professionals. Online learning platforms offer a flexible and accessible way to acquire new knowledge, master specific tools, or even pivot into this dynamic field. While a formal degree often forms the bedrock of a semiconductor engineer's qualifications, online courses and resources can effectively supplement this education or provide pathways for those with different backgrounds.

Core Technical Skills: VLSI Design and TCAD Simulation

Several core technical skills are central to semiconductor engineering. VLSI (Very Large Scale Integration) design is the process of creating integrated circuits by combining millions or even billions of transistors on a single chip. This involves understanding digital and analog circuit design, logic synthesis, layout techniques, and verification methodologies. Another crucial area is Technology Computer-Aided Design (TCAD). TCAD tools are software programs that simulate the fabrication processes (like etching and deposition) and the electrical behavior of semiconductor devices. Engineers use TCAD to model and predict how changes in design or manufacturing parameters will affect device performance, reducing the need for costly and time-consuming physical experiments.

Think of VLSI design as architectural drafting for microchips, and TCAD as a sophisticated virtual laboratory where engineers can test their "blueprints" and "manufacturing recipes" before committing to actual production. These skills are highly sought after in the industry.

Online courses can provide focused training in VLSI design principles and the use of specific TCAD software, enabling learners to build practical expertise. Consider these courses to start your journey.

Software Proficiency: SPICE, MATLAB, and Silvaco

Proficiency in specific software tools is a hallmark of a productive semiconductor engineer. SPICE (Simulation Program with Integrated Circuit Emphasis) and its variants are industry-standard tools for simulating the behavior of electronic circuits. MATLAB is a versatile programming and numeric computing platform widely used for data analysis, algorithm development, and modeling in various engineering disciplines, including semiconductor characterization and signal processing. EDA (Electronic Design Automation) tool suites from companies like Cadence, Synopsys, and Siemens (formerly Mentor Graphics) are extensively used for chip design and verification. For TCAD, software from providers such as Silvaco or Synopsys (Sentaurus) is common.

Mastering these software packages is akin to a craftsman learning to use specialized tools. Each piece of software serves a distinct purpose in the complex workflow of designing, simulating, and testing semiconductor devices. Online tutorials and specialized courses can accelerate the learning curve for these powerful tools.

Many online learning platforms offer courses that cover the fundamentals and advanced applications of these essential software packages. For those looking to explore circuit analysis, which often utilizes SPICE, this course might be beneficial.

Project-Based Learning: Designing Simple Circuits or Process Flows

Theoretical knowledge and software skills are best solidified through practical application. Project-based learning, where individuals or teams work on designing a simple circuit, simulating a basic fabrication process, or analyzing device data, offers invaluable experience. This could involve designing a fundamental logic gate, modeling a MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor), or developing a simplified process flow for a particular device structure. Such projects help bridge the gap between academic concepts and real-world engineering challenges. They also provide tangible evidence of one's skills to potential employers.

OpenCourser’s extensive catalog, which can be explored via the browse page, includes courses that incorporate hands-on projects. Furthermore, many universities and online communities offer resources and support for independent projects. Building a portfolio of such projects can significantly enhance a resume and demonstrate practical capabilities during job interviews.

Engaging with introductory device courses can provide the foundational knowledge needed to tackle such projects.

Certifications vs. Degree Equivalency in Industry

While a traditional engineering degree is the most common pathway into semiconductor engineering, the role of certifications is evolving. For highly specialized tools or methodologies, certifications offered by software vendors or industry organizations can demonstrate a specific level of proficiency. However, it's important to understand that in most core engineering roles, certifications are generally seen as supplementary to, rather than a replacement for, a relevant bachelor's or graduate degree. The depth of foundational knowledge in physics, mathematics, and engineering principles provided by a degree program is difficult to replicate solely through certifications.

For individuals looking to transition from related technical fields or those in technician roles aiming to move into engineering positions, a combination of targeted online courses, practical projects, and potentially a relevant graduate certificate or degree might be a viable path. The semiconductor industry does face talent shortages, and companies are increasingly open to candidates who can demonstrate strong skills and a commitment to continuous learning, regardless of their precise educational trajectory. Always research the specific requirements for the roles you are interested in. Tools like OpenCourser's "Save to list" feature can help you curate and compare relevant educational resources as you plan your skill development.

Career Progression and Specializations

A career in semiconductor engineering offers diverse pathways for growth and specialization. Starting from entry-level positions, engineers can advance to roles with increasing responsibility, technical depth, or managerial scope. The industry's dynamism also fosters the emergence of new specializations driven by technological advancements.

Entry-Level Roles and Early Career Development

Graduates with a relevant bachelor's degree typically enter the semiconductor industry in roles such as Process Engineer, Device Characterization Engineer, Test Engineer, or Junior Design Engineer. Process Engineers work in fabrication plants (fabs) to monitor and improve manufacturing steps. Device Characterization Engineers test and analyze the performance of newly fabricated semiconductor devices. Test Engineers develop and implement test programs and hardware to ensure chips meet quality standards. Junior Design Engineers assist senior engineers in designing and simulating circuits.

In these early years, engineers gain hands-on experience, learn industry-specific tools and methodologies, and develop a deeper understanding of the semiconductor ecosystem. This period is crucial for building a strong technical foundation and identifying areas of interest for future specialization. According to salary.com, the average salary for a Semiconductor Engineer in the US in 2023 was $118,154, though entry-level salaries would typically be lower and can vary significantly by location, company, and specific role. Some sources indicate entry-level salaries for technicians can be around $57,000, while semiconductor engineers might start around $77,000 to $96,000 annually.

Gaining broad exposure to different facets of semiconductor development can be beneficial early on. Online courses can help fill knowledge gaps or provide refreshers on specific topics.

Mid-Career Paths: Leadership and Technical Expertise

After gaining several years of experience, semiconductor engineers typically have opportunities to advance along either a technical or managerial track. Those who excel in technical problem-solving and innovation might become Senior Process Engineers, Principal Design Engineers, or R&D Team Leads, focusing on more complex projects and mentoring junior staff. They might lead the development of new manufacturing processes, design critical sections of next-generation chips, or spearhead research into novel device technologies.

Alternatively, engineers with strong organizational and interpersonal skills may move into management roles, such as Fab Manager, Engineering Manager, or Project Manager. These positions involve overseeing teams, managing budgets and schedules, and interfacing with other departments or customers. A Fab Manager, for example, is responsible for the overall operations of a semiconductor manufacturing plant. Mid-career salaries can range significantly, often from $80,000 to over $150,000, depending on experience, specialization, and leadership responsibilities.

Furthering one's education or gaining specialized knowledge in areas like advanced packaging or system-level design can open up more mid-career opportunities. These books offer insights into the architecture that underpins these complex systems.

Senior Positions and Executive Leadership

With extensive experience and a proven track record of success, semiconductor engineers can reach senior technical and executive positions. Roles like Chief Technology Officer (CTO) in a semiconductor firm involve setting the long-term technology vision and strategy for the company. Other senior roles might include Director of Engineering, Vice President of Manufacturing, or Senior Fellow/Distinguished Engineer, recognizing individuals for their profound technical contributions. These positions carry significant responsibility and influence, shaping the direction of major projects and the company's competitive standing. Salaries at this level can be substantial, often well into six figures and potentially higher with stock options and bonuses, reflecting the critical expertise and leadership required.

Reaching these echelons typically requires not only deep technical expertise but also strong leadership qualities, strategic thinking, and often, advanced degrees or significant contributions to the field in the form of patents or influential publications. Continuous learning and staying abreast of industry trends remain vital even at these senior levels.

Emerging Specializations: Adapting to New Frontiers

The semiconductor industry is in a constant state of evolution, leading to the emergence of new and exciting specializations. Photonic Integrated Circuits (PICs), which use light instead of electrons for transmitting data, are becoming increasingly important for high-speed communications and sensing. Neuromorphic computing, inspired by the architecture of the human brain, aims to create chips that can learn and process information in a more efficient and human-like way. Engineers specializing in these areas work on novel device designs, materials, and system architectures.

Other emerging fields include quantum computing components, which require expertise in quantum physics and specialized semiconductor materials, and advanced packaging technologies like 3D integration and chiplets, which involve stacking multiple dies or components in a single package to improve performance and functionality. As these technologies mature, they create new career opportunities for engineers with the right skills and knowledge. Keeping an eye on these trends through resources like OpenCourser Notes can help engineers anticipate future skill demands.

Courses that delve into the manufacturing aspects, particularly packaging, are relevant for these emerging areas.

Industry Applications and Market Impact

Semiconductors are the unsung heroes of the modern technological world, forming the critical foundation for a vast array of applications that impact nearly every aspect of daily life and the global economy. The innovations driven by semiconductor engineers translate directly into transformative products and services across numerous industries. The semiconductor market itself is a significant global industry, with projected revenues expected to continue growing and potentially reach over $1 trillion by 2030.

Role in AI Hardware (GPUs, TPUs)

The explosion of Artificial Intelligence (AI) and Machine Learning (ML) is heavily reliant on specialized semiconductor hardware. Graphics Processing Units (GPUs), initially designed for rendering images in video games, have proven exceptionally well-suited for the parallel processing demands of AI algorithms. Companies like NVIDIA and AMD are major players in this space. Beyond GPUs, custom-designed AI accelerator chips, such as Google's Tensor Processing Units (TPUs) and other application-specific integrated circuits (ASICs), are being developed to optimize performance for specific AI workloads like neural network training and inference. Semiconductor engineers are at the heart of designing these complex chips, pushing the boundaries of computational power and energy efficiency to enable increasingly sophisticated AI models. The demand for these high-performance chips is a major driver of growth in the semiconductor industry.

Understanding the architecture of these powerful chips is key. Consider these resources for foundational knowledge.

Automotive Semiconductor Demands (EVs, Autonomous Driving)

The automotive industry is rapidly transforming into a major consumer of semiconductors. Modern vehicles, especially Electric Vehicles (EVs) and those equipped with Advanced Driver-Assistance Systems (ADAS) and autonomous driving capabilities, are packed with chips. These semiconductors control everything from powertrain and battery management in EVs to infotainment systems, safety features (like automatic emergency braking and lane assist), and the complex sensor fusion and decision-making required for self-driving cars. The shift towards EVs and more autonomous vehicles is creating a surge in demand for a wide variety of chips, including microcontrollers (MCUs), sensors, power semiconductors, and high-performance processors. This trend is expected to continue, making automotive a key growth sector for the semiconductor market.

The increasing electronic content in cars highlights the importance of reliable and robust semiconductor components designed to withstand the demanding automotive environment.

Geopolitical Factors in Chip Manufacturing

The manufacturing of semiconductors has become a significant geopolitical issue. The global supply chain for chips is complex and geographically concentrated, with a few regions, notably Taiwan (home to TSMC, the world's largest dedicated independent semiconductor foundry), South Korea (Samsung), and the United States (Intel), dominating advanced manufacturing. This concentration creates vulnerabilities, as disruptions in one region due to political tensions, natural disasters, or other factors can have far-reaching impacts on global industries. Consequently, many countries and regions, including the US with its CHIPS Act and Europe with its own initiatives, are investing heavily to bolster domestic chip production and research to enhance their technological sovereignty and supply chain resilience. These efforts involve building new fabrication plants ("fabs") and fostering local talent.

These geopolitical dynamics influence investment decisions, trade policies, and international collaborations within the semiconductor industry. For an overview of the geopolitical landscape, consider resources like the IDC's analysis on geopolitical shifts.

Supply Chain Vulnerabilities and Market Cycles

The semiconductor industry is known for its cyclical nature, with periods of high demand and shortages often followed by periods of oversupply and price adjustments. Recent global events, such as the COVID-19 pandemic, exposed significant vulnerabilities in the semiconductor supply chain, leading to widespread chip shortages that affected numerous industries, from automotive to consumer electronics. These shortages highlighted the critical need for more resilient and diversified supply chains. Factors contributing to these cycles include long lead times for building new manufacturing capacity (a new fab can take years and billions of dollars to construct), fluctuations in global economic conditions, and rapid technological shifts. Semiconductor companies and their customers must navigate these market dynamics carefully. The industry is actively working on strategies to improve supply chain visibility and flexibility to mitigate future disruptions.

Deloitte’s global semiconductor industry outlook often provides insights into these trends and challenges.

Challenges in Semiconductor Engineering

While semiconductor engineering offers exciting opportunities and drives technological progress, it is not without its significant challenges. Engineers in this field grapple with fundamental physical limits, complex manufacturing hurdles, environmental responsibilities, and the constant pressure to innovate in a highly competitive global landscape. These challenges require ingenuity, significant investment, and collaborative efforts to overcome.

Physical Limits of Moore's Law

For decades, the semiconductor industry has been guided by Moore's Law, an observation made by Intel co-founder Gordon Moore, which predicted that the number of transistors on a microchip would double approximately every two years, leading to increased performance and decreased cost. However, as transistors have shrunk to the nanometer scale—approaching the size of individual atoms—engineers are encountering fundamental physical limits. Phenomena like quantum tunneling and increased heat generation become problematic at such small dimensions, making further miniaturization increasingly difficult and expensive. While the industry continues to innovate with new materials, device architectures (like FinFETs and gate-all-around transistors), and advanced packaging techniques (like 3D stacking), the traditional scaling predicted by Moore's Law is undeniably slowing down. This pushes engineers to find novel ways to continue improving computing power and efficiency beyond simple shrinking.

To understand the historical context and ongoing implications of this challenge, exploring Moore's Law in more detail can be very insightful.

Environmental Concerns: Water and Energy Usage in Fabs

Semiconductor fabrication is an incredibly resource-intensive process. Manufacturing plants (fabs) consume vast amounts of ultrapure water for cleaning wafers between process steps and enormous quantities of electricity to power the sophisticated equipment and maintain the stringent cleanroom environments. For example, a single advanced fab can use millions of gallons of water per day. The energy consumption also contributes significantly to the industry's carbon footprint, especially if the energy is sourced from fossil fuels. Additionally, the manufacturing processes involve various hazardous chemicals and generate waste products that require careful management and disposal. There is a growing focus within the industry and among regulatory bodies to improve sustainability by reducing water and energy consumption, increasing the use of renewable energy, finding greener chemicals, and minimizing waste. The NIST (National Institute of Standards and Technology) is one organization that highlights these environmental aspects.

This challenge requires semiconductor engineers to develop more eco-friendly manufacturing processes and materials without compromising device performance or cost-effectiveness.

Export Controls and Intellectual Property Security

The strategic importance of semiconductor technology has led to increased geopolitical tensions and governmental interventions, including export controls and concerns over intellectual property (IP) security. Governments may restrict the sale of advanced semiconductor manufacturing equipment or high-performance chips to certain countries for national security reasons. This can impact global supply chains and the ability of companies to access critical technologies or markets. Furthermore, the design and manufacturing of semiconductors involve highly valuable intellectual property. Protecting this IP from theft or unauthorized use is a major concern for companies, requiring robust security measures and legal frameworks. Navigating these complex trade regulations and ensuring IP protection are significant challenges for multinational semiconductor firms.

These controls and security measures add layers of complexity to international collaboration and competition within the semiconductor industry.

Talent Shortages in Advanced Technologies

The semiconductor industry is facing a growing challenge in attracting and retaining skilled talent, particularly in areas requiring highly specialized expertise such as advanced packaging, next-generation materials research, and AI chip design. As technology becomes more complex, the demand for engineers and technicians with advanced degrees and specific skill sets often outpaces the available supply. This talent shortage can hinder innovation and slow down the expansion of manufacturing capacity. Universities, industry, and governments are collaborating to address this gap through initiatives aimed at improving STEM education, offering specialized training programs, and encouraging more students to pursue careers in semiconductor engineering. Attracting a diverse workforce and retaining experienced professionals are key priorities for ensuring the long-term health and growth of the industry. According to one report, the semiconductor industry's workforce will need to grow by nearly 115,000 jobs by 2030, with a significant portion of these potentially going unfilled at current rates.

For those considering this career, the high demand for skilled professionals can translate into strong job prospects and competitive salaries. Platforms like OpenCourser can help individuals identify the skills needed for these in-demand roles and find relevant courses to build their expertise.

Future Trends in Semiconductor Engineering

The semiconductor industry is characterized by relentless innovation. Engineers are constantly exploring new materials, architectures, and manufacturing techniques to push the boundaries of performance, efficiency, and functionality. Several key trends are shaping the future of semiconductor engineering, promising exciting advancements and new opportunities.

Transition to Post-Silicon Materials

Silicon has been the workhorse of the semiconductor industry for decades, but it is approaching its physical limits for certain applications. To continue advancing performance, especially in areas like power electronics and high-frequency communication, researchers and engineers are actively investigating "post-silicon" materials. Wide-bandgap semiconductors like Gallium Nitride (GaN) and Silicon Carbide (SiC) are already gaining traction due to their ability to handle higher voltages, temperatures, and frequencies more efficiently than silicon. Beyond these, even more exotic materials are on the horizon. Two-dimensional (2D) materials like graphene (a single layer of carbon atoms) and transition metal dichalcogenides (TMDCs) offer unique electronic and optical properties that could enable ultra-thin, flexible, and highly efficient devices. The transition to these new materials presents significant research and manufacturing challenges but also holds the key to future breakthroughs.

This shift requires engineers to develop new process technologies and device designs tailored to the unique characteristics of these advanced materials.

Chiplet Architectures and 3D Integration

As making single, monolithic chips larger and more complex becomes increasingly challenging and costly (due to Moore's Law slowing down), new design paradigms are emerging. Chiplet-based architectures are one such trend. Instead of designing one large System-on-Chip (SoC), a chiplet approach involves creating smaller, specialized dies (chiplets) that perform specific functions. These chiplets can then be mixed and matched and interconnected within a single package, almost like Lego blocks. This offers greater design flexibility, potentially lower costs, and improved yield, as a defect on one small chiplet doesn't mean discarding an entire large chip.

Complementing chiplets is the advancement in 3D integration (or 3D-IC) technology. This involves stacking multiple layers of silicon dies or chiplets vertically and connecting them using through-silicon vias (TSVs). This vertical stacking allows for shorter interconnects between different functional blocks, leading to higher bandwidth, lower power consumption, and a smaller overall footprint. Both chiplet and 3D integration strategies require significant innovation in packaging technologies, interconnect methods, and thermal management.

Understanding advanced packaging is becoming increasingly important for semiconductor engineers.

Quantum Dot-Based Semiconductors

Quantum dots (QDs) are nanoscale semiconductor crystals whose electronic and optical properties change with their size and shape. This unique characteristic makes them promising for a variety of applications. In display technology, QDs are already used to enhance color purity and energy efficiency in QLED TVs. Beyond displays, quantum dots are being explored for use in highly sensitive photodetectors, next-generation solar cells, quantum computing (as qubits), and biomedical imaging. Semiconductor engineers working in this area focus on precisely controlling the synthesis of quantum dots, understanding their quantum mechanical behavior, and integrating them into functional devices. The ability to tune their properties by simply changing their size opens up a vast design space for novel electronic and photonic components.

This field merges materials science, quantum physics, and semiconductor device engineering.

AI-Driven Design Automation

The complexity of modern semiconductor design, with billions of transistors and intricate interconnections, is immense. Artificial intelligence (AI) and machine learning (ML) are increasingly being used to automate and optimize various stages of the chip design process. AI algorithms can assist in tasks like logic synthesis, physical layout (placement and routing of components), design verification, and even the generation of test programs. By learning from vast datasets of previous designs and performance metrics, AI can help engineers explore larger design spaces more quickly, identify optimal solutions, and reduce the time and effort required to bring a new chip to market. AI is also being applied to optimize manufacturing processes, predict yields, and detect defects in real-time. The synergy between AI and semiconductor engineering is a two-way street: semiconductors enable AI, and AI, in turn, helps design better semiconductors.

Proficiency in data analysis and an understanding of AI/ML principles can be valuable assets for future semiconductor engineers. Exploring the intersection of AI and hardware design can lead to innovative solutions.

Global Semiconductor Engineer Workforce Dynamics

The semiconductor industry is a truly global enterprise, with research, design, manufacturing, and talent distributed across numerous countries. Understanding the workforce dynamics, including regional hubs, talent mobility, and the nature of work in this sector, is crucial for anyone considering a career as a semiconductor engineer.

Regional Hubs: TSMC, Intel, ASML, and Beyond

Certain regions and companies have established themselves as major powerhouses in the semiconductor world. Taiwan, largely due to Taiwan Semiconductor Manufacturing Company (TSMC), is a dominant force in advanced chip manufacturing (foundry services). The United States is home to leading design companies and integrated device manufacturers (IDMs) like Intel, NVIDIA, AMD, and Qualcomm, and is significantly investing in onshore manufacturing capabilities. South Korea, with giants like Samsung, is another key player in both memory and logic chip production. The Netherlands is critical to the ecosystem, primarily because of ASML, the world's leading supplier of advanced photolithography equipment essential for cutting-edge chipmaking. Other significant players and growing regions include Japan, China, and parts of Europe, all making strategic investments to bolster their positions in the global semiconductor landscape. These hubs attract a high concentration of engineering talent and investment.

The presence of these major companies and the ecosystems that develop around them create concentrated areas of job opportunities for semiconductor engineers.

Immigration Policies and the Quest for Talent

Given the highly specialized skills required and the global nature of the industry, immigration policies play a significant role in the semiconductor workforce. Many leading semiconductor nations rely on international talent to fill critical engineering and research positions. For example, a substantial portion of postgraduate students in STEM fields in the U.S. are international students, many of whom go on to work in the tech industry, including semiconductors. However, restrictive immigration policies can make it challenging for companies to recruit and retain top global talent, potentially hindering innovation and growth. Conversely, policies that facilitate the immigration of skilled workers can give a country a competitive edge. The global competition for semiconductor talent is fierce, and nations are increasingly recognizing the need for policies that attract and retain these highly skilled professionals.

According to a report by the Semiconductor Industry Association (SIA) and Oxford Economics, the U.S. semiconductor industry faces a significant talent gap, and retaining more international advanced degree students is a key recommendation.

Cross-Cultural Collaboration in Multinational R&D Teams

Semiconductor research and development (R&D) is often a global, collaborative effort. Large multinational corporations have R&D centers and design teams spread across different countries. This means that semiconductor engineers frequently work in cross-cultural teams, collaborating with colleagues from diverse backgrounds and nationalities. Effective communication, cultural sensitivity, and the ability to work cohesively in a global environment are increasingly important skills. While English is often the common language of business and technology, understanding and appreciating different cultural perspectives can enhance teamwork and innovation. These international collaborations allow companies to tap into a wider talent pool and leverage diverse expertise to solve complex technical challenges.

This global interconnectedness means that projects can be worked on around the clock, with teams in different time zones contributing to different stages of development.

Remote Work Limitations in Fabrication Roles

While some aspects of semiconductor engineering, particularly in design, simulation, and software development, can lend themselves to remote or hybrid work arrangements, many roles, especially those directly involved in manufacturing and hardware testing, require an on-site presence. Fabrication engineers, equipment engineers, and many test and characterization engineers must work within the specialized cleanroom environments of semiconductor fabs or in physical laboratories. The hands-on nature of operating and maintaining complex manufacturing equipment, conducting physical experiments, and handling delicate wafers means that fully remote work is often not feasible for these positions. However, even in these roles, aspects like data analysis, process monitoring, and documentation might offer some flexibility. The industry is continually exploring how technology can enable more efficient operations, but the physical nature of chip production imposes certain limitations on remote work for a significant portion of its engineering workforce.

This practical constraint is an important consideration for individuals evaluating career paths within semiconductor engineering.

Frequently Asked Questions (Career Focus)

Choosing a career path involves many questions. Here are answers to some common queries about becoming and working as a semiconductor engineer, aimed at helping you assess if this field aligns with your aspirations.

Is a PhD required for semiconductor engineering roles?

A PhD is not universally required for all semiconductor engineering roles, but it can be highly advantageous or even necessary for certain positions, particularly in research and development (R&D), advanced process development, and academia. Many entry-level and mid-career positions in areas like process engineering, device characterization, test engineering, and even some design roles can be accessed with a Bachelor's or Master's degree in a relevant engineering field (like Electrical Engineering, Materials Science, or Chemical Engineering) or Physics. A Master's degree often provides a competitive edge and may lead to higher starting salaries or more specialized roles compared to a Bachelor's alone.

However, for roles that involve pioneering new technologies, leading fundamental research, or working at the cutting edge of semiconductor physics and materials science, a PhD is typically preferred or required. Companies often seek PhDs for their deep theoretical knowledge, research skills, and ability to tackle highly complex, novel problems. Ultimately, the necessity of a PhD depends on your specific career goals within the vast field of semiconductor engineering. Many successful engineers have built rewarding careers with Bachelor's or Master's degrees, particularly in manufacturing, operations, and applied design roles.

For those considering advanced degrees, exploring online graduate certificates or courses can be a way to sample specialized topics before committing to a full degree program. Purdue University, for example, offers a Graduate Certificate in Microelectronics and Semiconductors.

How does this career differ from general electrical engineering?

Semiconductor engineering is a specialized branch within the broader field of electrical engineering. While general electrical engineering covers a wide array of topics including power systems, telecommunications, control systems, and electronics, semiconductor engineering focuses specifically on the design, fabrication, and behavior of semiconductor devices and integrated circuits (ICs). Think of electrical engineering as the overarching discipline, and semiconductor engineering as a deep dive into the fundamental building blocks of modern electronics.

A general electrical engineer might design a complex electronic system, like a communication device or a power grid controller, using existing ICs and other components. A semiconductor engineer, on the other hand, is involved in creating those ICs themselves – designing the transistors and their interconnections at the micro or nano-scale, developing the manufacturing processes to produce them, or researching new semiconductor materials and device structures. Semiconductor engineering typically requires a more profound understanding of solid-state physics, quantum mechanics, materials science, and chemistry compared to some other branches of electrical engineering. While there's overlap, particularly in circuit design, semiconductor engineering is distinct in its focus on the physics and fabrication of the chips themselves.

Many online courses cater to both general electrical engineering principles and more specialized semiconductor topics, allowing learners to explore both areas. You can explore a variety of Electrical Engineering courses on OpenCourser.

What industries hire the most semiconductor engineers?

Semiconductor engineers are primarily hired by companies directly involved in the semiconductor ecosystem. This includes large Integrated Device Manufacturers (IDMs) like Intel and Samsung, which design, manufacture, and sell their own chips. Fabless semiconductor companies, such as NVIDIA, Qualcomm, AMD, and Broadcom, design chips but outsource the manufacturing to dedicated foundries. These foundries, like TSMC, GlobalFoundries, and SMIC, are major employers of process and manufacturing engineers.

Beyond these core semiconductor companies, engineers also find opportunities with suppliers to the industry. This includes companies that manufacture the sophisticated equipment used in fabs (e.g., ASML, Applied Materials, Lam Research, Tokyo Electron), and those that provide specialized materials (like silicon wafers, chemicals, and gases). Additionally, industries that are heavy consumers of advanced chips and are involved in custom chip design, such as telecommunications, automotive, aerospace, defense, and consumer electronics, may also hire semiconductor engineers or those with related skills for system integration and application-specific IC (ASIC) development. Research institutions and universities also employ semiconductor engineers for R&D and teaching.

The job market is quite broad, reflecting the foundational nature of semiconductors in modern technology. The demand is particularly strong in regions with a high concentration of semiconductor manufacturing and design activity.

How vulnerable is this career to automation?

While automation is a significant trend in semiconductor manufacturing, particularly in the highly repetitive tasks within fabrication plants (fabs), the role of the semiconductor engineer is generally less vulnerable to complete automation than some other jobs. Many routine operational tasks in a fab, such as wafer handling and some process control, are already heavily automated to ensure precision and minimize human contamination. However, the core responsibilities of a semiconductor engineer – design, problem-solving, research and development, process optimization, and failure analysis – require a high degree of critical thinking, creativity, and complex decision-making that is currently beyond the capabilities of AI and automation.

Instead of replacing engineers, automation and AI are more likely to become powerful tools that augment their capabilities. For example, AI can assist in analyzing vast datasets from manufacturing processes to identify areas for improvement or help in optimizing chip designs. Engineers will increasingly need to work alongside these automated systems and leverage AI tools to enhance their productivity and innovation. While the nature of some tasks may evolve, the fundamental need for human expertise in developing and advancing semiconductor technology is expected to remain strong. The industry continually pushes boundaries, creating new challenges that require human ingenuity.

Understanding how to work with data and automated systems will likely become an increasingly important skill for semiconductor engineers.

What are typical work environments: Labs vs. fabrication plants?

The work environment for a semiconductor engineer can vary significantly depending on their specific role. Many engineers, particularly those in process engineering, equipment engineering, and some aspects of manufacturing and yield enhancement, spend a considerable amount of their time in semiconductor fabrication plants, or "fabs". Fabs are highly controlled cleanroom environments designed to minimize dust and other contaminants that could ruin the delicate chip-making process. Working in a cleanroom typically involves wearing specialized protective garments (often called "bunny suits") and adhering to strict protocols. The environment is brightly lit, and the air is constantly filtered. These roles often involve hands-on work with sophisticated manufacturing equipment.

Other semiconductor engineers, especially those in design, simulation, research, and failure analysis, may work primarily in office settings or traditional laboratory environments (which are cleaner than a typical office but not as stringent as a fab cleanroom). Design engineers spend much of their time using CAD software at computer workstations. Research engineers might work in labs with specialized characterization equipment. Even for these roles, occasional visits to the fab or collaboration with fab-based teams are common. The specific blend of environments depends heavily on the engineer's specialization and the company's structure.

How is career stability during chip market downturns?

The semiconductor industry is known for its cyclical nature, experiencing periods of high demand and growth followed by downturns or periods of oversupply. During these downturns, companies might adjust their spending, which can sometimes lead to hiring freezes or, in more severe cases, layoffs. However, the long-term outlook for the semiconductor industry remains very strong due to the ever-increasing reliance of the global economy on electronic devices and digital technologies.

Engineers with strong, versatile skills and a willingness to adapt are generally better positioned to weather these cycles. Specialization in high-demand areas (like AI chip design, advanced packaging, or power semiconductors) can also enhance job security. Furthermore, the skills acquired as a semiconductor engineer – such as complex problem-solving, data analysis, and expertise in advanced manufacturing processes – are often transferable to other technology sectors. While market downturns can create temporary uncertainty, the fundamental importance of semiconductors means that skilled engineers will continue to be in demand over the long term. Governments worldwide are also recognizing the strategic importance of a stable semiconductor workforce and are investing to support the industry, which can contribute to greater stability.

Embarking on Your Semiconductor Journey

The path to becoming a semiconductor engineer is one of dedication to rigorous academic learning, continuous skill development, and a passion for innovation at the very core of modern technology. It is a field that powers our digital world, from the smallest consumer gadgets to the largest supercomputers, and from everyday automotive systems to groundbreaking advancements in artificial intelligence and healthcare. While the challenges are significant, ranging from pushing the physical limits of materials to navigating complex global dynamics, the rewards lie in contributing to transformative technologies that shape our future.

For those intrigued by the intricate dance of physics, chemistry, and engineering at the nanoscale, and for those who wish to be part of an industry with profound global impact, a career in semiconductor engineering offers a stimulating and impactful journey. Whether you are a student mapping out your educational path, a professional considering a career pivot, or a lifelong learner fascinated by technology, resources like OpenCourser's engineering and technology sections can provide valuable insights and learning opportunities. With the demand for skilled semiconductor professionals projected to grow, now is an opportune time to explore this dynamic and vital field.