Production Planner

Production Planner: A Career Guide

A Production Planner serves as a crucial link in the manufacturing and supply chain world, orchestrating the complex dance of resources, schedules, and materials to ensure goods are produced efficiently and on time. Their primary goal is to streamline operations, balancing production capacity with customer demand while keeping costs in check. This role is fundamental to the smooth functioning of any production process, making sure that everything from raw materials to the workforce is synchronized for optimal output.

Imagine the thrill of solving intricate puzzles daily, where the pieces are machines, materials, and manpower, and the goal is a perfectly executed production run. Production Planners get to do just that, applying analytical skills to forecast demand, optimize inventory, and schedule operations. They are at the heart of the action, collaborating across departments like sales, procurement, and logistics, ensuring alignment and tackling disruptions head-on. The role offers a tangible impact on a company's success, making it a potentially rewarding path for those who enjoy strategic thinking and problem-solving in dynamic environments.

Key Responsibilities of a Production Planner

The duties of a Production Planner are multifaceted, requiring a blend of analytical prowess, organizational skills, and effective communication. They are central figures in coordinating the entire production lifecycle.

Forecasting Demand and Managing Inventory

Accurate demand forecasting is a cornerstone of production planning. Planners analyze historical data, sales forecasts, and market trends to predict future demand for products. This foresight allows them to determine the necessary production volume.

Based on these forecasts, planners manage inventory levels for raw materials, work-in-progress (WIP), and finished goods. The objective is to ensure materials are available when needed without incurring excessive holding costs from overstocking or risking production halts due to stockouts. Effective inventory management is crucial for maintaining smooth production flow and controlling costs.

These foundational courses introduce core concepts in forecasting and inventory management, crucial for any aspiring planner.

Scheduling Production and Allocating Resources

Creating and maintaining a detailed production schedule is a primary responsibility. This involves mapping out timelines for manufacturing processes, considering machine availability, labor capacity, and material lead times. Planners must ensure schedules are realistic and achievable, aligning production activities with customer order deadlines and delivery commitments.

Resource allocation goes hand-in-hand with scheduling. Planners determine the necessary workforce for different production phases and ensure machinery and equipment are utilized effectively. They constantly monitor production progress, making adjustments to schedules and resource allocation as needed to address delays, bottlenecks, or changing priorities. This requires strong organizational skills and the ability to manage multiple tasks simultaneously.

These resources delve deeper into the specifics of planning, scheduling, and resource management within a production context.

Collaboration and Communication

Production Planners do not work in isolation; collaboration is key. They liaise extensively with various departments, including procurement (to ensure timely material arrival), sales and marketing (to understand demand forecasts), manufacturing/production teams (to assess capacity and progress), logistics/warehouse staff (for inventory monitoring), and quality control (to maintain standards).

Effective communication is vital for disseminating production schedules, conveying changes, and resolving issues. Planners act as a central communication hub, ensuring all stakeholders are informed and aligned with the production plan. Strong interpersonal skills are necessary to navigate cross-functional discussions and manage expectations effectively.

These resources provide insights into the broader supply chain context and the collaborative nature of the role.

Managing Risks and Improving Efficiency

Production Planners are often on the front lines of managing supply chain disruptions. Whether it's a supplier delay, equipment failure, or a sudden demand surge, planners must quickly assess the impact and adjust schedules to minimize negative consequences on timelines and costs. This requires strong problem-solving skills and adaptability.

Beyond reacting to problems, planners proactively seek ways to enhance efficiency and productivity. They analyze production data to identify bottlenecks, suggest process improvements, and implement measures to reduce waste and optimize resource utilization. Continuous improvement is an inherent part of the role, aiming for smoother, faster, and more cost-effective production.

These books offer strategic perspectives on managing operations and supply chains, valuable for understanding efficiency and risk mitigation.

Formal Education Pathways

Embarking on a career as a Production Planner typically involves a combination of formal education, practical experience, and often, specialized certifications. Understanding the common pathways can help aspiring planners chart their course.

Relevant Bachelor's Degrees

A bachelor's degree is often the minimum educational requirement for entry-level production planning roles. Degrees in fields like Supply Chain Management, Operations Management, Industrial Engineering, or Business Administration provide a strong foundation.

These programs equip students with knowledge in areas crucial to production planning, such as logistics, inventory control, manufacturing processes, forecasting techniques, and resource management. Coursework often includes quantitative analysis, statistics, and operations research, developing the analytical skills essential for the role.

Explore foundational knowledge in operations and supply chain management through these resources.

Professional Certifications

While not always mandatory, professional certifications can significantly enhance a Production Planner's credentials and competitiveness in the job market. The most widely recognized certifications in this field are offered by APICS (now part of the Association for Supply Chain Management - ASCM).

The Certified in Planning and Inventory Management (CPIM) designation is particularly relevant, focusing deeply on internal operations, planning, scheduling, and inventory control. It requires passing exams and typically some level of professional experience. The Certified Supply Chain Professional (CSCP) certification takes a broader, end-to-end view of the supply chain and also requires experience or a relevant degree. Holding these certifications demonstrates a standardized level of expertise.

Online courses can be instrumental in preparing for these rigorous certification exams, offering structured learning paths and practice materials.

Graduate Programs and Research

For those seeking advanced roles or specialization, a master's degree in Supply Chain Management, Operations Management, Industrial Engineering, or an MBA with a relevant concentration can be beneficial. Graduate programs often delve into more complex topics like supply chain optimization, advanced analytics, risk management, and strategic sourcing.

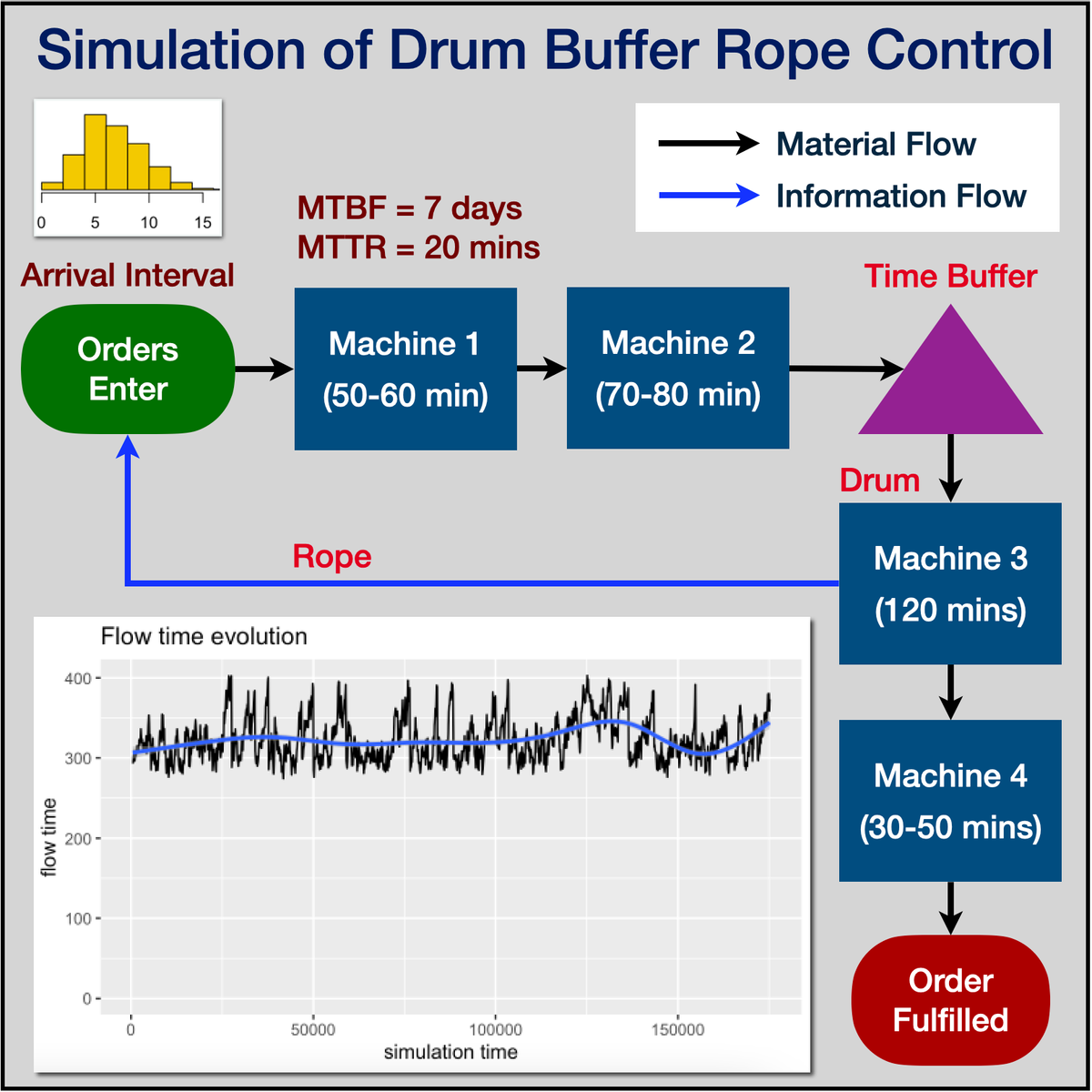

Opportunities for research, particularly at the PhD level, exist in areas related to production planning and supply chain optimization. Research topics might include the application of artificial intelligence and machine learning to demand forecasting, development of advanced scheduling algorithms, lean manufacturing principles, sustainability in production planning, or the impact of digital twin technology on operations. Online courses covering specific advanced techniques or technologies can supplement formal graduate studies or research endeavors.

This course offers a glimpse into advanced simulation techniques relevant to production control.

Career Progression in Production Planning

A career in production planning offers diverse opportunities for growth and advancement. It often serves as a solid foundation for roles across operations and supply chain management, providing pathways into leadership positions.

Entry-Level and Mid-Career Roles

Individuals often start in roles like Production Scheduler, Materials Analyst, or Junior Production Planner. These positions focus on specific aspects of the planning process, such as creating detailed schedules, monitoring material availability, or entering data into planning systems. Gaining experience in these roles builds essential skills and understanding of production environments.

With a few years of experience (typically 2-5 years), professionals can advance to Production Planner or Master Production Scheduler roles. These positions involve broader responsibilities, including developing comprehensive production plans, managing inventory strategies, and collaborating more extensively with other departments. Mid-career planners often take ownership of specific product lines or production areas.

Leadership Paths and Senior Roles

Experienced Production Planners can progress into senior planning roles or management positions. Titles like Senior Production Planner, Supply Chain Manager, or Production Manager are common next steps. These roles involve more strategic decision-making, overseeing planning teams, optimizing overall supply chain performance, and managing larger scopes of operation.

Further advancement can lead to executive positions such as Director of Operations, Director of Supply Chain, or even Vice President of Manufacturing/Operations. Reaching these levels typically requires significant experience, demonstrated leadership capabilities, and often, advanced education or certifications.

Lateral Moves and Related Fields

The skills developed as a Production Planner are highly transferable. Experienced planners may choose to move laterally into related fields within the supply chain. Common transitions include roles in procurement/sourcing, logistics engineering, inventory management, or quality control management.

The analytical and problem-solving skills honed in production planning are also valuable in broader operations management or even project management roles, although the focus differs. For those considering a career pivot into production planning, skills from project management, logistics, or data analysis can be advantageous starting points. The journey requires dedication, but the skills learned are widely applicable.

Industry Trends Impacting Production Planners

The field of production planning is constantly evolving, influenced by technological advancements, shifting economic landscapes, and growing emphasis on sustainability. Staying abreast of these trends is crucial for career longevity and effectiveness.

Digital Transformation and Advanced Analytics

Digital technologies are reshaping production planning. Increased use of Artificial Intelligence (AI) and Machine Learning (ML) enhances demand forecasting accuracy, optimizes schedules, and enables predictive maintenance. Advanced Planning and Scheduling (APS) systems leverage algorithms to create more realistic and optimized plans considering real-time constraints.

The Internet of Things (IoT) provides real-time data from the shop floor, improving visibility and enabling faster responses to disruptions. Concepts like the digital twin – a virtual replica of a physical process or asset – allow for simulation and optimization before implementation. These technologies demand planners to develop stronger analytical and digital skills. According to KPMG insights on 2024 supply chain trends, 50% of supply chain organizations plan to invest in AI and advanced analytics capabilities.

These courses explore the application of modern technologies in the supply chain.

Sustainability and Circular Economy

Environmental considerations are increasingly influencing production decisions. There's a growing push towards sustainable practices, including reducing waste, minimizing carbon footprint, and responsible sourcing. Planners may need to factor environmental impact into their scheduling and material selection processes.

The concept of the circular economy – focusing on reuse, refurbishment, and recycling – is gaining traction. This affects material sourcing strategies and reverse logistics planning, adding complexity but also contributing to environmental goals. Planners must navigate the potential tensions between sustainability objectives and cost-efficiency pressures.

Supply Chain Resilience and Agility

Recent global disruptions have highlighted the need for more resilient and agile supply chains. Companies are exploring strategies like nearshoring (moving production closer to home markets) or onshoring (bringing production back domestically) to reduce reliance on long, complex global supply chains. This impacts capacity planning and network design.

There's also a shift from purely "Just-in-Time" inventory strategies towards "Just-in-Case" approaches, involving holding more buffer stock to mitigate disruption risks. Planners need to adapt their strategies to balance lean efficiency with the need for robustness against volatility, uncertainty, complexity, and ambiguity (VUCA). Enhanced visibility and collaboration across the supply chain are critical for agility.

Automation and Labor Dynamics

Automation is increasingly prevalent in manufacturing and warehousing, impacting both production processes and planning tasks. Robotics and automated systems can enhance efficiency and address labor shortages but require careful integration and workforce adaptation, including upskilling. Automation might streamline some routine planning tasks, allowing planners to focus on more strategic activities.

While automation handles repetitive tasks, the planner's role evolves towards managing these complex, integrated systems, interpreting data generated by automated processes, and making strategic decisions. The human element of collaboration, problem-solving, and critical thinking remains vital.

Tools and Technologies for Modern Production Planners

Modern Production Planners rely on a suite of sophisticated tools and technologies to manage the complexities of manufacturing operations effectively. Proficiency with these systems is often a key requirement for the role.

Enterprise Resource Planning (ERP) Systems

Enterprise Resource Planning (ERP) systems serve as the backbone for managing core business processes, including production planning. Major ERP vendors like SAP and Oracle offer modules specifically designed for manufacturing and supply chain management. These systems integrate data from various departments (finance, HR, procurement, sales, production), providing a holistic view of resources and operations.

Within ERP systems, planners utilize functionalities for Material Requirements Planning (MRP) to determine material needs based on production schedules and Bill of Materials (BOM). They also manage master data (like item details, lead times, BOMs) and track inventory levels. Familiarity with specific ERP systems, particularly SAP (especially modules like PP - Production Planning or S/4HANA) or Oracle, is highly valued.

These courses offer practical training on widely used ERP systems in production planning.

Advanced Planning and Scheduling (APS) Software

While ERP systems provide foundational planning capabilities, Advanced Planning and Scheduling (APS) software offers more specialized and powerful tools for optimizing production schedules. APS systems use advanced algorithms to consider capacity constraints, material availability, labor resources, and complex production rules simultaneously, generating feasible and efficient schedules.

These tools often feature graphical interfaces for visualizing schedules (like Gantt charts) and allow for interactive adjustments and "what-if" scenario analysis. This helps planners quickly assess the impact of changes, such as rush orders or machine breakdowns, and find the best course of action. APS software can operate standalone or integrate with ERP and Manufacturing Execution Systems (MES).

Explore planning and scheduling software capabilities with these resources.

Analytics, AI, and Emerging Technologies

Data analysis tools are essential for Production Planners. Proficiency with spreadsheet software like Microsoft Excel for data manipulation, analysis (using features like Pivot Tables and V-Lookups), and reporting is typically required. Business intelligence tools like Tableau or Power BI are also increasingly used for data visualization and creating insightful dashboards.

Machine learning (ML) algorithms are being incorporated into planning tools for more accurate demand forecasting and predictive analytics. The Internet of Things (IoT) enables real-time monitoring of production processes and equipment status, feeding live data into planning systems for greater accuracy and responsiveness. As these technologies become more integrated, planners need to be comfortable working with data-driven insights and potentially AI-assisted decision support systems.

These courses focus on analytical techniques applicable to production and operations.

Challenges Faced by Production Planners

The role of a Production Planner, while rewarding, is not without its hurdles. Navigating complex systems, managing uncertainty, and balancing competing priorities are inherent parts of the job.

Balancing Efficiency and Buffers

A classic challenge is striking the right balance between lean manufacturing principles, like Just-in-Time (JIT) inventory, and the need for buffer stocks to mitigate risks. JIT aims to minimize inventory holding costs but leaves little room for error or disruption. Conversely, excessive buffer inventory ties up working capital and increases storage costs. Planners must constantly evaluate this trade-off based on demand variability, supplier reliability, and production stability.

This balancing act requires careful analysis and strategic decision-making. Planners use data and forecasting tools to determine optimal inventory levels but must also factor in qualitative aspects like potential supply chain vulnerabilities. The goal is to achieve efficiency without sacrificing resilience.

Managing Uncertainty and Disruptions

Production environments are often subject to volatility and unexpected events. Demand can fluctuate suddenly, suppliers might face delays, machinery can break down unexpectedly, or labor shortages might occur. These disruptions can wreak havoc on meticulously planned schedules.

Planners must be adept at managing this uncertainty. This involves building contingency plans, using scenario analysis tools (often found in APS software), and maintaining agility to adjust schedules quickly when disruptions occur. Strong problem-solving skills and the ability to remain calm under pressure are crucial.

Cross-Departmental Coordination Issues

Effective planning relies heavily on smooth communication and collaboration between different departments. However, communication gaps, conflicting priorities, or data silos between departments like sales, procurement, manufacturing, and logistics can create significant challenges. For instance, inaccurate sales forecasts or delayed information about material availability can undermine the production plan.

Planners often act as mediators, bridging these gaps and ensuring alignment. This requires strong interpersonal skills, the ability to influence without direct authority, and persistence in gathering accurate information from various sources. Facilitating regular cross-functional meetings, like Sales & Operations Planning (S&OP) sessions, is often part of the role.

Navigating Competing Objectives

Planners frequently face competing objectives. For example, there might be pressure to minimize production costs while simultaneously meeting tight customer deadlines and maintaining high quality standards. Similarly, sustainability goals might conflict with the most cost-effective material or process choices.

Balancing these often-conflicting demands requires careful analysis and prioritization. Planners need a solid understanding of the business's overall strategic goals to make informed trade-offs. Communicating the rationale behind planning decisions to stakeholders is also important for managing expectations.

Ethical Considerations in Production Planning

Beyond efficiency and cost, Production Planners increasingly navigate ethical considerations that impact their decisions and the broader supply chain. These concerns reflect a growing awareness of corporate social responsibility and sustainability.

Environmental Impact

Production processes inevitably have environmental consequences. Planners' decisions regarding production schedules, material choices, and waste management can influence energy consumption, resource depletion, and pollution levels. There is growing pressure to adopt greener practices and minimize the environmental footprint of manufacturing operations.

This involves considering factors like the energy efficiency of machines when scheduling, optimizing logistics to reduce transportation emissions, and planning for waste reduction or recycling. Planners may need to evaluate trade-offs between environmental goals and operational costs or efficiency targets.

Labor Practices and Supplier Networks

In globalized supply chains, production often relies on networks of suppliers spread across different countries with varying labor laws and standards. Planners, while primarily focused on scheduling and materials, operate within this broader context. Ensuring ethical labor practices throughout the supply chain, including fair wages, safe working conditions, and avoidance of forced labor, is a growing concern for businesses and consumers.

While direct oversight might fall under procurement or compliance departments, planners' choices regarding suppliers and production locations can have indirect ethical implications. Awareness of these issues and alignment with company policies on responsible sourcing are important aspects of the role. This book provides context on legal aspects of workplace safety.

Data Privacy and Analytics

Modern planning relies heavily on data, including information about customer demand, supplier performance, and internal operations. As analytics and AI become more integrated, handling this data responsibly is crucial. This includes ensuring data privacy, particularly when dealing with customer information used for forecasting, and maintaining transparency in how analytical models are used to make planning decisions.

Planners must adhere to company policies and regulations regarding data protection and usage. Ethical considerations also arise in ensuring that AI-driven planning tools do not perpetuate biases or lead to unfair outcomes for workers or suppliers.

Compliance and Material Sourcing

Specific industries face regulations regarding the sourcing of materials, such as conflict minerals regulations designed to prevent financing armed groups in certain regions. Planners involved in industries like electronics or automotive may need to ensure that their material planning aligns with these compliance requirements.

This involves working closely with procurement and compliance teams to verify the origin of materials and maintain appropriate documentation. Ethical sourcing extends beyond regulated materials to broader considerations of choosing suppliers who align with the company's values and ethical standards.

Frequently Asked Questions (Career Focus)

Choosing a career path involves many questions. Here are answers to some common queries about becoming and working as a Production Planner, designed to help you evaluate if this role aligns with your aspirations.

Is certification more valuable than experience?

Both certification and experience are valuable in production planning. Experience provides practical, hands-on understanding of real-world production challenges and nuances. Certifications like APICS CPIM or CSCP demonstrate standardized knowledge and commitment to the profession, potentially making candidates more competitive, especially for promotions or specific roles.

Often, the ideal combination is having both. Experience grounds theoretical knowledge, while certifications provide a structured framework and validate expertise. For entry-level roles, relevant experience (even through internships) might be prioritized, while certifications can become more important for mid-career advancement. Many certifications also require a certain amount of experience to be eligible.

How does this role differ from project management?

While both Production Planners and Project Managers involve planning, scheduling, and resource allocation, their focus differs significantly. Production Planners concentrate on ongoing, repetitive manufacturing or operational processes, aiming for continuous efficiency and meeting regular production targets. Their work is cyclical and tied to the production lifecycle.

Project Managers, conversely, typically oversee unique, temporary projects with defined start and end dates, specific goals, and deliverables. They manage project scope, budget, and timelines across various industries, not necessarily limited to manufacturing. While there's skill overlap (organization, communication, problem-solving), the context and objectives are distinct.

Is remote work feasible in production planning?

The feasibility of remote work for Production Planners can vary. Aspects of the role involving data analysis, scheduling using software, communication, and reporting can often be done remotely. However, production planning frequently requires close collaboration with on-site manufacturing teams, physical observation of production floors, and immediate responses to shop-floor issues, which can necessitate an on-site presence.

Hybrid models, combining remote work with some days on-site, are becoming more common where possible. Fully remote positions might be more prevalent in roles focused purely on strategic planning or data analysis, or in companies with highly digitized and integrated planning systems. Check specific job postings for remote work options.

What typical KPIs are used to evaluate planners?

Production Planners are often evaluated based on Key Performance Indicators (KPIs) that reflect the efficiency, timeliness, and cost-effectiveness of the production process. Common KPIs include:

Efficiency/Utilization: Capacity utilization, machine utilization, labor utilization, Overall Equipment Effectiveness (OEE).

Timeliness: On-Time Delivery (OTD) rate, schedule adherence/compliance, production cycle time, lead time.

Inventory Management: Inventory turnover rate, stockout rate, days of inventory on hand (DOH).

Cost/Quality: Production cost per unit, scrap/defect rate, first pass yield (FPY).

These metrics help gauge how well the planner is balancing resources, meeting demand, controlling costs, and ensuring smooth operations.

What are the career risks from automation/AI adoption?

Automation and AI are undoubtedly changing the landscape, automating some routine planning tasks like data entry or basic scheduling adjustments. This means planners whose roles consist primarily of these tasks might face pressure. However, AI is more likely to augment rather than completely replace the Production Planner role.

The need for strategic thinking, complex problem-solving, managing exceptions, collaborating with diverse teams, and interpreting the outputs of AI systems remains crucial. The risk lies more in failing to adapt. Planners who embrace new technologies, develop strong analytical skills, and focus on higher-level strategic contributions are likely to thrive. Continuous learning is key.

What are typical entry-level salary ranges globally?

Salary ranges for Production Planners vary significantly based on location, industry, company size, education, certifications, and years of experience. Providing a single global range is difficult. However, we can look at some data points.

In the US, Payscale reported an average salary of $64,770 for production planners in manufacturing as of March 2024, while noting CPIM holders averaged $84,000 annually. Glassdoor estimated total pay for supply chain planners (a closely related role) at $116,241 in 2025, including base salary and additional pay, but noted significant variation by location. Higher-level roles like Industrial Production Managers have higher median wages, reported by the U.S. Bureau of Labor Statistics (BLS) at $121,440 in May 2024. It's essential to research salary expectations specific to your region and target industry using resources like the BLS Occupational Outlook Handbook or reputable salary comparison websites.

Becoming a Production Planner involves developing a mix of analytical, organizational, and interpersonal skills. It's a role that places you at the center of manufacturing operations, offering opportunities to optimize complex systems and contribute directly to business success. While challenging, it provides a solid foundation for a career in supply chain and operations management. If you enjoy problem-solving, working with data, and collaborating with others in a dynamic environment, this path may be a fulfilling one for you. Explore resources on Manufacturing and Logistics on OpenCourser to start building your knowledge base. Remember to use features like "Save to List" to keep track of courses that interest you, and consult the Learner's Guide for tips on effective online learning.