Warehouse Manager

Navigating the World of Warehouse Management: A Career Guide

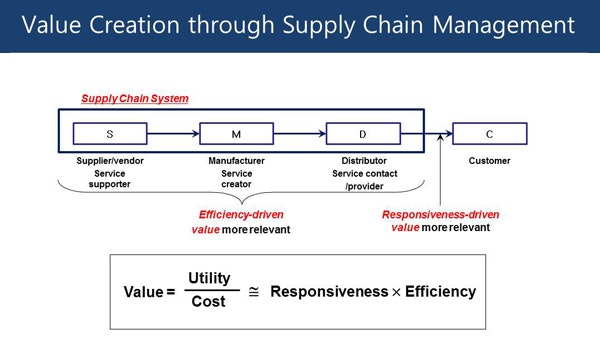

Warehouse Management is a critical function within the broader field of logistics and supply chain operations. It involves overseeing the efficient receipt, storage, and dispatch of a wide variety of goods. A Warehouse Manager is at the helm of these operations, ensuring that processes run smoothly, safely, and cost-effectively. This role is pivotal in maintaining the seamless flow of products from supplier to customer, making it an indispensable part of modern commerce.

Working as a Warehouse Manager can be a dynamic and engaging career. You'll find yourself at the center of a bustling environment, coordinating a multitude of activities and people. The role often involves strategic thinking, problem-solving, and the implementation of innovative technologies to optimize warehouse performance. For individuals who thrive in a structured yet fast-paced setting and enjoy both hands-on work and managerial responsibilities, a career in warehouse management can be exceptionally rewarding.

Core Responsibilities of a Warehouse Manager

The role of a Warehouse Manager is multifaceted, encompassing a wide range of duties critical to the success of a logistics operation. These responsibilities demand a blend of organizational prowess, leadership, and technical knowledge. Success in this field hinges on effectively managing people, processes, and systems.

Inventory Control and Stock Management Systems

A primary responsibility of a Warehouse Manager is meticulous inventory control. This involves accurately tracking all goods within the warehouse, from their arrival to their departure. Managers implement and oversee stock management systems, which can range from manual logs to sophisticated software, to maintain optimal inventory levels. The goal is to ensure products are available when needed, minimize storage costs, and prevent stockouts or overstocking. Effective inventory management is crucial for meeting customer demand and maintaining profitability.

Understanding and utilizing inventory data is key. This includes analyzing turnover rates, identifying slow-moving items, and forecasting future inventory needs. By keeping stock control systems up-to-date and ensuring inventory accuracy, managers can make informed decisions about procurement and storage.

For those looking to deepen their understanding of inventory management, several online courses can provide valuable insights and practical skills.

Several books also offer comprehensive knowledge on inventory systems and strategies.

Staff Supervision and Workforce Scheduling

Warehouse Managers are responsible for leading and managing warehouse staff. This includes recruiting, training, and supervising employees, assigning tasks, and monitoring their performance to ensure productivity and quality targets are met. Effective workforce scheduling is also a key component, ensuring that there is adequate staffing to handle the workload during different shifts and peak periods.

Creating a positive and productive work environment is essential. This involves clear communication, providing constructive feedback, and motivating the team to achieve operational goals. Managers must also ensure that staff are trained on safety procedures and the proper use of equipment.

Developing strong leadership and people management skills is crucial for this aspect of the role. Online courses can offer valuable training in these areas.

Safety Compliance and Risk Mitigation

Ensuring a safe working environment is a paramount responsibility for a Warehouse Manager. This involves implementing and maintaining health and safety standards, hygiene protocols, and security measures within the warehouse. Managers must devise risk prevention plans tailored to the specific tasks and nature of the facility. This includes ensuring that all staff are aware of and adhere to safety regulations to prevent accidents and injuries.

Regular inspections of equipment and the facility are necessary to identify and address potential hazards. Warehouse Managers are also responsible for investigating any accidents or incidents and implementing corrective actions to prevent recurrence. This includes overseeing the safe storage of all goods, especially hazardous materials or temperature-sensitive products.

Knowledge of relevant regulations, such as those set by the Occupational Safety and Health Administration (OSHA), is crucial. Staying informed about the latest safety best practices and ensuring compliance are ongoing tasks. For those new to the field, understanding the importance of a safety-first mindset cannot be overstated. It's not just about rules and regulations; it's about fostering a culture where every employee feels responsible for their safety and the safety of their colleagues.

Consider these resources for learning more about workplace safety.

For further reading on risk management within a warehouse context, this book can be a helpful resource.

Technology Integration (e.g., WMS, automation tools)

Modern warehouse operations heavily rely on technology, and Warehouse Managers play a key role in integrating and managing these systems. This includes Warehouse Management Systems (WMS), which are software applications designed to control and optimize day-to-day operations in a warehouse. WMS can help automate tasks such as inventory tracking, order picking, and shipping.

Beyond WMS, managers may oversee the implementation and use of various automation tools, such as conveyor systems, robotic arms, and automated storage and retrieval systems (AS/RS). The goal of technology integration is to improve efficiency, accuracy, and overall productivity. Staying abreast of new technological advancements is crucial for maintaining a competitive edge.

For individuals looking to pivot into warehouse management or those new to the field, embracing technology can seem daunting. However, many user-friendly systems are available, and numerous online courses provide foundational knowledge. Remember, technology is a tool to make your job more manageable and the warehouse more efficient. Starting with a basic understanding of how these systems operate can significantly ease the learning curve.

These courses offer insights into warehouse technologies and systems.

Educational Pathways to Warehouse Management

Embarking on a career as a Warehouse Manager can be achieved through various educational and experiential routes. While a specific degree isn't always mandatory, certain educational backgrounds and certifications can provide a strong foundation and enhance career prospects. Employers often prefer candidates who have a combination of education and practical experience.

Relevant Degrees (e.g., Supply Chain Management, Business Administration)

While a high school diploma is sometimes the minimum educational requirement, many employers prefer candidates with an associate's or bachelor's degree. Degrees in fields like Supply Chain Management, Logistics, Business Administration, or Operations Management are particularly relevant. These programs typically cover essential topics such as inventory control, transportation management, procurement, and business operations, providing a solid theoretical understanding of warehouse management principles.

A degree can equip aspiring managers with analytical, problem-solving, and strategic thinking skills that are highly valued in this role. For those considering a career change, it's worth noting that experience in related fields, coupled with relevant coursework or certifications, can also be a viable pathway. If a full degree program seems like a significant commitment, exploring individual courses or certificate programs in these areas can be an excellent starting point.

OpenCourser offers a wide array of courses in business and logistics that can help build this foundational knowledge. You can explore options through the Business category or the Logistics category.

Certifications (e.g., APICS, Six Sigma)

Professional certifications can significantly boost a candidate's credentials and demonstrate a commitment to the field. Organizations like APICS (now part of the Association for Supply Chain Management - ASCM) offer well-recognized certifications such as the Certified Supply Chain Professional (CSCP) and Certified in Logistics, Transportation and Distribution (CLTD). These certifications validate expertise in supply chain principles and practices.

Six Sigma certifications (Green Belt, Black Belt) are also valuable, as they focus on process improvement and quality management – skills that are directly applicable to optimizing warehouse operations. Other relevant certifications might cover areas like inventory management, occupational safety, or specific warehouse technologies. For individuals transitioning into warehouse management, certifications can be a faster way to acquire specialized knowledge and make their resumes more competitive.

Many online platforms offer preparatory courses for these certifications, making it convenient to study at your own pace.

Apprenticeships and On-the-Job Training Programs

Apprenticeships and on-the-job training programs offer a practical route into warehouse management, particularly for individuals who prefer hands-on learning. Some companies offer structured programs where trainees can learn the intricacies of warehouse operations while working alongside experienced professionals. These programs often combine paid work with part-time study, allowing individuals to earn while they learn.

Starting in an entry-level warehouse role, such as a warehouse operative or inventory clerk, and working your way up is a common path. This approach provides invaluable experience in understanding the ground-level challenges and processes within a warehouse. Employers often value this practical experience highly, especially when combined with relevant certifications or ongoing education. For those new to the industry, seeking out companies with strong training programs can be a strategic career move. These experiences build a solid foundation and demonstrate a practical understanding of the job's demands.

record:10

Role of Internships in Gaining Practical Experience

Internships provide an excellent opportunity for students and career changers to gain practical experience in a warehouse environment. An internship allows individuals to apply theoretical knowledge learned in classrooms to real-world scenarios, observe experienced managers, and contribute to actual warehouse operations. This hands-on experience is highly regarded by employers and can significantly enhance a resume.

During an internship, individuals can develop essential skills such as inventory tracking, process optimization, and teamwork. It's also a chance to network with professionals in the field and gain insights into the day-to-day realities of a Warehouse Manager's role. Even a short-term internship can provide a clearer understanding of whether this career path is the right fit. Many universities and colleges with logistics or supply chain programs facilitate internship placements, and proactive searching on company career pages can also yield opportunities.

Online Learning and Skill Development

The digital age has revolutionized how we acquire knowledge and skills, and the field of warehouse management is no exception. Online learning offers flexible and accessible pathways for both aspiring and current Warehouse Managers to enhance their expertise. Whether you are looking to build a foundational understanding, specialize in a niche area, or stay updated with the latest industry trends, online courses and resources can be invaluable.

Key Platforms Offering Logistics Courses

Numerous online learning platforms provide a wide array of courses relevant to logistics and warehouse management. Platforms like Coursera, edX, and Udemy host courses from universities and industry experts covering topics such as supply chain fundamentals, inventory management, logistics strategy, and warehouse operations. [0fkqmk, fwqij3] These platforms offer the flexibility to learn at your own pace, making them ideal for individuals balancing work or other commitments.

OpenCourser itself is a comprehensive catalog that helps learners find and compare thousands of online courses from various providers. Using OpenCourser, you can search for specific topics like "warehouse operations" or "supply chain analytics" to discover relevant courses tailored to your learning goals. The platform's features, such as course syllabi, reviews, and comparisons, can help you make informed decisions about which courses best suit your needs.

Here are some highly-rated courses that can provide a strong foundation or enhance existing knowledge in logistics.

For those interested in broader supply chain concepts, these books are excellent resources.

Micro-credentials for Specialized Skills (e.g., inventory analytics)

Micro-credentials, such as specialized certificates or digital badges, are becoming increasingly popular for demonstrating proficiency in specific skill sets. In warehouse management, these can be particularly useful for areas like inventory analytics, WMS software proficiency, or sustainable logistics practices. These focused programs are typically shorter than full degree or certification programs, allowing learners to quickly gain and validate new skills.

Platforms offering these micro-credentials often partner with industry leaders or academic institutions to ensure the content is relevant and up-to-date. For professionals looking to upskill or career changers wanting to add specific competencies to their profile, micro-credentials offer a targeted and efficient learning approach. They can be a great way to signal to employers that you have taken the initiative to acquire specialized knowledge in high-demand areas within warehouse management.

This course offers a focused look into the analytical side of managing inventory.

Blending Online Education with Hands-on Projects

While online courses provide valuable theoretical knowledge, supplementing this learning with hands-on projects is crucial for developing practical skills. Many online courses now incorporate project-based learning, case studies, or simulations that allow learners to apply concepts in a practical context. However, seeking out real-world opportunities to apply what you've learned can significantly deepen your understanding.

Consider volunteering for a small local business to help organize their storage space, or if you're currently employed, propose a small-scale project to improve a specific warehouse process. Even personal projects, like organizing a home storage system using inventory principles, can provide practical experience. For those making a career transition, documenting these projects, no matter how small, can showcase your initiative and problem-solving abilities to potential employers. Remember, the goal is to bridge the gap between theory and practice, and hands-on experience is the most effective way to do that.

Continuous Learning for Technology Adoption

The warehouse and logistics industry is constantly evolving, with new technologies and methodologies emerging regularly. Therefore, continuous learning is not just beneficial but essential for Warehouse Managers who want to stay relevant and effective in their roles. This includes keeping up-to-date with advancements in WMS, automation, data analytics, and sustainable practices.

Subscribing to industry publications, attending webinars, joining professional organizations, and regularly taking short online courses or workshops are all excellent ways to engage in continuous learning. OpenCourser's OpenCourser Notes blog often features articles on the latest trends in online education and skill development, which can be a valuable resource. Embracing a mindset of lifelong learning will ensure that you are always equipped to adapt to changes and leverage new technologies to improve warehouse operations. This proactive approach to professional development is highly valued by employers and is key to long-term career success in warehouse management.

These courses can help you stay updated on emerging technologies in the field.

Career Progression in Warehouse Management

A career in warehouse management offers various avenues for growth and advancement. The path often begins with entry-level positions, moving towards supervisory and managerial roles, and potentially leading to senior leadership positions within the broader supply chain and logistics sector. Understanding these progression pathways can help individuals plan their career development effectively.

Entry-level positions (e.g., Inventory Clerk)

Many Warehouse Managers start their careers in foundational roles within a warehouse or distribution center. Positions like Inventory Clerk, Warehouse Associate, Picker/Packer, or Material Handler provide essential hands-on experience with the day-to-day operations. These roles teach the fundamentals of inventory management, shipping and receiving procedures, order fulfillment, and safety protocols.

Gaining experience in these entry-level positions is crucial for understanding the intricacies of warehouse operations from the ground up. It provides a practical understanding of the challenges faced by warehouse staff and the importance of efficient processes. For those aspiring to management, excelling in these roles and demonstrating initiative can open doors to supervisory opportunities. Actively seeking to learn and take on more responsibility is key at this stage.

Mid-career roles (e.g., Operations Supervisor)

After gaining experience in entry-level positions, the next step in career progression often involves moving into supervisory roles. Positions such as Warehouse Lead, Operations Supervisor, or Team Leader involve overseeing a team of warehouse staff and managing specific operational areas. Responsibilities typically include coordinating daily tasks, ensuring team productivity, monitoring safety compliance, and contributing to process improvements.

These mid-career roles are critical for developing leadership and people management skills. Supervisors learn to motivate teams, solve operational problems, and communicate effectively with both staff and upper management. This stage is an excellent opportunity to hone decision-making abilities and gain a deeper understanding of workflow optimization and resource allocation. Successfully navigating these roles prepares individuals for the broader responsibilities of a Warehouse Manager.

Senior leadership opportunities (e.g., Logistics Director)

Experienced and successful Warehouse Managers can advance to senior leadership positions. Roles such as Distribution Center Manager, Logistics Director, Operations Director, or even Regional or National Operations Manager involve overseeing multiple facilities or entire logistics networks. These positions carry significant strategic responsibility, focusing on optimizing overall supply chain performance, managing budgets, and developing long-term operational strategies.

Reaching this level typically requires extensive experience, a proven track record of success, strong leadership capabilities, and often, advanced education or certifications. Senior leaders in logistics play a vital role in a company's overall success by ensuring that goods are moved, stored, and delivered efficiently and cost-effectively on a large scale. This career trajectory offers the potential for significant impact and reward.

Cross-functional movement to related fields

The skills and experience gained as a Warehouse Manager are transferable to various related fields within supply chain management and beyond. Professionals may choose to move into roles such as Procurement Manager, Supply Chain Analyst, Transportation Manager, or consultant. The understanding of logistics, inventory control, process optimization, and team management acquired in a warehouse setting is highly valuable in these areas.

For individuals seeking new challenges or different work environments, these cross-functional moves can offer exciting opportunities for growth and development. The ability to understand the interconnectedness of different supply chain functions is a key asset. Continuous learning and networking can facilitate such transitions, allowing professionals to leverage their warehouse management expertise in new contexts. Exploring different career paths on OpenCourser can provide insights into the skills required for these related roles.

Technological Innovations in Warehouse Management

The landscape of warehouse management is being continually reshaped by technological advancements. These innovations are driving greater efficiency, accuracy, and visibility across all aspects of warehouse operations. For Warehouse Managers, understanding and embracing these technologies is becoming increasingly crucial for success.

Automation systems (robotics, conveyor systems)

Automation is playing an increasingly significant role in modern warehouses. This includes the use of robotics for tasks such as picking, packing, and transporting goods within the facility. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are becoming more common, navigating warehouses to move inventory with minimal human intervention. Conveyor systems, both simple and sophisticated, also remain a staple for efficiently moving items through different stages of processing.

The integration of these automation systems aims to reduce manual labor for repetitive tasks, improve speed and accuracy, and enhance overall operational throughput. While the initial investment can be substantial, the long-term benefits in terms of productivity and cost savings are often compelling. For career explorers, familiarity with these automated systems, even at a conceptual level, will be an advantage.

These books discuss automation in warehousing and material handling.

AI applications in demand forecasting

Artificial Intelligence (AI) is being increasingly applied in warehouse management, particularly in the area of demand forecasting. AI algorithms can analyze vast amounts of historical sales data, market trends, weather patterns, and other relevant factors to predict future demand with greater accuracy than traditional methods. This enables warehouses to optimize inventory levels, reduce stockouts, and minimize holding costs for excess inventory.

Beyond forecasting, AI can also be used to optimize warehouse layouts, improve picking routes, and even assist in quality control by identifying defects through image recognition. The ability of AI to learn and adapt over time means that these systems can continuously improve their performance. As AI technology becomes more accessible, its role in creating smarter and more responsive warehouses will only grow.

This course provides a look into advanced AI techniques for supply chains.

IoT devices for real-time inventory tracking

The Internet of Things (IoT) is transforming inventory management by enabling real-time tracking and monitoring of goods. IoT devices, such as RFID (Radio-Frequency Identification) tags and sensors, can be attached to individual items, pallets, or containers. These devices transmit data wirelessly, providing constant updates on the location, status, and condition of inventory within the warehouse and even during transit.

This real-time visibility allows for more accurate inventory counts, reduces the risk of lost or misplaced items, and improves the efficiency of order fulfillment. IoT sensors can also monitor environmental conditions like temperature and humidity, which is crucial for storing sensitive goods. The data collected by IoT devices can be fed into WMS and analytical platforms to provide actionable insights for better decision-making.

To understand more about these technologies, these courses might be helpful.

Blockchain in supply chain transparency

Blockchain technology is emerging as a powerful tool for enhancing transparency and traceability throughout the supply chain. By creating a decentralized and immutable ledger, blockchain can record every transaction and movement of goods in a secure and verifiable way. This means that all permissioned participants in the supply chain can have access to a shared, trusted record of a product's journey from origin to consumer.

In a warehouse context, blockchain can help verify the authenticity of goods, track their provenance, and ensure compliance with ethical sourcing or regulatory requirements. It can also streamline processes like payments and settlements by using smart contracts that automatically execute when predefined conditions are met. While still an evolving technology in logistics, blockchain holds significant promise for creating more transparent, secure, and efficient supply chains.

You can learn more about how blockchain is being applied to improve supply chain operations from resources like this article from Deloitte on supply chain transparency and innovation, or by exploring topics related to Blockchain on OpenCourser.

Global Market Trends Affecting Warehouse Managers

The role of a Warehouse Manager is increasingly influenced by global market trends that reshape supply chains and operational demands. Staying aware of these macro-level factors is essential for navigating the complexities of modern logistics and for effective career planning. These trends present both challenges and opportunities for professionals in the field.

E-commerce growth and its operational impacts

The rapid and continuous growth of e-commerce has profoundly impacted warehouse operations. Warehouses now need to handle a higher volume of smaller, more frequent orders, destined directly for consumers. This shift necessitates faster picking and packing processes, more sophisticated order fulfillment strategies, and often, the ability to manage a wider variety of SKUs (Stock Keeping Units).

E-commerce also drives demand for greater visibility and faster delivery times, putting pressure on warehouses to be more agile and responsive. This has led to increased investment in automation, real-time tracking technologies, and strategically located fulfillment centers closer to end consumers. For Warehouse Managers, this means adapting to a more dynamic and customer-centric operational environment, often requiring skills in managing complex, high-velocity operations.

This course focuses on the specific demands of e-commerce supply chains.

Sustainability initiatives in logistics

There is a growing emphasis on sustainability within the logistics and warehousing sectors, driven by consumer expectations, regulatory pressures, and a desire for corporate social responsibility. For warehouses, this translates into initiatives aimed at reducing environmental impact. These include optimizing energy consumption through energy-efficient lighting and equipment, utilizing renewable energy sources like solar panels, and implementing comprehensive waste reduction and recycling programs.

Sustainable warehousing also involves considering the environmental impact of building materials and design, as well as optimizing transportation routes to reduce fuel consumption and emissions. Warehouse Managers are increasingly expected to understand and implement these green logistics practices. This not only helps in meeting regulatory compliance but can also lead to cost savings and an enhanced brand reputation. Familiarity with Sustainability principles is becoming a key competency.

These courses delve into sustainable supply chain practices.

These books offer insights into sustainable practices within warehousing and logistics.

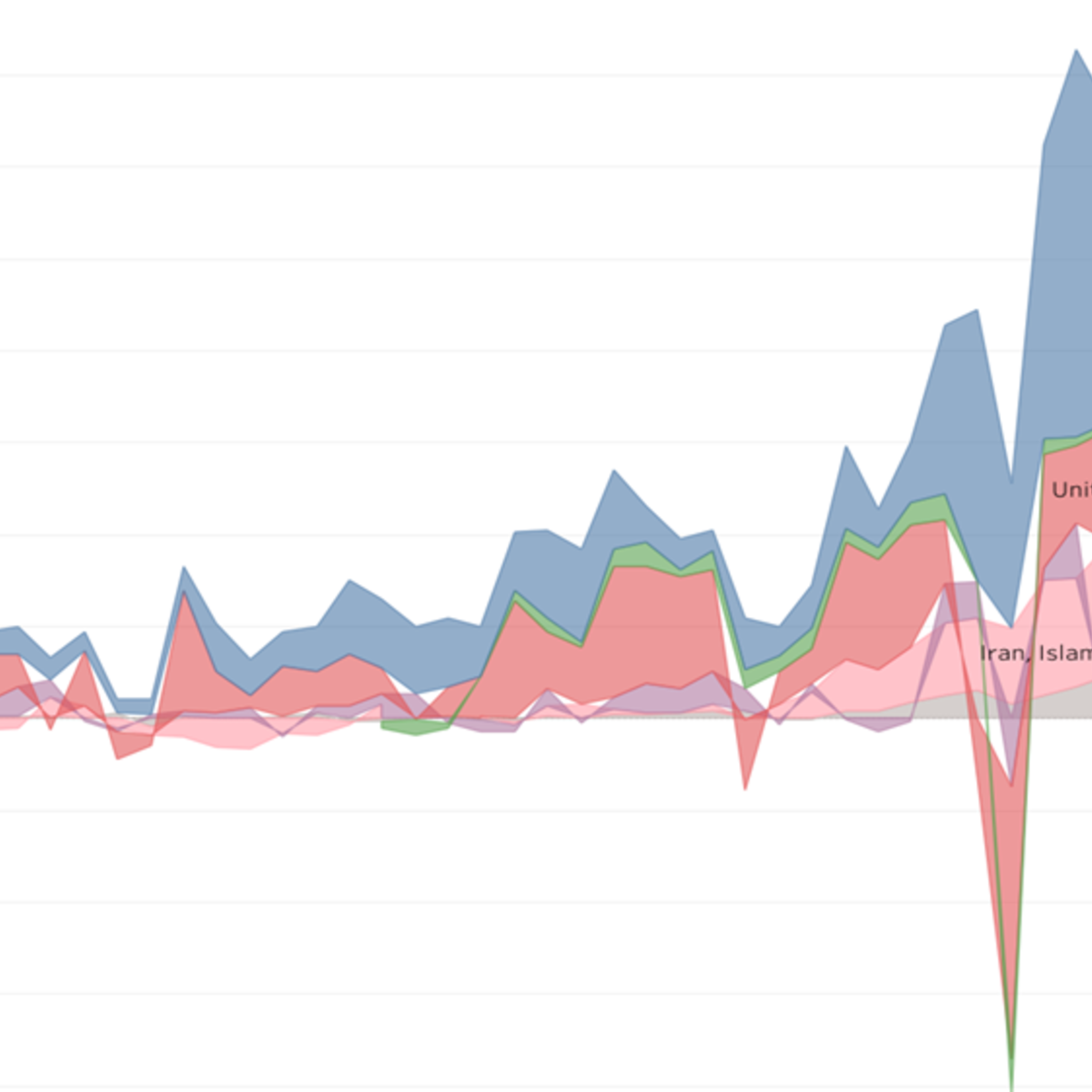

Geopolitical factors influencing supply chains

Geopolitical events, such as trade disputes, political instability, and changes in international regulations, can have significant and often unpredictable impacts on global supply chains. These factors can disrupt the flow of goods, alter transportation routes, and affect the cost and availability of materials. Warehouse Managers may need to adapt to these changes by finding alternative sourcing options, adjusting inventory strategies, or dealing with new customs and compliance requirements.

The ability to remain flexible and resilient in the face of geopolitical uncertainty is becoming increasingly important. This may involve developing contingency plans, diversifying supplier bases, and staying informed about international developments that could affect logistics operations. While directly controlling these macro factors is often impossible, proactive planning and risk management can help mitigate their impact on warehouse operations.

This course offers a perspective on global supply chain management.

This book discusses global logistics in detail.

Post-pandemic supply chain adaptations

The COVID-19 pandemic exposed vulnerabilities in global supply chains and accelerated several pre-existing trends. Companies are now placing a greater emphasis on supply chain resilience, which involves diversifying sourcing, increasing inventory of critical components (a shift from pure "just-in-time" to "just-in-case" for some items), and improving end-to-end visibility. Warehouses play a key role in these adaptations by needing to accommodate these changing inventory strategies and potentially handling a more diverse and geographically distributed supplier network.

There's also been an increased focus on worker safety and well-being, leading to new protocols and layouts within warehouses. The pandemic further fueled the growth of e-commerce, reinforcing the need for warehouses to be agile and technologically advanced. Warehouse Managers must navigate these evolving expectations, ensuring their operations are both robust and adaptable to future disruptions.

This course specifically addresses managing supply chain disruptions.

Ethical and Safety Considerations

Beyond operational efficiency and profitability, Warehouse Managers bear significant responsibility for upholding ethical standards and ensuring the safety and well-being of their workforce and the wider community. These considerations are integral to responsible warehouse management and are increasingly under scrutiny from regulators, consumers, and employees themselves.

Labor rights and fair working conditions

Warehouse Managers must ensure that all labor practices within their facility comply with legal requirements and ethical standards. This includes fair wages, reasonable working hours, and adherence to regulations regarding overtime pay and breaks. The U.S. Department of Labor provides resources and enforces laws like the Fair Labor Standards Act (FLSA) to protect workers' rights. In some jurisdictions, specific legislation like New York's Warehouse Worker Protection Act further outlines employer responsibilities regarding work speed data and quotas.

Creating a respectful and non-discriminatory work environment is also crucial. This means ensuring equal opportunities and preventing harassment or unfair treatment based on race, gender, age, or other protected characteristics. Managers should foster a culture where employees feel safe to voice concerns without fear of retaliation. For those entering the field, it's important to recognize that managing people fairly and ethically is as vital as managing inventory efficiently. Upholding labor rights contributes to employee morale, productivity, and the overall reputation of the organization.

Environmental regulations compliance

Warehouses are subject to a variety of environmental regulations aimed at minimizing their ecological footprint. These regulations may govern aspects such as waste disposal, the handling and storage of hazardous materials, and emissions from vehicles and equipment. Compliance often involves implementing practices to reduce energy consumption, manage water usage responsibly, and control pollution.

Warehouse Managers are responsible for understanding and adhering to these local, state, and national environmental standards. This may involve developing and implementing environmental management systems, training staff on compliant procedures, and maintaining accurate records for reporting purposes. Non-compliance can result in significant fines and damage to the company's reputation. Increasingly, proactive environmental stewardship is seen not just as a regulatory burden but as a component of responsible business practice and a way to enhance sustainability.

This book provides insights into sustainable warehousing.

Crisis management protocols

Warehouses can face various crises, including natural disasters (fires, floods, earthquakes), accidents, security breaches, or significant disruptions to the supply chain. Warehouse Managers must be prepared to handle such events by developing and implementing robust crisis management protocols. This involves identifying potential risks, creating emergency response plans, and training staff on how to react in different crisis scenarios.

Effective crisis management aims to protect employees, minimize damage to goods and property, and ensure business continuity as much as possible. This includes establishing clear communication channels, evacuation procedures, and protocols for securing the facility and its contents. Regular drills and reviews of the crisis management plan are essential to ensure its effectiveness. The ability to lead calmly and decisively during a crisis is a critical skill for any Warehouse Manager.

Data privacy in supply chain operations

As warehouses and supply chains become increasingly digitized, the management of data privacy and security is a growing concern. Warehouse operations often handle sensitive information, including customer data, supplier details, and proprietary business information. Warehouse Managers have a responsibility to ensure that this data is protected from unauthorized access, breaches, or misuse.

This involves implementing appropriate cybersecurity measures, adhering to data privacy regulations (such as GDPR or CCPA, depending on the jurisdiction and data handled), and training staff on data protection policies. Ensuring that technology vendors also meet high security standards is part of this responsibility. As data becomes a more valuable asset, safeguarding it is crucial for maintaining trust with customers and partners, and for avoiding legal and reputational damage.

While not specific to warehousing, general knowledge of data privacy is beneficial, and many resources are available through Information Security or Cybersecurity course categories.

Future Outlook for Warehouse Management Careers

The field of warehouse management is undergoing significant transformation, driven by technological advancements and evolving market demands. Understanding these trends is crucial for anyone considering or currently pursuing a career in this area. The future outlook presents both challenges and exciting opportunities for skilled and adaptable Warehouse Managers.

Automation's impact on employment trends

Automation, including robotics and AI, is undoubtedly changing the nature of work in warehouses. While some routine manual tasks may be automated, this doesn't necessarily mean a widespread loss of jobs for Warehouse Managers. Instead, the role is likely to evolve, requiring managers to oversee and coordinate these automated systems, manage the human workforce that interacts with them, and analyze the data generated by these technologies to make strategic decisions.

The focus may shift from direct supervision of manual labor to managing more complex, technology-driven operations. This means that skills in data analysis, technology management, and process optimization will become even more critical. For those entering the field, embracing technology and developing these skills will be key to long-term career viability. The human element of leadership, problem-solving, and strategic thinking will remain indispensable.

Growing demand for tech-savvy managers

As warehouses become more technologically advanced, there is a growing demand for managers who are comfortable working with and leveraging these new tools. Employers are increasingly seeking individuals who understand Warehouse Management Systems (WMS), data analytics, IoT devices, and automation technologies. The ability to integrate these technologies effectively to improve efficiency, accuracy, and safety is a highly valued skill.

This trend underscores the importance of continuous learning and upskilling. Aspiring and current Warehouse Managers should proactively seek opportunities to develop their technical competencies. This might involve taking online courses, attending industry workshops, or gaining hands-on experience with new software and hardware. Demonstrating tech-savviness can significantly enhance career prospects in this evolving landscape.

Consider these resources for understanding the technological aspects of modern supply chains.

Emerging specializations (e.g., cold chain management)

The increasing complexity of supply chains and the diverse nature of goods being handled are leading to emerging specializations within warehouse management. One prominent example is cold chain management, which involves handling temperature-sensitive products like pharmaceuticals, fresh food, and certain chemicals. This requires specialized knowledge of temperature control technologies, regulatory compliance, and handling protocols to maintain product integrity.

Other specializations might include managing warehouses for hazardous materials, e-commerce fulfillment centers with high-velocity picking operations, or facilities focused on reverse logistics and returns processing. Developing expertise in one of these niche areas can open up specific career opportunities and potentially lead to higher earning potential. Identifying and pursuing such specializations can be a strategic move for career advancement.

Long-term industry growth projections

Despite the changes brought by automation and technology, the long-term outlook for the warehouse and logistics industry generally remains positive. The continued growth of global trade, e-commerce, and the increasing complexity of supply chains all contribute to a sustained demand for efficient warehouse operations and skilled management. As long as goods need to be stored, managed, and moved, there will be a need for professionals who can oversee these critical functions.

However, the nature of the role will continue to evolve. Professionals who are adaptable, willing to embrace new technologies, and committed to continuous learning will be best positioned for success. The industry offers dynamic and challenging career paths for those who are prepared to meet the demands of a rapidly changing global marketplace. Information on labor market trends can often be found through resources like the U.S. Bureau of Labor Statistics Occupational Outlook Handbook, which provides insights into various professions.

These courses provide a broader understanding of supply chain management, a field closely tied to warehousing.

For comprehensive reading, these books cover fundamental and strategic aspects of supply chain management.

Frequently Asked Questions (Career Focus)

Navigating a career path, especially one as dynamic as Warehouse Management, often brings up many questions. Here are answers to some common queries that individuals at various career stages might have. These insights aim to provide clarity and practical advice.

What qualifications are essential for entry-level roles?

For many entry-level warehouse positions, such as warehouse associate or picker/packer, a high school diploma or GED is often the primary educational requirement. However, what's equally, if not more, important are foundational skills like attention to detail, reliability, a good work ethic, and the ability to work as part of a team. Basic math and communication skills are also generally expected.

While not always mandatory for starting roles, having some familiarity with basic computer operations can be beneficial, as many warehouses use digital systems for tracking inventory or orders. For those aiming to progress, showing an aptitude for learning new processes and a commitment to safety will be key. Some employers might also look for physical stamina, as many entry-level roles involve manual handling of goods.

Gaining a forklift license can be advantageous for certain positions and can improve employability. For individuals without prior warehouse experience, highlighting transferable skills from other jobs or educational experiences, such as organizational skills or experience in a fast-paced environment, can be helpful when applying.

How does warehouse management differ across industries?

Warehouse management principles remain broadly consistent across industries – efficient receipt, storage, and dispatch of goods. However, the specific challenges, priorities, and regulatory requirements can vary significantly. For example, a warehouse handling perishable food items (cold chain logistics) will have stringent temperature control requirements and rapid turnover needs, vastly different from a warehouse storing automotive parts, which might prioritize long-term storage durability and handling of bulky items.

In the pharmaceutical industry, adherence to strict regulatory compliance for drug storage and traceability (e.g., lot tracking, serialisation) is paramount. E-commerce fulfillment centers often deal with a high volume of small, individual orders requiring rapid picking, packing, and shipping directly to consumers, emphasizing speed and order accuracy. In contrast, a manufacturing warehouse might focus on supplying components to a production line, emphasizing just-in-time delivery and seamless integration with manufacturing schedules. Understanding these industry-specific nuances is crucial for effective warehouse management.

What are common career transition paths from this role?

A background in warehouse management opens doors to various other roles within the broader supply chain and logistics sector. Common transitions include moving into positions like Logistics Manager, Supply Chain Manager, Operations Manager, Distribution Manager, or Procurement Manager. The skills gained in managing inventory, optimizing processes, leading teams, and working with logistics technologies are highly transferable.

Some Warehouse Managers may choose to specialize further, perhaps in areas like transportation management, supply chain analytics, or consulting. Others might leverage their operational expertise to move into sales or account management roles for logistics service providers. With additional education or certification, transitions into related fields like industrial engineering or even business management are also possible. The key is to identify how the core competencies developed as a Warehouse Manager align with the requirements of other roles and to pursue any necessary upskilling.

How to maintain work-life balance in high-pressure environments?

Warehouse management can indeed be a demanding role, often involving long hours, especially during peak seasons, and the pressure to meet tight deadlines. Maintaining work-life balance requires proactive strategies. Effective time management and prioritization are crucial; learning to delegate tasks appropriately to capable team members can also alleviate some of the pressure.

Setting clear boundaries between work and personal life is important, though it can be challenging in a 24/7 operational environment. This might mean consciously disconnecting from work emails and calls during off-hours, where possible. Stress management techniques, such as regular exercise, hobbies, and spending quality time with family and friends, are also vital for overall well-being. Open communication with supervisors about workload and seeking support when needed can also be beneficial. Some companies are also increasingly recognizing the importance of work-life balance and may offer flexible scheduling or wellness programs.

This course, while in Spanish, touches upon order and time management, which are crucial skills.

What are the key metrics for measuring success in this role?

The success of a Warehouse Manager is typically measured by a range of Key Performance Indicators (KPIs) that reflect operational efficiency, cost-effectiveness, and customer satisfaction. Common metrics include inventory accuracy (the degree to which physical stock matches system records), order fulfillment rates (percentage of orders processed correctly and on time), and on-time shipping rates.

Cost-related KPIs are also critical, such as warehousing costs per unit, labor costs as a percentage of revenue, and transportation costs. Safety metrics, including the number of accidents or incidents and lost time due to injury, are paramount. Additionally, employee productivity, equipment uptime, and space utilization efficiency are often tracked. Ultimately, a successful Warehouse Manager contributes to a smooth-running, cost-effective warehouse that meets or exceeds customer expectations while maintaining a safe and productive work environment.

How to prepare for leadership roles in logistics management?

Preparing for leadership roles in logistics management, such as Logistics Director or VP of Supply Chain, involves a combination of gaining diverse experience, continuous learning, and developing strong leadership competencies. Beyond excelling in a Warehouse Manager role, seek opportunities to understand other facets of the supply chain, such as transportation, procurement, and demand planning. Taking on cross-functional projects or assignments can broaden your perspective.

Continuously develop your strategic thinking and financial acumen. Understand how logistics decisions impact the broader business goals and profitability. Pursuing advanced education, such as an MBA with a supply chain focus, or high-level certifications like APICS CSCP or CLTD, can strengthen your qualifications. Equally important is honing your leadership skills: learn to inspire and motivate larger teams, manage complex stakeholder relationships, communicate effectively with executive leadership, and drive change and innovation. Networking with senior leaders in the industry can also provide valuable mentorship and insights.

These courses and books provide foundational and advanced knowledge in supply chain and logistics management, essential for leadership roles.

Embarking on or advancing a career in Warehouse Management is a journey that requires dedication, continuous learning, and adaptability. The field offers diverse challenges and rewards for those who are prepared to meet them. By understanding the core responsibilities, educational pathways, technological trends, and career progression opportunities, individuals can strategically navigate their path to success in this vital sector of the global economy. Remember that resources like OpenCourser are available to help you find the educational tools you need to achieve your career aspirations.