Supply Chain Analyst

Supply Chain Analyst: A Career Guide

A Supply Chain Analyst works behind the scenes to ensure products move efficiently from their origin to their final destination. They analyze data, identify potential problems, and implement solutions to make the entire process smoother, faster, and more cost-effective. Think of them as the strategic thinkers and problem-solvers who keep the complex network of manufacturing, logistics, and delivery running optimally.

Working in this field can be quite engaging. You'll often find yourself tackling intricate puzzles involving global logistics, forecasting customer demand, and managing inventory across warehouses. The role requires collaboration with diverse teams—from procurement specialists negotiating with suppliers to sales teams understanding market needs. It's a dynamic career where data-driven insights directly impact a company's bottom line and customer satisfaction.

Introduction to Supply Chain Analyst Roles

What is Supply Chain Analysis?

Supply chain analysis involves examining every step involved in getting a product from raw material to the end consumer. This includes sourcing materials, manufacturing, inventory management, warehousing, transportation, and final delivery. The goal is to understand how all these pieces fit together and identify opportunities for improvement.

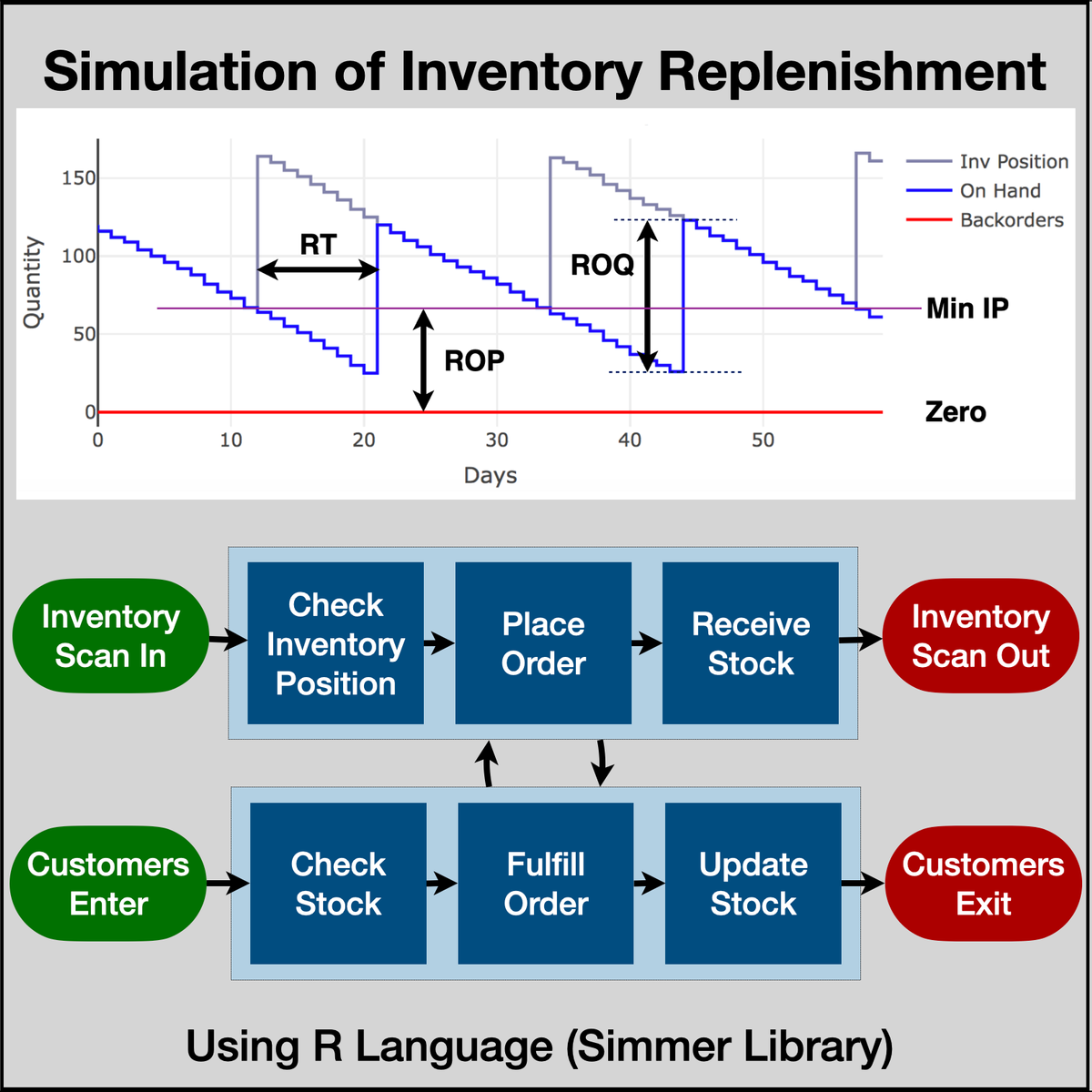

Analysts use data to map out these processes, measure performance, and pinpoint bottlenecks or inefficiencies. They look at factors like costs, lead times, inventory levels, and delivery accuracy. By understanding the current state, they can develop strategies to optimize the flow of goods, information, and finances throughout the supply chain.

The scope is broad, touching on various business functions. It requires a blend of analytical rigor, business understanding, and communication skills to translate complex data into actionable recommendations for stakeholders across the company.

Why Pursue This Career?

A career as a Supply Chain Analyst offers the chance to make a tangible impact on a company's success. The core objectives often revolve around significant goals like reducing operational costs and optimizing efficiency. Achieving these goals requires sharp analytical thinking and creative problem-solving, making the work intellectually stimulating.

If you enjoy working with data to uncover insights and solve complex, real-world problems, this role can be very rewarding. Analysts often work on specific projects, such as planning a product launch in a new market or finding ways to lower transportation expenses by identifying better routes or suppliers. This project-based nature keeps the work varied and dynamic.

Furthermore, the field is critical to global commerce. Understanding and managing supply chains effectively is essential for businesses to compete. This relevance translates into strong career prospects and the opportunity to develop highly valuable, transferable skills.

Where Do Analysts Work?

Supply Chain Analysts are in demand across a wide array of industries because nearly every company that produces or sells physical goods relies on a supply chain. Manufacturing companies need analysts to manage the flow of raw materials and finished products. Retailers, including e-commerce giants, depend on them to optimize inventory and ensure timely delivery to customers.

Logistics and transportation companies employ analysts to streamline shipping routes and warehouse operations. The technology sector needs them to manage the complex global networks for sourcing components and distributing electronics. Healthcare organizations rely on analysts to ensure the efficient delivery of medical supplies and pharmaceuticals.

Other sectors include aerospace, automotive, consumer goods, food and beverage, and even government agencies, particularly in defense logistics. This broad applicability means analysts can often find opportunities that align with their specific industry interests.

Connections to Other Roles

The Supply Chain Analyst role shares common ground with several adjacent functions within a business. There's significant overlap with logistics roles, which focus specifically on the storage and movement of goods. Analysts often work closely with Logistics Managers or Analysts to optimize transportation and warehousing.

Procurement or Sourcing Specialists, who are responsible for acquiring goods and services, also interact frequently with Supply Chain Analysts. Analysts provide data and insights that inform purchasing decisions and supplier relationship management.

Operations Management roles, which oversee the production processes, rely on supply chain analysis to ensure materials are available when needed and that production aligns with demand forecasts. The analytical skills are also similar to those found in Business Analyst or Data Analyst roles, though applied specifically to supply chain contexts.

Key Responsibilities of a Supply Chain Analyst

Analyzing Data for Insights

A core function of a Supply Chain Analyst is collecting, cleaning, and interpreting vast amounts of data. This data might relate to inventory levels, transportation costs, delivery times, supplier performance, or customer demand patterns. Analysts use tools ranging from spreadsheets like Excel to more sophisticated databases and analytics software.

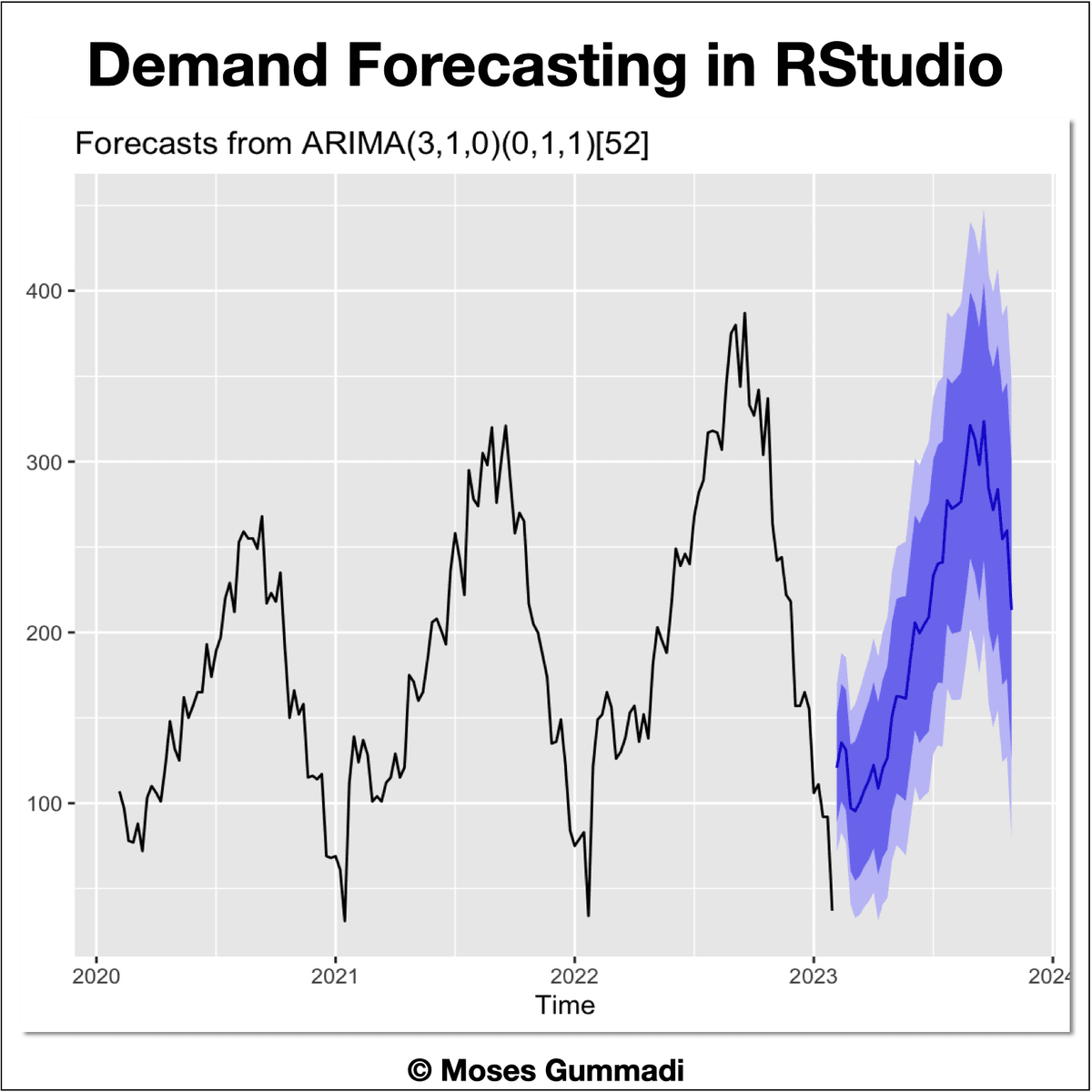

One crucial application is demand forecasting, where analysts use historical data and statistical models to predict future customer demand. Accurate forecasts are vital for effective inventory management, helping companies avoid costly stockouts or overstock situations.

Analysts also track Key Performance Indicators (KPIs) to monitor supply chain health. They generate reports and dashboards to communicate trends, identify areas needing improvement, and ultimately support data-driven decision-making across the supply chain function.

Collaborating Across Functions

Supply Chain Analysts rarely work in isolation. Their role inherently involves connecting with various departments within the organization to ensure alignment and smooth operations. Effective communication and collaboration are essential skills.

They work closely with procurement teams to provide data on supplier performance and material needs, helping inform sourcing strategies. Collaboration with sales and marketing teams is necessary to understand demand drivers and incorporate promotional plans into forecasts.

Analysts also liaise with logistics and warehouse teams to optimize storage and transportation, and with manufacturing or production teams to align supply plans with production schedules. They often act as a bridge, translating data insights into practical actions for different functional areas.

Identifying and Mitigating Risks

Modern supply chains are complex and vulnerable to various disruptions. A key responsibility for analysts is identifying potential risks and developing strategies to mitigate their impact. This requires staying informed about geopolitical events, trade policy changes, economic conditions, and even weather patterns.

Analysts assess risks associated with suppliers, such as financial instability or quality issues. They analyze transportation routes for potential delays and evaluate inventory levels to buffer against unexpected demand surges or supply interruptions. This involves understanding potential failure points throughout the network.

Based on this risk assessment, analysts contribute to developing contingency plans. This might involve diversifying the supplier base, securing alternative transportation routes, or adjusting inventory strategies to enhance supply chain resilience.

Driving Process Improvements

Beyond monitoring and reporting, Supply Chain Analysts are expected to proactively identify opportunities for improvement. They analyze processes to find bottlenecks, inefficiencies, or areas where costs can be reduced or service levels enhanced.

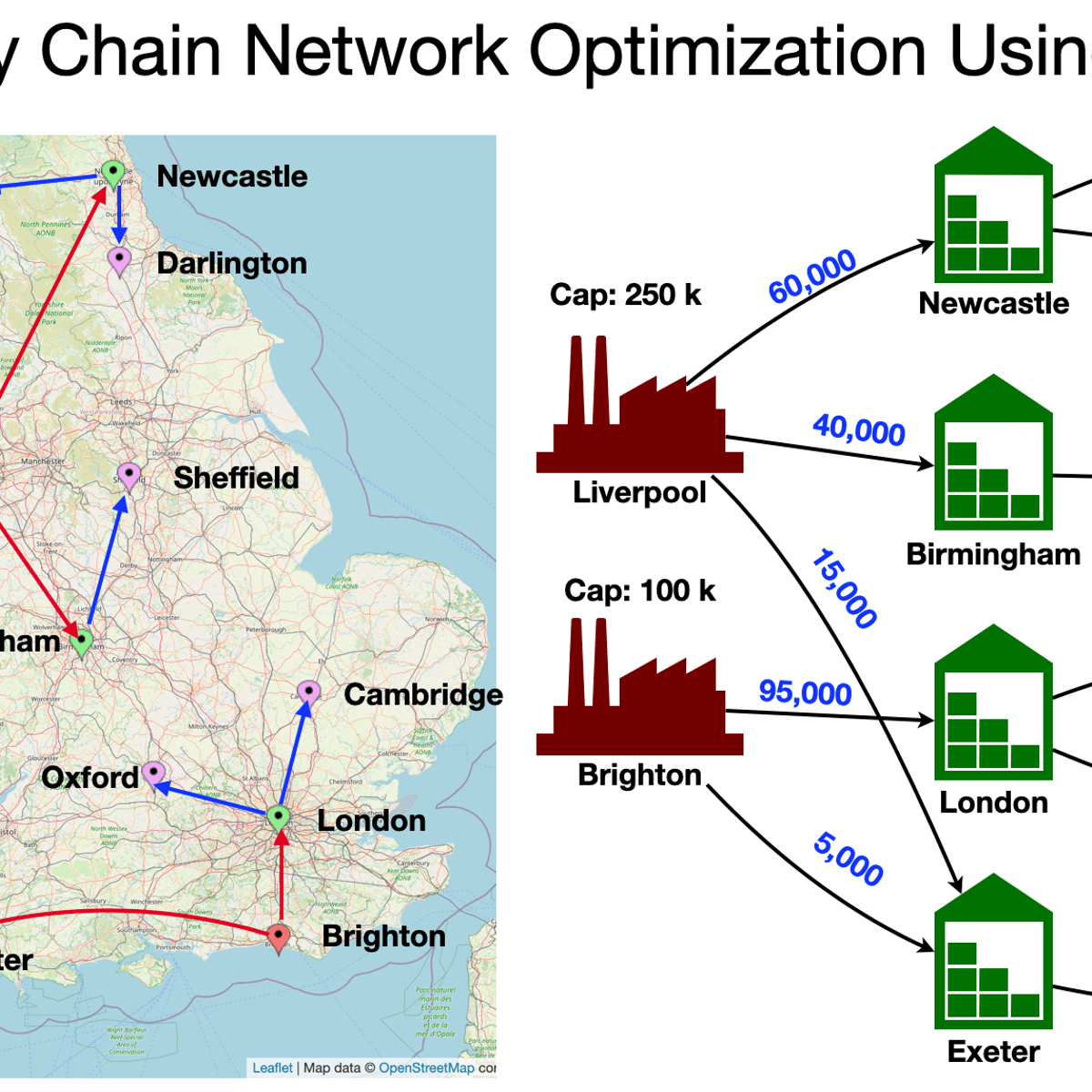

This might involve proposing changes to inventory policies, suggesting new transportation strategies, recommending investments in technology like warehouse management systems (WMS), or optimizing network design. Analysts use data to build a business case for these improvements.

Once improvements are implemented, analysts are responsible for tracking their impact and measuring results against initial goals. This continuous cycle of analysis, recommendation, implementation, and measurement is central to driving ongoing optimization within the supply chain.

Essential Skills and Qualifications

Technical Proficiencies

Supply Chain Analysts need a strong command of various software tools. Proficiency in Microsoft Excel is fundamental for data manipulation, analysis, and basic modeling. Many roles also require experience with Enterprise Resource Planning (ERP) systems like SAP or Oracle, which integrate data across business functions.

Familiarity with database querying languages like SQL is increasingly valuable for accessing and manipulating large datasets. Data visualization tools such as Tableau or Microsoft Power BI are also important for creating insightful reports and dashboards.

For more advanced analytical roles, knowledge of statistical software or programming languages like Python or R is beneficial. These tools enable sophisticated modeling, forecasting, and automation tasks.

These courses offer practical training in key software used by Supply Chain Analysts.

Analytical and Problem-Solving Skills

Beyond technical tools, strong analytical thinking is paramount. Analysts must be able to look at complex data sets, identify patterns and trends, and draw logical conclusions. This involves quantitative aptitude and an understanding of statistical concepts.

Problem-solving skills are equally critical. Analysts need to diagnose issues within the supply chain—like delivery delays or inventory imbalances—and develop practical, data-backed solutions. This often requires creativity and the ability to think systematically about interconnected processes.

Attention to detail is crucial for ensuring data accuracy and identifying subtle anomalies. Furthermore, strong communication skills are needed to present findings clearly to both technical and non-technical audiences, influencing decisions and driving action.

These books delve into the analytical and statistical methods often used in supply chain analysis.

Educational Foundation

A bachelor's degree is typically required for entry-level Supply Chain Analyst positions. Common fields of study include Supply Chain Management, Logistics, Business Administration, Industrial Engineering, Operations Management, Economics, or Data Science. Programs with a quantitative focus are often preferred.

Coursework in areas like statistics, operations research, database management, economics, and business analytics provides a strong foundation. According to data from Zippia, around 73% of supply chain analysts hold a bachelor's degree.

While not always necessary, a master's degree (such as an MS in Supply Chain Management or an MBA with a relevant concentration) can be advantageous, particularly for advancement into senior or management roles. About 15% of analysts hold a master's degree.

Professional Certifications

While not always mandatory, professional certifications can significantly enhance a Supply Chain Analyst's credentials and demonstrate specialized knowledge. They are often valued by employers and can provide a competitive edge in the job market.

Some of the most recognized certifications come from APICS (now part of the Association for Supply Chain Management, ASCM). These include the Certified in Planning and Inventory Management (CPIM), Certified Supply Chain Professional (CSCP), and Certified in Logistics, Transportation and Distribution (CLTD).

Other relevant certifications include those offered by the Institute for Supply Management (ISM), such as the Certified Professional in Supply Management (CPSM), or certifications from the International Supply Chain Education Alliance (ISCEA), like the Certified Supply Chain Analyst (CSCA). These certifications often require passing exams and may have experience prerequisites.

These courses can help prepare for valuable industry certifications.

Formal Education Pathways

Relevant Undergraduate Degrees

A bachelor's degree provides the foundational knowledge for a career as a Supply Chain Analyst. Degrees specifically in Supply Chain Management or Logistics are highly relevant, covering core concepts like procurement, inventory control, transportation, and network design.

Degrees in Business Administration, often with a concentration in operations or supply chain, are also common pathways. These programs provide a broader business context alongside specialized SCM coursework. Quantitative fields like Industrial Engineering, Operations Research, Economics, Mathematics, Statistics, or Business Analytics equip students with strong analytical and modeling skills applicable to supply chain problems.

Regardless of the specific major, strong performance in quantitative courses (math, statistics, data analysis) and business fundamentals (economics, finance) is beneficial. Internships during undergraduate studies offer invaluable practical experience.

Graduate Programs and Specializations

For those seeking deeper expertise or aiming for leadership roles, a graduate degree can be a valuable investment. Master of Science (MS) programs specifically in Supply Chain Management offer intensive, specialized training in advanced SCM concepts, analytics, and strategy.

An MBA (Master of Business Administration) with a concentration in Supply Chain Management or Operations provides both advanced SCM knowledge and broader management skills, preparing graduates for leadership positions. Programs in Operations Research or Business Analytics offer highly quantitative training focused on modeling, optimization, and data science techniques applicable to complex supply chain challenges.

Some universities offer specialized graduate certificates or MicroMasters programs focused on specific areas like Logistics or Analytics, which can be a faster way to gain targeted skills.

These courses represent graduate-level learning, often part of MicroMasters or similar programs.

Key University Coursework

University programs preparing students for supply chain analysis typically include a mix of core business, quantitative, and specialized SCM courses. Foundational topics often include microeconomics, macroeconomics, accounting, finance, and business statistics.

Core supply chain courses cover areas such as introduction to SCM, logistics and transportation management, inventory control, procurement and sourcing, operations management, and demand planning/forecasting. Analytical courses might include database management (SQL), statistical modeling, simulation, and optimization techniques.

Many programs also incorporate training in methodologies like Lean Six Sigma for process improvement and quality management. Courses focusing on specific software (like ERP systems or analytics tools) or addressing contemporary issues like global SCM, risk management, and sustainability are also increasingly common.

Research and Doctoral Paths

For individuals passionate about advancing the theoretical underpinnings of supply chain management or pursuing a career in academia, a PhD is the typical path. Doctoral programs in Supply Chain Management, Operations Management, Operations Research, or Industrial Engineering involve rigorous coursework in research methodologies, advanced statistics, and specialized SCM topics.

PhD candidates conduct original research, often focusing on developing new models, theories, or analytical techniques to address complex supply chain problems. This research culminates in a dissertation and contributes to the academic knowledge base of the field.

Graduates with a PhD typically seek positions as university professors, conducting research and teaching the next generation of supply chain professionals. Some also pursue research-intensive roles in industry think tanks or consulting firms focused on cutting-edge supply chain innovation.

Online Courses and Self-Directed Learning

Can Online Courses Launch Your Career?

Yes, online courses can be a viable and effective way to build the foundational knowledge and practical skills needed for a Supply Chain Analyst career, particularly for those transitioning from other fields. Platforms like OpenCourser aggregate thousands of courses covering everything from basic principles to advanced analytics and specific software tools.

Success through online learning requires discipline, self-motivation, and a structured approach. It's not just about watching videos; actively engaging with materials, completing assignments, and, crucially, applying learned concepts through projects is key to demonstrating competence to potential employers.

While a formal degree is often preferred, a portfolio of completed relevant online courses, coupled with demonstrated skills through projects and potentially certifications, can make a compelling case for career changers. It shows initiative and a commitment to acquiring the necessary expertise.

OpenCourser's Learner's Guide offers valuable tips on structuring your self-learning journey and staying motivated.

Core Topics for Online Study

When using online courses to prepare for a Supply Chain Analyst role, focus on core competency areas. Start with foundational courses covering the fundamentals of supply chain management, including key concepts, processes, and terminology.

Dive into specific functional areas like logistics and transportation, inventory management and optimization, procurement and sourcing, and demand planning and forecasting. Analytical skills are crucial, so seek courses on data analysis fundamentals, statistics, Excel for data analysis (including PivotTables and basic modeling), and potentially SQL.

Consider courses on specific ERP systems (like SAP or Oracle if you know target industries use them) and data visualization tools like Tableau or Power BI. Understanding process improvement methodologies like Lean Six Sigma is also beneficial.

These courses provide a good starting point for core supply chain knowledge.

Consider these books for a deeper understanding of core concepts.

Building a Portfolio with Projects

Completing online courses is a great start, but demonstrating practical application is essential, especially for career changers. Building a portfolio of projects allows you to showcase your acquired skills to potential employers.

Look for online courses that include hands-on projects or case studies. Alternatively, create your own projects based on publicly available data or hypothetical scenarios. For example, you could analyze shipping data to identify cost-saving opportunities, build a demand forecast for a fictional product, or design an optimized inventory policy for a small business scenario.

Document your projects clearly, explaining the problem, your methodology, the tools used (Excel, Python, SQL, Tableau), and your findings or recommendations. Including visualizations or dashboards you created can be particularly impactful. This portfolio serves as concrete evidence of your capabilities.

Supplementing Traditional Education

Online courses are not just for beginners or career changers; they are also excellent resources for those with formal degrees looking to specialize or update their skills. University curricula may not cover the latest software versions or niche analytical techniques.

A student or recent graduate with a business degree might take online courses in specific SCM software like SAP S/4HANA, advanced Excel modeling, Python for supply chain analytics, or data visualization with Tableau to gain practical, job-ready skills.

Working professionals can use online learning to stay current with emerging technologies like AI in supply chain, blockchain applications, or sustainable supply chain practices. These specialized modules can enhance expertise and open doors to new opportunities or promotions.

Use OpenCourser's "Save to List" feature to curate a personalized learning path combining formal education with supplementary online courses.

These courses cover specific, valuable skills that can supplement a broader education.

These books offer advanced perspectives and techniques.

Career Progression and Advancement

Starting Your Journey

Entry into the supply chain field often begins with roles like Supply Chain Coordinator, Logistics Coordinator, Junior Buyer, or Junior Supply Chain Analyst. These positions typically involve supporting more senior staff, collecting data, managing documentation, tracking shipments, and handling routine operational tasks.

These roles provide essential hands-on experience with fundamental supply chain processes, software systems, and data handling. They offer a chance to learn the practical realities of logistics, inventory, and procurement within a specific company or industry.

A bachelor's degree is often expected, along with proficiency in tools like Excel. Strong organizational skills, attention to detail, and a willingness to learn are key attributes for success at this stage.

Moving Up the Ladder

After gaining a few years of foundational experience, analysts typically progress to roles like Supply Chain Analyst or Senior Supply Chain Analyst. At this level, responsibilities shift towards more independent analysis, identifying trends, developing forecasts, managing specific projects, and recommending process improvements.

Further advancement can lead to positions such as Supply Chain Manager, Logistics Manager, Procurement Manager, or Demand Planning Manager. These roles often involve overseeing a specific function or team, managing budgets, developing strategies for their area, and interacting with senior leadership.

Strong analytical capabilities combined with leadership potential, project management skills, and a deeper understanding of business strategy are crucial for moving into these mid-career roles.

Reaching Leadership Positions

With significant experience and a track record of success, professionals can advance to senior leadership roles. These might include Director of Supply Chain, Director of Logistics, Director of Operations, or VP of Supply Chain Management.

At this level, the focus is highly strategic. Leaders are responsible for setting the overall direction for the supply chain, aligning it with business goals, managing large teams and budgets, negotiating major contracts, and driving large-scale transformation initiatives.

Strong leadership qualities, strategic vision, financial acumen, excellent communication skills, and the ability to navigate complex organizational dynamics are essential. An advanced degree like an MBA is often beneficial or required for these executive positions.

Pivoting to Related Fields

The skills developed as a Supply Chain Analyst are highly transferable, opening doors to related career paths. The analytical rigor is valuable in general Business Analyst or Data Analyst roles across various industries.

Experience in procurement analysis can lead to specialized roles in strategic sourcing or category management. Expertise in logistics and operations naturally aligns with careers in Operations Management or distribution center management.

Furthermore, seasoned supply chain professionals often move into consulting roles, advising multiple clients on optimizing their supply chains. This could be within large consulting firms or as independent consultants. The combination of analytical, process, and business knowledge makes analysts adaptable to many quantitative and operational roles.

Tools and Technologies in Modern Supply Chain Analysis

Essential Software

Proficiency with core business software is fundamental for Supply Chain Analysts. Enterprise Resource Planning (ERP) systems, such as SAP S/4HANA or Oracle Fusion Cloud SCM, are central hubs for managing data related to inventory, orders, production, and finance.

Specialized systems like Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) are used to optimize storage and logistics operations. Advanced skills in Microsoft Excel remain critical for data manipulation, ad-hoc analysis, and creating smaller-scale models and reports.

SQL databases are common for storing vast amounts of supply chain data, making query skills highly valuable. For presenting insights, familiarity with data visualization platforms like Tableau or Microsoft Power BI is increasingly expected.

Explore courses focused on essential supply chain software.

Analytics Languages

While traditional tools remain important, programming languages like Python and R are becoming increasingly prevalent in supply chain analytics, especially for more complex tasks. These languages offer powerful libraries for statistical analysis, machine learning, optimization, and data manipulation.

Python, with libraries such as Pandas for data handling, NumPy for numerical operations, Scikit-learn for machine learning, and Matplotlib/Seaborn for visualization, is widely used for building custom forecasting models, optimizing inventory levels, automating data processing tasks, and performing advanced analytics.

R is another popular choice, particularly strong in statistical modeling and visualization. Knowledge of these languages can significantly enhance an analyst's capabilities, allowing them to tackle more sophisticated problems and develop tailored analytical solutions beyond the scope of standard software.

These courses cover the application of Python and R in analytics and supply chain contexts.

This book introduces statistical learning concepts often implemented using R or Python.

Emerging Technologies Shaping the Future

The field of supply chain management is constantly evolving, driven by technological advancements. Artificial Intelligence (AI) and Machine Learning (ML) are being used for more accurate demand sensing, predictive maintenance, and optimizing logistics in real-time. According to Gartner, AI adoption in supply chains is rapidly increasing, expected to automate aspects of decision-making and reporting.

Blockchain technology offers potential for enhanced transparency and traceability, improving security and trust in transactions across complex networks. The Internet of Things (IoT) enables real-time tracking of goods and assets through sensors, providing unprecedented visibility into inventory location and condition.

Automation and robotics are transforming warehouse operations and logistics, improving speed and efficiency. Analysts need to stay aware of these emerging technologies and understand how they can be leveraged to create more resilient, efficient, and intelligent supply chains.

Challenges and Risks in the Field

Navigating Global Disruptions

Global supply chains are inherently susceptible to disruptions from various sources. Geopolitical instability, trade disputes, tariffs, and regulatory changes can suddenly alter sourcing options and costs. Natural disasters like hurricanes, earthquakes, or floods can cripple transportation infrastructure and halt production.

Events like the COVID-19 pandemic demonstrated the profound impact widespread disruptions can have on supply availability, logistics capacity, and consumer demand. Analysts must constantly monitor these external factors and assess their potential impact on operations.

Developing resilience requires anticipating these risks and building flexibility into the supply chain. This might involve diversifying suppliers across different regions, holding strategic inventory buffers, or having pre-planned alternative logistics routes.

Balancing Competing Priorities

Supply Chain Analysts often face the challenge of balancing conflicting objectives. There is constant pressure to reduce costs across procurement, manufacturing, inventory, and logistics. However, cost-cutting measures can sometimes negatively impact service levels, speed, or resilience.

Ensuring rapid delivery and high customer satisfaction might require higher transportation costs or larger inventory holdings. Building a resilient supply chain with backup suppliers or extra inventory adds cost but protects against disruptions. Increasingly, there is also a mandate to improve sustainability and ethical sourcing practices, which may involve different (and sometimes more expensive) choices.

Analysts must use data and analytical models to understand these trade-offs and help the business make informed decisions that align with overall strategic priorities. It requires navigating complex choices where optimizing one metric might negatively affect another.

Keeping Pace with Technology

The tools, technologies, and analytical techniques used in supply chain management are evolving rapidly. New software updates, advanced analytics methods, AI applications, and emerging technologies like blockchain or IoT constantly change the landscape.

Analysts must be committed to continuous learning to stay relevant and effective. This involves not only mastering current tools but also staying informed about new developments and understanding their potential applications and limitations.

This requires proactively seeking out training opportunities, reading industry publications, attending conferences or webinars, and experimenting with new tools and techniques. Failure to adapt can lead to skills obsolescence in this dynamic field.

Managing Stress and Pressure

The role of a Supply Chain Analyst can be demanding and sometimes stressful. Decisions made based on their analysis can have significant financial implications for the company. During supply chain disruptions or crises, the pressure to find solutions quickly can be intense.

Meeting tight deadlines for reports, forecasts, or project implementations is common. Collaborating with multiple stakeholders who may have different priorities can also add complexity and potential conflict.

Developing strong organizational skills, effective time management, resilience, and clear communication strategies are important for managing stress. While the work can be high-pressure, the satisfaction of solving critical problems and contributing to the smooth functioning of the business can be a significant motivator.

If you're considering this path, especially as a career change, know that challenges exist, but they are often matched by rewarding outcomes. Building a strong support network and focusing on continuous skill development can help navigate these pressures effectively.

Market Trends Shaping Supply Chain Analyst Roles

Automation and AI Impact

Artificial intelligence and automation are increasingly integrated into supply chain operations. AI is used for tasks like predictive demand forecasting, optimizing logistics routes, and automating warehouse processes. Generative AI is also emerging as a tool to potentially enhance workflows and reporting, though Gartner suggests widespread impact might take time.

This trend doesn't necessarily mean analysts will be replaced, but their roles are evolving. Analysts will need to work alongside AI tools, interpreting their outputs, validating results, and focusing on more strategic, complex problems that require human judgment and creativity. According to McKinsey insights for 2025, GenAI adoption for efficiency is a key theme.

The demand shifts towards analysts who can leverage these technologies effectively, understand data science concepts, and manage the integration of automated systems. Continuous learning in analytics and AI applications will be crucial.

Emphasis on Sustainability and Circularity

There is a growing focus on environmental, social, and governance (ESG) factors in supply chain management. Consumers, investors, and regulators are demanding more sustainable and ethical practices, pushing companies to reduce their carbon footprint, ensure fair labor conditions, and minimize waste.

Analysts are increasingly involved in measuring the environmental impact of supply chain activities, evaluating suppliers based on sustainability criteria, and exploring circular economy models. Circular supply chains aim to minimize waste by reusing, repairing, refurbishing, and recycling materials, moving away from the traditional linear "take-make-dispose" model. According to a World Economic Forum report, circularity is rapidly becoming a business necessity, with a significant increase in companies prioritizing circular solutions.

This trend requires analysts to develop new skills in areas like lifecycle assessment, carbon accounting, and understanding circular business models. Expertise in sustainability is becoming a valuable asset.

Network Reconfiguration (Reshoring/Nearshoring)

Recent global disruptions and geopolitical tensions have led many companies to rethink their supply chain network designs. The heavy reliance on distant, low-cost manufacturing hubs, particularly in Asia, is being re-evaluated in favor of greater resilience and shorter lead times.

This has fueled trends like reshoring (bringing manufacturing back to the home country) and nearshoring (moving production to nearby countries, e.g., Mexico for the US market). According to Kearney's 2022 Reshoring Index, this shift has moved from theory to market reality, with 96% of surveyed CEOs evaluating or implementing reshoring.

Supply Chain Analysts play a crucial role in evaluating these network reconfiguration options. They analyze the costs, risks, lead times, and logistical complexities associated with different manufacturing locations and help companies design more resilient and agile supply networks.

Evolving Inventory Strategies

The pandemic exposed the vulnerabilities of lean, Just-in-Time (JIT) inventory strategies, where minimal stock is held to reduce costs. Widespread shortages highlighted the need for a balance between efficiency and resilience.

Many companies are now shifting towards "Just-in-Case" or hybrid inventory models. This involves holding higher levels of safety stock for critical components or finished goods to buffer against unexpected disruptions or demand spikes. Some are also diversifying inventory locations.

This shift requires more sophisticated inventory analysis and planning. Analysts must use advanced modeling techniques to determine optimal safety stock levels, considering factors like demand variability, lead time uncertainty, and the cost of stockouts versus holding costs. Understanding inventory optimization techniques is more critical than ever.

Frequently Asked Questions

Is supply chain analysis recession-proof?

While no job is completely recession-proof, supply chain roles tend to be relatively resilient. Companies always need to manage the flow of goods, regardless of the economic climate. Efficient supply chain management becomes even more critical during downturns as companies focus intensely on cost reduction and operational efficiency.

Demand for skilled analysts who can optimize logistics, manage inventory effectively, and mitigate risks remains steady. The U.S. Bureau of Labor Statistics (BLS) projects strong growth for logisticians (a category including analysts), significantly faster than the average for all occupations, suggesting continued demand.

However, specific industries might be affected differently by economic cycles. Roles in non-essential goods manufacturing or retail might see more volatility than those in essential sectors like food, healthcare, or defense.

How much math is involved?

The level of mathematical rigor varies. Foundational roles require solid arithmetic and algebra skills for tasks like calculating costs, volumes, and basic metrics. Proficiency with spreadsheet functions in Excel is essential.

Most analyst roles require a good understanding of statistics for tasks like demand forecasting, inventory analysis (safety stock calculations), and performance measurement. Knowledge of concepts like mean, standard deviation, regression analysis, and probability distributions is common.

Advanced roles, particularly those involving optimization or complex modeling (e.g., network design, advanced forecasting), may require knowledge of operations research techniques, linear programming, simulation, and potentially calculus or more advanced statistical methods. Familiarity with statistical software or programming languages (R, Python) becomes important here.

Can I work remotely as a Supply Chain Analyst?

Yes, remote work is increasingly common for Supply Chain Analysts, though availability varies by company, industry, and specific role responsibilities. The rise of cloud-based SCM software, collaboration tools, and data accessibility has made remote analysis feasible for many tasks.

Roles heavily focused on data analysis, reporting, forecasting, and planning are often more suitable for remote or hybrid arrangements. However, positions requiring frequent hands-on interaction with physical operations (like warehouse management or production liaison) may necessitate more on-site presence.

Many companies now offer hybrid schedules, combining remote work with some days in the office for collaboration and meetings. The trend towards remote work has expanded opportunities, but it's important to check specific job requirements.

How do I transition from an unrelated field?

Transitioning requires a focused effort to acquire relevant knowledge and skills. Start by learning the fundamentals of supply chain management through online courses or certificate programs. Focus on core areas like logistics, inventory, procurement, and data analysis.

Develop key technical skills, especially proficiency in Excel, and consider learning SQL, Tableau/Power BI, or basics of an ERP system like SAP. Build a portfolio of projects applying these skills to supply chain problems to demonstrate practical capability.

Highlight transferable skills from your previous career, such as analytical thinking, problem-solving, project management, or communication. Networking with professionals in the field and pursuing relevant certifications (like CSCP or CPIM) can also significantly boost your chances.

What is the typical salary range?

Salaries for Supply Chain Analysts vary based on experience, location, industry, education, and certifications. According to BLS data from May 2022, the median annual salary for logisticians (including analysts) was $77,520. The lowest 10% earned less than $46,260, while the highest 10% earned over $124,050.

Salary data from sources like Robert Half suggests ranges for permanent positions often fall between $65,000 and $100,000, depending on the specific role and requirements. Data from Glassdoor (cited by Coursera) suggests total pay ranges like $89k-$136k for analysts with 2-4 years experience, and $124k-$184k for senior analysts.

Higher salaries are typically found in major metropolitan areas, in industries like tech or consulting, and for roles requiring advanced degrees, specialized skills (like advanced analytics or specific software expertise), or significant experience.

Will AI replace supply chain analysts?

AI is more likely to augment rather than replace Supply Chain Analysts. AI excels at processing large datasets, identifying patterns, and performing routine analytical tasks, potentially automating aspects of forecasting, optimization, and reporting.

However, human analysts remain crucial for interpreting AI outputs, understanding context, making strategic decisions, managing stakeholder relationships, and handling unforeseen exceptions or complex problems requiring nuanced judgment. AI tools can free up analysts from repetitive tasks, allowing them to focus on higher-value activities like strategy development, process innovation, risk management, and collaboration.

The future likely involves analysts working collaboratively with AI systems. Therefore, adaptability and the willingness to learn how to leverage AI tools effectively will be key skills for analysts moving forward, shifting the focus towards strategic thinking and complex problem-solving.

Helpful Resources

For those looking to deepen their understanding or connect with the supply chain community, several organizations offer valuable resources, certifications, and networking opportunities:

- Association for Supply Chain Management (ASCM): Formerly APICS, ASCM is a leading provider of research, education, and certifications like CPIM, CSCP, and CLTD. (ascm.org)

- Council of Supply Chain Management Professionals (CSCMP): Offers educational resources, research, networking events, and the SCPro™ certification. (cscmp.org)

- Institute for Supply Management (ISM): Provides resources, certifications (like CPSM), and research focused on procurement and supply management. (ismworld.org)

- U.S. Bureau of Labor Statistics (BLS): Offers occupational outlook information for related roles like Logisticians, including salary data and job growth projections. (bls.gov/ooh/business-and-financial/logisticians.htm)

Exploring these resources can provide further insights into industry trends, best practices, and career development opportunities.

Embarking on a career as a Supply Chain Analyst offers a path filled with intellectual challenges and tangible rewards. Whether you are starting fresh, transitioning from another field, or looking to advance within supply chain, the opportunities to learn, grow, and make a significant impact are abundant. With dedication to continuous learning and skill development, you can build a successful and fulfilling career in this vital and dynamic field.